Copyright © 2019, ASSA ABLOY Accessories and Door Controls Group, Inc. All rights reserved. Reproduction in whole or

in part without the express written permission of ASSA ABLOY Accessories and Door Controls Group, Inc. is prohibited.

80-9363-0009-020 Rev 3 12/19

2

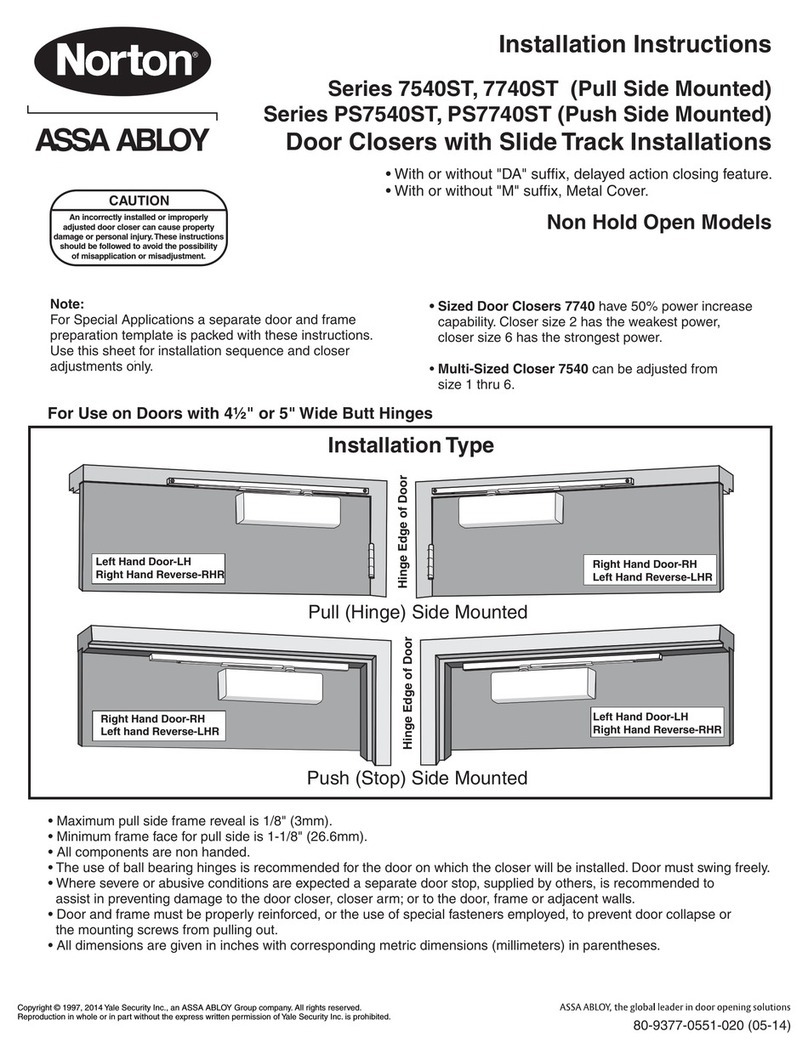

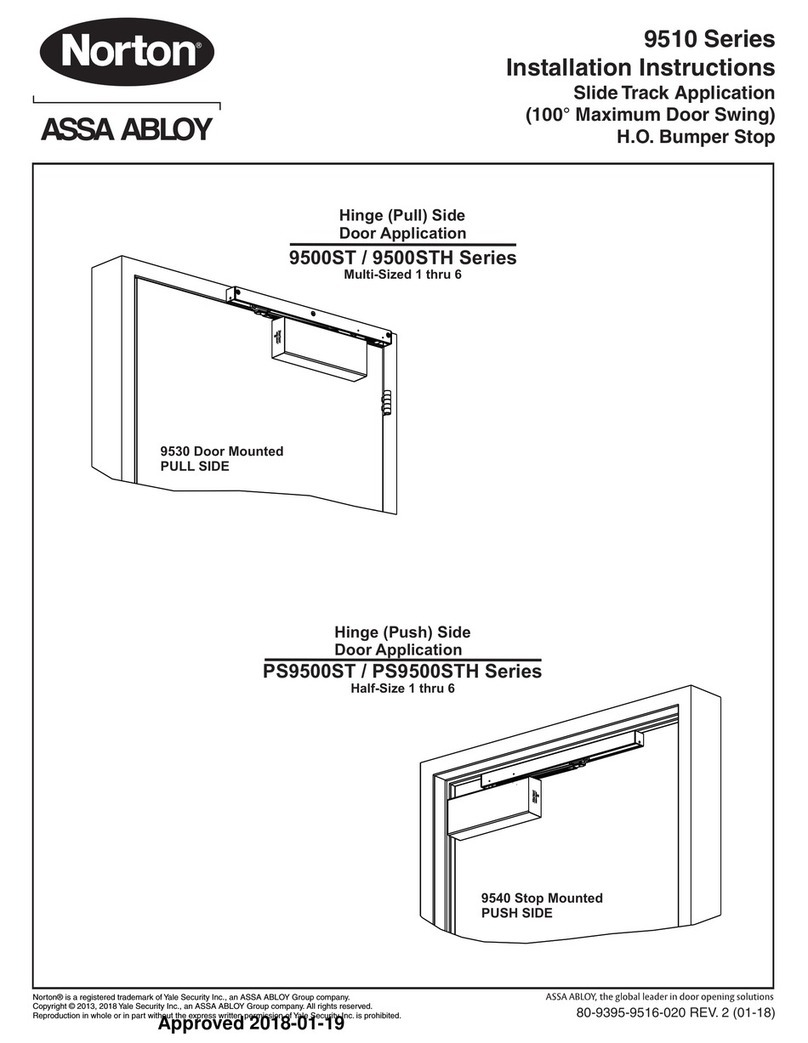

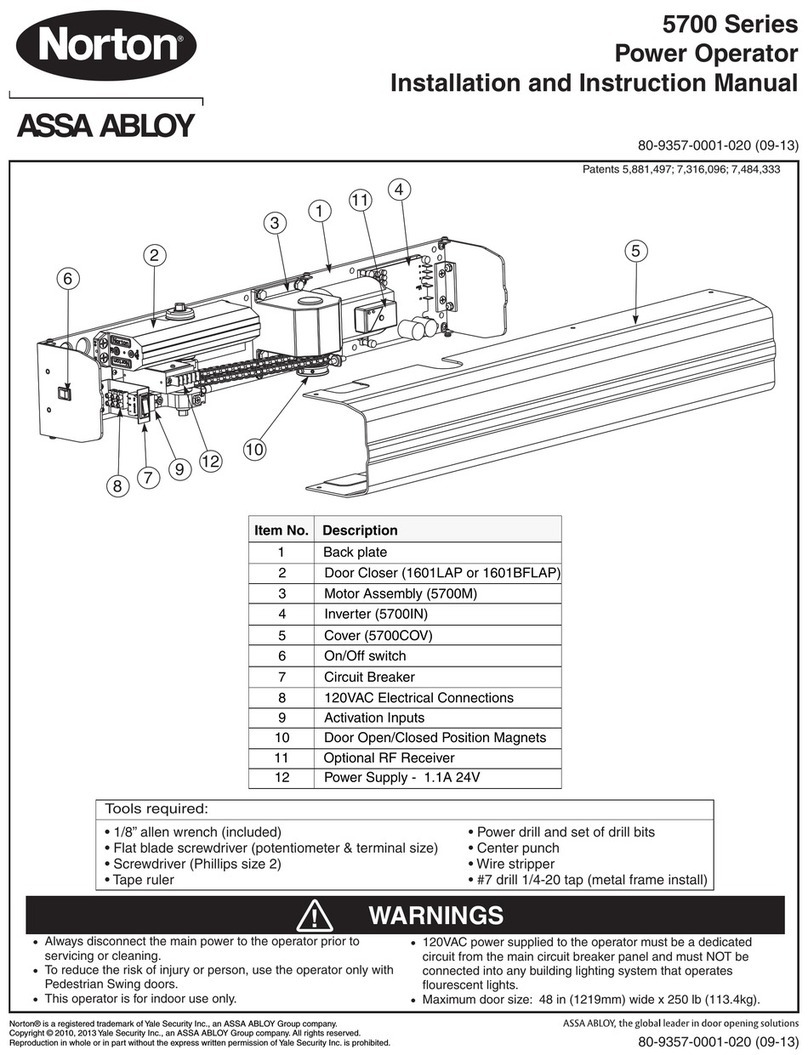

6332 Series (Push Side) Power Operator

Technical Data

Input power: 120VAC, 60Hz 3.0A

Power supply: 24 V DC, max. 6.5 Amp. ; 1.3A Available for Acc.

Door width: 36 - 48" (91-122 cm)

Door weight: 90-200 lb. (41-91 kg)

Push min angle: 110° with reveal of 6-3/4" max

Push max angle: 130° with reveal of 1/8" min

Pull max angle: 180°

Hold open time: 5-30 seconds (A.D.A. 5 seconds min.)

Indenite for Hold Open Input or Endcap 3

Position Switch

Notes:

• Permanent wiring is to be employed as required

by local codes.

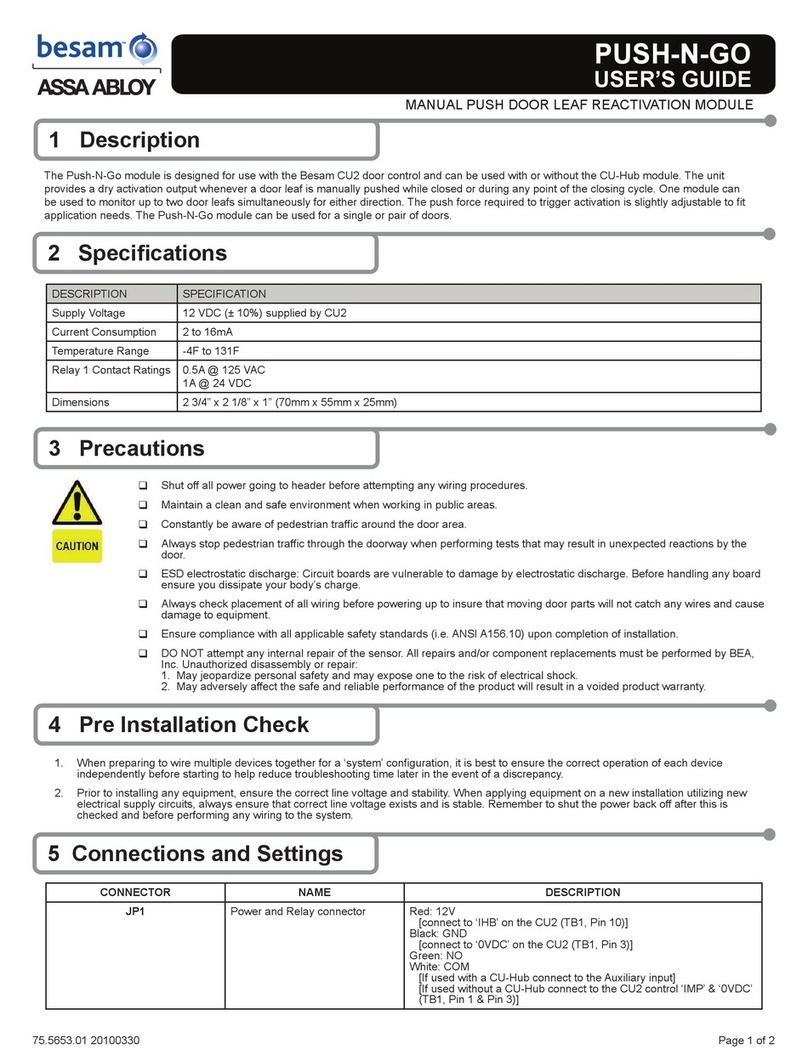

• Activation devices: push plates, access control,

mats, touchless wall switches, etc.

• Maximum wire size is:

12AWG at terminals LINE and NEUTRAL

(120VAC; 60Hz) on Power Input Terminal

14AWG at all other terminals

WARNING: To reduce risk of injury to person, use this operator only with Pedestrian Swing doors. FOR INDOOR USE ONLY

Product Safety Warnings

Certications and Standards

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Install only on a properly operating and balanced door.

A door that is operating improperly could cause severe

injury. Have qualied service personnel make repairs to any

hardware before installing the operator.

3. Remove, or make inoperative, all locks (unless mechanically

and/or electrically interlocked to the power unit) that are

connected to the door before installing the operator.

4. Do not connect the door operator to the source power

until instructed to do so.

5. Never let children operate or play with door controls. Keep

remote control (when provided) away from children.

• ETL Certied: Operator conforms to ANSI/UL standard 325 for automatic closing doors and UL10C Positive Pressure

Fire Test for Door Assemblies.

• ANSI A156.19: These products are designed to conform to this specication “for power assist and low energy power

operated doors.” These products are designed to exceed all the requirements for “Low Energy Power Operated Door”.

• Americans with Disabilities Act (A.D.A.): These door operators can be installed and adjusted to conform with A.D.A.

regulations.

• ANSI A117.1: These door controls permit door assemblies to conform to the requirements of this specication “for

buildings and facilities - providing accessibility and usability for physically handicap people”.

6. Personnel should keep away from a moving door in

motion.

7. Test door’s safety features at least once a month. After

adjusting either force or limit of travel, retest door

operator’s safety features. Failure to adjust operator

properly may cause severe injury or death.

8. KEEP DOOR PROPERLY OPERATING. See Door

Manufacturer’s Owner’s Manual. An improperly

operating door could cause severe injury or death.

Have a trained door systems technician make repairs.

9. SAVE THESE INSTRUCTIONS.

Contents

Certications and Standards...............................................................................2

Technical Data ............................................................................................2

Product Safety Warnings ..................................................................................2

Before You Begin ..........................................................................................3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Template..................................................................................................8