Rieber Varithek-1/1-ik User manual

Operating Instructions

Varithek-1/1-ik, -400-ik

from construction year 2005

[ Universal cooking and

heating units ]

Operating instructions

induction hob

varithek

®

Type: 1/1-ik 3500, 1/1-ik 5000, 400-ik 3500 und 400-ik 5000

Please read carefully before use

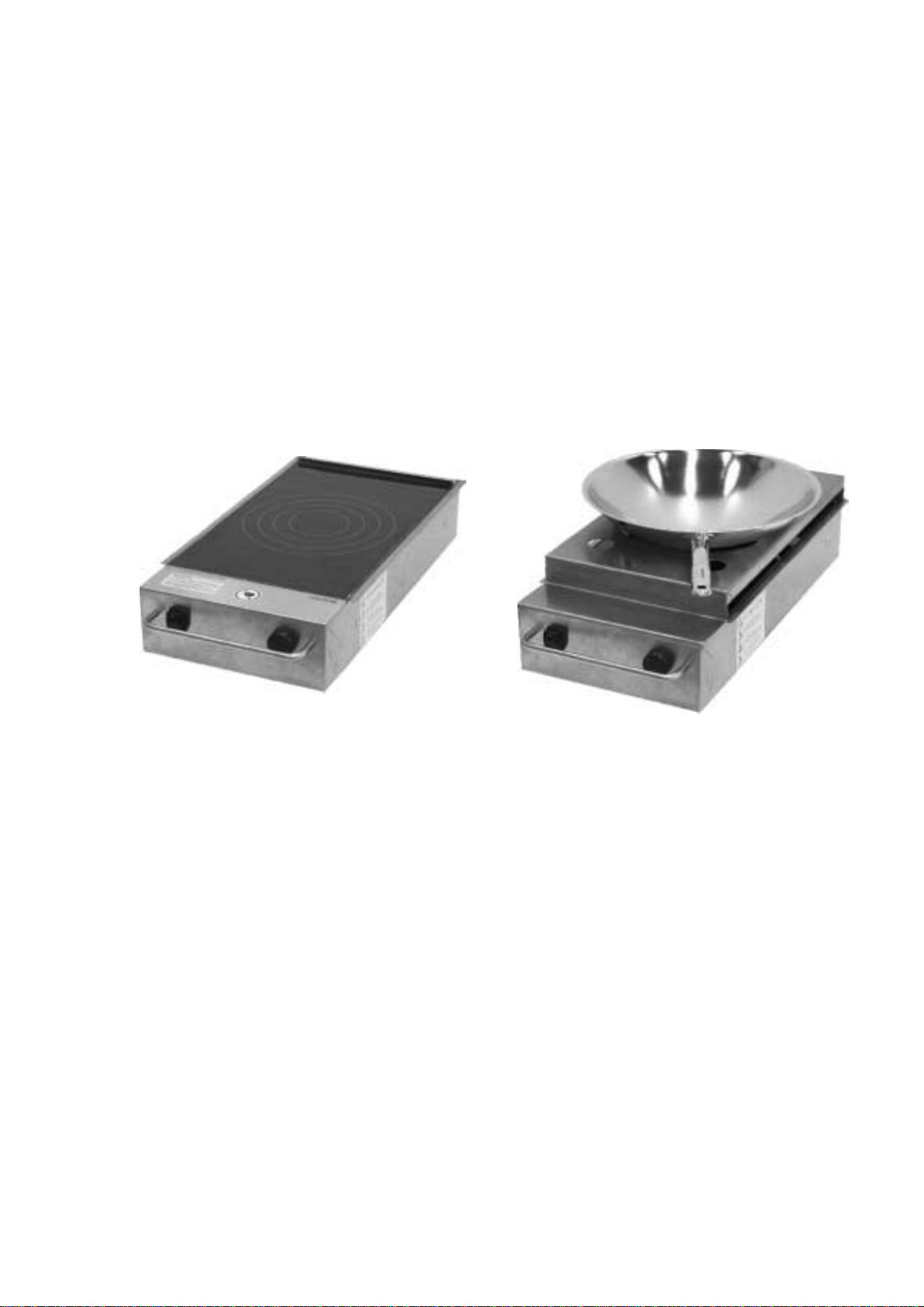

Fig.: varithek®induction hob 1/1-ik 3500 without

accessories and induction hob 1/1-ik 3500

with wok stand and wok

varithek®- The product innovation from Eisfink and Rieber

Page 2

induction hob

The conformity of the induction hobs 1/1-ik 3500, 1/1-ik 5000, 400-ik 3500 and 400-ik 5000 in

accordance with the directive 73/23/EWG, low voltage, is given. The manufacturer has the respective

documents.

varithekinduction hob 1/1-ik 3500 in

varithektable-top system module

AST 255

Subject to technical changes !

Figures´and technical data may change slightly due to continuous further developments.

Manufacturer’s address

EISFINK MAX MAIER GMBH & CO.KG

Im Werkzentrum Weststadt

Rheinlandstr. 11

D 71636 Ludwigsburg

Fon: +49/7141/479-0

Fax: +49/7141/479-299

http://www.eisfink.de or http://www.varithek.de

As per: 08/04/2005

Page 3

induction hob

Table of contents

1 General 4

1.1 Introduction 4

1.2 Symbols for operating information 4

1.3 Laws, standards and directives 4

1.4 Delivery scope 5

1.5 Information for the operator 5

1.6 Warranty 5

2 Safety 6

2.1 Proper use 6

2.2 Improper use 6

3 Product description 7

3.1 Basic dimensions and technical data 7

3.2 Functional conditions 7

3.3 Equipment and parts in the standard delivery 7

3.4 Accessories and their use: varithek®system modules 8

4 Positioning / assembly 9

4.1 Mechanical 9

4.2 Electrical 9

5 Operation 10

5.1 General safety information 10

5.2 Commissioning and operation 10a

6 Cleaning and care 11

6.1 General 11

6.2 Initial cleaning, everyday cleaning and care 11

7 End of operation and operating breaks 12

8 Troubleshooting and possible causes 13

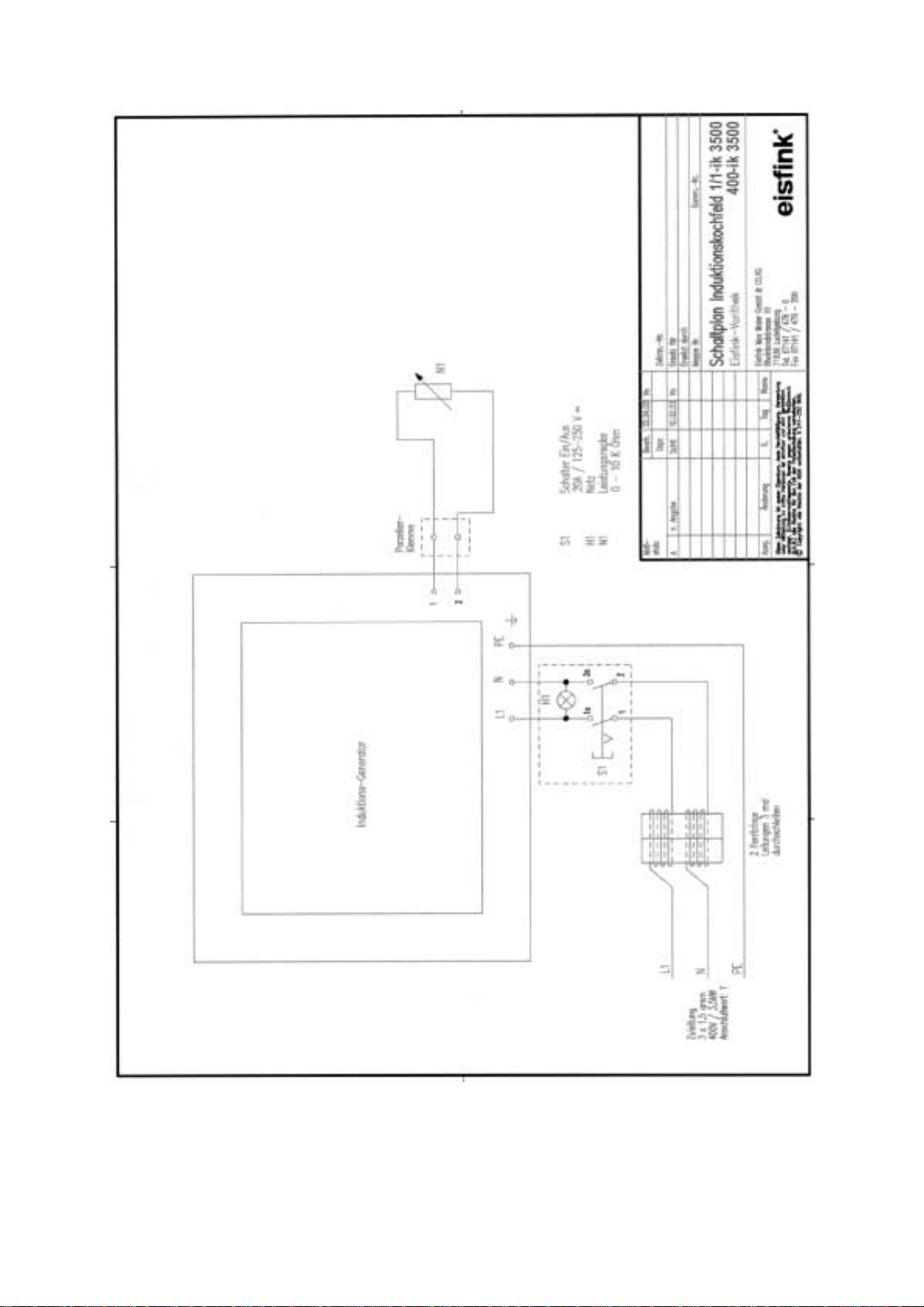

9 Circuit plan 1/1-ik 3500 and 400-ik 3500 14

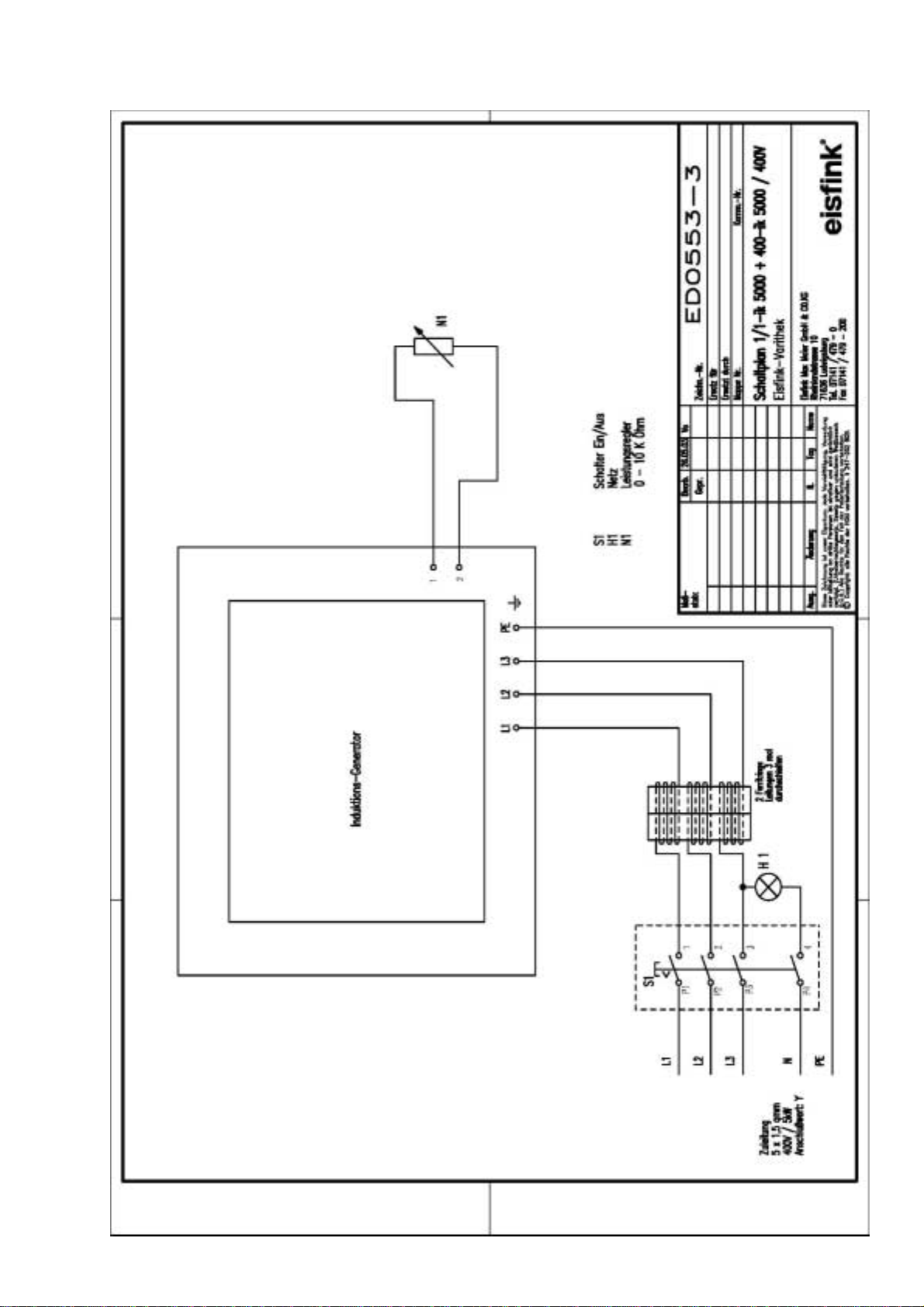

10 Circuit plan 1/1-ik 5000 and 400-ik 5000 15

Page 4

induction hob

1 General

1.1 Introduction

These operating instructions were specially compiled for the personnel operating the varithek®

induction hob. They contain important information about the assembly, operation and cleaning of the

system.

The operating instructions apply to all varithek®induction hobs.

Your induction hob version can be identified from the information on the type plate.

Read these operating instructions carefully before using the unit and ensure that all operators also

read these instructions before use. The operating instructions must always be available wherever the

unit is used. The operating instructions are part of the unit.

1.2 Symbols for operating information

Careful!

Indicates a potentially dangerous situation; non-observance could lead to slight or more serious injury

and/or damage.

Caution hot surfaces!

Indicates a potentially dangerous situation caused by hot surfaces; non-observance could lead to

burns and/or material damage.

Information!

Indicates operating advice for the best use of the appliance and other useful information.

1.3 Laws, standards and directives

The design and manufacture of this appliance conform with the requirements of the following guidelines and

regulations:

•Directive 93/43/EWG: Hygiene directive

•Directive 89/336/EWG: EMC

•Directive 73/23/EWG: Low-voltage directive

•EN 60335-1: Safety of household and similar electrical appliances

•EN 60335-2-36 EN 55011 EN 55014-2 EN 61000-3-2/-3-3

Page 5

induction hob

1.4 Delivery scope

•Please refer to the enclosed delivery papers for the scope of delivery and type of the individual parts.

•Remove the packaging from the parts and dispose the packaging material properly in an

environmentally friendly manner.

•Check the elements for any transportation damage. Record any damage on the haulage company’s

freight note and notify the supplier immediately.

1.5 Information for the operator

As the operator, you are responsible for:

•the proper and intended use of all parts of the varithek®induction hob,

•compliance with the safety provisions and safety information,

•training the operating personnel and ensuring their knowledge of the operating instructions,

•ensuring that the existing safety equipment functions properly,

•providing correct protective and work clothing and

•proper conditions for use.

1.6 Warranty

The current valid terms and conditions of sales and delivery of the company Rieber GmbH & Co. KG will

apply to all warranty claims. The terms and conditions of sales and delivery which are valid on the invoice

date shall apply.

Warranty claims made to the manufacturer must be based on the premise that the appliance has been used

properly (see the following chapter “Safety”).

Page 6

induction hob

2 Safety

2.1 Proper use

The varithek®induction hob is a professional cooking unit which allows a number of cooking processes to be

performed. This is only possible with pots and pans that are made of inductive material. The operating

instructions of the pot/pan manufacturers need to be observed for proper use of the pots and pans.

The following functions can be performed with the induction hob:

•Cooking, warming food up, keeping food warm,

•Frying and roasting.

Any other type of use is improper and could have unforeseeable consequences.

We recommend pot and pan material from Demeyère. We use pans from this manufacturer as

reference material which we test periodically.

2.2 Improper use

Improper use comprises all activities that are not listed in the cooking types above.

The following are particularly improper and dangerous:

•Heating objects other than food.

•Use of the induction hob to heat or humidify rooms.

Caution!

Never operate the unit unattended!

Warning! Danger of burns!

The Ceran®glass surface will become hot due to the radiation from the pots and pans.

The pots and pans heat up very quickly.

On a 5 KW unit at full power, oil will burn in max. 2 minutes.

Never pour oil / grease into pots and pans that are already hot. Danger of fire!

Never operate the unit with empty pots /pans

The safety and operating information stated in these operating instructions are not a substitute for

observance of legal and professional regulations (e.g. ZH1/37 –Safety rules for kitchens). These must be

observed in addition to the information provided in these instructions.

Caution!

People with pacemakers should consult their doctor as to whether they should stay close to an

induction hob.

Page 7

induction hob

3 Product description

The varithek®induction hob is a professional cooking unit designed as a table-top unit that can be used in

the varithek®table-top system modules AST 155 and AST 255 and the built-in system modules EST1 to

EST5. Inductive pots and pans with a diameter of 14 cm to 28 cm can be used on the induction hob.

The induction hob can be used as an induction wok when equipped with the varithek®wok stand and a

varithek®wok.

3.1 Basic dimensions and technical data

Dimensions / Model 1/1-ik 3500 1/1-ik 5000 400-ik 3500 400-ik 5000

Width 325 mm 325 mm 400 mm 400 mm

Depth 635 mm 635 mm 720 mm 720 mm

Height 140 mm 140 mm 140 mm 140 mm

Height with

wok stand 190 mm 190 mm 190 mm 190 mm

Connected load 1/N/PE 3/N/PE 1/N/PE 3/N/PE

AC 230 V 50 Hz AC 400 V 50 Hz AC 230 V 50 Hz AC 400 V 50 Hz

Connected output 3.5 kW 5.0 kW 3.5 kW 5.0 kW

Fuse 16 A 3x16 A 16 A 3x16 A

Electrical connection Earthed socket CEE plug Earthed socket CEE plug

IP protection class IP X4 IP X4 IP X4 IP X4

Weight: 9 kg 9 kg 9 kg 9 kg

3.2 Functional conditions

Tolerance, power supply Nominal voltage +6/-10%

Frequency 50 Hz

Diameter of pots/pans 140 mm (min.) to 280 mm (max.)

Wok diameter 380 mm

Ambient temperature +5°C to + 40°C

Relative humidity 30% to 90% (max.)

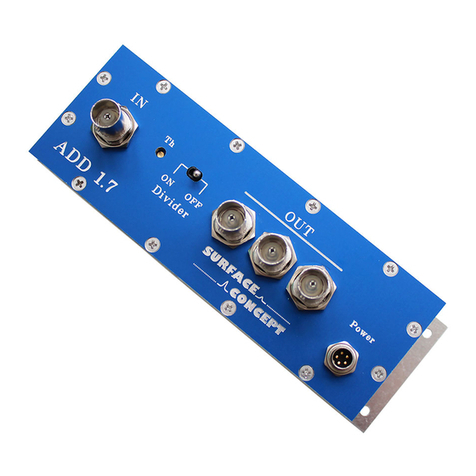

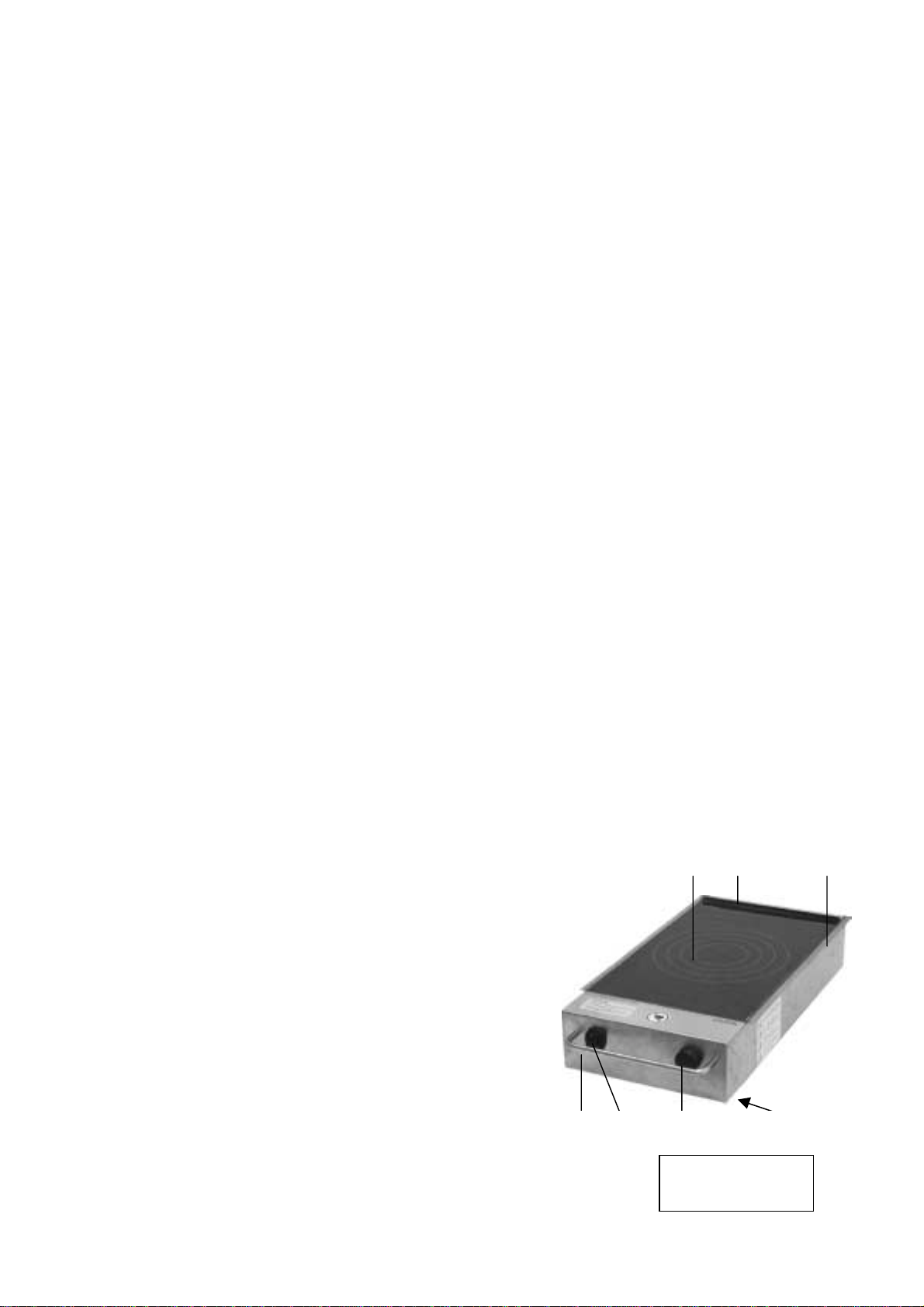

3.3 Equipment and parts in the standard delivery:

1: Carcass in stainless steel with integrated control casing

1.1: 4 rubber feet

1.2: Bracket for insertion in varithek®system module

1.3: Ceran®glass surface with markings on the induction

hob

1.4: Venting grille

1.5: Grease filter

1.6: Cleaning grille

1.7: Type plate

2: Carrying handle

3: Main switch with control lamp (1/1-ik 3500)

or rotary knob (1/1-ik 5000)

4: Output control (stepless)

5: Power cable with earthed plug (1/1-ik 3500)

or CEE plug (1/1-ik 5000)

1.3 1.4 1.2

Underneath not

shown

2 3 4 5

Page 8

induction hob

Information: ‘Cooking side’

3.4 Accessories and their use

1: varithek®wok WA

Use: The wok stand is placed on the carcass. Its opening must be placed exactly over the

markings on the Ceran®glass plate. It is the right way round if the information is on

the cooking side.

2: varithek®wok, stainless steel

Use: The wok is placed in the circular space of the wok stand which holds it in position.

The cut-out is designed so that there is a clearance of 1.5 mm between the lowest

point of the outer base of the wok and Ceran®glass plate.

3: varithek®table-top system module

AST 155 / AST 255

Use: The table-top system module is available in 2 different heights. It serves to hold

different varithek®function elements. It has moulded shelf rails on the left and right

inside walls which are used to hold the respective function element at the selected

height. The surface upon which the system module is placed must be horizontal.

When using varithek®function elements in the system modules, ensure that the

electrical power cables of the function elements are not caught and do not come into

contact with hot parts of the casing.

Correct positioning of the

induction hob without wok

on the upper shelf of the

system module

Correct positioning of the

induction hob without wok

stand in the second rail of the

side wall

4: varithek®built-in system module

EST 1 - 5

Use: As described in 3, however the built-in system module is usually permanently fitted

into an appropriate kitchen unit. The electrical power cables of the varithek®function

elements must either be reduced to the right length ex-works or shortened by a

specialist company as the built-in system module is equipped with 230 V earthed

sockets. 400 V units (induction hob 1/1-ik 5000) must be connected to a separate

400 V CEE socket with a 16 A fuse.

Page 8a

induction hob

Careful! Possible material damage!

Only the upper part of the front section of the system module may be opened.

The lower part of the front section must always remain closed so that the unit cannot slip out.

Page 9

induction hob

4 Positioning / assembly

When positioning and installing the unit, observe the electro-technical regulations, the fire safety and local

building regulations. There should be no flammable parts and objects close by. To ensure that the unit

functions properly and its operational safety, the unit must be installed, operated and serviced in accordance

with these operating instructions.

Careful! Possible material damage!

If the induction hob is moved to another location, the electrical connections should first be

disconnected and the accessories removed and transported separately.

4.1 Mechanical

Move the induction hob to its intended location. This must be even and clean.

The induction hob may not be placed on a flammable surface, next to flammable walls or on a hot surface.

When operating the induction hob close to a wall, partitions, kitchen furniture, decorative panelling etc. it is

recommended that these are made of non-flammable material, otherwise they must be cladded in a suitable

fire-proof heat-insulation material. The work surface must be able to bear a weight of at least 40 kg.

Careful! Possible material damage!

The openings for the ventilation and aeration should not be blocked or covered. Danger of

overheating!

2 Electrical

Before commissioning, check the power supply voltage and the type of power. In particular, check that these

comply with the information on the type plate. The type plate is located on the base of the control casing.

Observe the regulations of DIN / VDE 0100 ff. and the technical connection conditions (TAB) of the power

supply company (EVU).

The induction hob is equipped with a power cable with a 230 V earthed plug (1/1-ik 3500, 400-ik 3500)

and/or with a 400 V CEE plug (1/1-ik 5000, 400-ik 5000) for connection to a socket on site. Ensure that the

on-site socket has a fuse (16 A). The socket must be freely accessible so that the unit can be disconnected

from the power supply at all times. As a unit of the protection class 1, it must always be connected to the

protective conductor.

Careful! Possible material damage!

The power cable must be positioned so that it cannot become caught or overheated.

If in doubt, consult an electrician.

If the unit’s power cable is damaged, this must be replaced by the manufacturer, its customer service

or an electrician to avoid danger. Neutral conductor breaks may damage the unit.

Page 10

induction hob

5 Operation

5.1 General safety information

Careful! Possible material damage! Danger of injury! Danger of fire!

•Induction cooking units may only be operated with inductive pot and pan material.

Non-inductive pots will be recognised by the induction generator as unsuitable and

no energy will be radiated. Pots and pans that are made of semi-inductive material

will impair the cooking performance. The level of efficiency is significantly reduced;

the inductive generator may turn off automatically.

The induction generator can become damaged if unsuitable pots and pans

are used; in this case all warranty rights will be forfeited.

•The induction cooking units may never be operated unattended.

•Do not touch the Ceran®glass plate during operation. This becomes hot from the

heat radiated by pans used.

•The unit must be switched off and disconnected from the power supply if it is not

used for a longer period of time.

•Do not place any flammable substances (paper, card, material etc.) between the

cooking zone and the pots / pans as they may ignite.

•Do not place any metallic objects such as cutlery, tins, jewellery etc. on the cooking

area within the cooking zone. These will become hot very quickly.

•Do not keep any parts that are sensitive to magnetic energy (credit cards,

telephone cards, cassettes, watches etc.) close to the induction cooking units.

•The unit must be switched off immediately if there is any damage to the glass plate,

in particular tears.

•Aluminium foil or plastic vessels may not be placed on the glass ceramic surface.

•Please be aware that metal objects that the user wears, e.g. watches, rings and

other similar objects, may become hot if close to the surface of the cooking area.

•Any repairs may only be performed by qualified persons or persons recommended

by the manufacturer.

•Never operate the unit with empty pots/pans.

•The unit may not be transported during operation or as long as hot pots/pan are on

top.

Page 10a

induction hob

5.2 Commissioning and operation

The function of the induction hob was checked after production. Before commissioning for the first time,

please ensure that there is no packaging material or any other objects inside ventilation grille, cleaning grille

and the filters and that the unit is positioned correctly.

The induction hob is switched on by pressing the main switch or the rotary knob (0/1) and switched off again

by resetting the switch/knob. If the induction hob is switched on, the control lamp will shine (green).

Place the inductive pan in the centre of the induction hob (see markings on the hob) so that the base of the

pot/pan is heated evenly.

By turning the stepless output control to the right, energy is supplied immediately. Set the output control to

the required level.

If the pot / pan is removed from the hob, the induction generator will automatically regulate down.

Warning! Danger of fire! Danger of burns!

Never heat a pot or pan which is empty.

Page 11

induction hob

6 Cleaning and care

6.1 General

Careful! Danger of injury!

Allow the induction hob and the used pots / pans to completely cool down before starting to clean

them.

Careful! Possible material damage!

Do not use acidic cleaning agents. Cleaning agents may not contain any hydrochloric or

hydrofluoric acid because these can cause discoloration on the surfaces or even rust. Do not use

sharp-edged cleaning objects.

Careful!

Never clean with a water jet!

Cleaning agents

The casing parts of the unit should only be cleaned with the defined cleaning agents and a little

water. The cleaning agent is used in accordance with the manufacturer’s specifications. Heavy

soiling can be removed by first cleaning with e.g. a soft plastic fleece and then rinsing with clean

water. Then remove any cleaning agent residues with a damp cloth.

6.2 Initial cleaning, everyday cleaning and care

Before commissioning for the first time, clean the unit thoroughly to remove all packaging and soiling caused

by transportation.

Careful! Possible material damage!

Before cleaning the units, disconnect all electrical connections. Protect those parts (plastic parts)

that could react sensitively to the cleaning agent.

To clean the casing parts use a soft cloth and soaked in water containing a mild, grease-releasing, non-

abrasive cleaning agent. Grease and greasy pigment dirt can be removed easily using a general cleaning

agent, neutral cleaning agents or alkaline cleaning agents.

Solvent cleaning agents and non-abrasive emulsions are effective for removing heavy greasy soiling

(hardened oils and grease) on parts of the casing.

The casing parts, the connecting parts of the elements and the lower edges and reverse joints need to be

cleaned very carefully as this is where bits of food and dirt can collect.

Page 12

induction hob

Careful! Danger of injury

When cleaning the induction hob, take care of sharp edges. For this reason, always wear gloves

that are suitable for cleaning.

To clean the Ceran®glass, use a special Ceran®glass cleaner with a soft cloth or possibly a Ceran®glass

scraper to remove heavier soiling.

To completely remove all cleaning agent residues, clean with a damp soft cloth and water (not water jets)

until no more residues can be seen.

Careful! Possible material damage!

Do not use sharp-edged objects to clean the Ceran®glass as the Ceran®glass may become

scratched.

The induction hob must be cleaned after each use otherwise dirt will burn the next time it is used. Sugar and

food and residues containing sugar need to be removed from the Ceran®glass plate as soon as possible.

Please ensure that the induction unit is equipped with a grease filter in the base. The air cooling system and

the service life of the unit will be impaired by a heavily soiled grease filter.

Careful! Possible material damage!

Please ensure that the grease filter is cleaned in the dishwasher once a week!

Before inserting the grease filter, ensure that it does not contain any residual water.

7 End of operation and operating breaks

Switch the unit off after every use or before operational breaks by turning the output control to the left to

position “1”and the ON/OFF switch to “OFF”. The green control light will extinguish.

Careful! Danger of burns!

The used pots / pans store heat even after the unit has been switched off so that there is still a

danger of burns.

Careful! Danger of crushing!

Secure the induction hob against slipping.

Careful! Keep children out of danger zone!

Ensure that no children are allowed near the induction hob or play with the unit.

Page 13

induction hob

8 Troubleshooting and possible causes

In case of case of a malfunction, switch the induction hob off with the main switch or rotary knob (1/1-ik 5000,

400-ik 5000) and disconnect from the power supply.

Repairs to the induction hob may only be performed by a specialist company authorised by the manufacturer.

Careful!

Any work inside the casing or unit technology that is not performed by qualified personnel

authorised by the manufacturer will automatically lead to a forfeit of all warranty rights.

In case of any malfunctions that are not caused by dirt or inadequate cleaning, we recommend contacting

the supplier who will then name an authorised specialist company.

Warning!

Only original spare parts of the respective manufacturer may be used for repairs.

If the connecting cable of the induction hob has been damaged, the unit may no longer be used and

must remain disconnected from the power supply until the power cable has been replaced with an

original spare part by the manufacturer or an authorised specialist company.

Malfunction Possible cause Rectified by / with

Does not heat up

ON/OFF switch remains dark No power supply Check the fuse

Check plug connection

Defective cable Customer service should rectify

Does not heat up

ON/OFF switch shines green No inductive pan material Use the pan material recommended

by the manufacturer

Unit has been overheated Output will automatically reduce to 0

Switch off unit and allow to cool

Diameter of pan is less than

140 mm Use larger pan

Insufficient heating output Ventilation and aeration slits are

covered Uncover ventilation and aeration slits

Ventilator defective or dirty Customer service should rectify

Cleaning grille dirty Clean the cleaning grille in the

dishwasher and allow to dry

Vertretungen Inland (Domestic agents)

Baden-Württemberg Nord

Hans-Joachim Merkle

Hoffmannstraße 44

D-72770 Reutlingen

Tel. (0 71 21) 518-0

Fax (0 71 21) 518-302

Mobil (0172) 717 31 37

hans.merkle@rieber.de

Baden-Württemberg Süd

Martin Müller

Hoffmannstraße 44

D-72770 Reutlingen

Tel. (0 71 21) 518-0

Fax (0 71 21) 518-302

Mobil (0172) 939 98 42

martin.mueller@rieber.de

Berlin

Rieber Vertriebszentrum Nord

Am Bohldamm 5

D-14959 Trebbin

Tel. (03 37 31) 8 59-0

Fax (03 37 31) 8 06 45

hartmut.gutt@rieber.de

Dresden

Rieber

Vertriebszentrum Süd

Kieler Straße 41a

D-01109 Dresden

Tel. (03 51) 88 54 70

Fax (03 51) 8 80 78 34

gerhard.jacob@rieber.de

Frankfurt

Rieber Verkaufsbüro Mitte

Limburger Straße 74

D-65555 Limburg - Offheim

Tel. (0 64 31) 77 87-0

Fax (0 64 31) 77 87-29

hans.bien@rieber.de

Hamburg

Rieber Verkaufsbüro Nord

Meckelfelder Weg 2

D-21079 Hamburg

Tel. (040) 55 49 21-0

Fax (040) 55 49 21-90

sacha.lindenberg@rieber.de

Hannover

(Home Office)

Wolfgang Hirsch

Hannoversche Straße 34

D-30916 Isernhagen

Tel. (05 11) 61 00 30

Fax (05 11) 61 09 31

Mobil (0172) 717 33 97

wolfgang.hirsch@rieber.de

Köln

Rieber Vertriebszentrum West

Siemensstraße 1-5

D-50259 Pulheim

Tel. (0 22 38) 30 24-0

Fax (0 22 38) 30 24-24

werner.juhnke@rieber.de

Lotte (Home Office)

Andreas aus dem Moore

An der Dorfkirche 39

D-49504 Lotte

Tel. (0 54 04) 99 79 79-1

Fax (0 54 04) 99 79 79-2

Mobil (0172) 939 98 32

andreas.aus-dem-moore

@rieber.de

München

Rieber Verkaufsbüro Süd

Grabmeirstraße 1a

D-85276 Pfaffenhofen

Postfach 1331

D-85263 Pfaffenhofen

Tel. (0 84 41) 2775-0

Fax (0 84 41) 2775-27

uwe.kleinbeck@rieber.de

Tochtergesellschaften (Subsidiaries)

Österreich

Austria

Rieber + Grohmann GesmbH

Seybelgasse 13

A-1230 Wien

Tel. + 43 [0] 1/ 8 65 15 10

Fax + 43 [0] 1/ 8 65 15 10-10

www.rieber.at

office@rieber.at

Schweiz

Switzerland

Rieber ag

Handelszentrum Schöntal

Rorschacher Straße

Postfach 118

CH-9402 Mörschwil

Tel. + 41 [0] 71/ 868 93 93

Fax+ 41 [0] 71/ 866 27 37

www.rieber.ch

mail@rieber.ch

Holland

Netherlands

Rieber Benelux B. V.

Kamerlingh Onnesweg 2

NL-2952 BK Alblasserdam

Tel. + 31 [0] 78/ 6 91 83 05

Fax + 31 [0] 78/ 6 93 14 39

www.rieber.de

jerry.hol@nl.rieber.de

Frankreich

France

Rieber S.à.r.l.

8, rue du Périgord

B. P. 37

F-68272 Wittenheim Cedex

Tel. + 33 [0] 3 89/ 62 50 60

Fax+ 33 [0] 3 89/ 57 17 94

www.rieber.de

daniel.rewell@fr.rieber.de

Großbritannien

Great Britain

BGL-Rieber Ltd.

Unit 6 Lancaster Park

Industrial Estate, Bowerhill,

Melksham

GB-Wiltshire SN12 6TT

Tel. + 44 [0] 1225/ 70 44 70

Fax + 44 [0] 1225/ 70 59 27

www.bglrieber.co.uk

sales@bglrieber.co.uk

Tschechien

Czech Republic

Rieber spol. s.r.o.

Pod Zvahovem 25 A/1059

CZ-152 00 Praha 5

Tel. + 420 [0] 2/ 51 68 05 89

Fax+ 420 [0] 2/ 51 68 06 31

www.rieberCZ.cz

rieber@rieberCZ.cz

Polen

Poland

Gastromedia Sp.z.o.o.

ul. Sobocka 19

PL-01-684 Warszawa

Tel. + 48 [0] 22/ 8 33 87 07

Fax + 48 [0] 22/ 8 33 87 22

www.gastromedia.pl

gastro@gastromedia.pl

Vertretungen (Agencies)

Italien

Italy

Rational Distribution S.r.l.

Via Giotto 6 B

Zona Commerciale Sud

I-39100 Bolzano

Tel. + 39 [0] 471/ 93 13 31

Fax + 39 [0] 471/ 93 15 91

www.rational.it

staff@rational.it

Spanien

Spain

Oms y Vinas S.R.C.

Carrer Pere IV, 459

E-08020 Barcelona

Tel. + 34 [0] 93/ 2 78 09 60

Fax + 34 [0] 93/ 2 78 12 02

www.oyv.es

oyv@oyv.es

Adresse (address)

Rieber GmbH & Co. KG

Hoffmannstraße 44

D –72770 Reutlingen

Tel. +49 [0] 7121 / 518 - 0

Fax +49 [0] 7121 / 518 - 302

E-Mail: info@rieber.de

www.rieber.de

Stempel des Fachhändlers

(Dealer stamp)

ZNW 11930924,000,00,1 09/2005

Nr.:36642607/

This manual suits for next models

3

Table of contents

Other Rieber Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Giorik

Giorik Stoddart 700 Series Installation, operation & maintenance manual

Henny Penny

Henny Penny FlexFusion Platinum installation manual

Frigomat

Frigomat AGG.2014 Series Use and maintenance manual

Atlas Metal

Atlas Metal WQHC Series Service and installation manual

FM

FM STF 610 user manual

Royal Catering

Royal Catering RCCC-238-W user manual