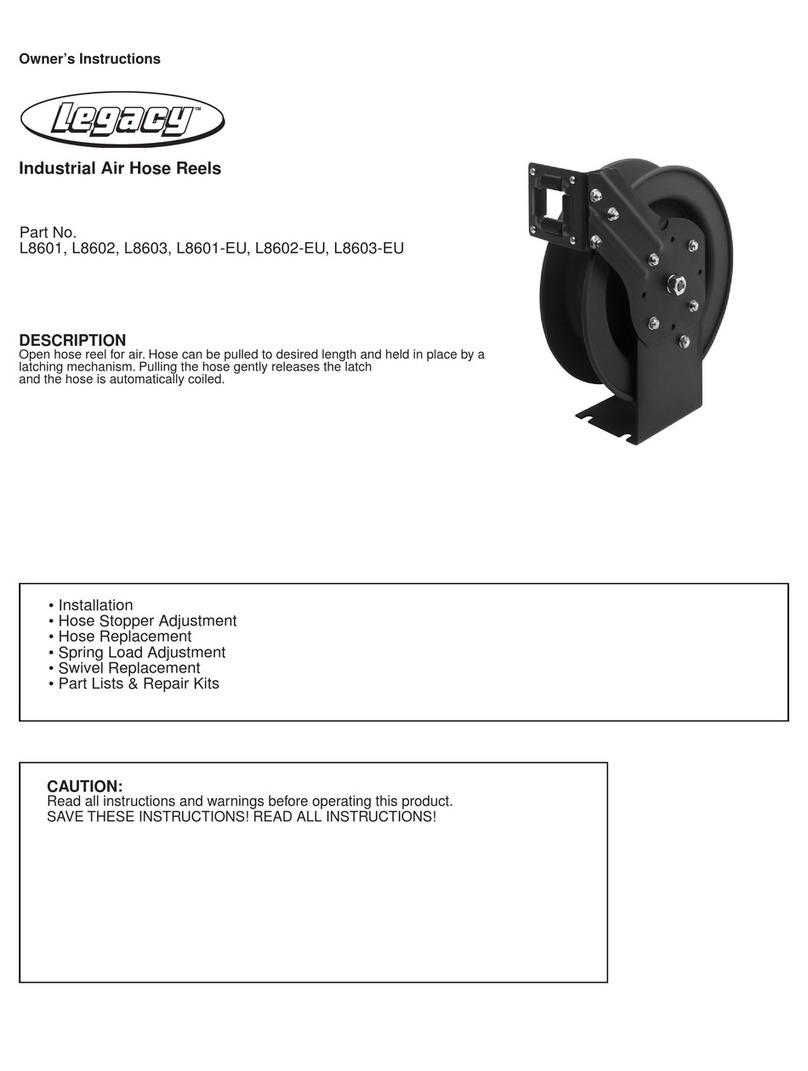

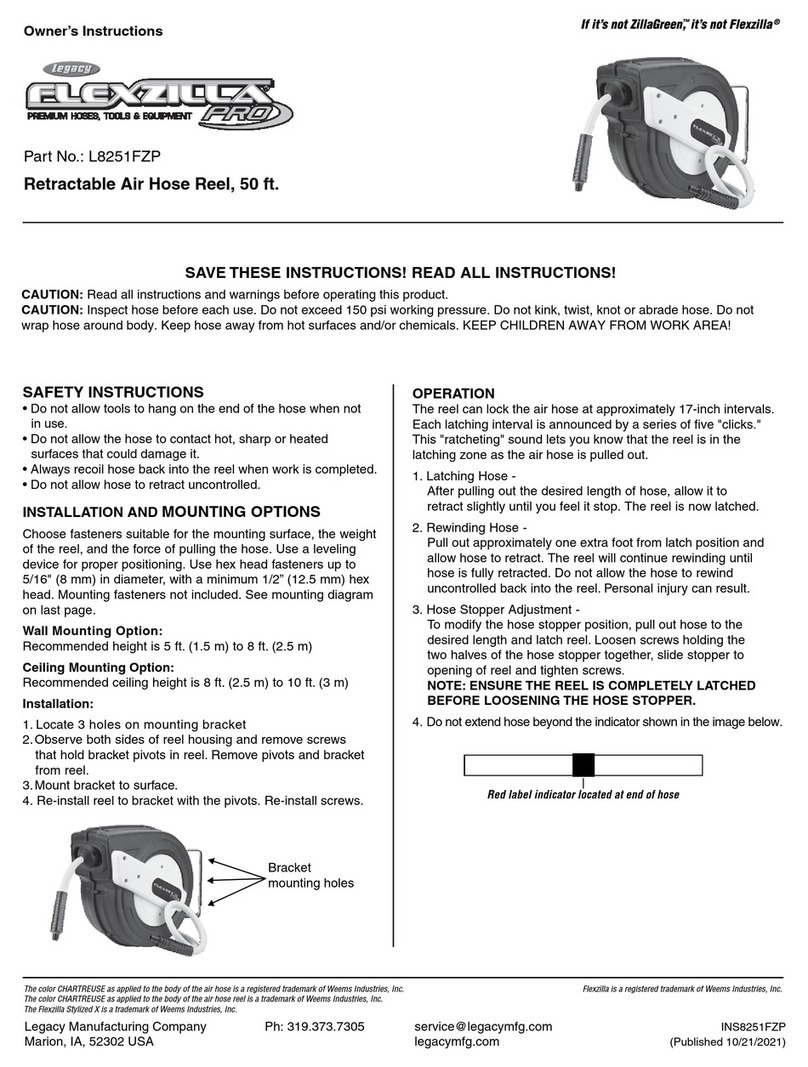

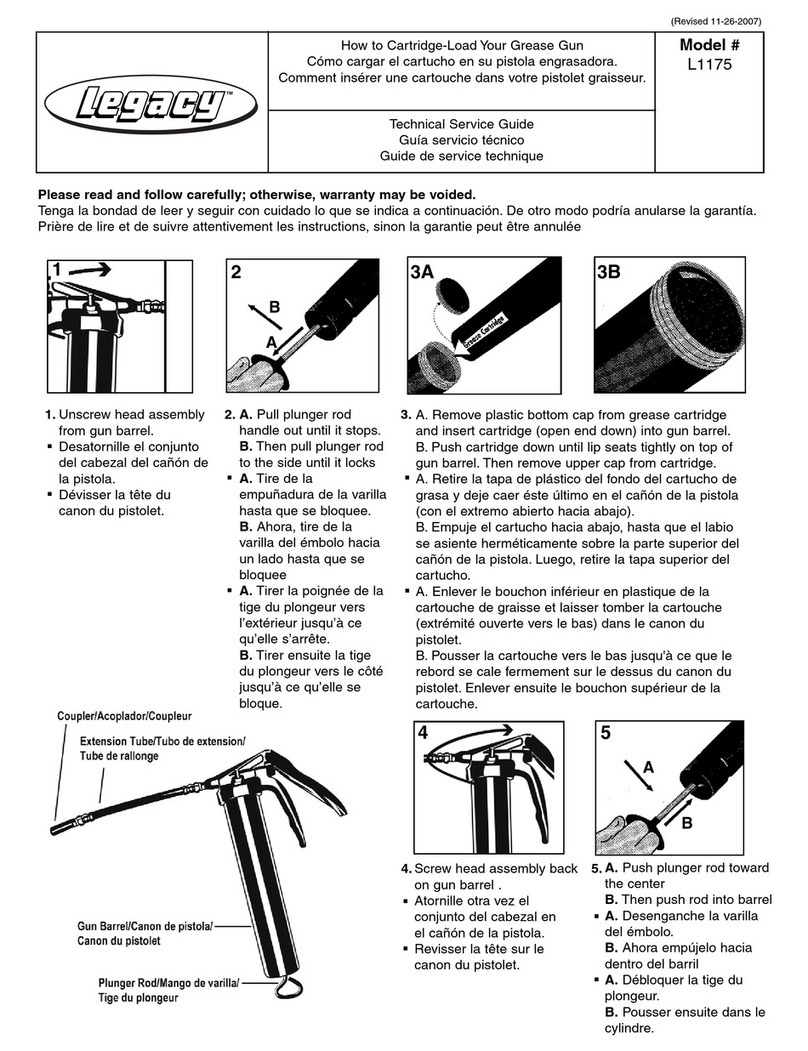

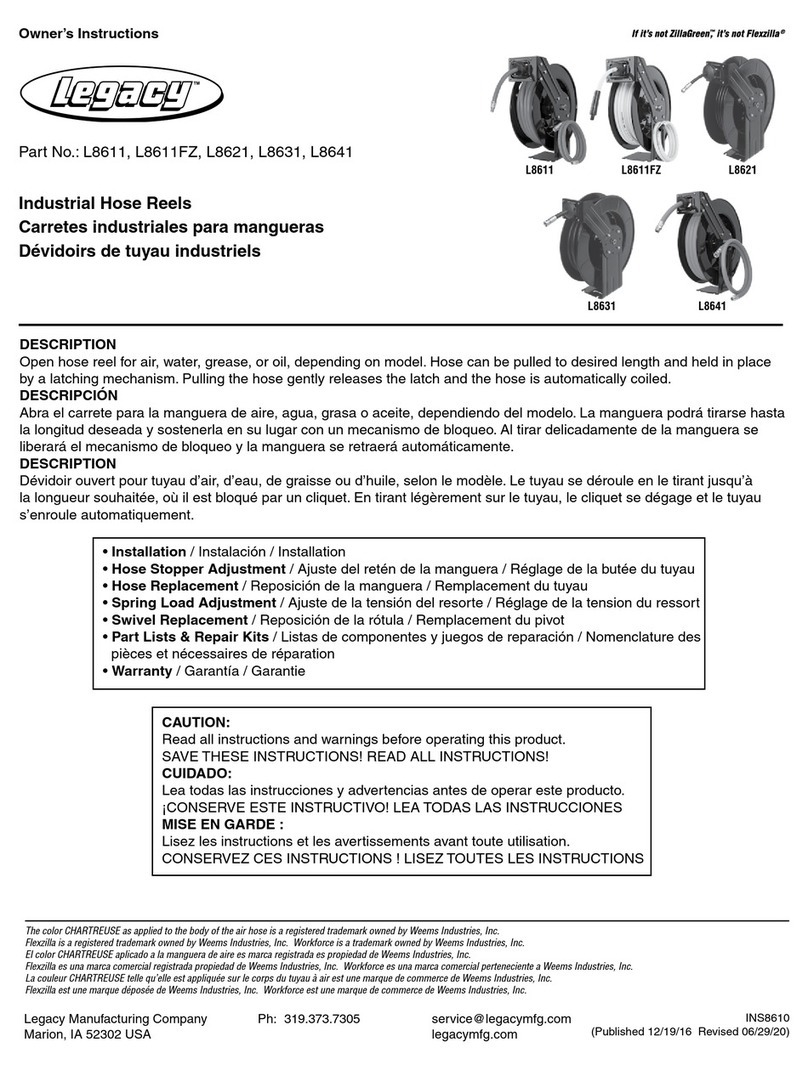

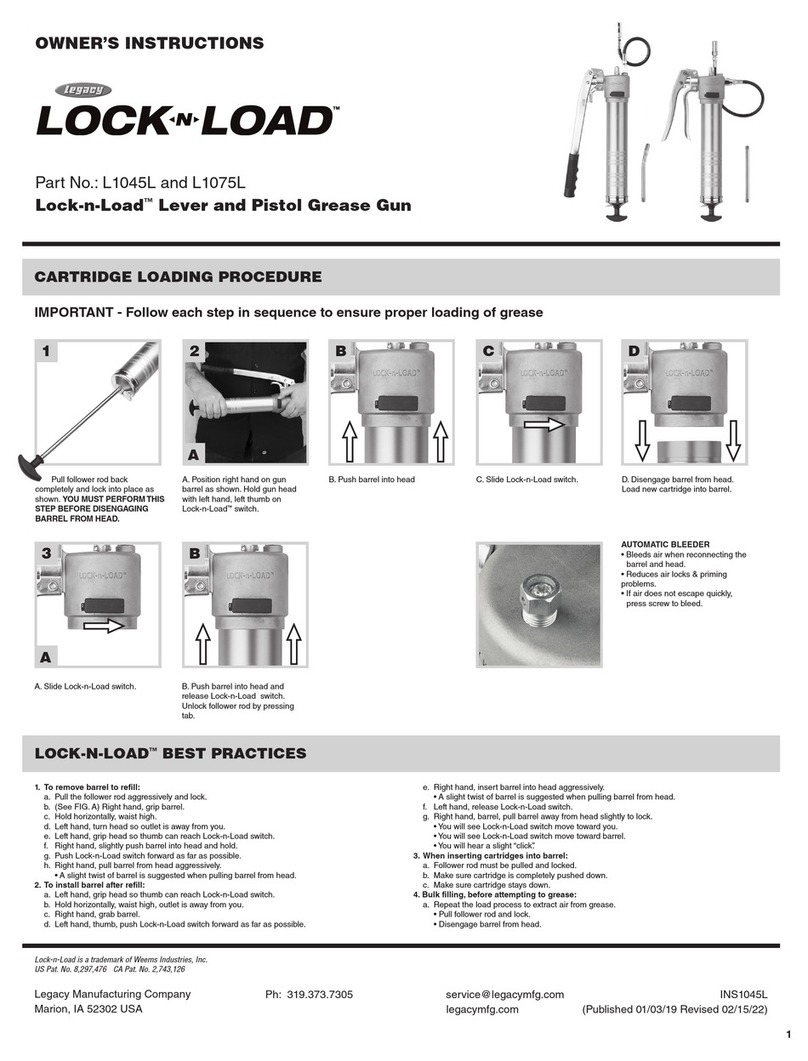

INSTALLATION

The hose reel can be bench, wall, high wall or ceiling mounted.The hose

guide arm and the hose outlet opening must be positioned according

to figure A to ensure a smooth operation of the reel and to increase the

hose life.To move the hose guide arm and the hose outlet opening, the

screws marked with an arrow on figure B must be removed. Move the arm

and hose outlet to its correct position, replace screws and tighten.

HOSE STOPPER ADJUSTMENT

To modify the hose stopper position, pull out hose to the desired length

and latch reel. Loosen the hose stopper and place it at the opening of the

hose guide.

NOTE: CHECK THAT THE REEL IS PERFECTLY LATCHED BEFORE

REMOVING THE HOSE STOPPER.

HOSE REPLACEMENT

CAUTION: REEL IS SPRING-LOADED. INJURY WILL RESULT IFYOU

DO NOT MAINTAIN CONTROL OF REEL AND HOSE AT ALL TIMES.

1. Unwind hose completely then allow it to rewind to the first locked

position. Secure vise grips or other device on spool assembly, near

the guide arm assembly to prevent the reel from retracting. DO NOT

CRUSH LIP.

2. Remove hose from the reel.Insert new hose through hole in spool and

attach clamps.Attach hose stop.

3.With one hand on the hose remove the vise grips and allow the hose to

rewind.

4. Once service gun is installed, verify that the spring tension is adequate.

If the spring tension is not adequate, follow the steps below to add ad-

ditional spring tension.

SPRING LOAD ADJUSTMENT

1.The hose reels are supplied with a spring tension, which is factory

adjusted according to the hose.If the spring tension is to be adjusted

afterwards CHECK that the required length of the hose can be pulled

out WITHOUT STRETCHING THE SPRING TO THE LIMIT.The lowest

spring tension possible increases the life of the spring.

2.Too much spring tension will shorten the life of the spring and put

excessive wear and tear on the hose. Do not exceed 18 turns from

unwound position.

3.To adjust tension, pull out approximately 6 ft.or 2 m of hose and allow

the drum to latch.

4. Remove hose stopper from hose and feed hose back through guide.

5.Wrap the pulled hose one more time around the drum to increase

tension, or un-wrap hose one time from drum to decrease tension. Do

not exceed 18 turns from unwound position.

6. Re-feed hose through guide and install hose stopper.

7. Unlatch drum and check tension.Pull hose from reel, and adjust

stopper position if necessary.

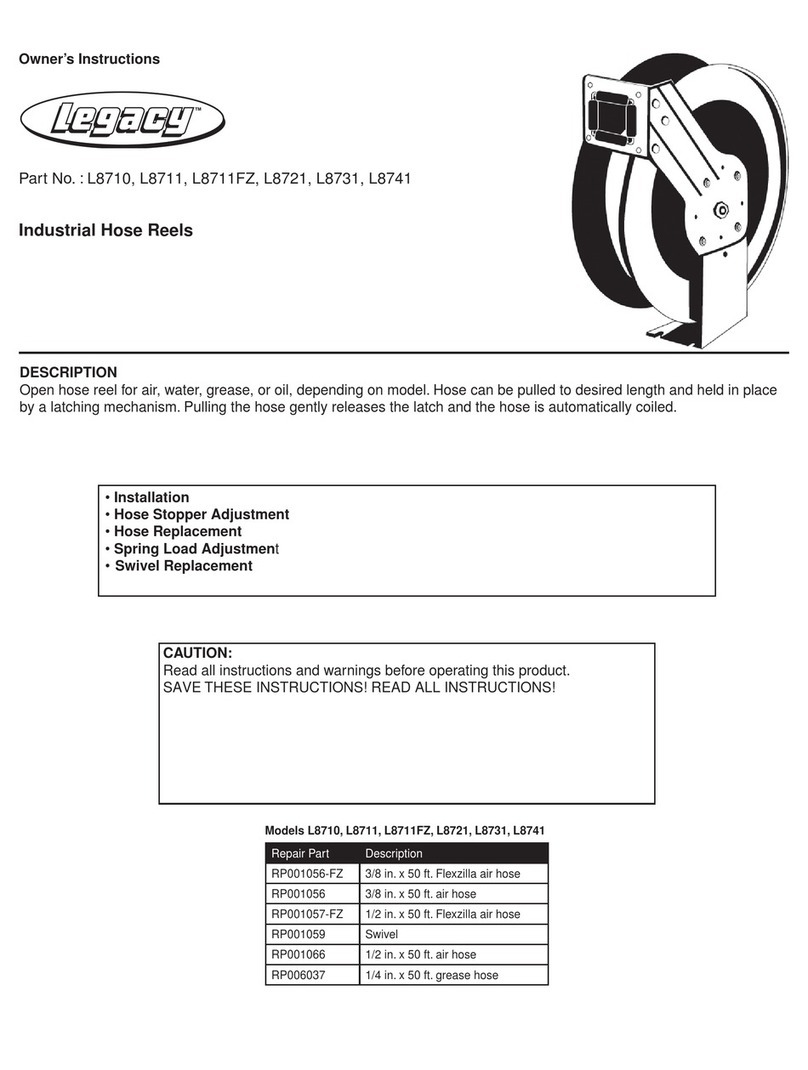

SWIVEL REPLACMENT

IMPORTANT:BEFORE REMOVING THE OLD SWIVEL, CLOSETHE

NEAREST CONTROLVALVE TO THE REEL AND OPEN THE FLUID

CONTROL GUNTO RELEASETHE PRESSURE INSIDE THE GUN AND

HOSE.

1.With the hose completely coiled, remove the fluid inlet hose and the old

swivel. (Fig. C).

2. Replace the old swivel with the new one.

3.To tighten the swivel, hold the reel drum while you tighten it. (Fig. D).

4. Connect the inlet hose again.

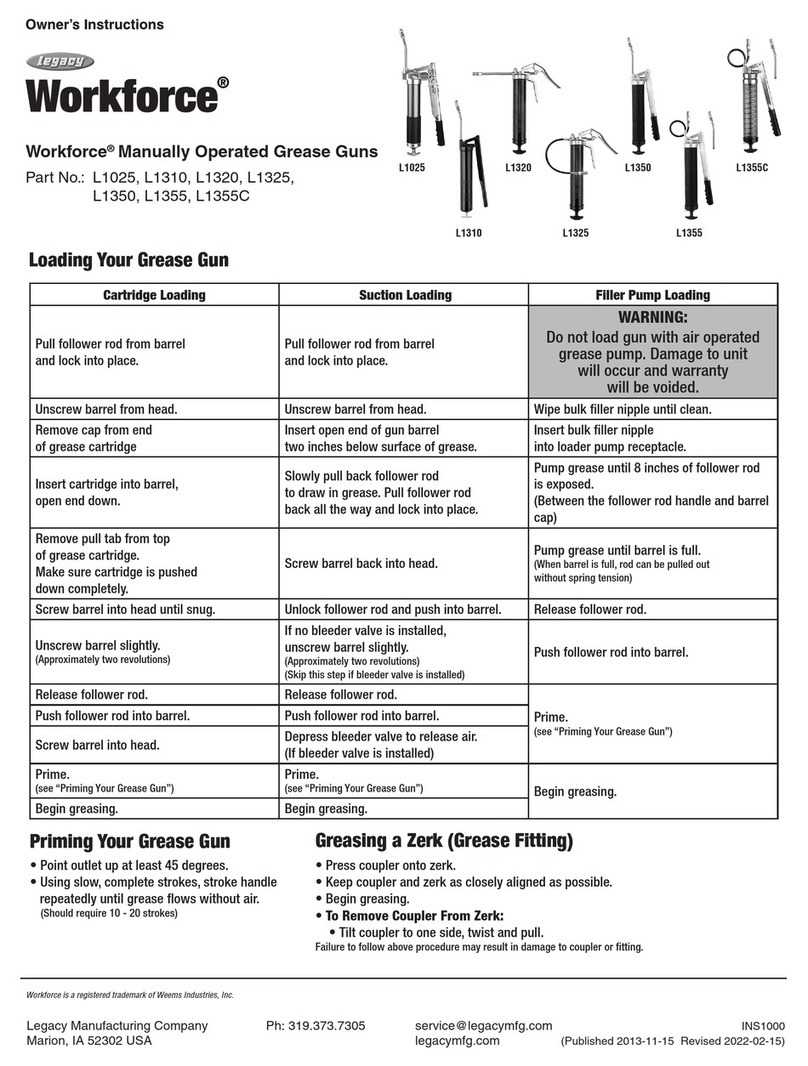

Working Pressure Burst Pressure

L8611, L8611FZ

300 PSI 1200 PSI

L8621 5000 PSI 20,000 PSI

L8631, L8632 2000 PSI 8000 PSI

L8641 300 PSI 1200 PSI

PRESSURE RATINGS at 68°F/ 20°C:

Lead-in Hoses:

L8611LI for reel L8611

L8621LI for reels L8620 and L8621

L8631LI for reels L8630, L8631 and L8632

L8611FZLI for reel L8611FZ

Bench

Truck Ceiling

Wall High Wall