HBK FUSION User manual

BN2622-12

USER MANUAL

Version 2022.0

Although reasonable care has been taken to ensure the information in this document is accurate, nothing herein

can be construed to imply representation or warranty as to its accuracy, currency or completeness, nor is it

intended to form the basis of any contract.

Content is subject to change without notice – contact HBK for the latest version of this document.

HBK ADVANTAGE, HBK FUSION, HBK COMPANION and all other trademarks, service marks, trade names, logos and

product names are the property of Hottinger Brüel & Kjær A/S or a third-party company.

Copyright © Hottinger Brüel & Kjær. All rights reserved.

November 2022

Contents

About HBK FUSION 7

Release Info 8

About the system 8

The frame 8

The boards 8

The software 9

Optional mobile app 9

Barcodes 10

Health and safety information 11

Before use 11

End of use 11

Warnings 11

Safety instructions 12

Proper use 13

System integration 14

Handling of heavy loads 14

Declaration of conformity 15

Testing with high EMC immunity 16

Supported accessories 17

Software licensing 17

Acquiring a license 18

License checks 18

Contact HBK support 18

Getting Started 19

What's in the box? 19

Parts overview 20

Install HBK FUSION 21

Rack mounting 21

Tabletop mounting 22

Connecting sensors 23

Connect the sensor to a cable 23

Connect the sensor cable to an input board 30

Install HBK ADVANTAGE 31

Start the software 31

Discover your hardware in HBK ADVANTAGE 33

Reading the Devices explorer 33

(Optional) Import channel setup to HBK ADVANTAGE 34

Configure your hardware 35

Set up the hardware 35

Set up with HBK ADVANTAGE 37

Optional: Set up with HBK COMPANION 38

Using HBK COMPANION 39

The use of barcodes in the app 39

Configure channel parameters in HBK ADVANTAGE 40

Configure a bridge board (B201-10) 40

Configure a CCLD board (B301D-12) 40

Configure sensor parameters in HBK ADVANTAGE 41

When the sensor is a bridge 41

When the sensor is a resistance thermometer 42

When the sensor is voltage 42

When the sensor is a potentiometer 43

When the sensor is a CCLD transducer 43

When the sensor is a direct voltage transducer 44

Sensor characteristics 44

Sample rate 46

Bridge board sample rate/filter combinations 46

(Optional) Using OPC UA 48

Operating HBK FUSION 49

Qualified operating personnel 49

User control 49

Power 50

Connecting power 50

Disconnecting 50

Network setup 50

Direct connection to a PC 51

Network settings 51

Security 51

Volatile and non-volatile memory 51

Correct positioning during operation 52

Frames in a rack 52

Frames on a tabletop 52

Boards in the frame 52

Calibration 53

Synchronization 53

HBK FUSION's use of PTP 53

Temperature control 54

Frame fan control 54

Switching boards 54

Removing a board 55

Inserting a board 56

Check your hardware 58

Devices explorer in HBK ADVANTAGE 58

Using the Devices explorer 59

Devices table in HBK ADVANTAGE 59

Symbols in the table 60

Availability 60

User 60

Firmware version 61

LED status 61

Device web page 62

Information provided on the device web page 62

Functions provided on the device web page 63

Update firmware 63

Edit network settings 64

Edit synchronization settings 65

Edit fan settings 65

Fan modes of operation 66

Reset the device 66

Maintenance and care 67

Qualified maintenance personnel 67

Replacing air filters 68

Cleaning 68

Transportation, storage and disposal 68

Diagnostics and troubleshooting 70

Device troubleshooting 70

Network troubleshooting 70

Diagnostics in HBK ADVANTAGE 70

System monitor 71

Event log 72

Glossary 74

About HBK FUSION

ABOUT HBK FUSION

HBK introduces a new era of data acquisition hardware with the HBK FUSION system of frames and boards.

With universal inputs, scalable channel number, time-synchronised data and more, you gain high efficiency,

high performance and reliability, and reduce the time to results.

HBK FUSION data acquisition hardware enables a team to build a multi-domain system using a single front

end. Sound, vibration, strain, force, acceleration, displacement, pressure, and temperature – the HBK

FUSION hardware combines all relevant measurands to assess structural integrity in a single unit for best-in-

class data quality and high-efficiency testing.

The benefits of HBK FUSION include:

Reduced setup time

With the entire system, which includes HBK ADVANTAGE data acquisition software and HBK COMPANION

mobile app, you can reduce your total setup time by up to 30% with an easy and secure team collaboration

requiring just a few clicks to make the right decisions.

Open on all levels

Open ecosystem for integration of additional hardware or for integration into different software solutions to

achieve the best possible result.

Versatile system

The multi-physics application platform for various test and measurement applications in the time and

frequency domain.

Secure connection

lEncrypted and authenticated communication with HBK ADVANTAGE software.

lAuthentication of firmware before updating.

lLimitation of only one user per HBK FUSION board.

High performance and reliability

High system performance and throughput built on topnotch technology to secure continuous productive

testing.

HBK assured

One service contract for calibration, extended warranty, priority support and other benefits across the life

cycle of your equipment.

- 7 -

Release Info

Release Info

Version:

Version 2022.0

Release date:

November 2022

Manufacturer:

Hottinger Bruel & Kjaer A/S

Teknikerbyen 28

DK-2830 Virum

Denmark

Phone: +45 77412000

Fax: +45 77412100

Email: [email protected]

About the system

The HBK FUSION modular system allows the test equipment to easily grow with your testing needs. Start

with a single board in a frame, then add up to 15 more boards to expand your channel count. Add more

frames and boards as needed.

The frame

Each HF-16 frame houses up to 16 boards in a robust casing for industrial and rigourous everyday use.

Frames (with one or more boards) can be used for single front-end systems, or as part of a distributed

system.

Sample synchronisation, using precision time protocol (PTP), enables communication between the boards in

the frame and between frames on a system level.

Boards lock into place within the frame and can be easily swapped or removed without the use of any tools,

allowing you to configure and reconfigure your front end, or send a board for calibration.

See the HBK FUSION datasheet for specifications.

The boards

Bridge board

Bridge Board B201-10 is a 10-channel input board with a signal bandwidth up to 2kHz.

RJ45 channel connectors allow for quick and easy connection of sensors without soldering, and a patented

wiring configuration compensates for wire resistance, eliminating the need for shunting.

- 8 -

The software

The board supports DC and carrier-frequency excitation, allowing you to choose either a wider dynamic

range or a higher noise immunity, as well as a 5 – 24 V supply for active transducers.

Remote sensing is included to ensure measurement accuracy and enable ratiometric measurements.

See the HBK FUSION datasheet for specifications.

CCLD board

CCLD Board B301D-12 has 12 input channels and is designed for CCLD1transducers.

The benefit of CCLD is that the same wire is used for both the signal and the supply current. Even TEDS data

can be transmitted over the same wire. This enables the use of costeffective coaxial cables and SMB

connectors popularly used in general applications.

Both CCLD and direct input transducers are supported, including microphones and accelerometers, for

general sound and vibration measurements.

See the HBK FUSION datasheet for specifications.

Blank board

Blank Board B701 is functionless board that is required to fill a frame (if not all slots are in use by an input

board). For example, a single input board can be ordered and mounted in a frame, as long as 15 blank

boards are in the remaining slots.

The software

HBK ADVANTAGE provides for hardware configuration, basic data acquisition and a rich set of standard

functionalities paving the way into the future. It is a native Windows®installation with a 64-bit architecture

that supports multiple cores for the highest data throughput and smooth workflow.

The core application of HBK ADVANTAGE is initially designed for general purpose static and fatigue test

applications and will expand to include sound and vibration capabilities.

See the HBK ADVANTAGE datasheet for specifications.

Optional mobile app

The HBK COMPANION app enables you to set up a project ahead of testing by scanning devices and sensors

and identifying measurement positions and channel configurations. By importing the setup in HBK

ADVANTAGE, sensor and channel configuration is automated. Thanks to the synchronization between HBK

COMPANION and HBK ADVANTAGE, pictures and other documentation of the setup can be automatically

assigned to the sensors.

See the HBK COMPANION datasheet for specifications.

1Constant current line drive. Different manufacturers market transducers using the CCLD principle under different names, including

DeltaTron®and IEPE.

- 9 -

Barcodes

Barcodes

All hardware devices are labelled with barcodes – this includes supported HBK sensors. Many HBK sensors

are shipped with datasheets that also include the sensor barcodes.

Use these barcodes to:

lOpen the product datasheet or product page on hbkworld.com

lUsing HBK COMPANION app, scan to read device information such as serial number and type

number. You may also detect the sensor's measurement direction

- 10 -

Health and safety information

HEALTH AND SAFETY INFORMATION

This document contains information and warnings which must be followed to ensure safe operation and to

maintain the product in safe condition.

This product has been designed and tested in accordance with:

lEN/IEC61010-1 and ANSI/UL61010-1: Safety requirements for electrical equipment for

measurement, control and laboratory use

lEN55011:2016: Industrial, scientific and medical equipment – Radio-frequency (RF) disturbance

characteristics. Limits and methods of measurement

Group1: Devices that intentionally generate no more than 9kHz of RF energy

If the product is not used as intended, the protection provided by the product may be impaired.

Before use

When it is unpacked, check the product for visible signs of damage. If damage has occurred, the product

must not be operated.

If the product is damaged, operated without being acclimatized, or incorrectly stored or transported, the

protection provided by the product may be impaired.

End of use

HBK complies with the EU’s Waste Electrical and Electronic Equipment (WEEE) Directive, which

issues the following waste handling instructions:

lWaste electrical and electronic equipment or batteries may be returned to your local

HBK office for disposal.

lDo not dispose of electronic equipment or batteries as unsorted municipal waste.

Warnings

If the product is used outside the rated operating conditions or is not used as intended, the protection

provided by the product may be impaired.

According to EN55011, this is a Class A product, suitable for use in all areas, apart from the domestic

environment, where devices are directly connected to a low-voltage power supply network. This product

may cause radio interference in a domestic environment, and therefore you should take extra measures to

avoid this.

- 11 -

Safety instructions

Labelling

The product will be marked with this symbol when it is important that you refer to the

associated danger or warning statement given in this document.

This document uses this symbol when a danger or warning statement is applicable.

Hazardous Voltage/Electricity. Both the product and this document use this symbol when

there is a risk for shock or electrocution.

Danger Signals an imminent hazardous situation, which, if not avoided, will result in death or serious

injury.

Warning Signals a possibly hazardous situation, which, if not avoided, will result in death or serious

injury.

Caution Signals a hazardous situation, which, if not avoided, could result in minor or moderate injury

or damage to the product.

Notice Signals a situation or practice that requires attention, but does not directly result in personal

injury if ignored.

Safety instructions

Environmental hazards

Do not cover the fan outlets or the bottom of the device.

Do not operate on a tabletop without unfolding the feet.

If the product has been stored or transported in extreme temperatures, wait at least 2hours before

switching it on.

Do not expose the product to direct sunlight or intense sunlight for too long, including behind car windows.

Protect the product against direct contact with water and moisture. Should condensation form during

transportation or storage, acclimatize the product for at least 2hours before operating.

Do not operate the product above the maximum operational altitude of 2000m.

The product is designed for use in clean and dry rooms with pollution degree 2.

The product must not be operated where there is a risk of explosion or in an aggressive chemical

environment.

In the event of ambient temperatures outside the specified range, the system will take measures to ensure

proper cooling (increase fan speed) and eventually securely switch off the system if sufficient cooling cannot

be ensured.

- 12 -

Proper use

Electrical hazards

Voltages with no energy limit that exceed one of the following values are rated as dangerous according to

EN61010:

lAC voltage, 30Vrms value

lAC voltage, 42.4Vpeak value

lDC voltage, 60V

When applying dangerous contact voltages, you must comply with all related safety requirements.

Risk due to poor insulation of external circuits: only devices that comply with the requirements of IEC61010-

1, IEC61010-2-030 and IEC60950 may be connected.

To avoid injury from coming into contact with dangerously active electric potential: do not wear jewellery

(rings, watches, etc.) and do not touch any live parts. Comply with safety rules: isolate, secure, check, ground

and short-circuit, cover and safeguard.

Proper use

Connection

For devices connected to a network, safety precautions must be taken to ensure that line breaks and other

signal transmission interruptions do not occur in order to minimise data loss and other undefined states.

Only approved accessories can be used or connected to the product.

To disconnect the product and its power supply from the AC supply completely, unplug the mains power

cable.

Working safely

When it is unpacked, check the product for visible signs of damage. If damage has occurred, the product

must not be operated.

Proper and safe operation requires proper transportation, correct storage, siting and mounting and careful

operation. Follow all instructions in this manual to ensure the proper and safe operation of your product.

In the following situations, the product must be shut down and secured to prevent inadvertent operation:

lVisible signs of damage to the product

l(Audibly) loose parts in the product

lThe product no longer works

The covers protect the user from live parts and should only be removed by suitably qualified personnel for

maintenance and repair purposes. The product must not be operated with the covers removed.

At the rear of the product, there is a cover with non-functional slots. Do not remove during operation. Do

not attempt to use the slots.

- 13 -

System integration

System integration

If the product is integrated into a system, it is the responsibility of the system installer to keep the system

safe.

The scope of supply and performance of the product covers only a small area of measurement technology.

Before starting up the product in a system, a project planning and risk analysis must first be implemented,

taking into account all the safety aspects of measurement and automation technology so that residual

dangers are minimized. This particularly concerns personnel and machine protection. In the event of a fault,

the relevant precautions must establish safe operating conditions.

System integration must also take into account the relevant national and local accident prevention

regulations in plants where malfunctions could cause major damage, loss of data or even personal injury.

Additional risks may occur when the product is integrated into plants or systems and the protection

provided by the product may be impaired.

Handling of heavy loads

The EU’s Council Directive90/269/EEC – Manual Handling of Loads, lays down the minimum health and

safety requirements for the manual handling of loads where there is a risk particularly of back injury to

workers.

As the weight of the frame may exceed 24kg with 16boards installed (8.5kg without any boards), please

take appropriate actions before lifting the product.

The user may be at risk if:

lHe/she is physically unsuited to carry out the task in question.

lHe/she does not have adequate or appropriate knowledge or training.

Before lifting the product, refer to the occupational health and safety organization, or equivalent, in your

country for more information.

Remember, before lifting or carrying a heavy object, the following questions should be asked:

lCan one person lift this load safely, or do two people need to lift the load?

lHow far will the load have to be carried?

lIs the path clear of clutter, cords, slippery areas, overhangs, stairs, curbs or uneven surfaces?

lWill closed doors that need to be opened be encountered?

lOnce the load is lifted, will it block the carrier’s view?

lCan the load be broken down into smaller parts?

lShould the carrier wear gloves to get a better grip and to protect hands?

- 14 -

Declaration of conformity

Declaration of conformity

NOTE

The following is only guaranteed using accessories listed in this document.

Conforms with the following national and international standards or technical specifications:

The CE marking is the manufacturer's declaration that the product meets the

requirements of the applicable EU directives.

RCM mark indicates compliance with applicable ACMA technical standards – that is, for

telecommunications, radio communications, EMC and EME.

China RoHS mark indicates compliance with administrative measures on the control of

pollution caused by electronic information products according to the Ministry of

Information Industries of the People’s Republic of China.

WEEE mark indicates compliance with the EU WEEE Directive.

The UKCA (UK Conformity Assessed) marking is a UK product marking that is used for

goods being placed on the market in Great Britain.

Safety EN/IEC61010-1 and ANSI/UL61010-1: Safety requirements for electrical equipment for

measurement, control and laboratory use.

EMC Emission EN/IEC61326-1: Electrical equipment for measurement, control and laboratory use –

EMC requirements.

CISPR 11 and EN55011: Industrial, scientific and medical equipment. Radio-frequency

disturbance characteristics. Limits and methods of measurement.

CISPR32 and EN 55032: Radio disturbance characteristics of information technology

equipment. Class A Limits.

FCC Rules, Part 15: Complies with the limits for a Class A digital device.

This ISM device complies with Canadian ICES-001 (standard for interference-causing

equipment).

EMC Immunity EN/IEC61326-1: Electrical equipment for measurement, control and laboratory use –

EMC requirements.

Note: Please see this document for information on cables, connectors and shielding

concept to be applied to ensure the product EMC compliance.

Temperature EN/IEC60068-2-1: Environmental Testing. Cold.

EN/IEC60068-2-2: Environmental Testing. Dry Heat.

Operating Temperature: –20 to +60°C (–4 to 140°F) Storage Temperature: –40 to

+75°C (–40 to 167°F)

- 15 -

Testing with high EMC immunity

Humidity EN/IEC60068-2-78: Damp Heat: 5 to 95% RH (non-condensing)

Mechanical Non-operating:

IEC60068-2-6: Vibration: Accel.: 19.6m/s2(2gn); Dur.: 60min; Freq.: 5 to 500Hz; Dir.:

3axes

IEC60068-2-27: Shock: Accel.: 245m/s2(25gn); Pulse: 6ms; Impacts: 3 (pos/neg 3axes)

Operating:

IEC60068-2-6: Vibration: Accel.: 9.8m/s2(1gn); Dur.: 60min; Freq.: 5 to 500Hz; Dir.:

3axes

IEC60068-2-27: Shock: Accel.: 98.1m/s2(10gn); Pulse: 11ms; Impacts: 1000 (pos/neg

3axes)

Enclosure IEC60529: Protection provided by enclosures: IP20

Testing with high EMC immunity

The cable used for testing with high EMC immunity is a pairwise doubly shielded, 8-wire cable with the

following characteristics:

lThe cable houses three pairs of wires (black/blue, red/white, green/gray), each wrapped in a separate

shielding.

lTwo extra wires (purple and brown) are shielded individually.

lAll wires in the cable are bundled by an external braided shielding layer.

The following figure shows the wire configuration in such a cable:

- 16 -

Supported accessories

NOTE

For good EMC immunity, it is very important to keep the internal and the external shielding

galvanically isolated from each other.

Supported accessories

Each HBK FUSION delivery includes:

lThe relevant number of blank boards to ensure that all empty slots in the frame are filled

lLAN cable

lMains power cable

l4 × cross-head screws for rack mounting

The following additional accessories are available from HBK:

Item number Description

B701 Blank board

F1A-12 Detachable front panel for the 12-channel CCLD Board

DS-0003 Air filter (pack of 5 units)

To order new or replacement items, contact your local HBK representative.

Software licensing

HBK ADVANTAGE requires a valid license to run. A license grants a PC access to the software, based on the

PC's host ID and type of license:

lPaid license: A leased license for any paid features.

lFree license: A scaled-down version of the software that is free-of-charge.

Free licenses

A free license is a scaled-down version of the software offering basic features that allow you to try out the

software. Features that require a paid license are visible, but disabled. You can upgrade to a paid version at

any time.

- 17 -

Acquiring a license

What is available:

lHBK FUSION discovery and connection

lSupport for bridge, RTD (resistance temperature detector)/temperature, voltage and potentiometer

sensor setup

lY(t) display

lDigital indicator display

lManual data recording

lData recording in .bkc file format

What is not available:

lCustomizable column filters and sorting

lStrain gauge rosette calculations

lXY display

lPrediction lines

lTriggered data recording

lChannel table import from HBK COMPANION mobile app

lHardware setup export

Acquiring a license

You can upgrade to a paid license or renew an expired license in one of two ways:

lContact your HBK Global Customer Care agent

lRequest a license on the HBK website

With all licenses, you will receive an email that includes a license file containing your license key and, where

relevant, a specific number of tokens. Save the license file to a location on your PC or network. For more

tokens, contact your license administrator or HBK Customer Care agent.

You can find contact information for your local Customer Care office on the HBK website.

License checks

When you open HBK ADVANTAGE for the first time, you will have to configure your license.

Subsequently, license checks are performed every time you open the software to ensure your license is valid

and/or there are available tokens for you to use.

The system automatically generates alert messages when your license is about to expire.

Contact HBK support

For training and support, contact your local HBK representative.

- 18 -

Getting Started

GETTING STARTED

The following pages will help you get up and running with your new HBK FUSION hardware.

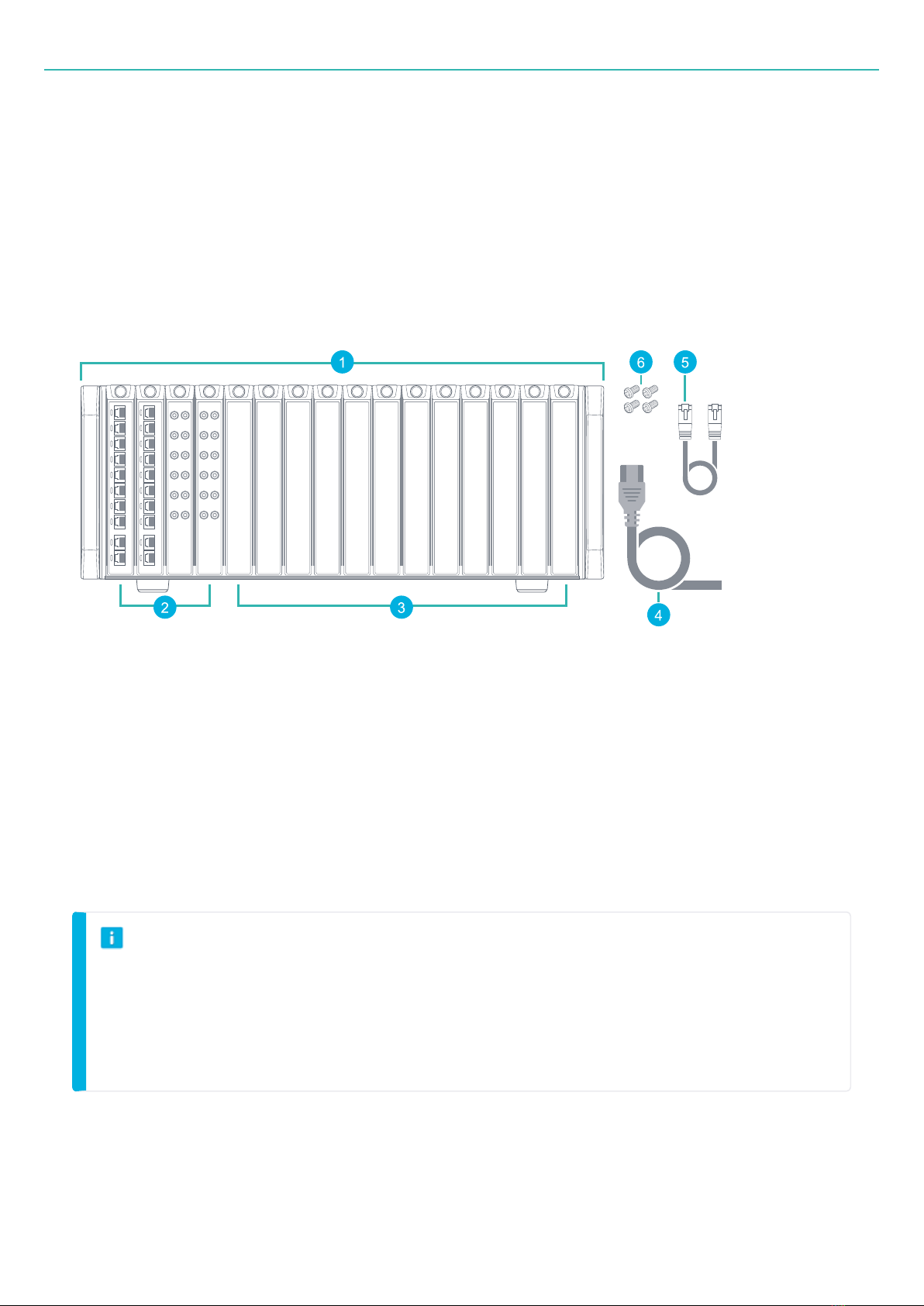

What's in the box?

1. Frame (housing)

2. Input boards

3. Blank boards

4. Power supply cable with plug

5. Ethernet cable

6. 4 × cross-head screws for rack mounting, screwdriver not included

NOTE

lAll slots must contain a board (input or blank) during operation.

lThe 16 slots can be filled with any combination of HBK FUSION boards.

lThe figure above shows a sample configuration. Your system may differ (all the same type or a

combination with or without blank boards).

- 19 -

Parts overview

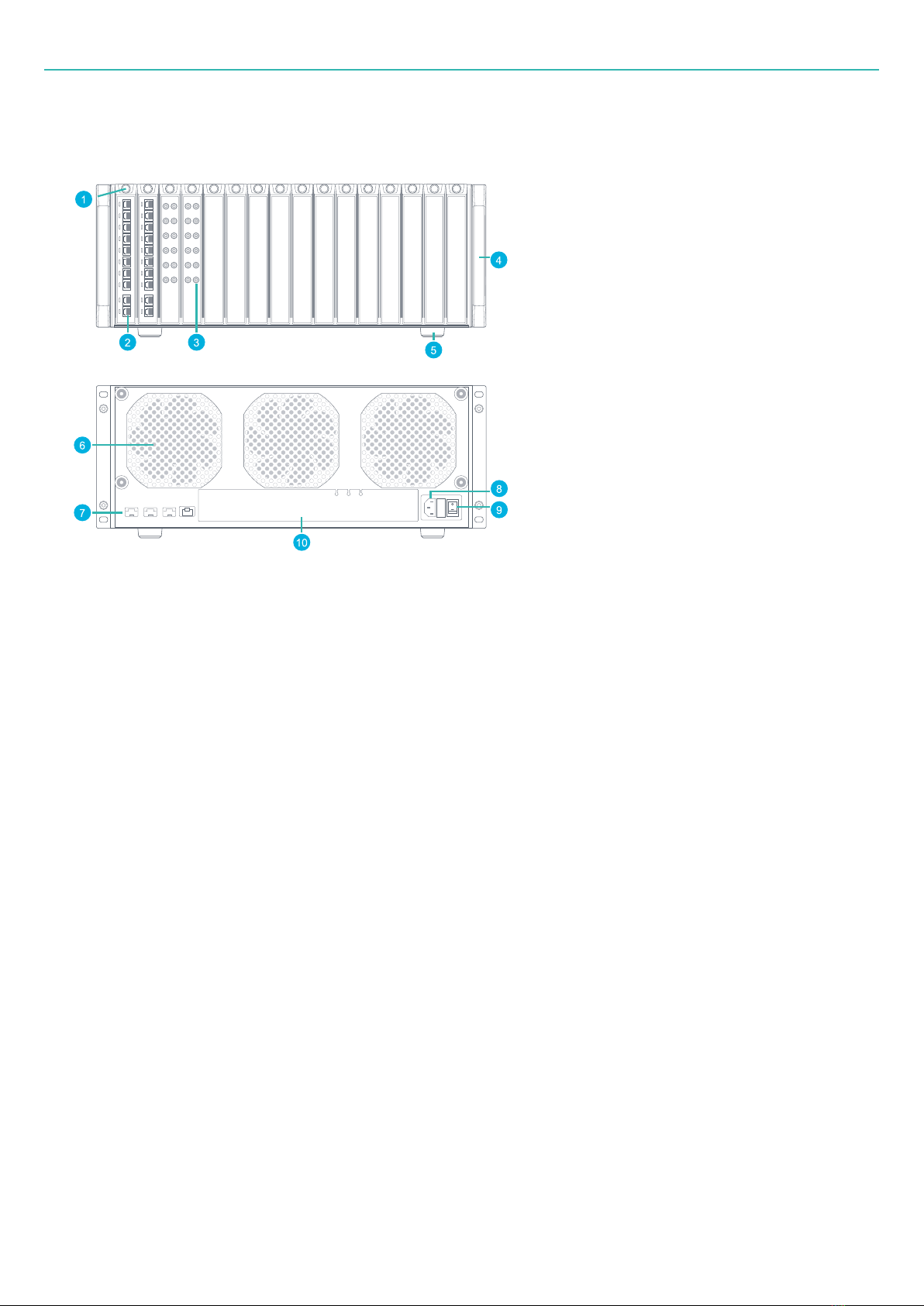

Parts overview

1. Board fastener

2. Input connectors

3. Input connectors

4. Plastic handle cover

5. Foot for tabletop mounting

6. Fan

7. Ethernet ports:

a. 1 × RJ45 (up to 2.5 Gbit/s)

b. 3 × optional SFP modules for optical/copper (up to 10 Gbit/s)

8. Power socket

9. On/Off switch

10. Cover with non-functional slots. Do not remove during operation. Do not attempt to use slots.

- 20 -

Table of contents

Other HBK Industrial Equipment manuals