ProPress XL-C

RIDGID makes ProPress XL-C Rings for use with

ProPress XL-C Fittings. ProPress XL-C Rings are de-

signed to mechanically press ProPress XL-C fittings onto

21/2", 3" and 4" tubing. An individual ring is required for each

tubing size. ProPress XL-C Rings are actuated with V2

actuators and Standard Series Press Tools such as the

CT-400, 320-E or RP 330. ProPress XL-C Rings cannot be

used with the Compact Series Press Tools.

The ProPress XL-C rings must be used perpendicular to

the fitting and tube being pressed but the ball pocket/tip

feature on the rings and actuators allows the actuator and

press tool to swivel up to 90 degrees in each direction.

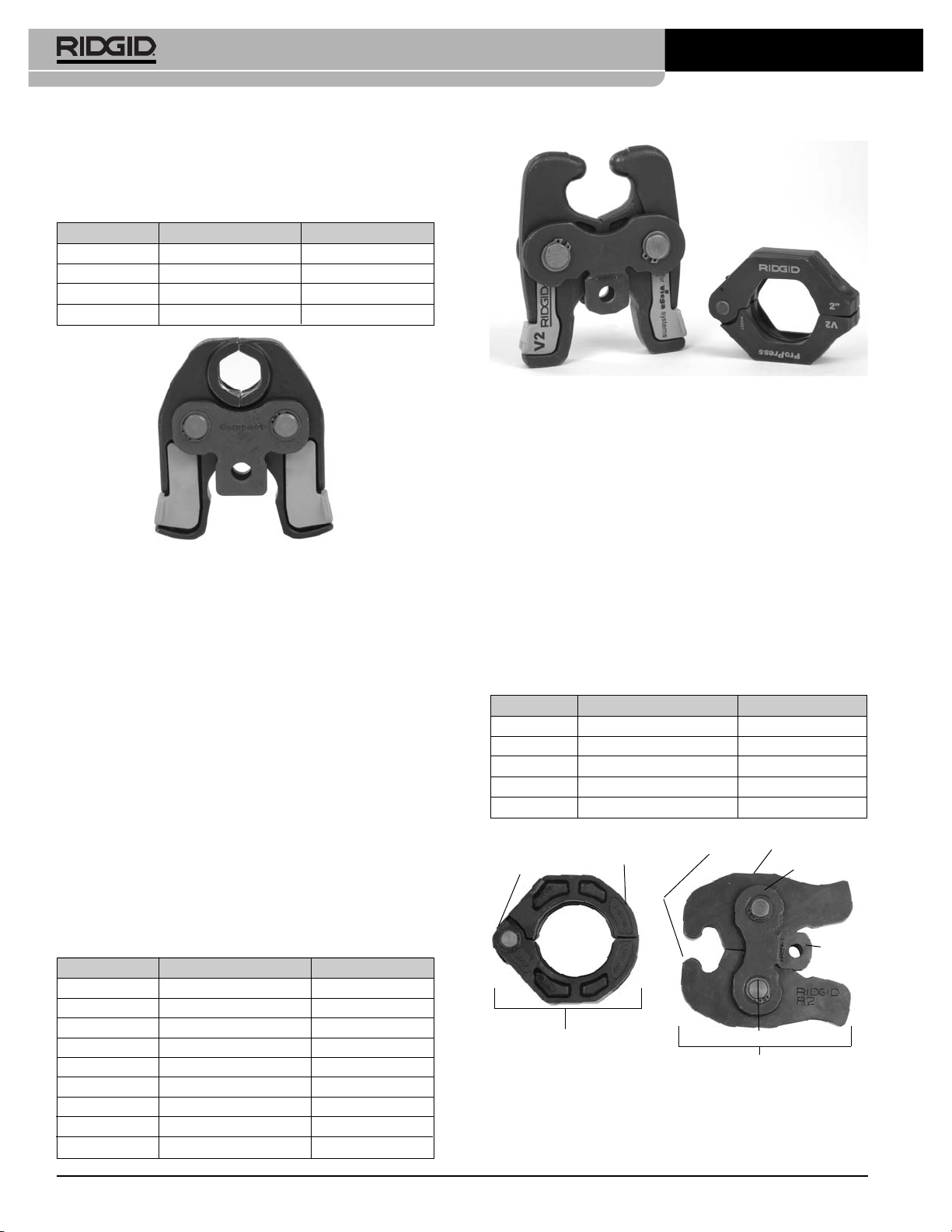

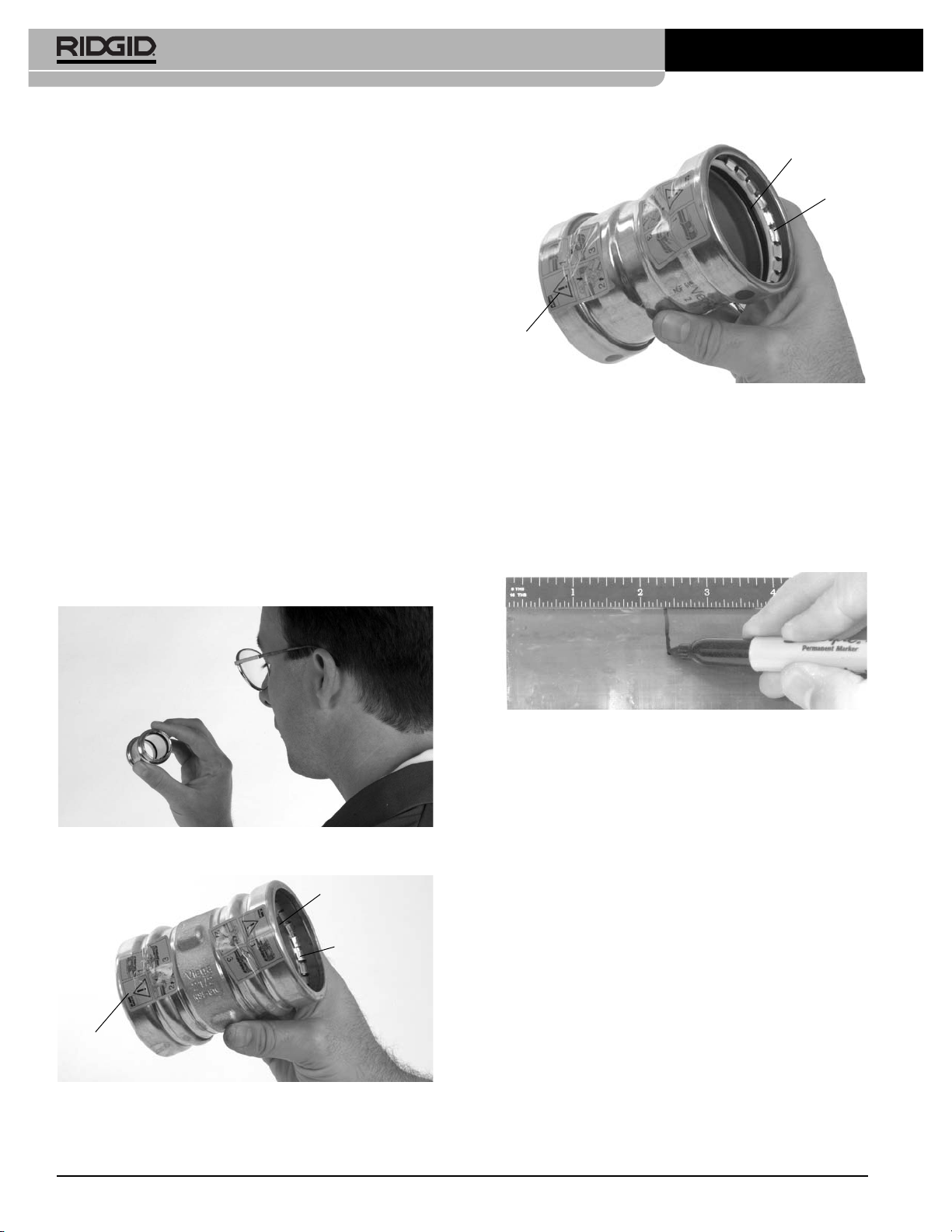

Figure 5 – ProPress XL-C Press Ring and RIDGID V2

Actuator

RIDGID Press Tool Attachments are protected under

various U.S. and International patents and pending patent

applications, including U.S. patents:

6,434,998 6,477,757 6,694,586 6,729,009 6,923,037

7,000,448 7,059,166 7,146,839 7,155,955 7,188,508

7,237,427 7,260,975 7,363,799 D562,098

Only use RIDGID Press Tools and RIDGID

press tool attachments (jaw sets, rings, actuators, etc.)

when specified by the fitting manufacturer for use with their

system. Use of incorrect press tools and/or attachments

for a system can cause system leaks, damage the press

tool or attachment, void warranties or cause severe per-

sonal injury.

Contact the fitting manufacturer for specific

information on their system, including compatible tubing,

materials, installation instructions, minimum distance

between fittings, seal material, inspection, testing, etc.

Incorrect installation can cause system leaks and exten-

sive property damage.

Contact Ridge Tool Technical Services Department at

list of press fitting system and valve manufacturers that

specify RIDGID pressing tools and attachments for their

systems.

Inspecting the Press Tool and

Attachments

WARNING

Inspect your pressing tool and attachments daily

and correct any problems to reduce the risk of seri-

ous injury from electric shock, tool and attachment

failure and other causes and to prevent tool and

property damage.

1. Inspect press tool according to the specific tool oper-

ator's manual.

2. Clean any oil, grease or dirt from the tool and attach-

ments, especially the handles and controls. This

reduces the risk of the tool or attachment slipping from

your grip and makes inspection easier.

3. Closely inspect all pressing attachment components

(jaw sets, rings, actuators, etc.) for any cracked, bro-

ken, worn, missing, mis-aligned or binding parts or any

other sign of damage that may prevent proper and

safe operation. Damaged parts can cause the attach-

ment to make incorrect pressed connections or fail

during use, and cause serious injury or property dam-

age. If any damage is found, the attachment should

discarded and replaced.

Always discard the complete pressing

attachment. Never replace individual components or

exchange parts between assemblies. Failure to replace

the entire assembly may result in component failure

and serious injury.

Do not modify pressing attachments or use modified

attachments. A pressing attachment component that

has been welded, ground, drilled or modified in any

manner can shatter during pressing, resulting in sharp fly-

ing objects, severe injury or death. Discard and replace

damaged pressing attachments.

4. Inspect the attachment markings to make sure that it

is clearly marked as to the system and size that it is

appropriate for. Do not use an attachment that is not

clearly marked.

Ridge Tool Company 5

ProPress®Fitting System

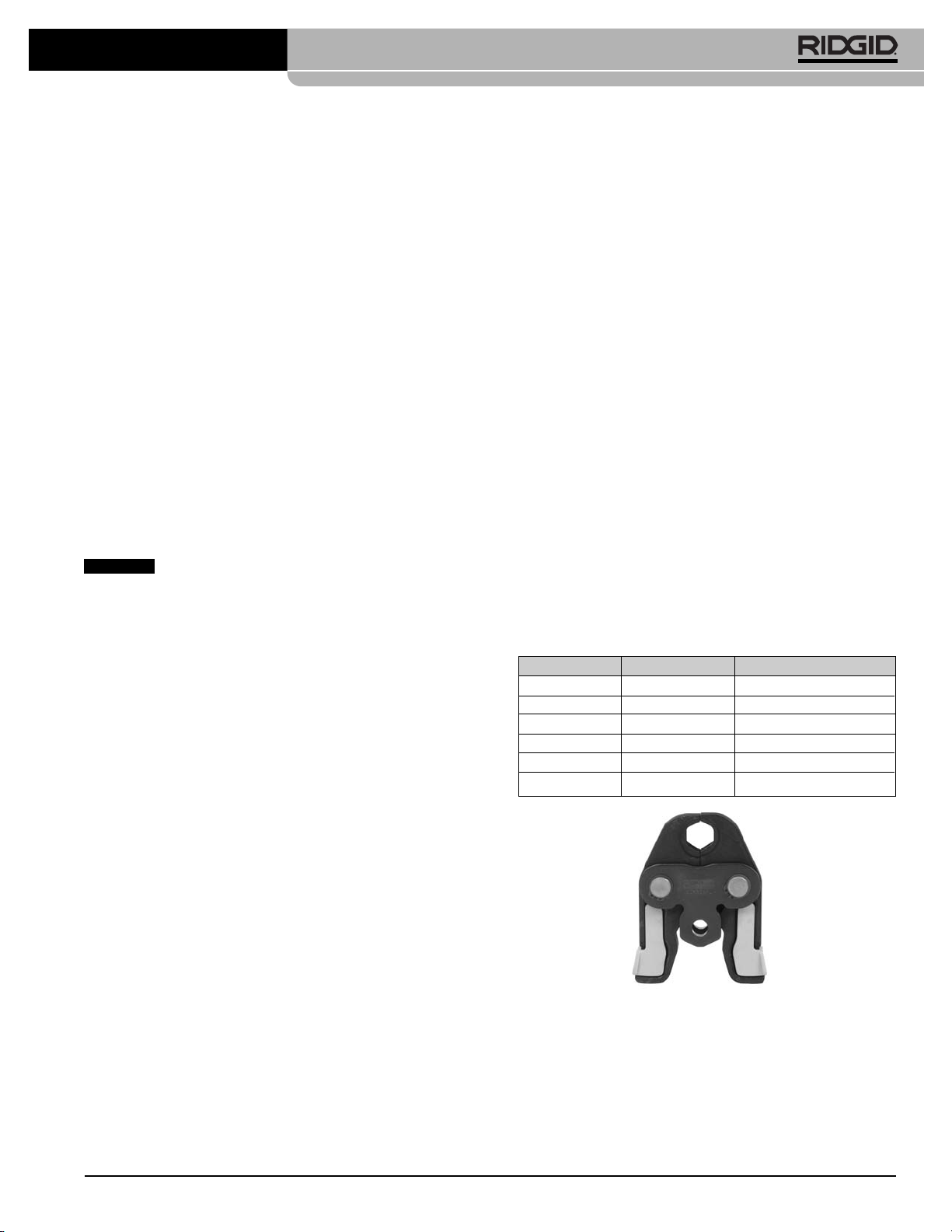

Catalog No. Size Weight

20543 21/2" XL-C Press Ring 5.46 lbs (2,48 kg)

20548 3" XL-C Press Ring 9.63 lbs (4,37 kg)

20553 4" XL-C Press Ring 11.08 lbs (5,03 kg)

21878 V2 Actuator 6.71 lbs (3,04 kg)

21103 Carrying Case 6.15 lbs (2,79 kg)

Press Ring Actuator

Pocket (Not Visible) V2 Actuator Arm

V2 Side Plate

V2 Actuator

Torsion

Spring (Not

Visible)

ProPress XL-C Press Ring

XL-C Press Ring

Pivot Pin &

Torsion Spring

(Not visible)

RIDGID V2 Actuator

V2 Actuator

Spherical Tip

NOTICE

WARNING

WARNING