Pub. No. 1177 - Febuary 2003

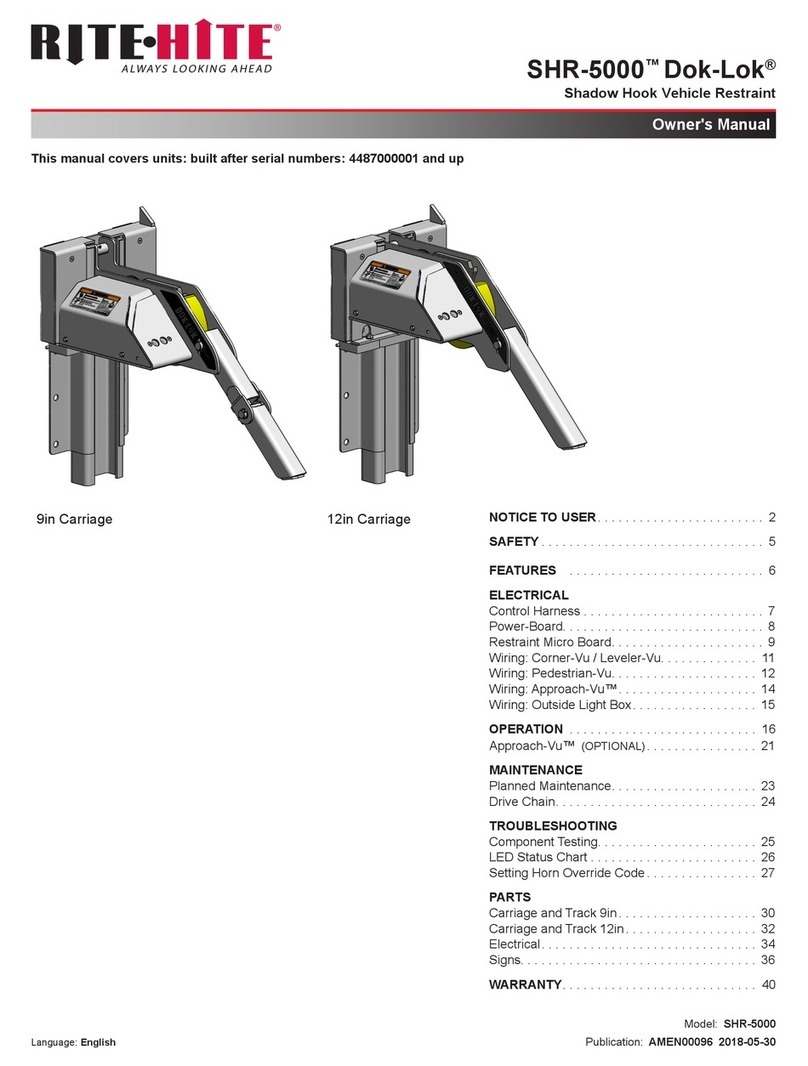

RITE-HITE GWL-2300 Owner’s Manual

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 2

SAFETY WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OWNER RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DEFINITION AND FUNCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ELECTRICAL SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . 15

OPERATING PROCEDURES & TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MAINTENANCE (BASED ON TYPICAL APPLICATIONS OF 8 TRUCKS PER DAY). . . . . . . . . . . . . . . . . . . . . . . . 23

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

HORN OVERRIDE CODE AND DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

TABLE OF CONTENTS

INTRODUCTION

Read and understand this manual before attempting to install or operate. For best results, have this product serviced

by your authorized RITE-HITE®representative.

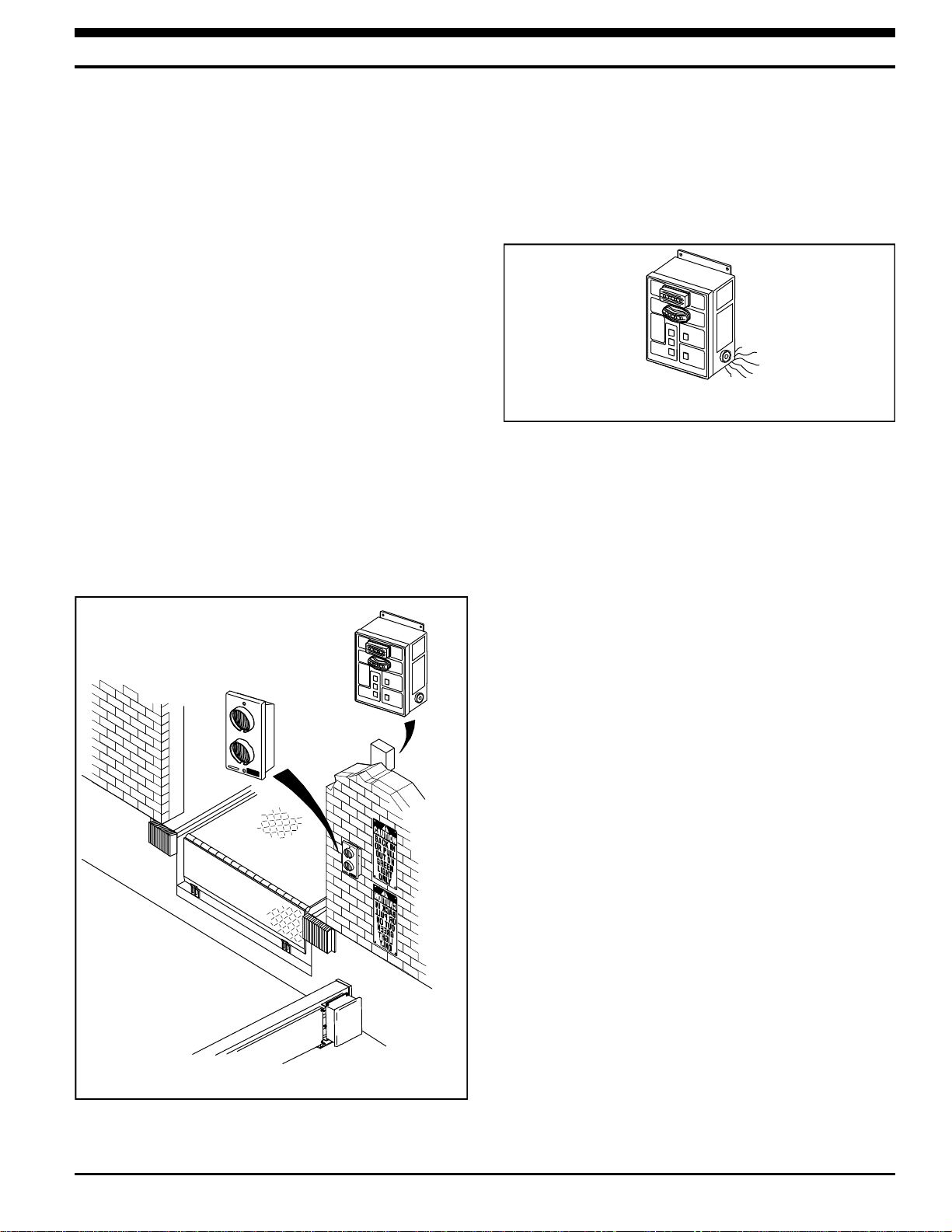

The GWL-2300 vehicle restraint by RITE-HITE is intended to provide a safer workplace for workers in shipping and

receiving dock areas. The GWL-2300 vehicle restraint is a restraint device that, when properly installed and operated,

retains a secure connection between the truck and dock. Signal lights, warning horn and signs provide instructions to

the truck driver and GWL-2300 vehicle restraint operator that a safe condition exists. The GWL-2300 vehicle restraint

is operated by pressing push buttons on an inside control box.

NOTICE TO USER

Your local RITE-HITE®representative provides a Planned Maintenance Program (P.M.P.) which can be fitted to your

specific operation. Call your local representative or the RITE-HITE®Corporation at 414-355-2600.

The RITE-HITE®products in this manual are covered by one or more of the following U.S. patents: 4,531,248;

4,560,315 (RE: 32,968); 4,570,277; 4,605,353 (RE: 33,154); 4,634,334; 4,692,755; 4,744,121; 4,819,770; 4,843,373;

4,865,507; 4,920,598; 4,995,130; 5,040,258; 5,111,546; 5,212,846; 5,271,183; 5,299,386; 5,311,628; 5,323,503;

5,375,965; 5,440,772; 5,442,825; 5,453,735; 5,531,557; 5,546,623; 5,553,987; 5,582,498; 5,664,930; 5,702,223;

5,762,459 (RE: 37,570); 5,882,167; 5,964,572; 6,010,297; 6,065,172; 6,070,283; 6,074,157; 6,085,375; 6,092,970;

6,106,212; 6,116,839; 6,190,109; 6,220,809; 6,627,016; 6,238,163; 6,322,310; 6,311,352; 6,360,394; 6,368,043,

6,431,819; and pending U.S. and foreign patent applications. RITE-HITE®, LEVEL-RITETM, GUARDRITE®, SAFE-T-

LIP®, HYDRACHEK®, WHEEL-LOKTM , DOK-LOK®, DUAL-DOK®, and SAFE-T-GATE®are trademarks of RITE-HITE®

Corporation.