1

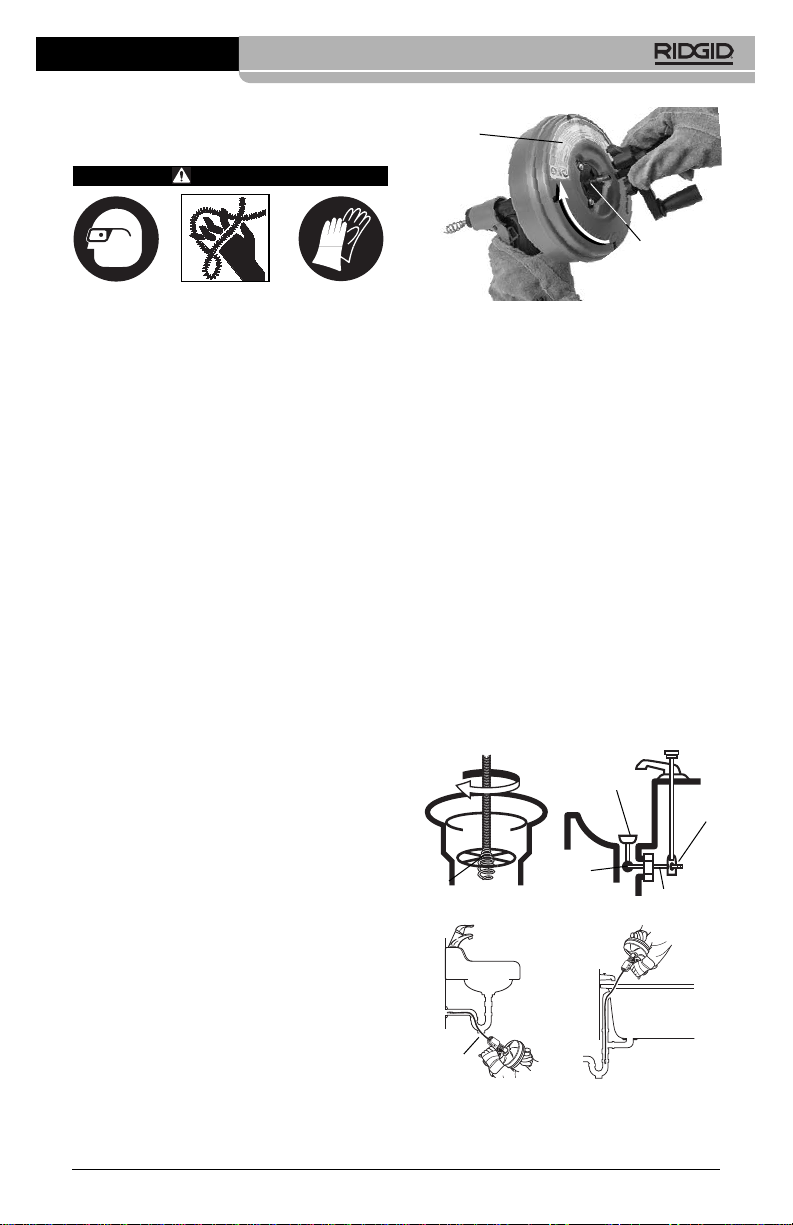

POWER SPIN+™ Drain Cleaner

•Do not wear loose clothing or jewelry.

Keep your hair and clothing away from

moving parts. Loose clothing, jewelry or

hair can be caught in moving parts.

•Do not operate this machine if operator

or machine is standing in water. Oper -

ating machine while in water increases the

risk of electrical shock.

•nly use drain cleaner to clean drains

of recommended sizes according to

these instructions. Other uses or modify-

ing the drain cleaning machine for other

applications may increase the risk of injury.

•Read and understand these instruc-

tions, the battery drill instructions and

the instructions for any other equip-

ment used with this tool before operat-

ing. Failure to follow all instructions may re-

sult in property damage and/or serious in-

jury.

The EC Declaration of conformity (890-011-

320.10) will accompany this manual as a sep-

arate booklet when required.

Description

The RID ID®POWER SPIN+™ Drain Cleaner

is used to clean drain lines such as bathroom

and kitchen sinks, bathtub and shower drains.

It features RID ID MAXCORE®Cable that is

positively retained in the drum to prevent cable

pullout. It is equipped with the AUTOFEED®

mechanism that advances and retrieves the

cable with just the pull of a trigger while the

drum is rotating. The POWER SPIN+Drain

Cleaner can be operated either manually or

driven with a battery powered drill.

The POWER SPIN+is not recommended for

use with toilets.

Specific Safety

Information

WARNING

This section contains important safety

information that is specific to this tool.

Read these precautions carefully before

usin the POWER SPIN+™™Drain

Cleaner to reduce the risk of electrical

shock or other serious personal injury.

SAVE ALL WARNINGS

AND INSTRUCTIONS FOR

FUTURE REFERENCE!

Keep this manual with machine for use by

the operator.

Drain Cleaner Safety

•Always use safety glasses and leather

work gloves in good condition while

handling or using. Use latex or rubber

gloves, face shields, protective clothing,

respirators or other appropriate protective

equipment when chemicals, bacteria or

other toxic or infectious substances are

suspected to be present to reduce the risk

of infections, burns or other serious per-

sonal injury. Wear latex gloves or rubber

gloves under leather gloves.

•Practice good hygiene. Use hot, soapy

water to wash hands and other body parts

exposed to drain contents after handling or

using drain cleaning equipment. Do not

eat or smoke while operating or handling

drain cleaning equipment. This will help

prevent contamination with toxic or infec-

tious material.

•Do not use with a corded drill. Operating

with a corded drill increases the risk of elec-

trical shock.

•Do not allow the end of cable to stop

turning while the machine is running.

This can overstress the cable and may

cause twisting, kinking or breaking of the

cable and may result in serious personal in-

jury.

•Position machine within 4" (10 cm) of

the drain inlet or properly support ex-

posed cable when the distance exceeds

4" (10 cm). reater distances can cause

control problems leading to twisting, kinking

or breaking of the cable. Twisting, kinking or

breaking cable may cause striking or crush -

ing injuries.

POWER SPIN is a registered trademark of RID ID, Inc. in the U.S.