278-104-411.10_REV F4

K-750 Drain Cleaning Machine

tion except as described in this manual. Operating in

reverse can result in cable damage and is used to

back the cable end out of blockages.

•Do not wear loose clothing or jewelry. Keep your

hair and clothing away from moving parts. Loose

clothing, jewelry or hair can be caught in moving parts.

•Do not operate this machine if operator or machine

is standing in water. Operating machine while in water

increases the risk of electrical shock.

•Do not use if there is the risk of contact with other

utilities (such as natural gas or electric) during op-

eration. Visual inspection of the drain with a camera is

a good practice. Crossbores, improperly placed utilities

and damaged drains could allow the cutter to contact

and damage the utility. This could cause electrical

shock, gas leaks, fire, explosion or other serious dam-

age or injury.

•Read and understand these instructions and the in-

structions and warnings for all equipment and ma-

terials being used before operating this tool to

reduce the risk of serious personal injury.

RIDGID®Contact Information

If you have any question concerning this RIDGID®product:

– Contact your local RIDGID®distributor.

– Visit RIDGID.com to find your local RIDGID contact

point.

– Contact Ridge Tool Technical Service Department at

Cana da call (800) 519-3456.

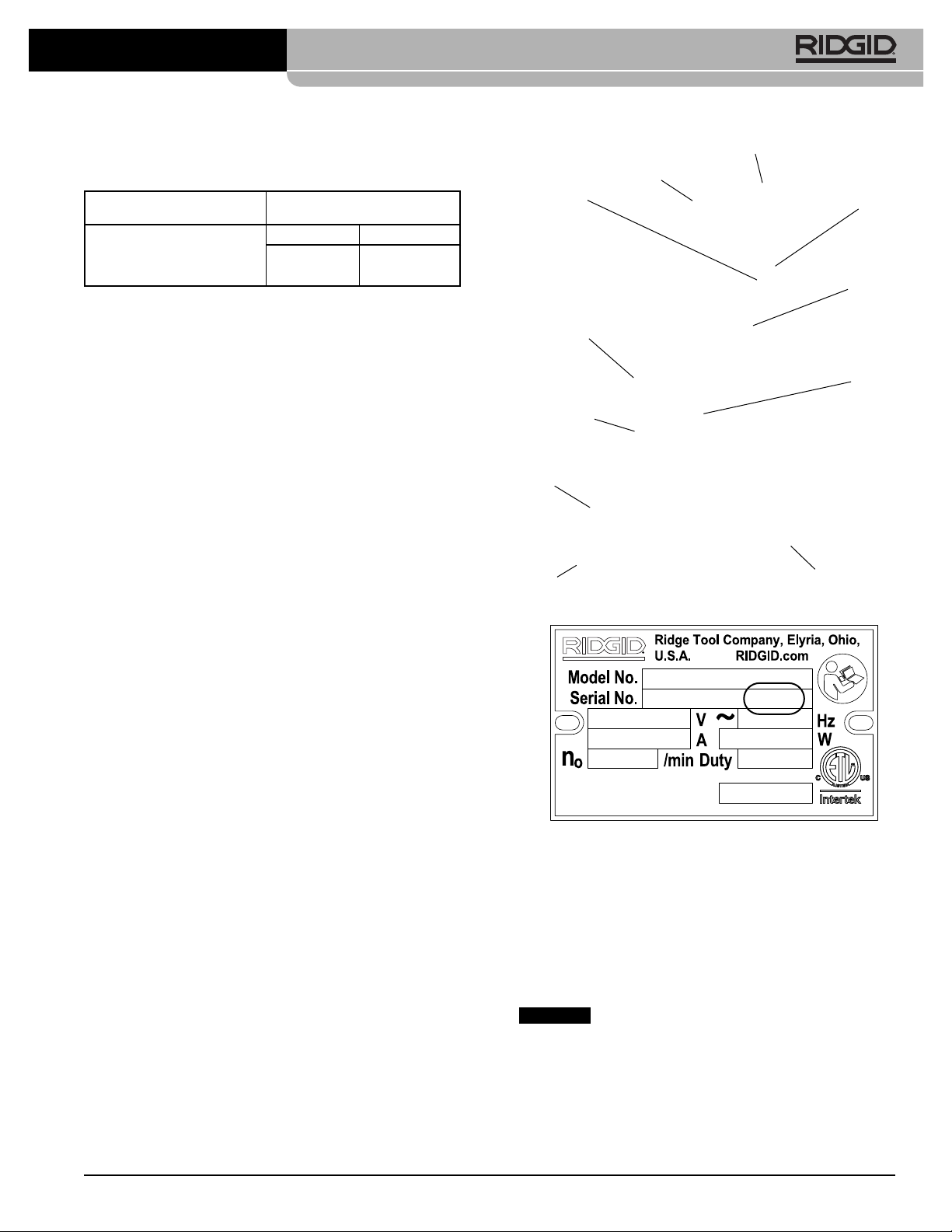

Description, Specifications and

Standard Equipment

Description

The RIDGID®K-750 Drain Cleaning Machine will clean

drain lines 3" to 8" in diameter and 200 feet in length de-

pending on size of cable. Corrosion resistant cable drum

holds 100 feet of 3/4" diameter cable or 125 feet of 5/8" di-

ameter cable. Cable spins at 200 RPM.

The drum is belt-driven by a 1/2P electric motor that

has a grounded electrical system. An integral Ground

Fault Interrupter (GFCI) is built into the line cord. A pneu-

matic foot switch provides ON/OFF control of the motor. A

“kickstand” base is provided for machine stability during op-

eration.

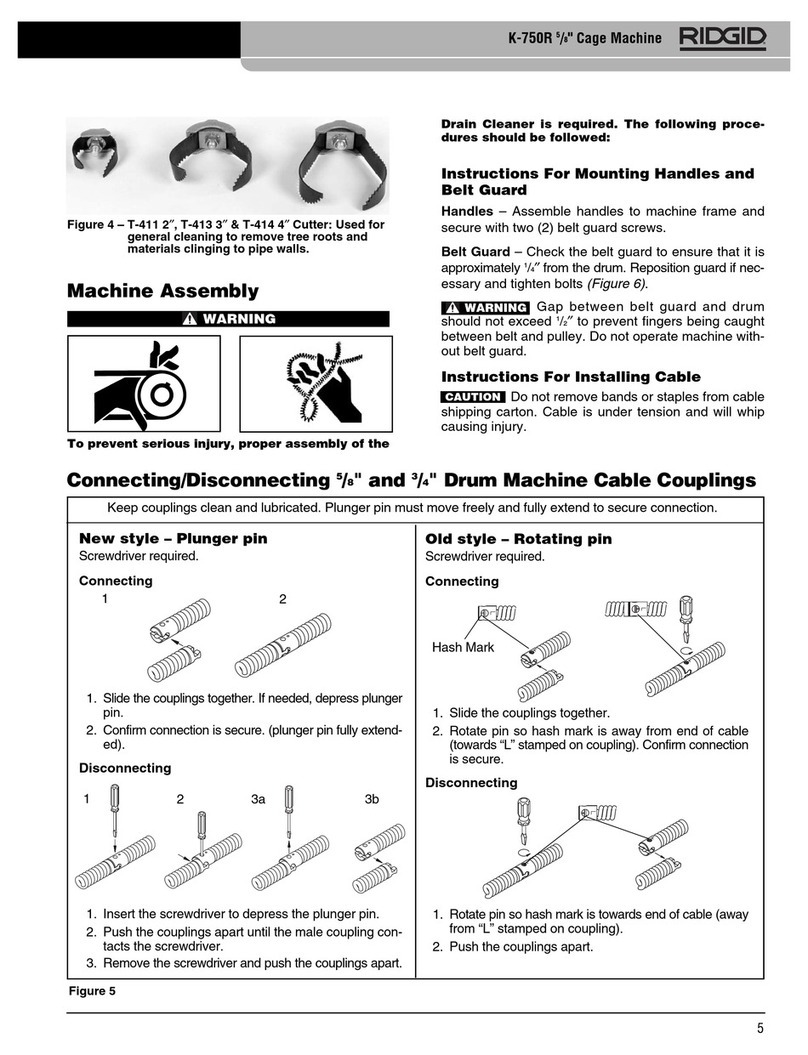

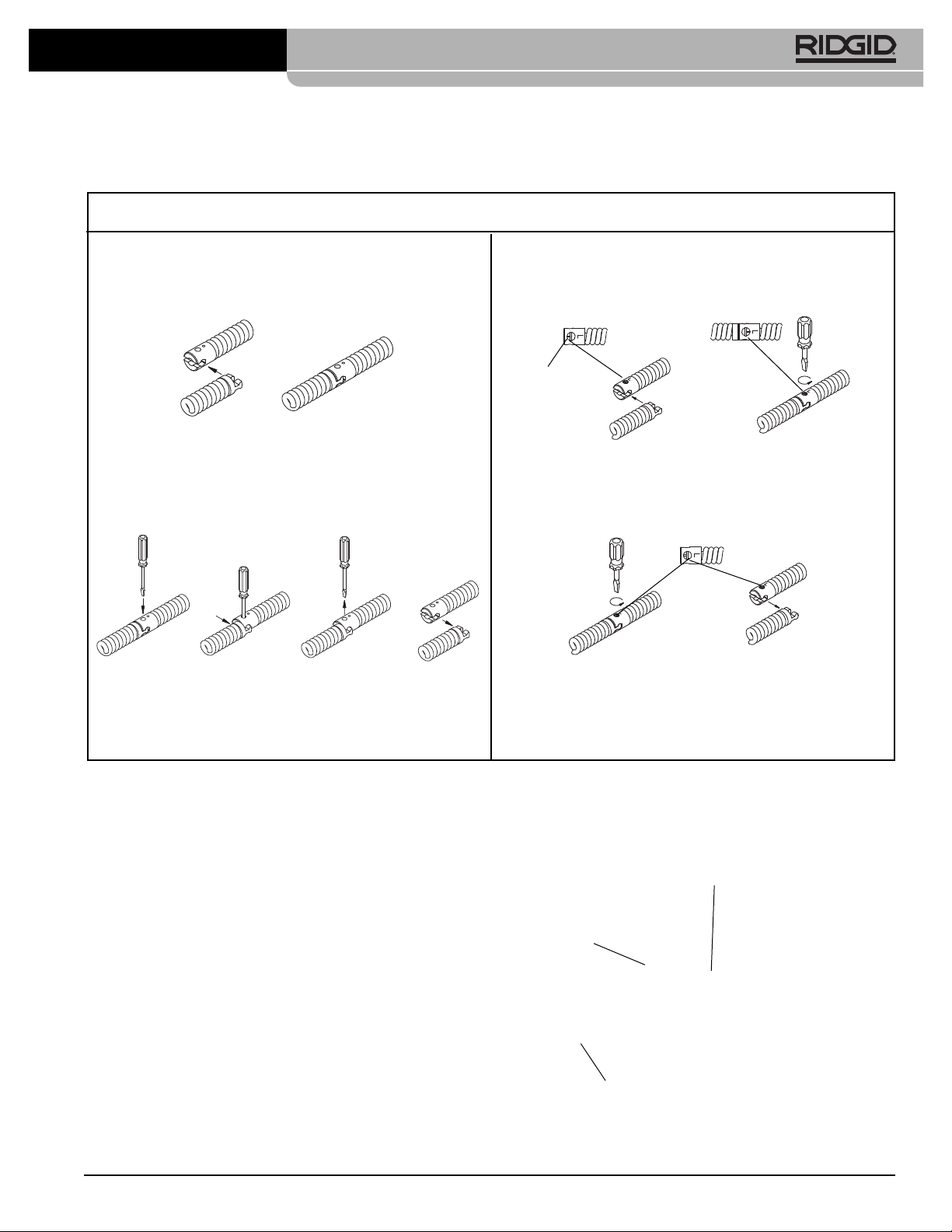

The cable has a quick change coupling system for con-

necting or disconnecting tools. An optional AUTOFEED ad-

vances or retracts the cable at a rate up to 20 feet per

minute. A manual feed option is also available.

•Only use extension cords that are protected by a

GFCI. The GFCI on the machine power cord will not

prevent electrical shock from extension cords.

•Only grasp the rotating cable with gloves recom-

mended by the manufacturer. Latex or loose fitting

gloves or rags can become wrapped around the cable

and may result in serious personal injury.

•Do not allow the cutter to stop turning while the

cable is turning. This can overstress the cable and

may cause twisting, kinking or breaking of the cable and

may result in serious personal injury.

•One person must control both the cable and the

foot switch. If the cutter stops rotating, the operator

must be able to turn the machine motor OFF to prevent

the cable from twisting, kinking and breaking.

•Use latex or rubber gloves inside the gloves rec-

ommended by the manufacturer, goggles, face

shields, protective clothing, and respirator when

chemicals, bacteria or other toxic or infectious

substances are suspected to be in a drain line.

Drains may contain chemicals, bacteria and other sub-

stances that may cause burns, be toxic or infectious or

may result in other serious personal injury.

•Practice good hygiene. Do not eat or smoke while

handling or operating the tool. After handling or op-

erating drain cleaning equipment, use hot, soapy

water to wash hands and other body parts ex-

posed to drain contents. This will help reduce the risk

of health hazards due to exposure to toxic or infectious

material.

•Only use the drain cleaner for the recommended

drain sizes. Using the wrong size drain cleaner can

lead to twisting, kinking or breaking of the cable and may

result in personal injury.

•Keep hands away from rotating drum and guide

tube. Do not reach into drum unless machine is un-

plugged. and may be caught in the moving parts.

•Keep glove-covered hand on the cable whenever

the machine is running. This provides better control of

the cable and helps prevent twisting, kinking and break-

ing of the cable and may result in serious personal in-

jury.

•Position machine cable outlet within 3' (0.9 m) of

the drain inlet or properly support exposed cable

when the distance exceeds 3' (0.9 m). Greater dis-

tances can cause control problems leading to twisting,

kinking or breaking of the cable. Twisting, kinking or

breaking cable may cause striking or crushing injuries.

•Do not operate the machine in REV (reverse) rota-