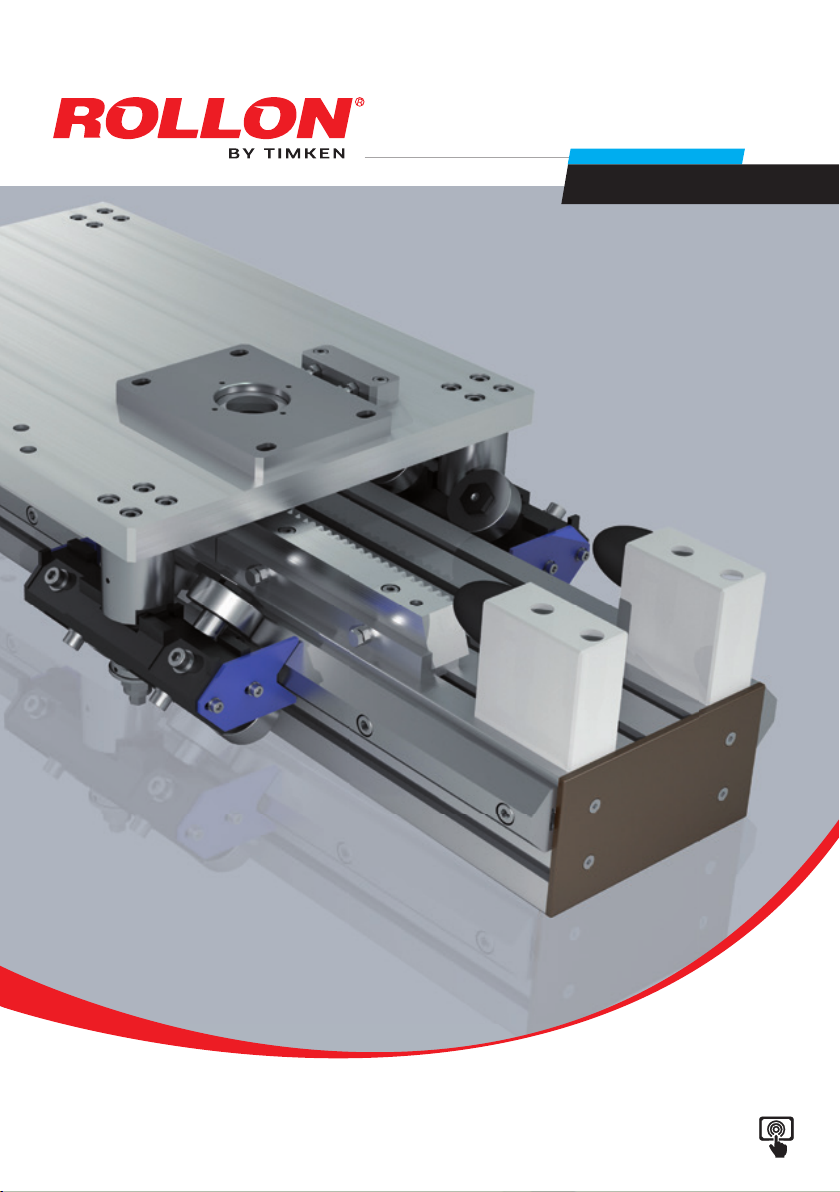

Tecline

UM-5

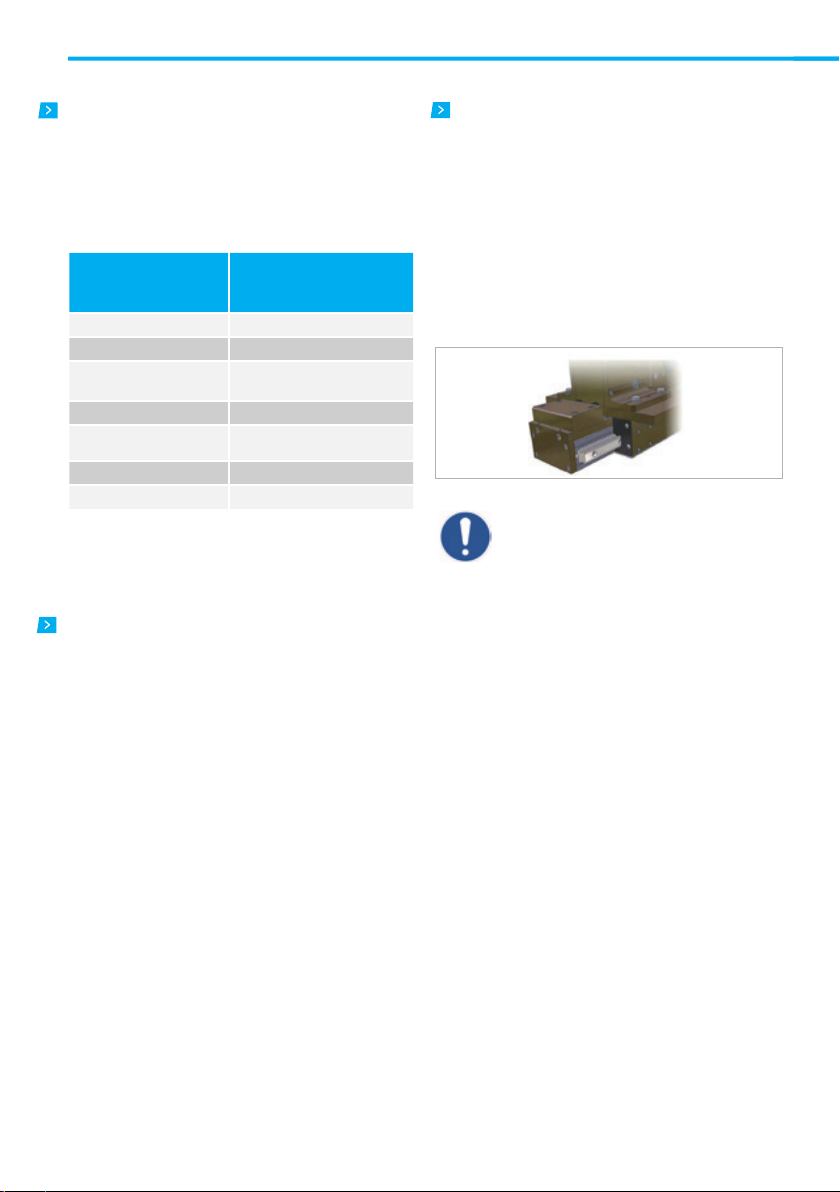

The Partly Completed Machinery shown in this catalog is to be

considered a mere supply of simple Cartesian axes and their ac-

cessories agreed when the contract is stipulated with the client. The

following are therefore to be considered excluded from the contract:

1. Assembly on the client’s premises (direct or final)

2. Commissioning on the client’s premises (direct or final)

3. Testing on the client’s premises (direct or final)

It is therefore understood that the aforementioned operations

in points 1.,2., and 3. are not chargeable to Rollon. Rollon is the

supplier of Partly Completed Machinery, the (direct or final) client

• Mechanical risks due to the presence of moving elements (X, Y axes).

• Risk of fire resulting from the flammability of the belts used on the axes,

for temperatures in excess of 250 °C in contact with the flame.

• The risk of the Z axis dropping during handling and installation

operations on the partly completed machinery, before commissioning.

• Risk of the Z axis dropping during maintenance operations in the case

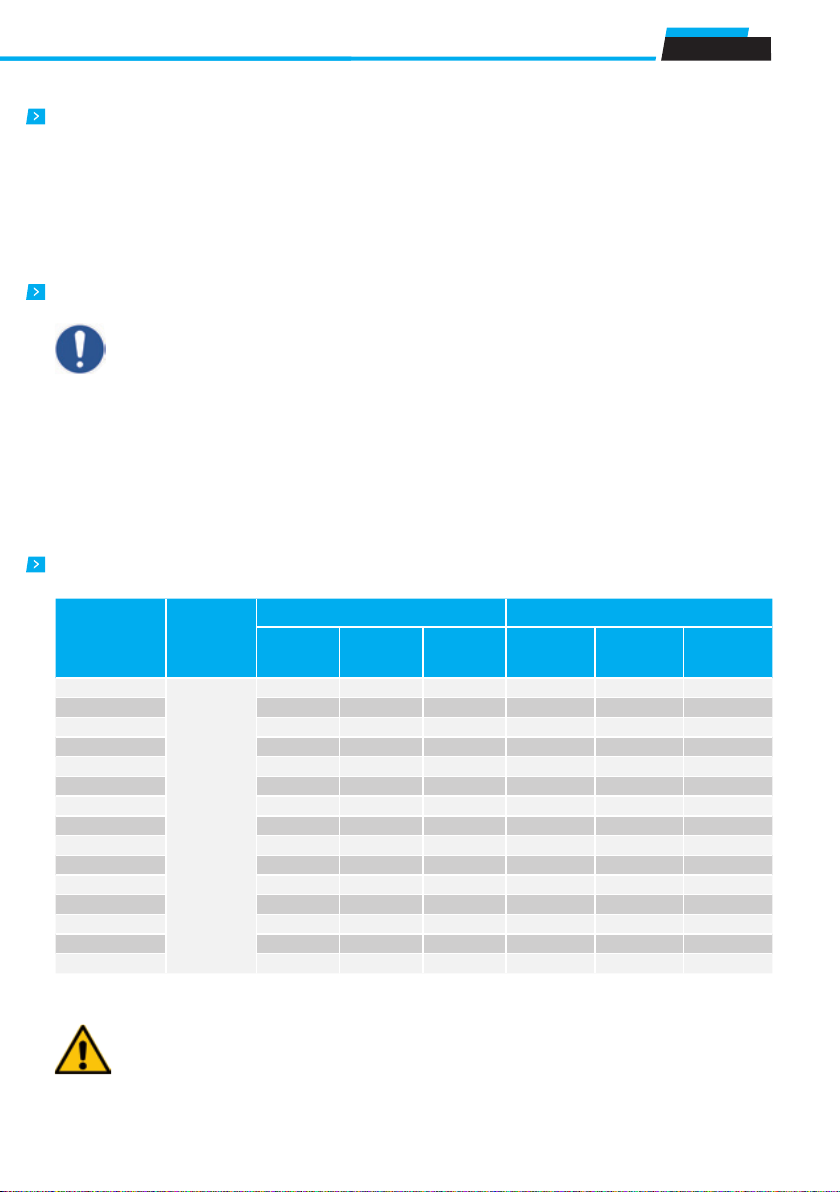

All the screws belong to the UNI-3740. Locking assemblies are provided with class 12.9 fastening screws.

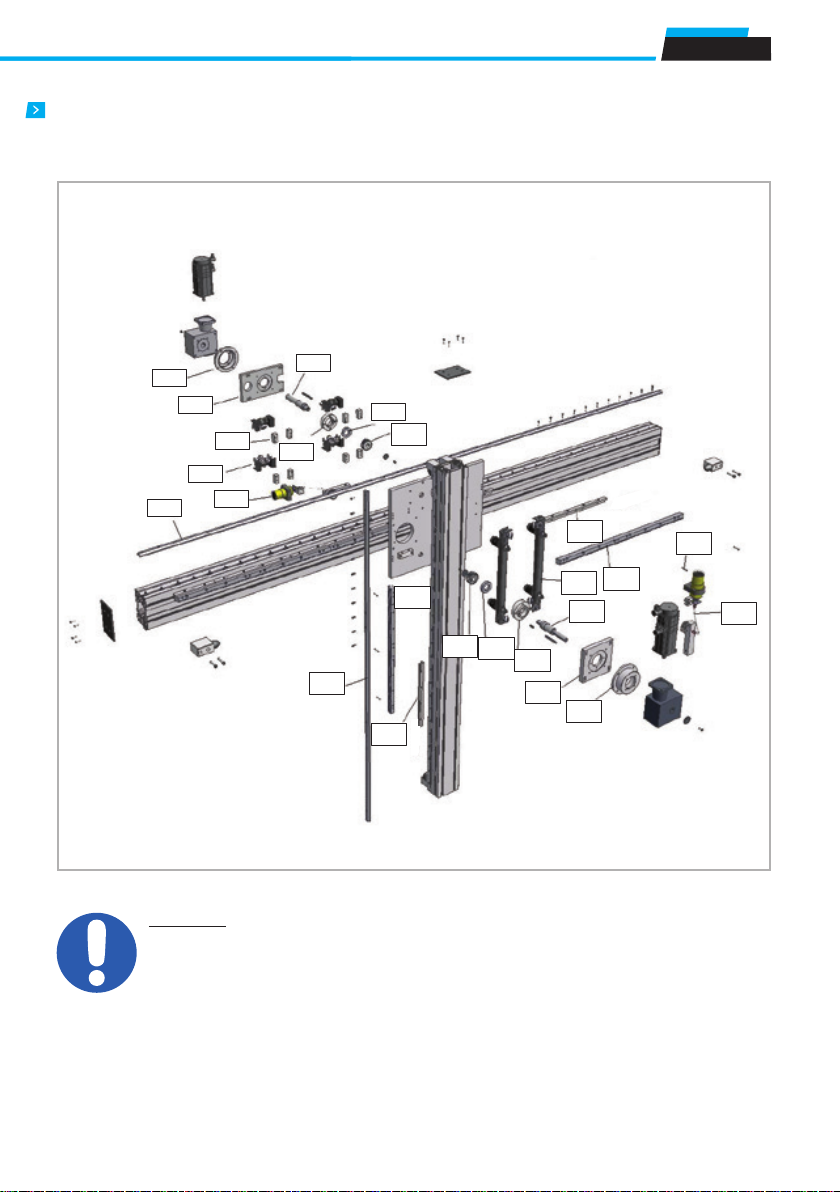

Basic components

Residual risks

Tightening torque and traction vector values

Thread

Friction

coefficient

Tightening torque [Nm] Traction vector [Nm]

Resistance

grade

8,8

Resistance

grade

10,9

Resistance

grade

12,9

Resistance

grade

8,8

Resistance

grade

10,8

Resistance

grade

12,8

M3

0,15

1,21 1,21 2,09 2075 3048 3567

M4 2,78 4,09 4,79 3594 5279 6178

M5 5,5 8,1 9,5 5886 8645 10116

M6 9,5 14,0 16,4 8302 12194 14269

M8 23 34 40 15242 22388 226498

M10 46 67 79 24275 35655 41724

M12 79 116 136 35401 51995 60845

M14 127 187 219 46816 71408 83563

M16 1998 291 341 66955 98340 115079

M18 283 402 471 8346 119454 139787

M20 402 570 667 107941 153657 179811

M22 552 783 917 134806 192157 224865

M24 691 981 1148 155489 221266 258928

M27 1022 1452 1700 204577 291534 341157

M30 1387 1969 2305 248811 354209 414500

is responsible for testing and safely checking all equipment whi-

ch, by definition, cannot be theoretically tested or checked at our

facilities where the only movement possible is manual movement

(for example: motors or reduction gears, cartesian axes movements

that are not manually operated, safety brakes, stopper cylinders,

mechanical or induction sensors, decelerators, mechanical limit

switches, pneumatic cylinders, etc.). The partly completed machine

must not be commissioned until the final machine, in which it is to

be incorporated, has been declared compliant, if necessary, with the

instructions in Machinery Directive 2006/42/CE.

IMPORTANT!

All screws used for installing ROLLON modules have self-

locking washers or semi-permanent threadlock fluid (blue,

such as Loctite 243). We recommend that the user also

employ these devices, both while setting up the partially

assembled machine in this manual, and during the assembly

or maintenance phases: If this is not done, the manufacturer

of the partially assembled machine declines all responsibility

for any accidents, breakage, damage and the consequences

of said events on people, animals and property, due to the

failure of fixing elements.

of a drop in the electrical power supply voltage.

• Crushing hazard near moving parts with divergent and convergent

motion.

• Shearing hazard near moving parts with divergent and convergent

motion.

• Cutting and abrasion hazards.