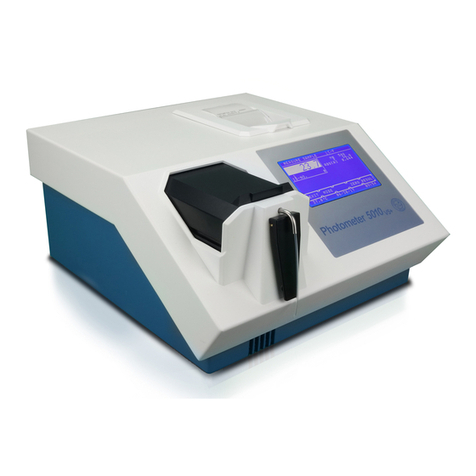

Riele Photometer 5010 User manual

Photometer 5010

Version 4.x

upwards serial no. 5000

Service Manual

CONTENTS

chapter headline page file

RIELE BERLIN Photometer 5010 / V4 1 11.05.2004

1 General notes Sm_V4_a.pdf

1.1 Contact partner 1.1 Sm_V4_a.pdf

1.2 Proved security 1.1 Sm_V4_a.pdf

1.3 Precautions and hazards 1.2 Sm_V4_a.pdf

2 Service concepts Sm_V4_a.pdf

2.1 Service level 2.1 Sm_V4_a.pdf

2.2 Conditions 2.2 Sm_V4_a.pdf

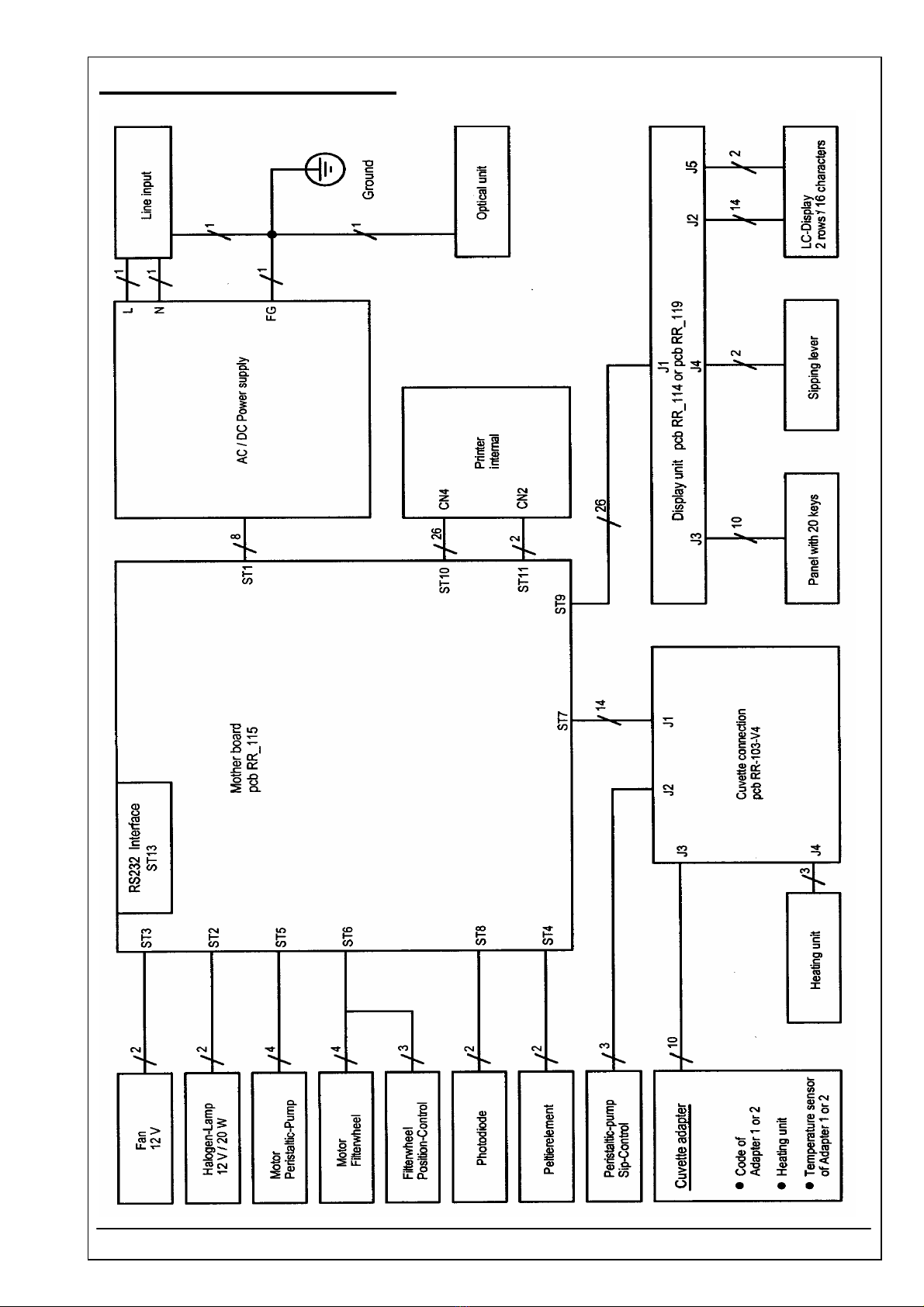

3.1 Block diagram 3.1.1 Sm_V4_a.pdf

3.2 Short instruction guide 3.2.1 Sm_V4_a.pdf

3.3 Service tools 3.3.1 Sm_V4_a.pdf

3.4 Plug identification 3.4.1 Sm_V4_a.pdf

4.1 Mains power circuit 4.1 Sm_V4_b.pdf

4.2 Mains connector 4.2 Sm_V4_b.pdf

4.3 AC / DC power supply 4.3 Sm_V4_b.pdf

4.10 Optical unit 4.10.1 Sm_V4_b.pdf

4.11 Filter wheel 4.11.1 Sm_V4_b.pdf

4.12 Halogen lamp 4.12.1 Sm_V4_b.pdf

4.13 Photodiode with plug 4.13.1 Sm_V4_b.pdf

4.14 Heating unit 4.14.1 Sm_V4_b.pdf

4.15 Peltier element 4.15.1 Sm_V4_b.pdf

4.16 Pump motor 4.16.1 Sm_V4_b.pdf

4.17 Tooth belt 4.17.1 Sm_V4_b.pdf

4.18 Step motor filter wheel 4.18.1 Sm_V4_b.pdf

4.19 Light barrier filter wheel 4.19.1 Sm_V4_b.pdf

4.20 Bubble detector 4.20.1 Sm_V4_b.pdf

4.21 Flow-through cuvette adaptor 4.21.1 Sm_V4_b.pdf

4.22 Standard cuvette adaptor 4.22.1 Sm_V4_b.pdf

4.23 Connector bubble detector 4.23.1 Sm_V4_b.pdf

4.24 Lamp holder 4.24.1 Sm_V4_b.pdf

4.25 Cuvette lense kit 4.25.1 Sm_V4_b.pdf

4.26 Tubes 4.26.1 Sm_V4_c.pdf

CONTENTS

chapter headline page file

RIELE BERLIN Photometer 5010 / V4 2 11.05.2004

4.30 Top case 4.30.1 Sm_V4_c.pdf

4.31 Display glass 4.31.1 Sm_V4_c.pdf

4.32 Metal tube inlet 4.32.1 Sm_V4_c.pdf

4.33 Micro switch 4.33.1 Sm_V4_c.pdf

4.34 Keyboard 4.34.1 Sm_V4_c.pdf

4.35 Printer mechanism 4.35.1 Sm_V4_c.pdf

4.40 Mother board RR_115 Sm_V4_d.pdf

General description 4.40.1 Sm_V4_d.pdf

Component diagram 4.40.2 Sm_V4_d.pdf

Voltages 4.40.3 Sm_V4_d.pdf

Voltage 12 VDC of halogen lamp 4.40.4 Sm_V4_d.pdf

Fuses F1, F2 and F3 4.40.4 Sm_V4_d.pdf

Amplifier of photocurrent and ADC 4.40.5 Sm_V4_d.pdf

Adjustment of amplifier stage 4.40.6 Sm_V4_d.pdf

Contrast of LCD 4.40.7 Sm_V4_d.pdf

Temperature control 4.40.8 Sm_V4_d.pdf

Adjustment of temperature control 4.40.9 Sm_V4_d.pdf

Thermal adjustment 4.40.10 Sm_V4_d.pdf

Installation instruction 4.40.11 Sm_V4_d.pdf

Circuit diagrams 4.40.13 Sm_V4_e.pdf

Circuit diagrams 4.40.17 Sm_V4_f.pdf

4.42 Display unit pcb RR_114 or pcb RR_119 4.42.1 Sm_V4_g.pdf

4.43 Cuvette connection pcb RR-103-V4 4.43.1 Sm_V4_g.pdf

4.44 Printer controller pcb 4.44.1 Sm_V4_g.pdf

4.50 Fan 4.50.1 Sm_V4_g.pdf

4.51 Bottom case 4.51.1 Sm_V4_g.pdf

4.52 Carton Photometer 5010 4.52.1 Sm_V4_g.pdf

5 Mantling / Dismantling Sm_V4_h.pdf

CONTENTS

chapter headline page file

RIELE BERLIN Photometer 5010 / V4 3 11.05.2004

6.1 Communication protocol 6.1 Sm_V4_h.pdf

6.2 Exchange of EPROM 6.6 Sm_V4_h.pdf

6.3 DOS: Download to FLASH MEMORY 6.7 Sm_V4_h.pdf

6.4 WINDOWS: Resume after malfunction 6.9 Sm_V4_h.pdf

6.5 Initialization of bootstrap 6.12 Sm_V4_h.pdf

7 Trouble shooting 7.1 Sm_V4_h.pdf

8 Spare parts 8.1 Sm_V4_h.pdf

9.1 Calibration procedure of Photometer 5010

Subject: Cuvette temperature 9.1.1 Sm_V4_h.pdf

1 GENERAL NOTES

RIELE BERLIN Photometer 5010 / V4 1.1 20.08.2003

The data and information provided in this manual correspond to the state of knowledge existing at

the time of introducing the Photometer 5010 on the market. Any important changes will be taken

into account in the next edition of this manual.

In any case, the respective packaging leaflet should be regarded as authoritative.

This service manual was created for the telephone service and technical service staff.

1.1 Contact Partner

Technical product management and support:

ROBERT RIELE GmbH & Co KG

Address: Kurfürstenstraße 75 - 79

D - 13467 Berlin

Germany

Phone: ++49 / 30 / 404 40 87

Fax: ++49 / 30 / 404 05 29

1.2 Proved Security

This instrument has been constructed under the regulations of EN 61010-1:1993 and

EN 61010-1/A2:1995.

This device was examined and left the factory in perfect technical condition. To preserve this and

protect safe and faultless operation, the user must follow the orders and remarks of this service

manual.

To preserve this condition and to guarantee a safe working, informations and working advices,

which are included in this working instructions, have to be heeded by the applier.

This instruments meets protection 1 (earth conductor wire).

1.3 Precaution and Hazards

All electrical equipment is potentially hazardous. Never remove covers without first ensuring that it

is isolated from the AC supply, unless specific maintenance instructions or repairs are being carried

out by authorized ROBERT RIELE personnel.

The hard- and software is subject to a program of continuos evaluation and improvement and,

therefore, may be changed in the future. This also concerns service requirements.

All samples and reagents should be treated with caution accorded to those known to contain

pathogenic organisms. Similarly, the cleaning of component part of Photometer 5010 should be

done with respect to human health.

1 GENERAL NOTES

RIELE BERLIN Photometer 5010 / V4 1.2 20.08.2003

Warning: All components used on Photometer 5010 must be regarded as potentially dangerously

contaminated when doing repair work. Use rubber gloves or double gloves whenever cleaning or

sterilizing components. The most frequently used components (tubings, cuvette, measuring

chamber flap, sip. lever and waste container) should be cleaned and treated with a suitable

disinfecting solution (75% alcohol) prior to doing any service work.

Disinfect and wash hands after work is completed.

This instrument has been constructed and checked in accordance with Standards IEC 1010. When

the instrument leaves our factory it is in perfect condition from the point of view of work safety. To

keep it that way and to ensure safe operation the user must follow the instructions and warnings

given in the operation instruction manual.

The electrical protection of the apparatus corresponds to Class I (it has a protective earth).

The power plug must only be inserted into a socket that has a protective contact. The protection

must not be abolished by using an extension lead that does not have a protective earth wire.

Warning:

Any break in the earth wire inside or outside the apparatus and any loose connection of the earth

wire can make the operation of the apparatus dangerous. A deliberate break or interruption is not

allowed.

When the housing is opened or the components are being removed (except when this can be done

by hand), live parts may be exposed. Connection may also be live.

Therefore, if the carrying out of an adjustment, service or repair on the open apparatus in the live

state is unavoidable, this must be done by an expert who is familiar with the dangers involved.

Make sure you only use fuses of the specified type and rated amperage when replacing the old

ones. Repaired fuses must not be used and the fuse holder must not be bypassed.

If you have any reason to believe that the instrument can no longer operate safely, take it out of

use and make sure no one can use it accidentally.

It must be assumed that safe operation is no longer possible when the instrument:

•shows visible signs of demage

•fails to operate

•has been stored under unfavourable conditions for a fairly long time

•has been transported under rough conditions

The Photometer 5010 should be used by appropriately qualified persons only.

2 SERVICE CONCEPTS

RIELE BERLIN Photometer 5010 / V4 2.1 21.08.2003

2.1 Service Level

From the early stage of development, Photometer 5010 was designed for simple error detection

and easy exchangeability of modules. This gives the service workshops the possibility of a fast and

easy repair of the instrument on service level A (module level). No big stock or expensive

equipment is necessary and service technicians are easier to train. Also, a permanent technical

improvement in layout and components took and takes place for better productivity and economic

production.

On repairable modules the quality and function is always provided by the manufacturer according

to the latest technology. This keeps Photometer 5010 always on the highest quality level.

The exchange price for modules will be kept on a low level to guarantee repairs, on an economical

basis.

2.2 Conditions

Warranty period

for instruments ...

The warranty period for instruments is 16 months starting with the date of

shipment ex works Berlin/Federal Republic of Germany or 12 months

starting with the date of the first installation, whichever period is shorter.

... and spare parts For spare parts a warranty of 6 months from installation date of the part

applies. Prerequisite for this is, that the warranty period for spare parts shall

not fall short of the warranty period of the instrument where a spare part has

been installed. A further prerequisite is, that this period shall not exceed a

period of 24 months starting with the delivery of the spare part ex works

Berlin/Federal Republic of Germany.

Hint:

In case the instrument has a remaining warranty period of more than

6 months, the parts remain under warranty until the warranty period of the

instrument expires.

Handling of

warranty claims

Replacement of parts

The defective parts have to be handled via Return Authorization (RA)

procedure. Please answer all the questions on the RA form with the greatest

care.

Especially a detailed fault description is needed or the warranty claim will not

be accepted by the manufacturer.

Complete instruments are not accepted unless this has been agreed with

the service department of ROBERT RIELE GmbH & Co KG.

Important information:

−Only parts marked with "A" in the price list are generally accepted under

warranty.

−Only return those parts marked with "R" in the spare part list.

−All defective parts ( non-"R" and "A" parts ) should be kept on stock for

a period of 7 months. In case the manufacturer needs the part for

investigation it will be requested from Berlin.

−All parts returned to Berlin and not requested by Berlin will be sent back

at the expense of the dealer/customer.

2 SERVICE CONCEPTS

RIELE BERLIN Photometer 5010 / V4 2.2 21.08.2003

Exclusion of

warranty

The aforementioned warranties do not apply in case of improper use,

handling, transportation or storage, faulty installation, repair or maintenance,

Chemical influence or contamination as well as damages resulting from that,

failure to follow operating instructions, alterations or modifications of

instruments or parts thereof not authorized or recommended by

ROBERT RIELE GmbH & Co KG and resulting damages, normal wear and

tear and in case of other circumstances beyond the control of

ROBERT RIELE GmbH & Co KG.

Handling of

repairs

As a general rule, all instrument repairs should be carried out by authorized

and trained personel only.

Repair of parts marked with "R"

Parts which are economically worth repairing are marked with "R" in the

spare parts price list. The defective parts have to be handled via Return

Authorization procedure. For correct handling of the exchange it is

absolutely necessary to return the complete filled in RA form (preferable via

electronic mail), giving full details of the defect.

Repair of instruments

Complete instruments are not accepted for replacement or repair unless

this has been agreed with ROBERT RIELE GmbH & Co KG.

Before replacement or repair can take place, the validity of the request must

be examined and the question of costs must be settled in a written

agreement with ROBERT RIELE GmbH & Co KG.

Terms of delivery All shipping conditions for spare parts to the dealer/customer are

ex. work Berlin.

Emergency shipments require additional costs to be charged.

Emergency

shipment

In case of emergency, a copy of the complete RA form should be sent by fax

ROBERT RIELE GmbH & Co KG, Berlin

marked with EMERGENCY

If fax was used for Emergency RA the original RA form has to be mailed or

sent by electronic mail to Berlin.

Handling of costs Replacements for R-parts are shipped at a repair price. In case the parts are

no longer repairable, the dealer/customer will be charged lateron with the

difference of the new price.

Replacements for warranty requests are shipped free of charge.

In case the manufacturer does not accept the warranty request, the

dealer/customer will be charged lateron with the R-price for R-parts and the

new price for non R-parts.

2 SERVICE CONCEPTS

RIELE BERLIN Photometer 5010 / V4 2.3 21.08.2003

RA form (see

form at next page)

Return Authorization

Please answer all the questions on the RA form with the greatest care and

sign the form.

−Date (problem date)

−Type of instrument

−Serial No. (of the instrument)

−Installation date (of instrument)

−mark Spare Part (instruments should not be returned)

−Mat.-No. of the spare part

−Fault description (incl. error code and job codes)

−mark request e.g. Repair and Replacement

−fill in RA-number

−give place and date (when filled in form) and sign RA form

Note: RA sent via electronic mail to Berlin is valid without a

signature.

In case of

instrument out of

warranty

−Installation date of spare part when part was installed within the last

6 months.

All returned parts should be individually labelled with the corresponding RA

No. and shipped together with the completed RA form (if not sent via

electronic mail) to:

ROBERT RIELE GmbH & Co KG

Kurfürstenstraße 75 −79

D-13467 Berlin

Germany

3.1 BLOCK DIAGRAM

RIELE BERLIN Photometer 5010 / V4 3.1.1 11.05.2004

3.2 SHORT INSTRUCTION GUIDE

RIELE BERLIN Photometer 5010 Service 3.2.1 22.08.2003

MODE FUNCTIONS

The mode functions serve for changing definite basic settings during a course of method. It is not necessary to

exit the method and to change to the level of UTILITY PROGRAMS (OM chapter 8). Also temporary parameters

remain unchanged. Corresponding to these features this group of functions is available only within the repetition

sequence of a course of method (chapter 5.5 – DESCRIPTION OF METHOD COURSES).

Change to the selection level of the mode functions with [MODE].

Selection level of the mode functions: Selecting the desired mode function by

direct selection i.e. input of the number key in question (see table) or by scrolling

through all mode functions with [+] ... [+]. Confirm with [ENTER].

Exit the selection level of the mode functions and change back to the course of

method with [BREAK].

After working off a mode function the return is carried out to the course of method.

MODE FUNCTIONS

Key/-combination

Function Chapter

[MODE] [4]

Parallel printers ON / OFF 5.6

[MODE] [5]

Multi-standard tools 5.10

[MODE] [6]

Pump utilities 5.7

[MODE] [7]

Serial interface utilities 5.8

[MODE] [8]

Changing sample numerator 5.9

MODE FUNCTIONS

3.2 SHORT INSTRUCTION GUIDE

RIELE BERLIN Photometer 5010 Service 3.2.2 22.08.2003

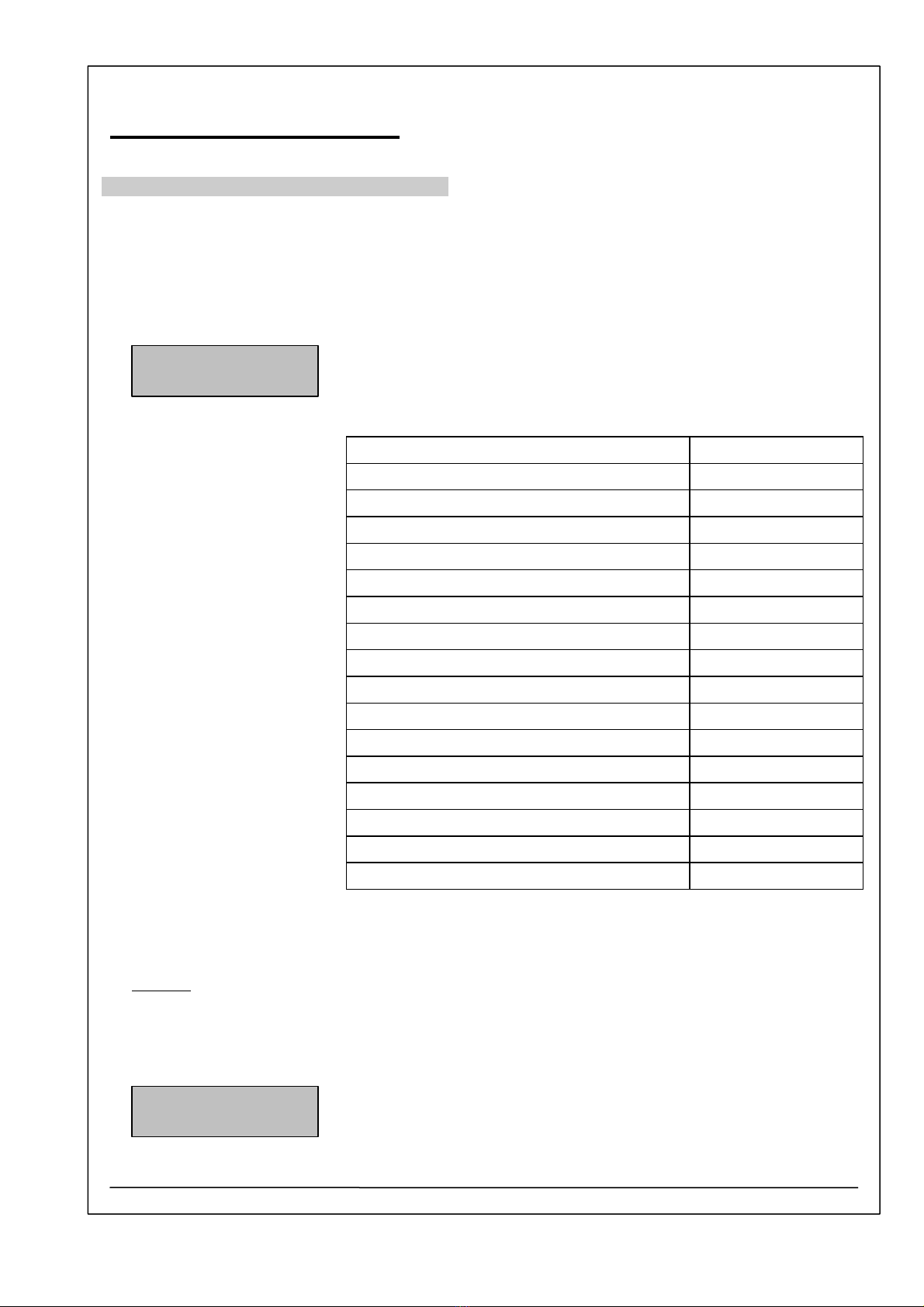

SELECTION OF UTILITY PROGRAMS

Method selection: change to utility program selection with [MODE].

Confirm with [MODE].

Utility program selection: direct selection of required utility program, i.e. input of

concerning identity no. (see table) and confirming with [ENTER], or by scrolling

through all utility programs with [+] ... [+].

Abort of utility program selection and return to program selection with [BREAK].

A utility program can be broken off with [BREAK] at any time with return to the

selection of utility programs.

After working off a utility program automatic return to the selection of utility

programs.

Identity

-No.

Utility Program Descript

ion

in

chapter

1 Dark level adjustment 8.2.1

2 Adjustment of bubble detector 8.2.2

3 Error list 8.2.3

4 Deleting method 8.2.4

5 Language selection 8.2.5

6 Beep ON / OFF 8.2.6

7 Temperature control ON / OFF 8.2.7

8 Temperature calibration 8.2.8

9 AD-Transducer 8.2.9

10 ADC dark current values 8.2.10

11 Display test 8.2.11

12 Printing device configuration 8.2.12

13 Real time clock ON / OFF 8.2.13

14 Filter wheel test 8.2.14

15 Temperature correction single cuvette

adaptor

8.2.15

16 Temperature correction flow-through

adaptor

8.2.16

17 Printing user defined methods 8.2.17

INPUT 1-n/+

UTILITIES

METHOD NO.

INPUT 1-250

3.3 SERVICE TOOLS

RIELE BERLIN Photometer 5010 / V4 3.3.1 19.09.2003

SELECTION OF SERVICE TOOLS

In the service program level there are functions influencing special basic parameters of the instrument.

Because they are allowed to be changed divergent from the work configuration only in exceptions and only by

trained staff, their unintentional selection is protected by a password.

Program selection: Change to service program selection with [MODE].

Confirm with [LF].

Enter password [13467]. Confirm with [ENTER].

The service level will be opened until to the next shutdown of the device.

Service tools selection: Direct selection of desired service tool, i.e. input of

concerning item no. (see table) and confirming with [ENTER], or by scrolling

through all service tools with [+] ... [+].

Abort of service tool selection and change back to program selection with

[BREAK].

A service tool can be broken off with [BREAK] at an any time. Then a change is

carried out back to the selection of service tools.

After working off a service tool the return is carried out to the selection of service

tools.

Item no. Service tool Description

in chapter

1 System initialization S1

2 Free methods initialization S2

3 Parameter initialization S3

4 Serial number S4

5 Boost mode S5

6 Filter select S6

7 Automatic Result S7

8 Temperature functions S8

9 Block Code Character from

method

S9

10 Analog-digital converter

correction

S10

11 Voltages S11

12 Reduction of lamp voltage S12

13 Attribut of PCB layout S13

14 Patients data initialization S14

METHOD NO.

INPUT 1-250

PASSWORD 13467

SERVICE TOOLS

INPUT 1-n/+

SERVICE TOOLS

3.3 SERVICE TOOLS

RIELE BERLIN Photometer 5010 / V4 3.3.2 19.09.2003

DESCRIPTION OF SERVICE TOOLS

S1 System initialization

With this function the default parameters will be set.

Start menu by [MODE] [LF] [1]:

Confirm with [ENTER].

Following settings are then typed over in the battery powered RAM. They remain

active, even after switching the instrument off/on, until they are specifically

changed. This action ends with a long beep and a print-out of the program

release.

Beeper ON

Printer internal ON

Printer external OFF

Real time clock ON

Boost mode up to 390 nm

Language english

Analog-digital converter correction 75

Temperature control: Correction values 3000

EDP OFF

EDP protocol STX/ETX/BCC

Baud rate 9600 bps

Resulting factors of methods based on standard cleared

Error list cleared

Laboratory name not affected

User name not affected

Patients data not affected

Bubble detector ON

S2 Free methods initialization

Attention! With this function all methods edited by the user are deleted without call-back. In the case of doubt

these methods should be checked before: Scroll through all methods with the method editor and note them

down for an optional later new programming.

Start menu by [MODE] [LF] [2]:

Confirm with [ENTER].

This action ends with a long beep.

SYSTEM INIT. S1

SERVICE TOOLS

FR.METH.INIT. S2

SERVICE TOOLS

3.3 SERVICE TOOLS

RIELE BERLIN Photometer 5010 / V4 3.3.3 19.09.2003

S3 Parameter initialization

Attention! The extended memory for the parameters of all nonlinear methods is deleted by this function without

call-back and the corresponding user defined methods become useless.

Start menu by [MODE] [LF] [3]:

Confirm with [ENTER].

This action ends with a beep.

S4 Serial number

Display of the current serial number. A new number can be entered with max. five digits.

Start menu by [MODE] [LF] [4]:

Confirm with [ENTER].

Confirm the input with [ENTER].

S5 Boost mode

To improve the low light gain at small wavelengths, the measurement time is extended when operating below

a definite wavelength. This definite wavelength will be displayed for approx. 2 sec. when starting this service

program. The default value is 390 nm.

Start menu by [MODE] [LF] [5]:

Confirm with [ENTER].

Enter [0] = BOOST OFF or a value between 300 and 900 as definite wavelength

in nanometers, below which the boost mode is activated. Finally confirm the input

with [ENTER].

S6 Filter select

The assignment of filter positions can be made.

Start menu by [MODE] [LF] [6]:

Confirm with [ENTER].

Select filter position by numeric key. Confirm the input with [ENTER].

Enter new wavelength by numeric key. Confirm the input with [ENTER].

Finish the operation with [BREAK].

PARAM. INIT. S3

SERVICE TOOLS

SERIAL NO. S4

SERVICE TOOLS

BOOST ON/OFF S5

SERVICE TOOLS

FILTERSELECT S6

SERVICE TOOLS

3.3 SERVICE TOOLS

RIELE BERLIN Photometer 5010 / V4 3.3.4 19.09.2003

S7 Automatic Result

With this service program a continuous measuring mode based on calculation procedure 1 (endpoint with

factor) is possible. After the input of wavelength, factor and delay-time and after measuring blank the con-

tinuous measuring mode is started.

Start menu by [MODE] [LF] [7]:

Confirm with [ENTER].

This mode is active until [BREAK] is pressed (and held for a while).

S8 Temperature functions

A sub menu with eight items for temperature functions is called.

Start menu by [MODE] [LF] [8]:

Confirm with [ENTER].

Direct selection of desired service tool, i.e. input of concerning item no. and

confirming with [ENTER], or by scrolling through all temperature functions

with [+] ... [+].

Item no. Service tool Description

in chapter

1 Temperature regulation on / off S8.1

2 Temperature value of standard

cuvette adaptor

S8.2

3 Temperature value of

flowthrough cuvette adaptor

S8.3

4 Temperature calibration S8.4

5 Temperature required / actual S8.5

6 Temperature Analog-Digital-

Converter

S8.6

AUTO. RESULT S7

SERVICE TOOLS

TEMP. FUNCT. S8

SERVICE TOOLS

3.3 SERVICE TOOLS

RIELE BERLIN Photometer 5010 / V4 3.3.5 19.09.2003

S8.1 Temperature regulation on / off

The temperature regulation can be switched on or switched off. In the display the current setting is shown.

Start menu by [1]:

Confirm with [ENTER].

Changing of the setting with the keys [1] = ON or [0] = OFF.

The displayed setting becomes active with [ENTER] and [BREAK].

Select temperature level by [1], [2] or [3] in case of setting ON.

S8.2 Temperature value of standard cuvette adaptor

Display of the current setting. The correction of the temperature regulation is possible by change of the

temperature setting.

Start menu by [2]:

Confirm with [ENTER].

Select temperature level by [1], [2] or [3].

Enter new temperature value and confirm with [ENTER]

or finish operation with [BREAK]. The window shows for example the value 13047

for the temperature level 37 °C.

S8.3 Temperature value of flowthrough cuvette adaptor

Display of the current setting. The correction of the temperature regulation is possible by change of the

temperature setting.

Start menu by [3]:

Confirm with [ENTER].

Select temperature level by [1], [2] or [3].

Enter new temperature value and confirm with [ENTER]

or finish operation with [BREAK]. The window shows for example the value 13047

for the temperature level 37 °C.

TEMP. ON/OFF

INPUT +/E/B

HEATING OFF

1/ON 0/OFF

E-TEMP. VALUE

INPUT +/E/B

HEATING ON

1/25 2/30 3/37

E-TEMP. VALUE

1/25 2/30 3/37

37C VALUE E

13047

D-TEMP. VALUE

INPUT +/E/B

D-TEMP. VALUE

1/25 2/30 3/37

37C VALUE D

13047

3.3 SERVICE TOOLS

RIELE BERLIN Photometer 5010 / V4 3.3.6 19.09.2003

S8.4 Temperature calibration

The correction of the temperature regulation is possible by input of the temperature which is measured in the

cuvette with an external measuring system (only when the temperature regulation is stabilized).

Start menu by [4]:

Confirm with [ENTER].

Confirm with [ENTER].

The display shows the current temperature level at the required value of 37 °C.

Enter the actual temperature value always four-digit in °C e.g. [3] [7] [,] [2] [0]

[ENTER] measured by an external measuring system. The system calculates and

stores the new setting for 37.0 °C and starts working with it at once.

S8.5 Temperature required / actual

The correction of the temperature regulation is possible by input of the temperature which is measured in the

cuvette with an external measuring system (only when the temperature regulation is stabilized).

Start menu by [5]:

Confirm with [ENTER].

Confirm with [ENTER].

The display shows in the second line the required value (e.g. 14270),

the actual value (e.g. 14275) and the type of cuvette adapter (e.g. D).

S8.6 Temperature Analog-Digital-Converter

Display of the counter value of the temperature ADC and of the current stability value.

Start menu by [6]:

Confirm with [ENTER].

Confirm with [ENTER].

The display shows in the second line the actual value of the ADC (e.g. 954),

and the stability value S (e.g. 0).

TEMP. CALIBR.

INPUT +/E/B

INPUT DEGREE C

37C 37.20

TEMP. REQU / ACT

INPUT +/E/B

TEMP. REQU / ACT

14270 14275 D

TEMP. ADC

INPUT +/E/B

TEMP. ADC

ADC 954 S 0

3.3 SERVICE TOOLS

RIELE BERLIN Photometer 5010 / V4 3.3.7 19.09.2003

S9 Block Code Character from method

To check the correct storing of a user-defined method, the special test byte BCC concerning the data in the

memory is used. With this service program the BCC of a method can be determined.

Start menu by [MODE] [LF] [9]:

Confirm with [ENTER].

The number of the concerning method must be entered and confirmed with

[ENTER]. Then the BCC is displayed in the decimal form.

Press [ENTER] and select another number of a method.

Press [BREAK] for exit.

S10 Analog-digital converter correction

Display of the actual correction value of the analog-digital converter (photometric measuring system). In the

delivering condition the value is 75.

Start menu by [MODE] [LF] [10]:

Confirm with [ENTER].

By input of a correction value between 0 and 255 and confirming with [ENTER]

measurements seeming too low can be increased a little bit. This correction

recognizably affects only at high results (~ 2 Absorbance).

S11 Voltages

Display of the actual voltages on the pcb.

Start menu by [MODE] [LF] [11]:

Confirm with [ENTER].

Confirm with [ENTER].

The display shows the actual voltages of

+ 12 VDC of halogen lamp / fan (1. line left)

+ 12 VDC and - 12 VDC of analogic circuits (1. line right)

+ 5 VDC of VCC (2. line left)

+ 15 VDC of power supply (2. line middle)

VDC voltage of Peltier element (2. line right)

BCC FROM METH.S9

SERVICE TOOLS

ADC CORRECT.S10

SERVICE TOOLS

VOLTAGES S11

SERVICE TOOLS

12.03 12+0.07

-4.93 14.75 0.01

3.3 SERVICE TOOLS

RIELE BERLIN Photometer 5010 / V4 3.3.8 19.09.2003

S12 Reduction of lamp voltage

The voltage + 12 VDC of halogen lamp can be reduced for lamp adjustment in vertical direction.

Start menu by [MODE] [LF] [12]:

Confirm with [ENTER].

Confirm with [ENTER]. Adjust lamp in vertical direction.

Press [BREAK] for exit.

S13 Attribut of PCB layout

The attribut of the PCB layout can be read and set. Software applications may be dependent on this attribut.

The attribut is labeled on the PCB RR_111 near plug ST13 (RS232C interface).

Start menu by [MODE] [LF] [13]:

Confirm with [ENTER].

Confirm with [ENTER].

In the second line the display shows the version of PCB layout, e.g. the value „c“.

Change the value by [+] in case of a deviation and confirm the input by [ENTER].

Leave the window by [BREAK] in case of no change.

S14 Patients data initialization

The memory of patients data mangement is cleared completely.

Start menu by [MODE] [LF] [14]:

The memory is cleared by confirming with [ENTER].

This action ends with a long beep.

PCB LAYOUT S13

SERVICE TOOLS

DEL.PATIENTS S14

SERVICE TOOLS

LAMP DOWN S12

SERVICE TOOLS

PCB LAYOUT S13

c +EB

Table of contents

Other Riele Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Power Test

Power Test Superflow SF-Black Widow Operator's manual

UEi

UEi HUB2 instruction manual

Sensia

Sensia CALDON SVM 289Ci user manual

Shodex

Shodex CLNpak EV2000AC-12F Operation manual

Pres Block

Pres Block AFNOR NF S 90-116 Use and maintenance handbook

Compressed Air Alliance

Compressed Air Alliance POM100 user manual

R.M. Young

R.M. Young 05305V instructions

YOKOGAWA

YOKOGAWA ADMAG TI Series Read me first

water & more

water & more Aquameter Installation and operating instructions

weschler instruments

weschler instruments Power Series Plus user manual

Endress+Hauser

Endress+Hauser Liquicap M FTI51 operating instructions

Omega

Omega HHTQ35 user manual