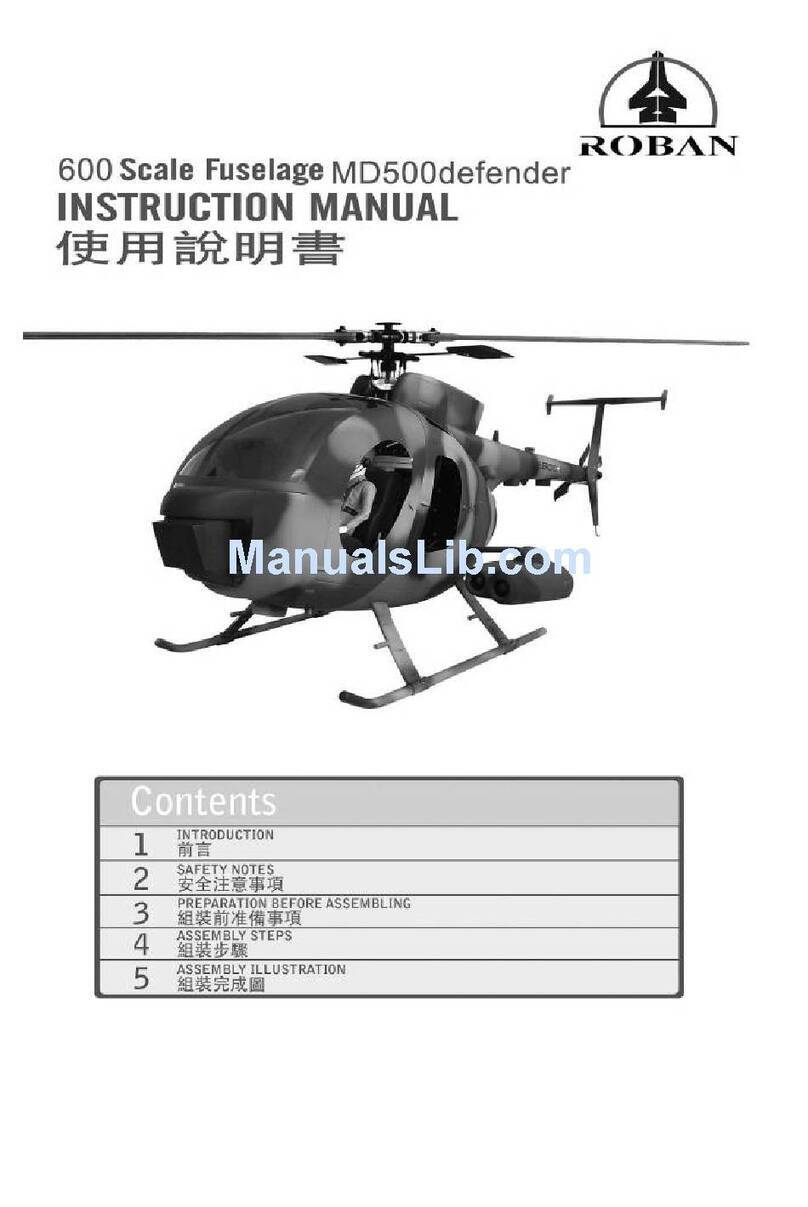

Copyright@2015 - Roban Limited – All rights reserved

IMPORTANT NOTES

*This radio controlled airplane is not a toy.

*This radio controlled airplane can be very dangerous.

*This radio controlled airplane is a technically complex device which has to be built and handled very carefully.

*This radio controlled airplane must be built following these instructions. This manual provides the necessary information

to correctly assemble the model. It is necessary to carefully follow all the instructions.

*Inexperienced pilots must be monitored by expert pilots.

*All operators must wear safety glasses and take appropriate safety precautions.

*A radio controlled airplane must only be used in open spaces without obstacles, and far enough from people to

minimize

the possibility of accidents or of injury to property or persons.

*A radio controlled airplane can behave in an unexpected manner, causing loss of control of the model, and make it a

very

dangerous flying object.

*Lack of care with assembly or maintenance can result in an unreliable and dangerous model.

*Neither Roban Limited nor its agents have any control over the assembly, maintenance and use of this product.

Therefore, no

responsibility can be traced back to the manufacturer. You hereby agree to release Roban Limited from any

responsibility or

liability arising from the use of this product.

SAFETY GUIDELINES

*Fly only in areas dedicated to the use of model airplanes.

*Follow all control procedures for the radio frequency system.

*It is necessary that you know your radio system well. Check all functions of the transmitter before every flight.

*The blades of the model rotate at a very high speed; be aware of the danger they pose and the damage they may

cause.

*Never fly in the vicinity of other people.

NOTES FOR ASSEMBLY

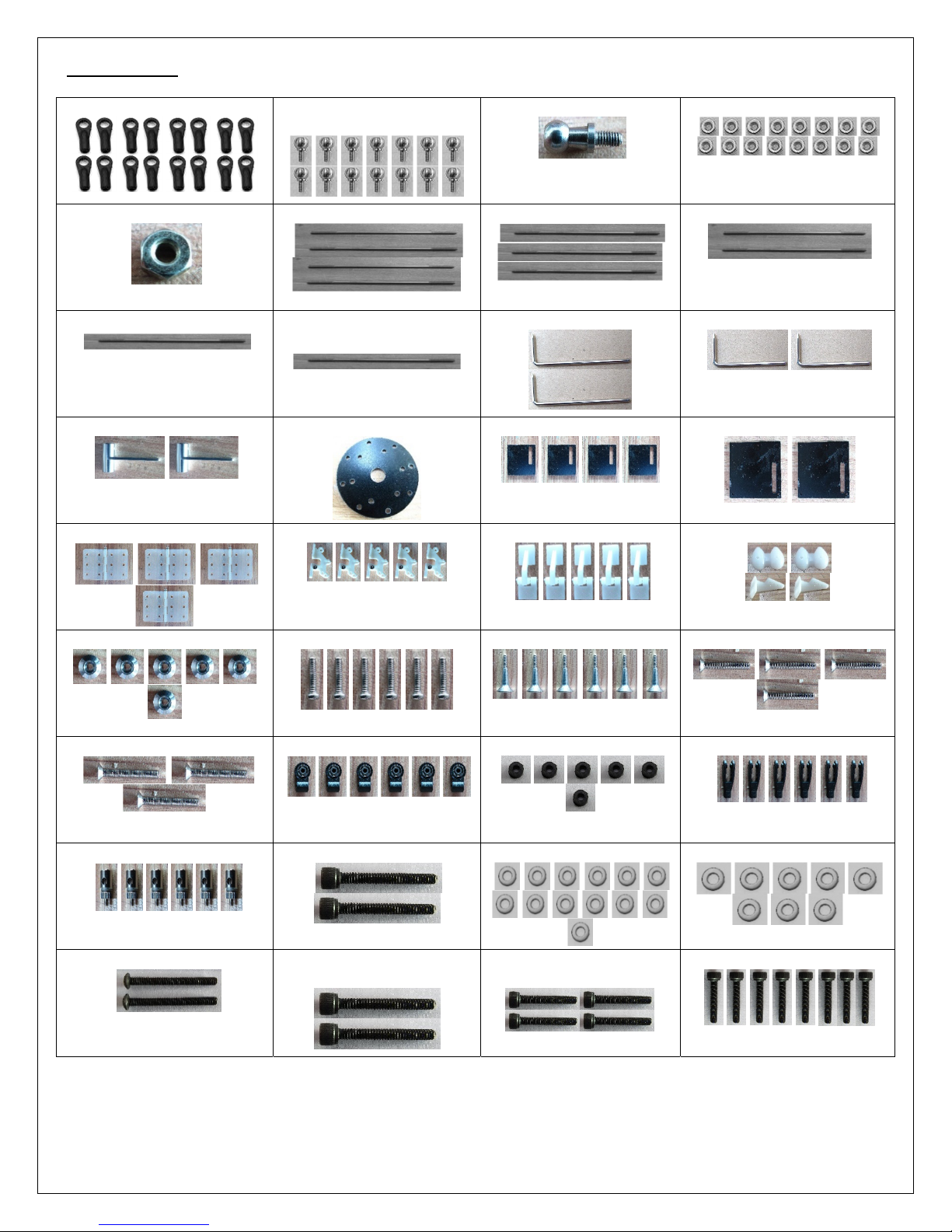

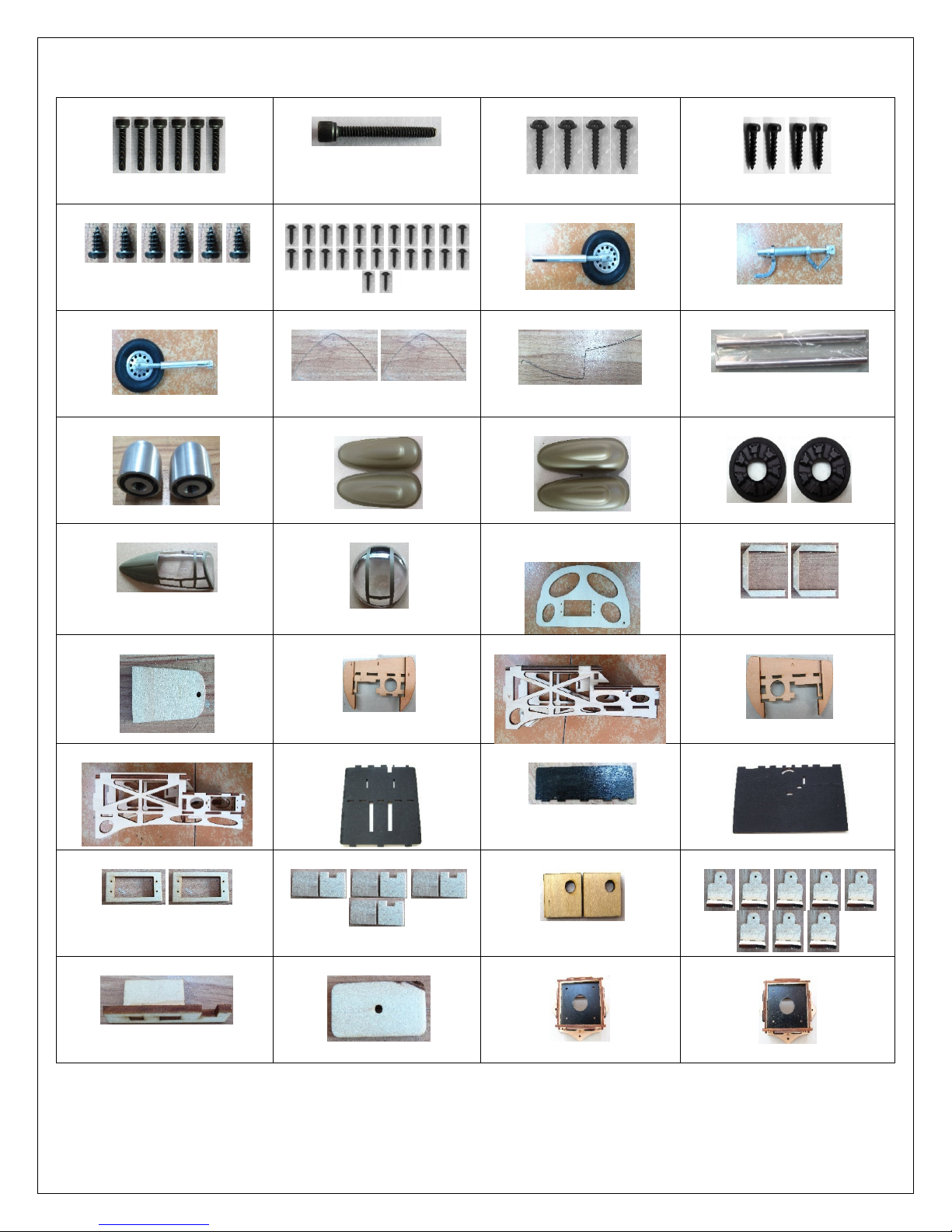

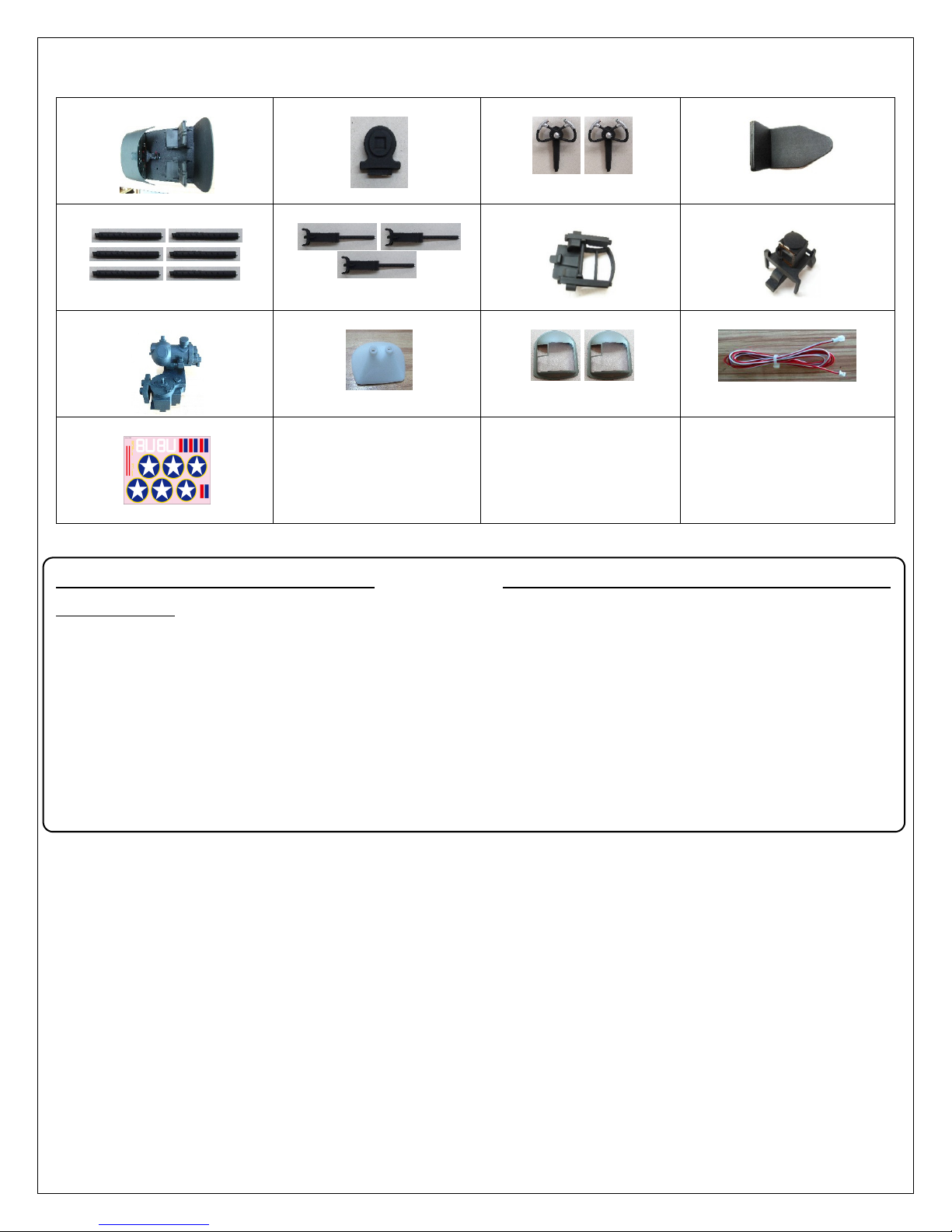

Please refer to this manual for assembly instructions for this model.

Follow the order of assembly indicated. The instructions are divided into chapters, which are structured in a way that

each step is based on the work done in the previous step. Changing the order of assembly may result in additional or

unnecessary steps.

Use thread lockers and retaining compounds as indicated. In general, each bolt or screw that engages with a metal part

requires thread lock.

Factory pre-assembled components have been assembled with all the required thread lock and lubricants,

and have passed quality control. It is not necessary to disassemble and re-assemble them.

We do not recommend the use of thin cyanoacrylate glue for surface mount of painted parts. The fumes of the curing

glue leave white stains on the clear coat, which are hard to remove.