Rishabh RISH CON - I User manual

IC 15001063 REV. C - 17/12/13

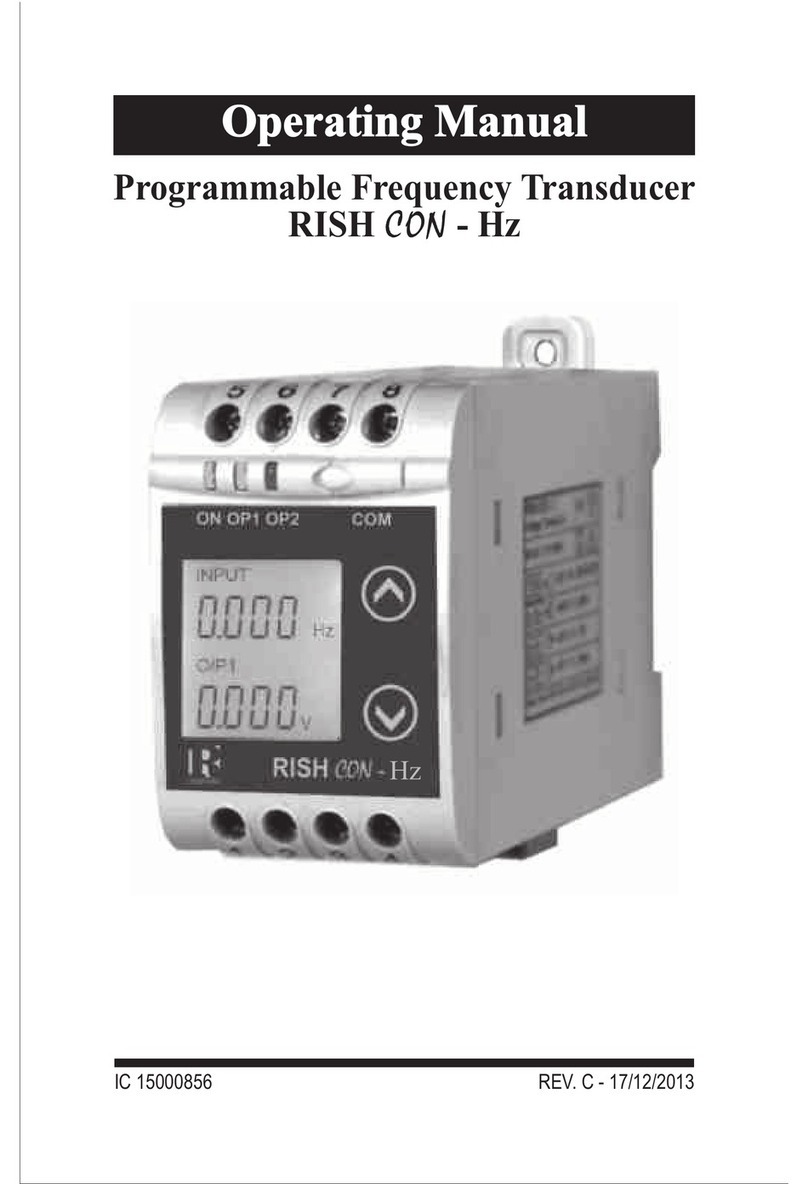

Operating Manual

I

Programmable Current Transducer

RISH CON - I

1Introduction

2 Input and Output screens

3 Programming

3.1 Programming via Front LCD & Two keys

3.1.1 Password Protection

3.1.1.1 Password verification

3.1.1.2 Editing Existing Password

3.1.2 Current Transformer parameter

Setting

3.1.2.1 Current Transformer primary

value

3.1.2.2 Current Transformer secondary

value

3.1.3 Communication Parameter Setting

3.1.3.1 Address Setting

3.1.3.2 RS 485 Baud rate

3.1.3.3 RS 485 Parity selection

3.1.4 Output Type selection

3.1.4.1 Output 1 Type selection

3.1.4.2 Output 2 Type selection

3.1.5 Input characteristics Setting

3.1.5.1 End value of input

3.1.5.2 Start value of input

3.1.5.3 Elbow Function Selection

3.1.5.4 Elbow value of input

1

Programmable Current Transducer

Installation & Operating Instructions

Current Transducer

SectionContents

3.1.6 Output characteristics Setting

3.1.6.1 Output 1 characteristics Setting

3.1.6.1.1 End value of output 1

3.1.6.1.2 Start value of output 1

3.1.6.1.3 Elbow value of output 1

3.1.6.2 Output 2 characteristics Setting

3.1.6.2.1 End value of output 2

3.1.6.2.2 Start value of output 2

3.1.6.2.3 Elbow value of output 2

3.2 Programming Via programming port available at

front of Transducer using optional PRKAB600

Adapter.

Installation

5.1 EMC Installation Requirements

5.2 Case Dimensions

5.3 Wiring

5.4 Auxiliary Supply

5.5 Fusing

5.6 Earth / Ground Connections

5.7 Maintenance

6. Specifications

7. Connection Diagrams

3.3

DIP Switch setting for output

4.

Programming Via optional RS485(MODBUS)

communication port.

3.3.1

RS 485 ( ModBus )

4.1 Accessing 3X Resistors

4.2 Accessing 4X Resistors

5.

2

1. Introduction

The Current Transducer is a DIN Rail/wall mounted 43.5 X

65.5mm Transducer.

Input

Current and Output Voltage / Current is displayed on LCD

and indicated by LED’s.

The Current Transducer is used to measure and convert AC

Current input into proportional DC current or voltage output

signal. Output signal generated is proportional to the True

RMS (upto 15th Harmonic) of the input Current.

Current Transducer can be

configured and programmed at

site for the following CT Primary

,CT Secondary (1A to 5A) , Input

Characteristics (i.e start, end and

elbow value of Input) and Output

parameters (i.e as Voltage or as

Current and Characteristics of

start, end and elbow value of

outputs).

A

A

1.1 LED Indication

3

Green LED Continuous ON

Green LED Continuous ON

Green LED Continuous ON

Red LED Continuous ON

Red LED Continuous ON

LED Operating Status

Output1 Voltage

Output1 Current

Output2 Voltage

Output2 Current

O/P 2

ON

O/P 1

LED

LED Operating Condition

Aux. Supply healthy Condition

The front panel has two keys through which the user may

scroll through the output screens and configure the product.

2. Input and Output screens

In normal operation the user is presented with display test

screen followed by version screen to one of the output

screen. These screens may be scrolled through one at a

time Output 1 or Output 2 by pressing the “ Up key” or

“ Down key”.

screen 1 : Display Test Screen 2 : Version Screen

Table 1: Measured parameters

Measured parameters Unit of Measurement

Current A

Screen 3 : Current Input and

Output 1 as Voltage

Screen 4 : Current Input

and Output 1 as Current

4

Screen 5 : Current Input and Screen 6 : Current Input &

Output 2 as Voltage Output 2 as Current

l

3. Programming

3.1 Programming via Front LCD & Two keys

The following sections comprise step by step procedures for

configuring the Current Transducer for individual user

requirements.

To access the set-up screens press & hold the“ down” &

“ up” keys simultaneously for 5 seconds. This will take the

User into the Password Protection Entry Stage .

Programming of transducer can be done in three ways :

3.1. Programming Via Front LCD & two keys.

3.2. Programming Via Programming port available at front of

Current transducer using option PRKAB60 Adapter.

3.3. Programming Via optional RS485(MODBUS)

communication port.

5

3.1.1. Password Protection

3.1.1.1 Password verification

Password protection can be enabled to prevent

unauthorised access to set-up screens, by default password

protection is not enabled.

Password protection is enabled by selecting a four digit

number other than 0000, setting a password of 0000

disables the password protection.

Enter Password, prompt for first

digit. (*Denotes that digit will be

flashing).Pressing the “ Down”

key will scroll the value of the first

digit from 0 through t o 9 , t h e

value will wrap from 9 round to 0.

Pressing the “ Up” key will

advance the operation to the next

digit and set the first digit.

In the special case where the Password is “0000”pressing

the “ Up” key when advance to password set or confirm

screen.

Enter Password, first digit

entered, prompt for second digit.

(*Denotes that digit will be

flashing).

Pressing the “ Down key will

scroll the value of the second digit

from 0 through to 9, the value will

wrap from 9 round to 0.

Pressing the “ Up” key will advance the operation to the

next digit and set the second digit. In this case to “2”.

A

6

Enter Password, second digit

entered, prompt for third digit.

(*Denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the third digit

from 0 through to 9, the value will

wrap from 9 round to 0.

Pressing the “ Up” key will advance the operation to the

next digit and set the third digit. In this case to “3”.

Enter Password, third digit

entered, prompt for fourth digit.

(*Denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the fourth digit

from 0 through to 9, the value will

wrap from 9 round to 0.

Pressing the “ Up” key will

advance the operation to the “Password Set / Confirmed”

and set the fourth digit. In this case to “4”.

Password Set/Confirmed.

Pressing “ Down” key will

enter to the “New /change Password”

entry stage.(section 3.1.1.2)

Pressing the “ Up” key will

confirm New password and

advance to current Transformer

parameter setting (section 3.1.2).

7

*

Password Incorrect.

This screen is displayed when the

unit has not accepted the

Password entered.

Pressing the " Down" key will

re-enter to the “Enter Password”

entry stage.

Pressing the “ Up” key will exit

the setup menu.

3.1.1.2 Editing Existing Password

New / Change Password

(*Denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the first digit

from 0 through to 9, the value will

wrap from 9 round to 0.

Pressing the “ Up” key will

advance the operation to the next digit and set the first digit,

in this case to “4”.

Enter New Password, first digit

entered, prompting for second

digit. (*Denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the second

digit from 0 through t o 9 , t h e

value will wrap from 9 round to 0.

Pressing the “ Up” key will advance the operation to the

next digit and set the second digit, in this case to “1”.

8

Enter New Password, second digit

entered, prompting for third digit.

(*Denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the third digit

from 0 through to 9, the value will

wrap from 9 round to 0.

Pressing the “ Up” key will advance the operation to the

next digit and set the third digit, in this case to “ 4”

Enter New Password, third digit

entered, prompting for fourth digit.

(*denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the fourth digit

from 0 through to 9, the value will

wrap from 9 round to 0.

Pressing the “ Up” key will advance the operation to the

“New Password Confirmed” and set the fourth digit, in this

case to “1”.

New/changed Password

confirmed.

Pressing the “ Down” key

will re-enter to the “New

Password”entry stage.

Pressing the “ Up” key will

confirm new password and

a d v a n c e t o t h e C u r r e n t

Transformer parameter Setting (section 3.1.2).

9

A

*

3.1.2. Current Transformer Parameter Setting

3.1.2.1 Current Transformer primary value

This screen allows the user to set the CT Primary value

from 1 to 9999 A.

Pressing the “ Down” key will

enter the “New/Change CT

Primary value edit” mode.

Pressing “ Up” key will confirm

the present value as CT Primary

and advance to the CT secondary

setting (section 3.1.2.2).

New / Change CT Primary value

(*Denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the first digit

from 0 through to 9, the value will

wrap from 9 round to 0

Pressing the “ Up” key will

advance the operation to the next digit and set the first

digit, in this case to “0”

Enter New / Change CT Primary

value, first digit entered, prompting

for second digit. (*Denotes that

digit will be flashing).

Pressing the “ Down” key will

scroll the value of the second digit

from 0 through to 9, the value will

wrap from 9 round to 0.

A

10

Pressing the “ Up” key will advance the operation to the

next digit and set the second digit, in this case to “0”.

Enter New / Change CT Primary

value, second digit entered,

prompting for third digit.

(*Denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the third digit

from 0 through to 9, the value will

wrap from 9 round to 0.

Pressing the “ Up” key will advance operation to the next

digit and set the third digit, in this case to “0”.

Enter / New CT primary value third

digit entered, prompt for fourth

digit (* Denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the fourth digit

from 0 through to 9, the

value will wrap from 9 round to 0.

Pressing the “ Up” key will

advance the operation to the “New

/ Changed CT Primary value

confirmation” and set the fourth

digit, in this case to “5”.

New/changed CT Primary

value confirmed.

Pressing the “ down” key will

re-enter to the “New / Change CT

11

Primary value.

Pressing the “ Up” key will confirm New CT Primary value

& advance to the CT secondary setting (section 3.1.2.2).

This screen allows the user to set

the CT Secondary value.

Pressing the “ Down” key will

enter the “New/Change CT

Secondary value edit” mode .

Pressing the “ Up” key will

confirm the present value as CT

Secondary and advance to the

Communication parameter Setting (section 3.1.3).

New / Change CT Secondary value

( * Denotes that digit will be

flashing ).

Pressing the “ Down” key will

scrollthe value of the fourth digit

from 1 through to 5, the value will

wrap from 5 round to 1.

Pressing the “ Up” key will

advance the operation to the “New

/ Changed CT Secondary value

confirmation” and sets the fourth

digit, in this case to “5”.

New/changed CT Secondary

value confirmed.

Pressing the “ Down” key will

return to the “New / Change CT

3.1.2.2 Current Transformer secondary value

12

Secondary value edit” mode.

Pressing the “ Up” key will confirm the CT Secondary &

advance to the Communication parameter Setting (section

3.1.3).

3.1.3. Communication Parameter Setting

3.1.3.1 Address Setting

This screen applies to the RS 485 output only.

This screen allows the user to set RS485 parameter for

instruments. The range of allowable address is 1 to 247

Pressing “ Down” key will

advance to the “New/Change

address value edit” mode.

Pressing the “ Up” key will

confirm the present value as

Address and advance to Baud

Rate selection (3.1.3.2).

New/Change Address value

(*Denotes that digit will be flashing).

First digit is always blank.

Pressing the “ Down “ key will

scroll the value of the second digit

from 0 through to 2, value will wrap

from 2 round to 0.

Pressing the “ Up” key will

advance the operation to the next

digit and set the second digit, in this case to “0”

Enter New/change Address value, second digit entered,

prompting for third digit. (*Denotes that digit will be flashing).

Pressing the “ Down” key will scroll the value of the third digit

13

from 0 through to 9, the value will

wrap from 9 round to 0. Pressing

the “ Up” key will advance the

operation to the next digit and set

the third digit, in this case to “9”.

Enter New/Change Address value,

third digit entered, prompting for

fourth digit. (*denotes that digit will

be flashing).

Pressing the “ Down” key will

scroll the value of the fourth digit

from 0 through to 9, the value will

wrap from 9 round to 0.

Pressing the “ Up” key will

advance the operation to the New/changed Address value

confirmed’ and set the fourth digit in this case to “6”

New/Changed Address value

confirmed.

Pressing the “ Down” key will re-

enter to the ‘New/change Address

value edit”mode. Pressing the” Up

key will confirm New Address value

and advance to Baud Rate

selection (section 3.1.3.2).

3.1.3.2 RS 485 Baud rate

This screen allows the user to set Baud Rate of RS 485 port .

The values displayed on screen are in kbaud Pressing the

“ Down” key will enter the ‘baud Rate edit” mode and scroll the

14

value through 2.4,4.8,9.6,19.2 and

back to 2.4(values are flashing).

Pressing “ Up” key will confirm the

present value as Baud rate and

advance to the Parity Selection

(section 3.1.3.3).

RS 485 Baud Rate confirmation

Pressing “ Down” key will be re-

enter into the. “Baud Rate Edit”

mode.

Pressing the “ Up” key will confirm

the Baud rate value and advance to

the Parity Selection (section

3.1.3.3).

3.1.3.3 RS 485 Parity Selection

This screen allows the user to set

Parity & number of stop bits of RS

485 port.

Pressing the “ Down” key will

enter the “Parity & stop bit edit”

mode and scroll the value through

E : even parity with one stop bit

odd : odd parity with one stop bit

no. 1S : no parity with one stop bit

no. 2S : no parity with two stop bit

Pressing “ Up” key accepts the present value and advance

to the Output Type selection (section 3.1.4).

15

RS 485 Parity confirmation

Pressing “ Down” key will be re-

enter into Parity Edit mode.

Pressing the “ Up” key will set the

value and advance to the Output

Type selection (section 3.1.4).

3.1.4. Output Type Selection

3.1.4.1 Output 1 Type selection

This screen allows the user to set

the output 1 type as Voltage or

Current.

Pressing the “ Down” key will

enter the “output 1 type edit”

mode and scroll between voltage

and current.

Pressing “ Up” key will confirm

the present type for Output 1 and advance to the Output 2

type selection (section 3.1.4.2).

Output 1 Type confirmation

Pressing “ Down” key will re-

enter into Output 1 type Edit

mode.

Pressing the “ Up” key will set

the type and advance to the

Output 2 type selection(section

3.1.4.2).

3.1.4.2 Output 2 Type Selection

This screen allows the user to set the output 2 type as a

16

voltage or current.

Pressing the “ Down” key will

enter the “output 2 type edit”

mode and scroll between

voltage and current.

Pressing “ Up” key accepts

the present type for Output 2

and advance to the Input

Characteristics setting (section 3.1.5).

Output 2 Type confirmation

Pressing “ Down” key will re-

enter into Output 2 type Edit

mode.

Pressing the “ Up” key will set

the type and advance to the

Input Characteristics setting

(section 3.1.5).

3.1.5. Input characteristics Setting

3.1.5.1 End value of Input

This screen allows the user to set

the End value of Input. End

value of Input can be set from

50% to 120% of set CT

secondary value.

Pressing the “ Down” key will

enter the “New/Change End

value of Input edit” mode.

Note: After Changing Output Type please insure to change

DIP Switch setting (Refer Section 3.3.1). If DIP Switches are

already change then switch ON/OFF Transducer.

17

A

Pressing “ Up” key will confirm the present value as End

value of Input and advance to the Start value of Input setting

(section 3.1.5.2).

New / Change End value of

Input

(*Denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the second

digit from 0(2) through

to1(6), the value will wrap from

1(6) round to 0(2) for 1A(5A) CT secondary.

Pressing the “ Up” key will advance the operation to the

next digit and set the second digit, in this case to “5”.

Enter New / Change End value of

Input, second digit entered,

prompting for third digit.

(*Denotes that digit will be

flashing).

Pressing the “ Down” key will

scroll the value of the third digit

from 0 through to 9, the value will

wrap from 9 round to 0.

Pressing the “

to the

next digit and set the third digit, in

this case to “0”.

Enter New /Change End value of

Input,third digit entered,

prompting for fourth digit.

up” key will

advance the operation

18

A

*

A

*

A

*

Table of contents

Other Rishabh Transducer manuals

Popular Transducer manuals by other brands

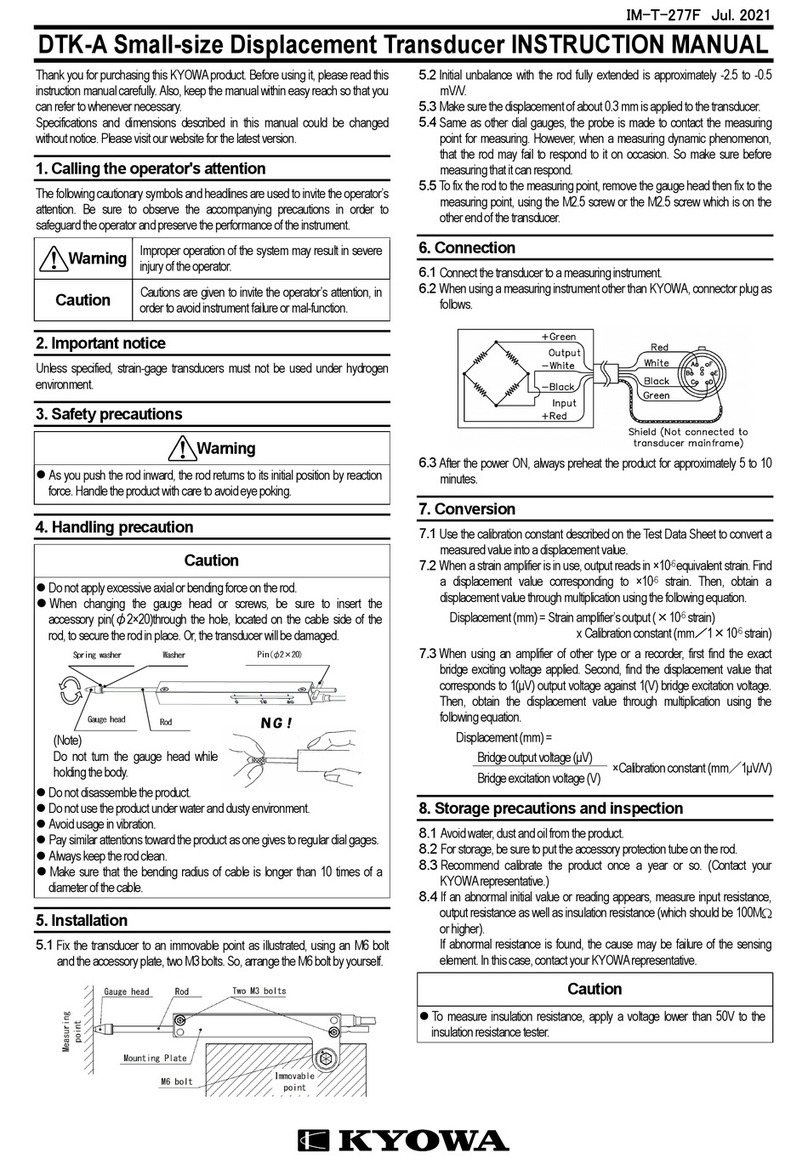

KYOWA

KYOWA DTK-A instruction manual

S+S Regeltechnik

S+S Regeltechnik AERASGARD RTM-C02 Operating Instructions, Mounting & Installation

Ametek

Ametek 953N Series Configuration manual

B-K Medical

B-K Medical Type 8817 user guide

B-K Medical

B-K Medical 8567-S user guide

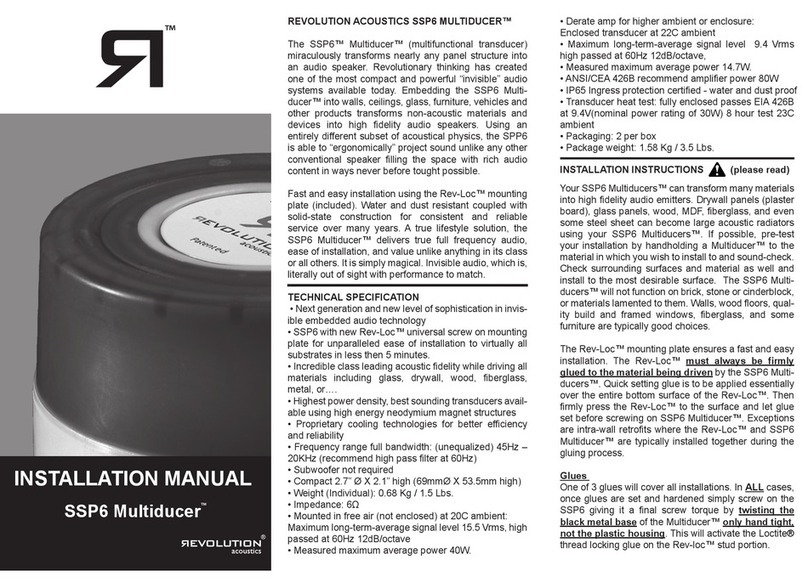

R/Evolution

R/Evolution Multiducer SSP6 installation manual

B-K Medical

B-K Medical Type 8559-S user guide

Caen ELS

Caen ELS Flucs CT -100 user manual

Raymarine

Raymarine Realvision RV-220P installation instructions

BIOPAC Systems, Inc.

BIOPAC Systems, Inc. MP150 Hardware guide

Raymarine

Raymarine DownVision CPT-70 installation instructions

S+S Regeltechnik

S+S Regeltechnik THERMASGARD RTM1-U Operating Instructions, Mounting & Installation