CHAPTER 1: MAINTENANCE

[ 1 - 6 ]

Sensor types

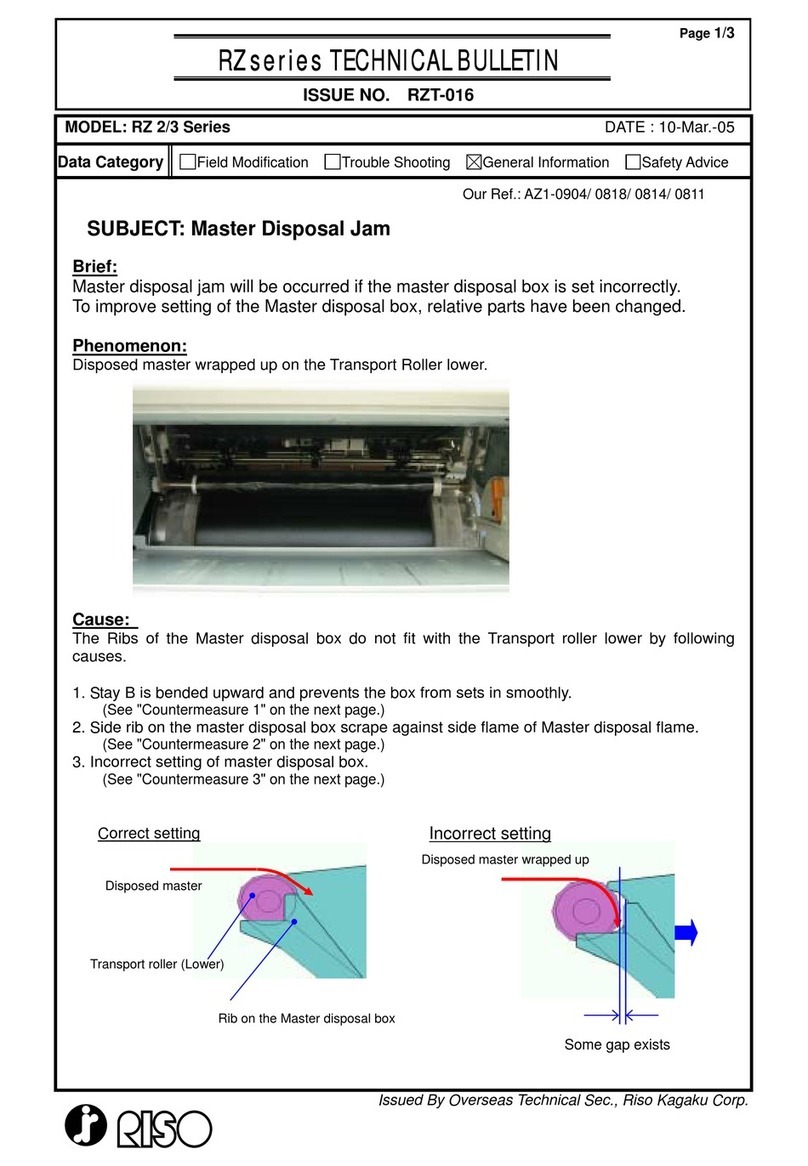

• Photoelectric sensors may be broadly divided into

the following four types: interrupt types (U-

shaped), actuator types, reflective types, and

transmittive types.

• Magnetic sensors use Hall ICs, which react to the

magnetic force in magnets.

• Always turn off the power before plugging or

unplugging sensor connectors.

COM

N.C.

N.O.

N.C.

N.O.

COM

Electrical system work

• After removing wire bundles, fasten them with wire

bundle bands (bar lock ties) so that they will not

sag.

• When installing parts, be careful to avoid pinching

or damaging the wire bundles.

• If a fuse blows, always replace it with one with the

specified capacity.

• Using a fuse with a larger capacity can not only

damage parts, but may cause fires.

• Be careful not to drop image scanners, thermal

print heads, and other sensors as they can be

easily damaged.

Interrupt types

Reflective types

Transmittive types

Actuator types

Receiver

Sender

Receiver

Sender

Sender Sender

Receiver

Receiver

0104

0105 0106

0107

Reflective (prism) types

Send

Receive Prism

Wiring bundle bands

(bar lock ties)

Switch types

• Microswitches may be divided between normally

open (N.O.) types and normally closed (N.C.) types.

With an N.O. connection, an internal contact is

connected when the switch actuator is pressed.

With an N.C. connection, an internal contact is

disconnected when the switch actuator is pressed.

Note

The machine is comprised of many gears. When inspecting or replacing parts, apply grease to the

gears. If they are not properly greased, the gears may make abnormal sounds, and malfunctions or

mechanical problems may occur.