SHR-5000™ Dok-Lok®Owner's Manual Rite-Hite®

10 Publication: AMEN00096 2018-05-30

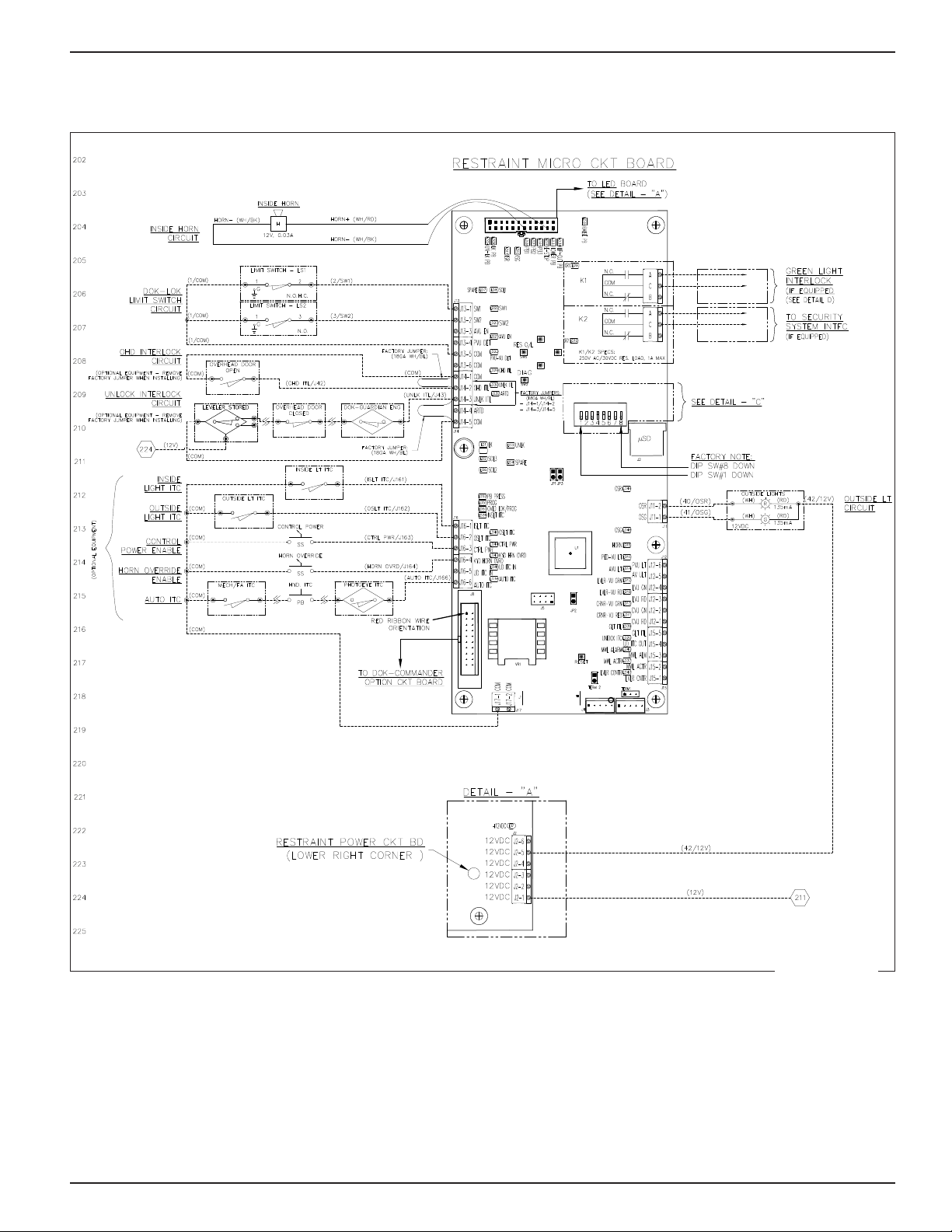

ELECTRICAL

Restraint Micro Board Continued

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

1

U4

J1

D64

D63

5

1

INSD

10

6

1

1

J4

J3

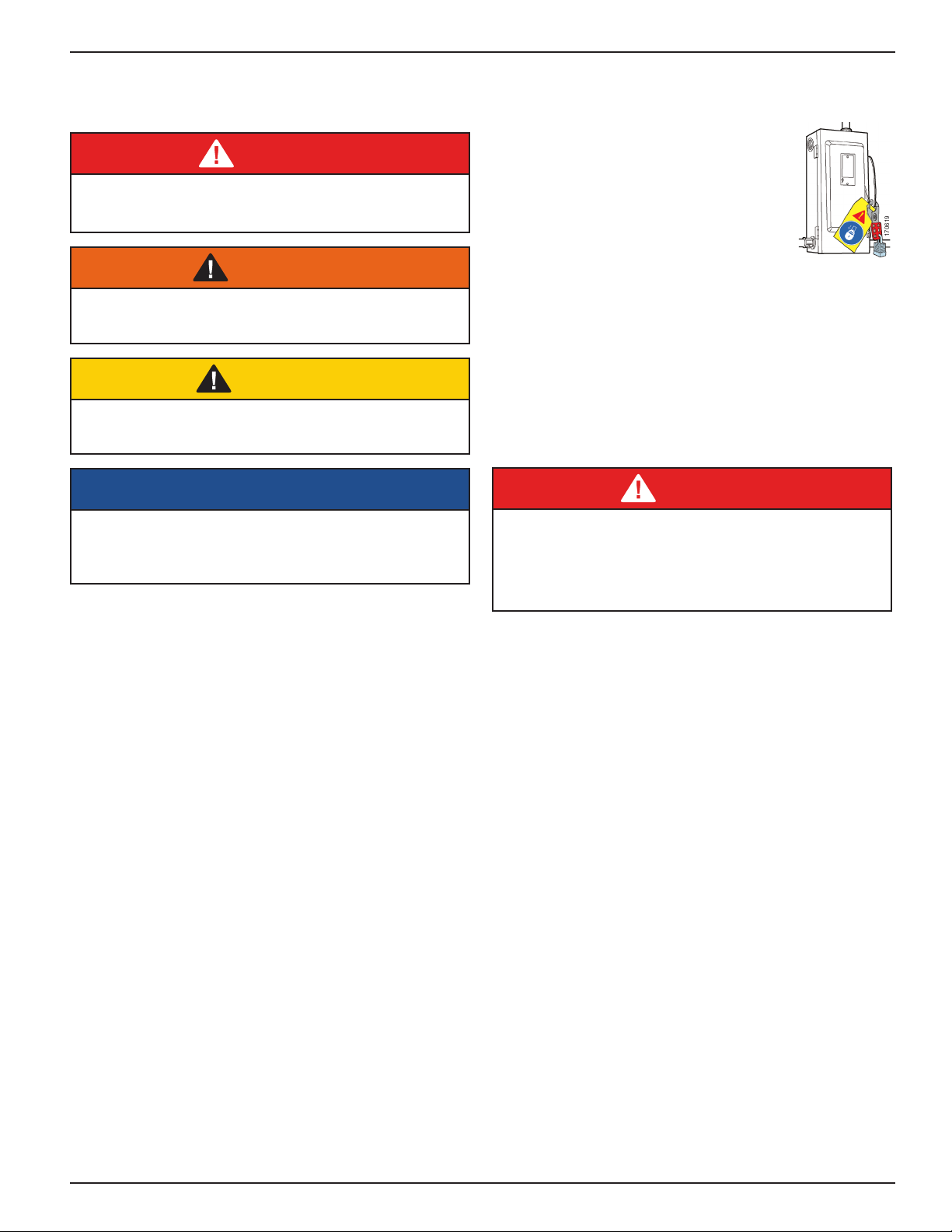

DETAIL B - BACK OF COVER

OSLT RED

SYSTEM

CONTROL

HARNESS

(FROM MICRO PCB)

RIBBON CABLES

(FROM MEMBRANE LABEL)

RESET

OSLT GREEN

DETAIL - "C" MICRO CONTROL BOARD DIP SWITCH SETTINGS

FLASH

UP:

SW3

LIGHTS

DOWN:

STEADY

1234 56 78

DETAIL - "D" GREEN LIGHT INTERLOCK VARIATIONS

LEGEND:

DENOTES WIRE CONNECTIONS THRU TERMINAL BLOCK.

DENOTES FIELD WIRES.

DENOTES WIRE NUT CONNECTION.

DENOTES MALE/FEMALE PLUG CONNECTOR.

GREEN

PB

"RAISE"

FROM LEVELER POWER

OR CONTROL VOLTAGE

TO LEVELER MOTOR

OR CONTACTOR

(

1/L1

)(

2/T2

)

SSR1-1

LEVELER

CONTROL BOX

(PIT LEVELER)

LEVELER

CONTROL BOX

(VERT LEVELER)

OVERHEAD DOOR

CONTROLLER

(BY OTHERS)

COMPETITIVE LEVELER

CONTROL BOX

(OPTIONAL EQUIPMENT)

"RAISE" MOTOR STARTER

"LOWER" MOTOR STARTER

"OPEN"

(CONTROL VOLTAGE)

(CONTROL VOLTAGE)

(CONTROL VOLTAGE)

(OPEN CONTACT)

1. INSTALL PER LOCAL ELECTRICAL CODES. REFER ALL INSTALLATION AND

SERVICE TO QUALIFIED PERSONNEL.

2. ALL INCOMING POWER (FROM DISCONNECT TO CONTROL BOX) AND

MOTOR FIELD WIRING TO BE MINIMUM #14GA. 60°/75°C COPPER

WIRE, INSULATED SUFFICIENTLY FOR INCOMING VOLTAGE.

3. ALL CONTROL FIELD WIRING TO BE MINIMUM #14GA. 60°/75°C

COPPER WIRE ONLY, INSULATED SUFFICIENTLY FOR INCOMING VOLTAGE.

4. ALL INTERNAL WIRING TO BE #14GA. MINIMUM FOR POWER CIRCUITS AND

CIRCUIT BOARD POWER,

#16GA MINIMUM FOR CONTROL CIRCUITS, 90°C,

RED COPPER WIRE UNLESS

OTHERWISE NOTED, INSULATED SUFFICIENTLY

FOR INCOMING VOLTAGE.

5. TORQUE REQUIREMENTS:

-PCB TERMINAL BLOCK POWER (J3/J5): 7.0 LB-IN

-PCB TERMINAL BLOCK ALL OTHER: 4.0 LB-IN

-GROUND TERMINAL: 35 LB-IN

6. LS1 & LS2 PROVIDED BY RITE-HITE WITH VEHICLE RESTRAINT.

OTHER FIELD DEVICES ARE OPTIONAL. SEE SPECIFIC ELECTRICAL SCHEMATIC.

7. FUSED DISCONNECT NOTES:

-FUSED DISCONNECT IS NOT PROVIDED BY RITE-HITE PRODUCTS

CORPORATION. DISCONNECT MUST BE PROVIDED BY OTHERS AND

INSTALLED PER LATEST EDITION OF UL508A AND NEC REQUIREMENTS.

-A BRANCH CIRCUIT DISCONNECT SHALL BE LOCATED WITHIN A 50 FT.

RADUIS AND BE VISIBLE FROM THE CONTROL BOX LOCATION.

[REFERENCE LATEST EDITION OF NEC, SECTION 430]

8. CLASS 1 CONTROL CIRCUIT.

J7 Description J1 Description

1USART2_RX1MICROPCB_RX BLUE

2USART2_TX2MICROPCB_TX GRAY

3

4

5

6

7

8

9

10

11

12

13 12V [Vext] 512V [Vext] RED

14 OSG INDICATOR9 OSG INDICATORWHITE/GREEN

15 OSR INDICATOR10OSR INDICATORWHITE/ORANGE

16 ISR8ISRORANGE

17 ISG7ISGGREEN

18

19 HORN [-

HITE/BLACK

20 GND4DIGITAL GNDWHITE/BLUE

21 RESERVED 6RESERVED BLACK

22 USART2_RTS 3MICROPCB_RTSWHITE

23 12V [HORN +]

System Control Harness - MEMBRANE

SWITCH

SETTING OPTION/FUNCTION

1DOWNFACTORY USE

2DOWNINSIDE RED LIGHT

3DOWNINSIDE GREEN LIGHT

4UPCORNER & LEVELER-VU RED

5UPCORNER & LEVELER-VU GREEN

6DOWNOUTSIDE LIGHTS - RED/GREEN

7UPPEDESTRIAN-VU

UP CODED HORN OVERRIDE

DOWN STANDARD HORN OVERRIDE

8

<Electrical Schematic-Page3.eps>

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

1

U4

J1

D64

D63

5

1

INSD

10

6

1

1

J4

J3

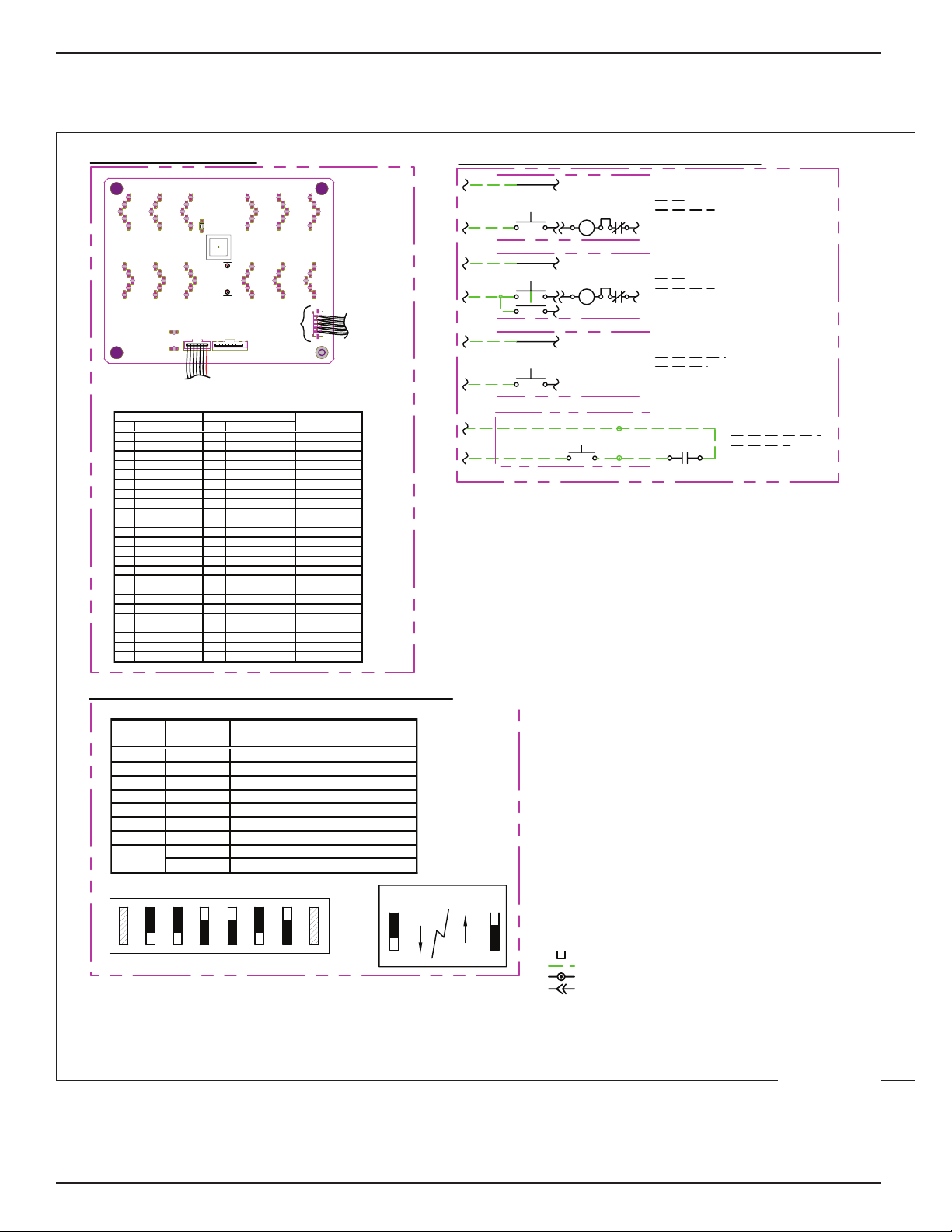

DETAIL B - BACK OF COVER

OSLT RED

SYSTEM

CONTROL

HARNESS

(FROM MICRO PCB)

RIBBON CABLES

(FROM MEMBRANE LABEL)

RESET

OSLT GREEN

DETAIL - "C" MICRO CONTROL BOARD DIP SWITCH SETTINGS

FLASH

UP:

SW3

LIGHTS

DOWN:

STEADY

1234 56 78

DETAIL - "D" GREEN LIGHT INTERLOCK VARIATIONS

LEGEND:

DENOTES WIRE CONNECTIONS THRU TERMINAL BLOCK.

DENOTES FIELD WIRES.

DENOTES WIRE NUT CONNECTION.

DENOTES MALE/FEMALE PLUG CONNECTOR.

GREEN

PB

"RAISE"

FROM LEVELER POWER

OR CONTROL VOLTAGE

TO LEVELER MOTOR

OR CONTACTOR

(

1/L1

)(

2/T2

)

SSR1-1

LEVELER

CONTROL BOX

(PIT LEVELER)

LEVELER

CONTROL BOX

(VERT LEVELER)

OVERHEAD DOOR

CONTROLLER

(BY OTHERS)

COMPETITIVE LEVELER

CONTROL BOX

(OPTIONAL EQUIPMENT)

"RAISE" MOTOR STARTER

"LOWER" MOTOR STARTER

"OPEN"

(CONTROL VOLTAGE)

(CONTROL VOLTAGE)

(CONTROL VOLTAGE)

(OPEN CONTACT)

1. INSTALL PER LOCAL ELECTRICAL CODES. REFER ALL INSTALLATION AND

SERVICE TO QUALIFIED PERSONNEL.

2. ALL INCOMING POWER (FROM DISCONNECT TO CONTROL BOX) AND

MOTOR FIELD WIRING TO BE MINIMUM #14GA. 60°/75°C COPPER

WIRE, INSULATED SUFFICIENTLY FOR INCOMING VOLTAGE.

3. ALL CONTROL FIELD WIRING TO BE MINIMUM #14GA. 60°/75°C

COPPER WIRE ONLY, INSULATED SUFFICIENTLY FOR INCOMING VOLTAGE.

4. ALL INTERNAL WIRING TO BE #14GA. MINIMUM FOR POWER CIRCUITS AND

CIRCUIT BOARD POWER,

#16GA MINIMUM FOR CONTROL CIRCUITS, 90°C,

RED COPPER WIRE UNLESS

OTHERWISE NOTED, INSULATED SUFFICIENTLY

FOR INCOMING VOLTAGE.

5. TORQUE REQUIREMENTS:

-PCB TERMINAL BLOCK POWER (J3/J5): 7.0 LB-IN

-PCB TERMINAL BLOCK ALL OTHER: 4.0 LB-IN

-GROUND TERMINAL: 35 LB-IN

6. LS1 & LS2 PROVIDED BY RITE-HITE WITH VEHICLE RESTRAINT.

OTHER FIELD DEVICES ARE OPTIONAL. SEE SPECIFIC ELECTRICAL SCHEMATIC.

7. FUSED DISCONNECT NOTES:

-FUSED DISCONNECT IS NOT PROVIDED BY RITE-HITE PRODUCTS

CORPORATION. DISCONNECT MUST BE PROVIDED BY OTHERS AND

INSTALLED PER LATEST EDITION OF UL508A AND NEC REQUIREMENTS.

-A BRANCH CIRCUIT DISCONNECT SHALL BE LOCATED WITHIN A 50 FT.

RADUIS AND BE VISIBLE FROM THE CONTROL BOX LOCATION.

[REFERENCE LATEST EDITION OF NEC, SECTION 430]

8. CLASS 1 CONTROL CIRCUIT.

J7 Description J1 Description

1USART2_RX1MICROPCB_RX BLUE

2USART2_TX2MICROPCB_TX GRAY

3

4

5

6

7

8

9

10

11

12

13 12V [Vext] 512V [Vext] RED

14 OSG INDICATOR9 OSG INDICATORWHITE/GREEN

15 OSR INDICATOR10OSR INDICATORWHITE/ORANGE

16 ISR8ISRORANGE

17 ISG7ISGGREEN

18

19 HORN [-]WHITE/BLACK

20 GND4DIGITAL GNDWHITE/BLUE

21 RESERVED 6RESERVED BLACK

22 USART2_RTS 3MICROPCB_RTSWHITE

23 12V [HORN +]

System Control Harness - MEMBRANE

1DOWNFACTORY USE

2DOWNINSIDE RED LIGHT

3DOWNINSIDE GREEN LIGHT

4UPCORNER & LEVELER-VU RED

5UPCORNER & LEVELER-VU GREEN

6DOWNOUTSIDE LIGHTS - RED/GREEN

7UPPEDESTRIAN-VU

UP CODED HORN OVERRIDE

DOWN STANDARD HORN OVERRIDE

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

1

U4

J1

D64

D63

5

1

INSD

10

6

1

1

J4

J3

DETAIL B - BACK OF COVER

OSLT RED

SYSTEM

CONTROL

HARNESS

(FROM MICRO PCB)

RIBBON CABLES

(FROM MEMBRANE LABEL)

RESET

OSLT GREEN

DETAIL - "C" MICRO CONTROL BOARD DIP SWITCH SETTINGS

FLASH

UP:

SW3

LIGHTS

DOWN:

STEADY

1234 56 78

DETAIL - "D" GREEN LIGHT INTERLOCK VARIATIONS

LEGEND:

DENOTES WIRE CONNECTIONS THRU TERMINAL BLOCK.

DENOTES FIELD WIRES.

DENOTES WIRE NUT CONNECTION.

DENOTES MALE/FEMALE PLUG CONNECTOR.

GREEN

PB

"RAISE"

FROM LEVELER POWER

OR CONTROL VOLTAGE

TO LEVELER MOTOR

OR CONTACTOR

(

1/L1

)(

2/T2

)

SSR1-1

LEVELER

CONTROL BOX

(PIT LEVELER)

LEVELER

CONTROL BOX

(VERT LEVELER)

OVERHEAD DOOR

CONTROLLER

(BY OTHERS)

COMPETITIVE LEVELER

CONTROL BOX

(OPTIONAL EQUIPMENT)

"RAISE" MOTOR STARTER

"LOWER" MOTOR STARTER

"OPEN"

(CONTROL VOLTAGE)

(CONTROL VOLTAGE)

(CONTROL VOLTAGE)

(OPEN CONTACT)

1. INSTALL PER LOCAL ELECTRICAL CODES. REFER ALL INSTALLATION AND

SERVICE TO QUALIFIED PERSONNEL.

2. ALL INCOMING POWER (FROM DISCONNECT TO CONTROL BOX) AND

MOTOR FIELD WIRING TO BE MINIMUM #14GA. 60°/75°C COPPER

WIRE, INSULATED SUFFICIENTLY FOR INCOMING VOLTAGE.

3. ALL CONTROL FIELD WIRING TO BE MINIMUM #14GA. 60°/75°C

COPPER WIRE ONLY, INSULATED SUFFICIENTLY FOR INCOMING VOLTAGE.

4. ALL INTERNAL WIRING TO BE #14GA. MINIMUM FOR POWER CIRCUITS AND

CIRCUIT BOARD POWER,

#16GA MINIMUM FOR CONTROL CIRCUITS, 90°C,

RED COPPER WIRE UNLESS

OTHERWISE NOTED, INSULATED SUFFICIENTLY

FOR INCOMING VOLTAGE.

5. TORQUE REQUIREMENTS:

-PCB TERMINAL BLOCK POWER (J3/J5): 7.0 LB-IN

-PCB TERMINAL BLOCK ALL OTHER: 4.0 LB-IN

-GROUND TERMINAL: 35 LB-IN

6. LS1 & LS2 PROVIDED BY RITE-HITE WITH VEHICLE RESTRAINT.

OTHER FIELD DEVICES ARE OPTIONAL. SEE SPECIFIC ELECTRICAL SCHEMATIC.

7. FUSED DISCONNECT NOTES:

-FUSED DISCONNECT IS NOT PROVIDED BY RITE-HITE PRODUCTS

CORPORATION. DISCONNECT MUST BE PROVIDED BY OTHERS AND

INSTALLED PER LATEST EDITION OF UL508A AND NEC REQUIREMENTS.

-A BRANCH CIRCUIT DISCONNECT SHALL BE LOCATED WITHIN A 50 FT.

RADUIS AND BE VISIBLE FROM THE CONTROL BOX LOCATION.

[REFERENCE LATEST EDITION OF NEC, SECTION 430]

8. CLASS 1 CONTROL CIRCUIT.

J7 Description J1 Description

1USART2_RX1MICROPCB_RX BLUE

2USART2_TX2MICROPCB_TX GRAY

3

4

5

6

7

8

9

10

11

12

13 12V [Vext] 512V [Vext] RED

14 OSG INDICATOR9 OSG INDICATORWHITE/GREEN

15 OSR INDICATOR10OSR INDICATORWHITE/ORANGE

16 ISR8ISRORANGE

17 ISG7ISGGREEN

18

19 HORN [-]WHITE/BLACK

20 GND4DIGITAL GNDWHITE/BLUE

21 RESERVED 6RESERVED BLACK

22 USART2_RTS 3MICROPCB_RTSWHITE

23 12V [HORN +]

System Control Harness - MEMBRANE

1DOWNFACTORY USE

2DOWNINSIDE RED LIGHT

3DOWNINSIDE GREEN LIGHT

4UPCORNER & LEVELER-VU RED

5UPCORNER & LEVELER-VU GREEN

6DOWNOUTSIDE LIGHTS - RED/GREEN

7UPPEDESTRIAN-VU

UP CODED HORN OVERRIDE

DOWN STANDARD HORN OVERRIDE

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

1

U4

J1

D64

D63

5

1

INSD

10

6

1

1

J4

J3

DETAIL B - BACK OF COVER

OSLT RED

SYSTEM

CONTROL

HARNESS

(FROM MICRO PCB)

RIBBON CABLES

(FROM MEMBRANE LABEL)

RESET

OSLT GREEN

DETAIL - "C" MICRO CONTROL BOARD DIP SWITCH SETTINGS

FLASH

UP:

SW3

LIGHTS

DOWN:

STEADY

1234 56 78

DETAIL - "D" GREEN LIGHT INTERLOCK VARIATIONS

LEGEND:

DENOTES WIRE CONNECTIONS THRU TERMINAL BLOCK.

DENOTES FIELD WIRES.

DENOTES WIRE NUT CONNECTION.

DENOTES MALE/FEMALE PLUG CONNECTOR.

GREEN

PB

"RAISE"

FROM LEVELER POWER

OR CONTROL VOLTAGE

TO LEVELER MOTOR

OR CONTACTOR

(

1/L1

)(

2/T2

)

SSR1-1

LEVELER

CONTROL BOX

(PIT LEVELER)

LEVELER

CONTROL BOX

(VERT LEVELER)

OVERHEAD DOOR

CONTROLLER

(BY OTHERS)

COMPETITIVE LEVELER

CONTROL BOX

(OPTIONAL EQUIPMENT)

"RAISE" MOTOR STARTER

"LOWER" MOTOR STARTER

"OPEN"

(CONTROL VOLTAGE)

(CONTROL VOLTAGE)

(CONTROL VOLTAGE)

(OPEN CONTACT)

1. INSTALL PER LOCAL ELECTRICAL CODES. REFER ALL INSTALLATION AND

SERVICE TO QUALIFIED PERSONNEL.

2. ALL INCOMING POWER (FROM DISCONNECT TO CONTROL BOX) AND

MOTOR FIELD WIRING TO BE MINIMUM #14GA. 60°/75°C COPPER

WIRE, INSULATED SUFFICIENTLY FOR INCOMING VOLTAGE.

3. ALL CONTROL FIELD WIRING TO BE MINIMUM #14GA. 60°/75°C

COPPER WIRE ONLY, INSULATED SUFFICIENTLY FOR INCOMING VOLTAGE.

4. ALL INTERNAL WIRING TO BE #14GA. MINIMUM FOR POWER CIRCUITS AND

CIRCUIT BOARD POWER,

#16GA MINIMUM FOR CONTROL CIRCUITS, 90°C,

RED COPPER WIRE UNLESS

OTHERWISE NOTED, INSULATED SUFFICIENTLY

FOR INCOMING VOLTAGE.

5. TORQUE REQUIREMENTS:

-PCB TERMINAL BLOCK POWER (J3/J5): 7.0 LB-IN

-PCB TERMINAL BLOCK ALL OTHER: 4.0 LB-IN

-GROUND TERMINAL: 35 LB-IN

6. LS1 & LS2 PROVIDED BY RITE-HITE WITH VEHICLE RESTRAINT.

OTHER FIELD DEVICES ARE OPTIONAL. SEE SPECIFIC ELECTRICAL SCHEMATIC.

7. FUSED DISCONNECT NOTES:

-FUSED DISCONNECT IS NOT PROVIDED BY RITE-HITE PRODUCTS

CORPORATION. DISCONNECT MUST BE PROVIDED BY OTHERS AND

INSTALLED PER LATEST EDITION OF UL508A AND NEC REQUIREMENTS.

-A BRANCH CIRCUIT DISCONNECT SHALL BE LOCATED WITHIN A 50 FT.

RADUIS AND BE VISIBLE FROM THE CONTROL BOX LOCATION.

[REFERENCE LATEST EDITION OF NEC, SECTION 430]

8. CLASS 1 CONTROL CIRCUIT.

J7 Description J1 Description

1USART2_RX1MICROPCB_RX BLUE

2USART2_TX2MICROPCB_TX GRAY

3

4

5

6

7

8

9

10

11

12

13 12V [Vext] 512V [Vext] RED

14 OSG INDICATOR9 OSG INDICATORWHITE/GREEN

15 OSR INDICATOR10OSR INDICATORWHITE/ORANGE

16 ISR8ISRORANGE

17 ISG7ISGGREEN

18

19 HORN [-]WHITE/BLACK

20 GND4DIGITAL GNDWHITE/BLUE

21 RESERVED 6RESERVED BLACK

22 USART2_RTS 3MICROPCB_RTSWHITE

23 12V [HORN +]

System Control Harness - MEMBRANE

1DOWNFACTORY USE

2DOWNINSIDE RED LIGHT

3DOWNINSIDE GREEN LIGHT

4UPCORNER & LEVELER-VU RED

5UPCORNER & LEVELER-VU GREEN

6DOWNOUTSIDE LIGHTS - RED/GREEN

7UPPEDESTRIAN-VU

UP CODED HORN OVERRIDE

DOWN STANDARD HORN OVERRIDE

Figure 5