Ridge Tool Company

4

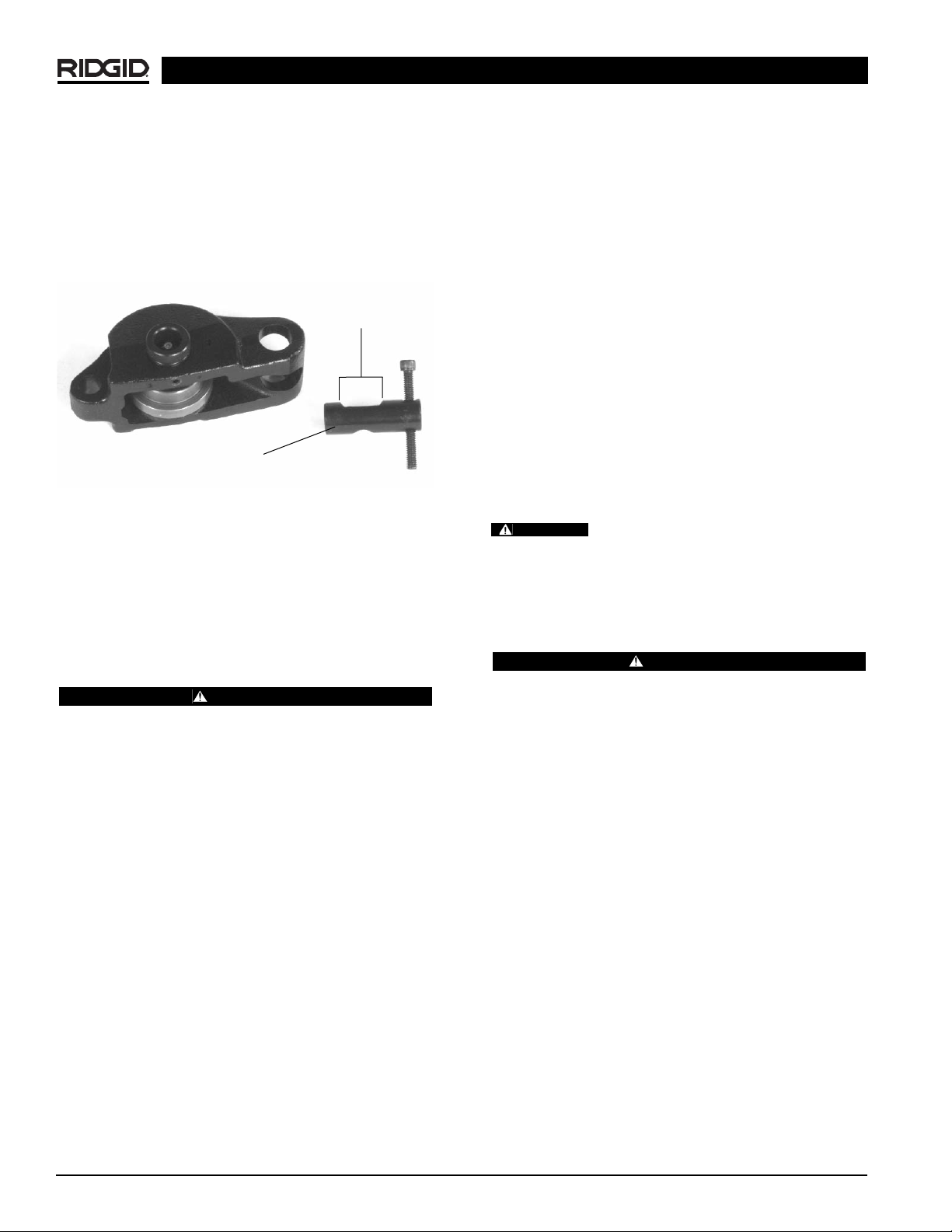

3. Use groover rolls and accessories that are designed for

your Roll Groover and meet the needs of your appli-

cation. The correct groover tools and accessories

allow you to do the job successfully and safely.

Accessories designed for use with other equipment

may be hazardous when used with this Roll Groover.

4. Clean any oil, grease or dirt from all handles and

controls. This reduces the risk of injury due to a tool or

control slipping from your grip.

5. Inspect the groove rolls to insure they are not dam-

aged or worn. Worn groover rolls can lead to slippage

and poor quality grooves.

Roll Groover and

Work Area Set-Up

WARNING

To prevent serious injury,

proper set-up of the Groover and work area is

required. The following procedures should be fol-

lowed to set-up the machine:

1. Insure work area has adequate lighting.

2. Clean up the work area prior to setting up any equip-

ment. Always wipe up any oil that may be present.

3. Check the groove and drive rolls to insure they are the

correct size.

Use of roll sets on both carbon and stainless

steel pipe can lead to contamination of the stainless steel

material. This contamination could cause corrosion and

premature pipe failure. To prevent ferrous contamina-

tion, use roll sets dedicated for stainless steel grooving.

4. Make sure pipe/tube is secured and not free to rotate

prior to roll grooving.

• If pipe is not installed, use a bench vise or tristand

vise to secure the pipe. Pipe supports must be used

if pipe is greater than 36″in length.

Failure to properly support the pipe can

result in the pipe falling.

Place vise and stands on a flat level surface. Be

sure the pipe, vise and stands are stable.

• If the pipe/tube is installed, care must be taken to

prevent pipe rotation or movement. Make sure that

the added weight and force required of the 915

can be supported by the pipe hangers and clamps.

Operating the 915 Roll Groover

WARNING

Do not wear loose clothing when operating a Roll

Groover. Keep sleeves and jackets buttoned.

Always wear eye protection to protect eyes from

dirt and other foreign objects. When working over-

head, wear a hard hat and keep personnel clear of

area.

Keep hands away from grooving rolls. Do not wear

loose fitting gloves when operating groovers. Use

pipe stands to support pipe when using a pipe vise.

Unit to be hand driven only. Do not power with drill

or other types of units.

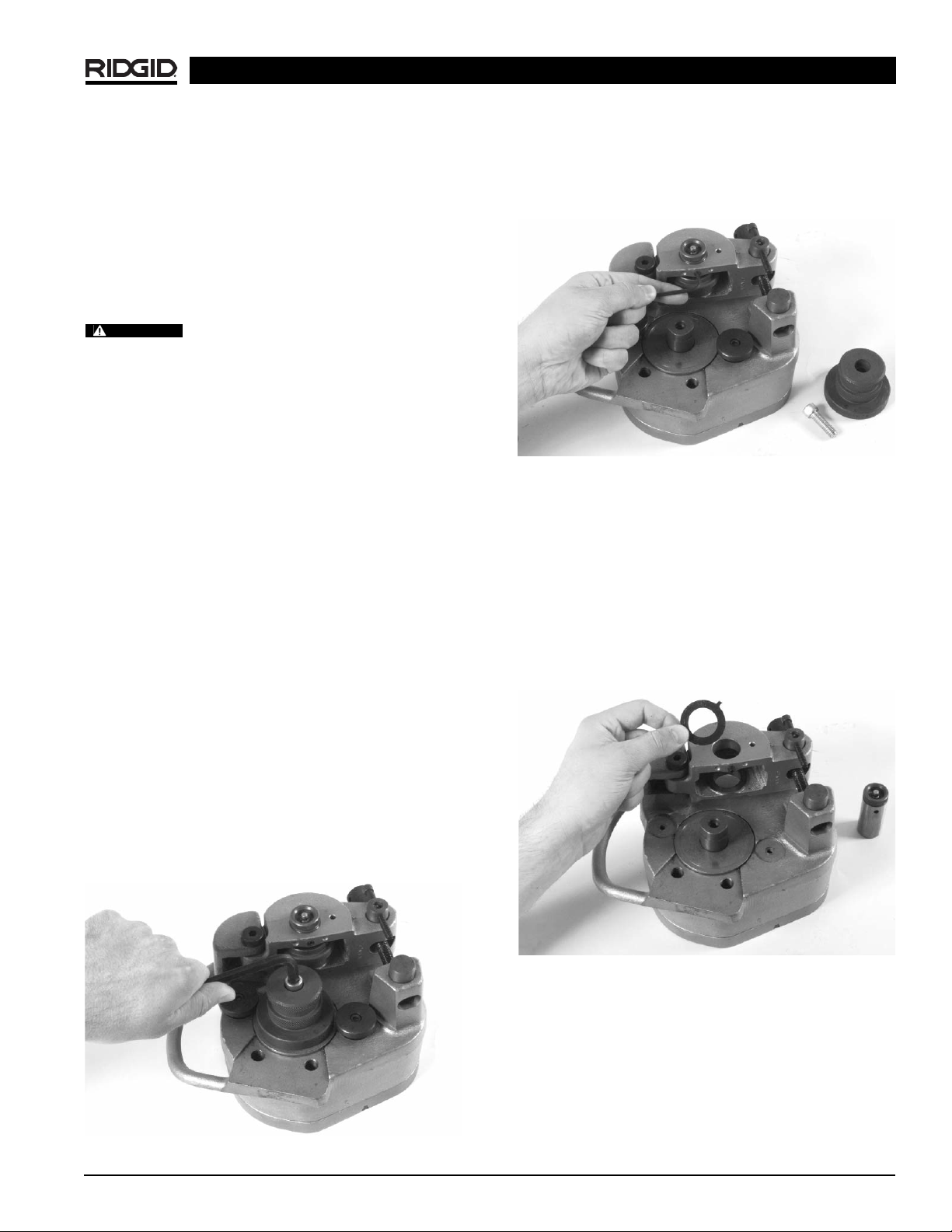

Pipe Preparation

1. Make sure pipe/tube end is cut square and free of

burrs. Do not attempt to groove pipe that has been cut

with a torch.

2. Pipe/tube out-of-roundness must not exceed the

total O.D. tolerances listed in the dimension specifi-

cation

(Table 1).

NOTE! Determine out-of-roundness by measuring max-

imum and minimum outside dimensions at 90

degree increments. Compare minimum and

maximum numbers with pipe diameter column

in

Table 1

.

3. All internal or external weld beads, flash or seams

must be ground flush at least 2″back from the pipe

end.

IMPORTANT! Do not grind flats on the pipe outside wall

where the coupling gasket seals (gasket

seat area).

4. The 915 Roll Groover will orbit around the pipe/tube.

Care must be taken that adequate space is provided

completely around material.

NOTE! The RIDGID 915 can roll groove pipe/tube with-

in 31/2″of a wall, ceiling or any other obstruction.

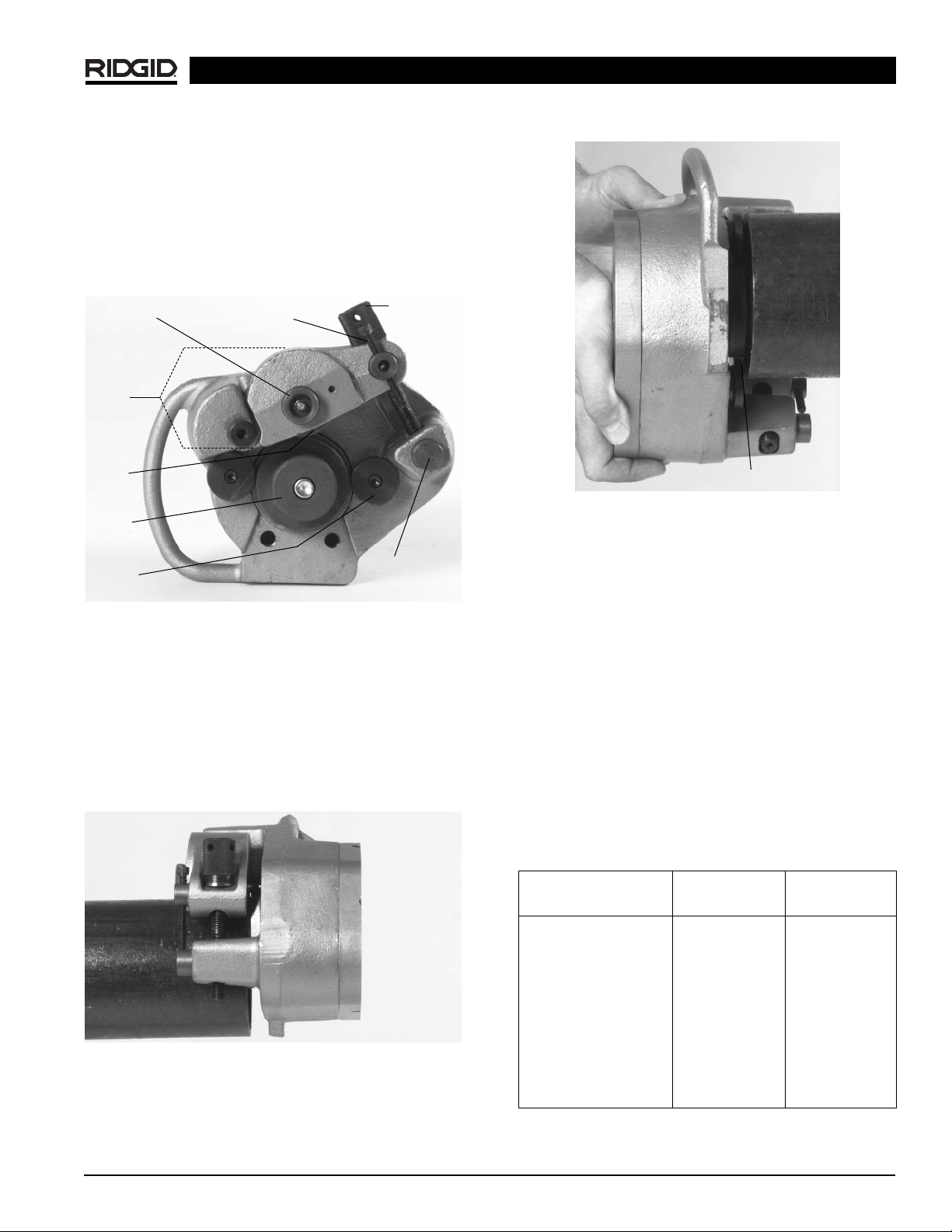

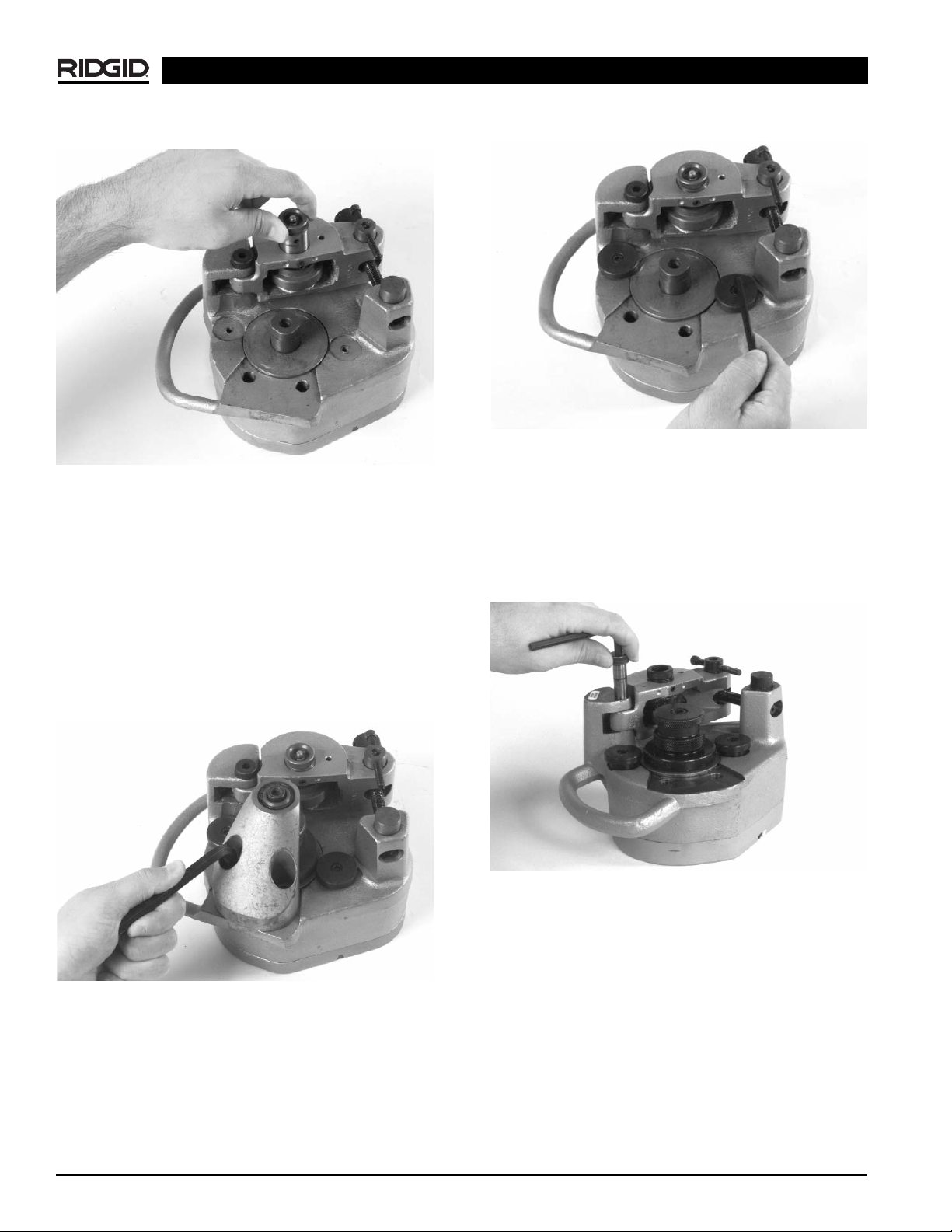

915 In Place Roll Groover

CAUTION

WARNING