WARNING

Read and understand these instructions, the electrical tool in-

structions, and the warnings and instructions for all equip-

ment and material being used before operating this tool to

reduce the risk of serious personal injury.

SAVE THESE INSTRUCTIONS!

•Keep your fingers and hands away from the Scissor Cutter

Head during the cutting cycle. Your fingers or hands can be

crushed, fractured or amputated if they are caught in the head or

between the head and other objects.

•This head is not insulated for use on or near energized con-

ductors. Use of this head on or near energized conductors may

lead to electrical shock, causing severe injury or death.

•Large forces are generated during product use that can break

or throw parts and cause injury. Stand clear during use and wear

appropriate protective equipment, including eye protection.

•Never repair a damaged head. A head that has been welded,

ground, drilled or modified in any manner can break during use.

Only replace components as indicated in these instructions.Discard

damaged heads to reduce the risk of injury.

•Only use a RIDGID®or ILSCO®ElectricalTool with this RIDGID®

SC-60C Scissor Cutter Head.Use of other tools with this head may

damage the head, tool, cutting edge, or result in serious injury.

Description

The RIDGID SC-60C Scissor Cutter Head can be used to cut class B

copper and aluminum electrical wire up to 750 MCM (400mm²) or

ACSR (Aluminum Cable Steel Reinforced) up to 500 MCM (250mm2)

depending on the blades installed.

The Scissor Cutter Head attaches to the RIDGID or ILSCO Electrical

Tools and can rotate 360 degrees with the RIDGID QuickChange Sys-

tem™ (QCS™).

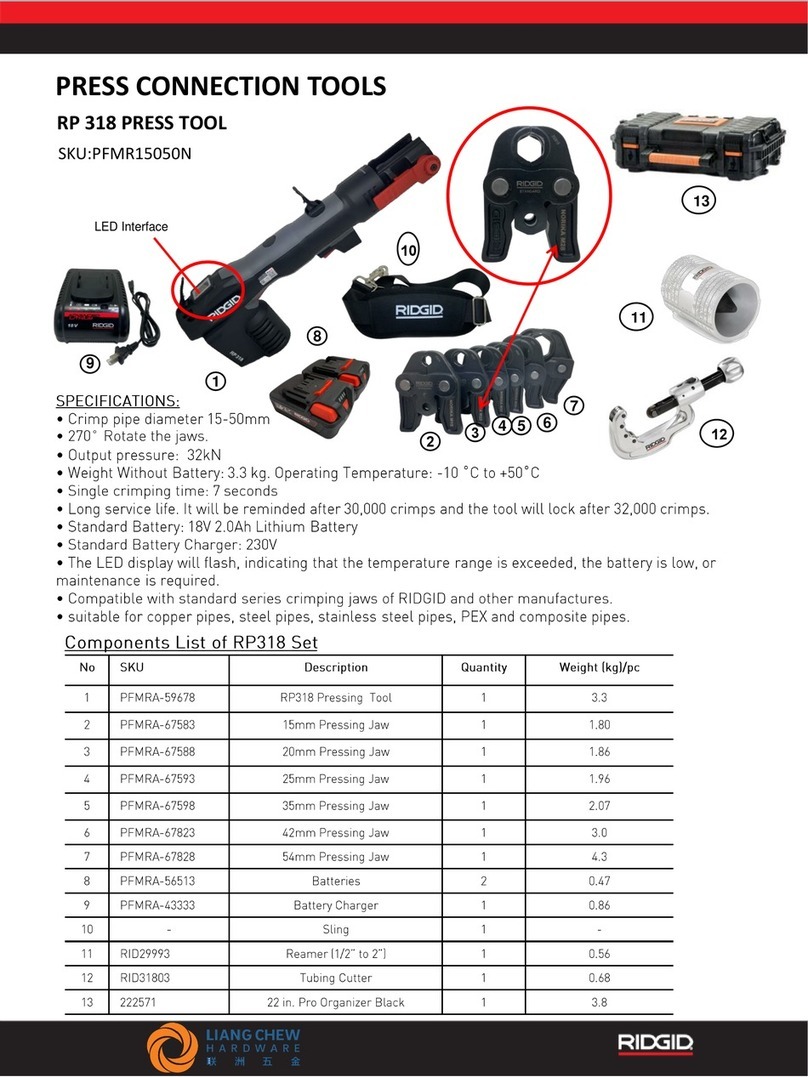

Figure 1 – SC-60C Scissor Cutter Head

Specification

Cable Blade Set Cat#

Class B copper building wire, up to 750MCM (400mm2) 47923

Aluminum building wire, up to 750MCM (400mm2)

Copper flex wire, up to 750MCM (400mm2)

Max.Dia.with insulation = 1.97" (50mm)

ACSR cable, 8GA to 500MCM (250mm2) 47928

Max.Dia.= 1.18" (30 mm)

Compatible QCS

Type ......................6T QCS

60kN QCS

Max.Input Force......60 kN (13500 lbf)

Weight....................4.85 lb (2.2 kg)

Cutting capacity depends on a variety of factors including material

thickness, type, hardness and configuration.Cuts may not be able to

be completed based on these and other variables.

Only cut material that the blades are rated for.Any other ma-

terial, such as steel, can dull and damage the blades.

Inspection/Maintenance

Inspect the Scissor Cutter Head before each use for issues that could

affect safe use.

1. With the battery removed from the tool, depress the QCS sleeve

and remove the head.

2. Clean the head and remove all dirt, oil, grease, and debris to aid

in inspection and improve control.Pay close attention to the QCS

coupling to ensure there is no debris to damage the coupling.

3. Inspect the head for:

• Proper assembly and completeness. Make sure guards are

present and secure.

• Wear, corrosion or other damage.Dimples in the grooves of the

QCS are normal with use and are not considered damage.

• Presence and readability of head markings.

If any issues are found, do not use head until corrected.

4. Inspect the electrical tool and any other equipment being used as

directed in their instructions.

5. The QCS coupling is lubricated for life at the factory and does not

require any further lubrication. Monthly or as required, lubricate

the pivot points of the Scissor Cutter Head with a light weight gen-

eral purpose lubricating oil.Wipe off any excess oil.

6. Changing cutting blades

– Remove the eight guard screws (A) and the guards (B).

– Remove the blade bolt (C) and nut (D).

– Remove the clips (E) and blade pins (F).

– Remove blades (G).

– Reverse steps to install a new, matched set of cutting blades.

– Tighten blade bolt until blades will not move.Loosen blade bolt

1/5turn and tighten blade bolt nut. Manually move blades past

each other to confirm proper function.

Figure 2 – Changing Blades

Set Up/Operation

1. Determine the size and type of material to be cut. Select the ap-

propriate equipment per its specifications.If needed, change cut-

ting blades.Do not cut steel wire.Mark the cut location on the wire.

2. Make sure all equipment is inspected and set up per its instruc-

tions.

3. Remove the battery from the tool. Depress the QCS sleeve on

the electric tool and insert the Scissor Cutter Head. Release the

sleeve to retain the head. Confirm that the head is fully inserted

and locked into tool before turning ON. (If head will not lock into

QCS, ensure tool ram is fully retracted by pressing the pressure

release button.)With dry hands install the tool battery.

4. Place the wire between the cutting edges of the Scissor Cutter

Head, and squarely line up the cutting edge with the cut location.

Do not try to cut the wire at an angle.

SC-60C Scissor Cutter Head Instructions

NOTICE

Blade

Guards

QCS Coupling

Blade Guide

Blade Bolt

A

E

F

G

C

D

B

Printed 6/14

944-732-974.10

EC40700 REV. B

©2014, RIDGID, Inc.

The Emerson logo and RIDGID logo are registered trademarks of Emerson Electric Co.or RIDGID, Inc.in the U.S. and other countries.

All other trademarks belong to their respective holders.