2

Using the Service Manual

If the instructions accompanying this symbol are ignored and the

machine is operated incorrectly, death or serious injury is likely to

result.

If the instructions accompanying this symbol are ignored and the

machine is operated incorrectly, death or serious injury, or else material

damage, is likely to result.

A " " symbol tells you that a certain action is forbidden. Precisely what

is forbidden is indicated by a picture inside the symbol (in the example

here, the picture means that disassembly is forbidden), or in writing at

the side of the symbol.

A "●" symbol means that a certain action is forbidden and/or that a

specic instruction must be followed. The specic instruction is indicated

by a picture inside the symbol (in the example here, the instruction is

"Remove the power plug from the socket").

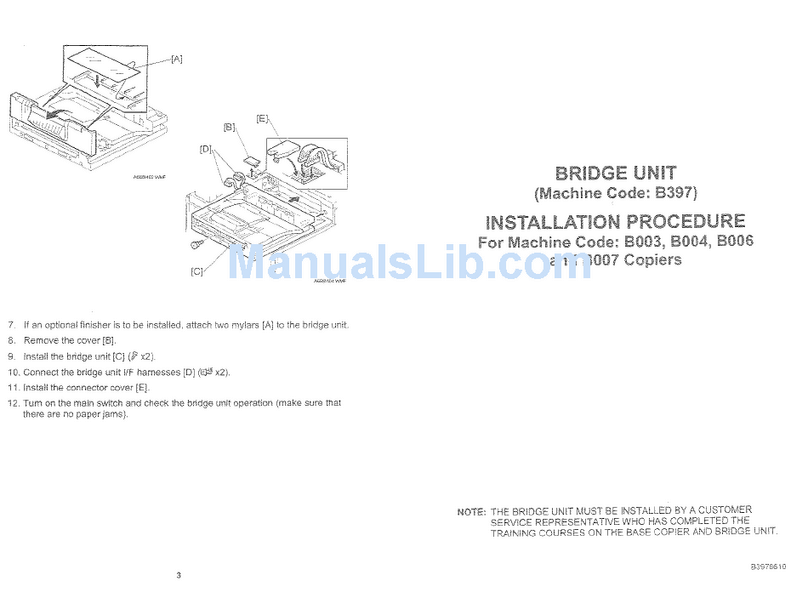

●This manual contains the following information: structure and function of major parts,

disassembly and reassembly procedures, specications, and procedures for adjustment,

maintenance, inspection and corrective action. This information is current as of September

2015, and applies basically to the model ADF DF7010. From time to time, parts are changed

to improve quality, performance or safety.

Note therefore that in some cases, certain parts or machine structure aspects described in

the text or illustrations of this manual may not be precisely the same as the product being

serviced.

●Safety instructions marked with a " " (WARNINGS and CAUTIONS) are very important for

safety and must be observed.

■ Using the Service Manual

● Safety-related instructions

● Service work-related instructions

WARNING:

CAUTION:

Examples of pictorial symbols

Draws attention to important information. If this information is ignored and

the machine is operated or serviced incorrectly, the machine's

performance could drop, or it could break down.

Draws attention to information that is useful for operation or maintenance

of the machine, and to information about its performance, etc.

IMPORTANT

REFERENCE