TierTime UP300D User manual

1

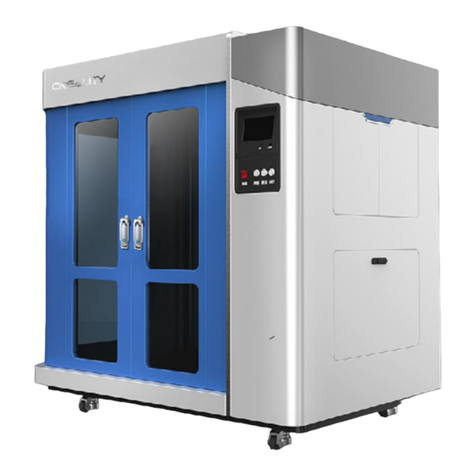

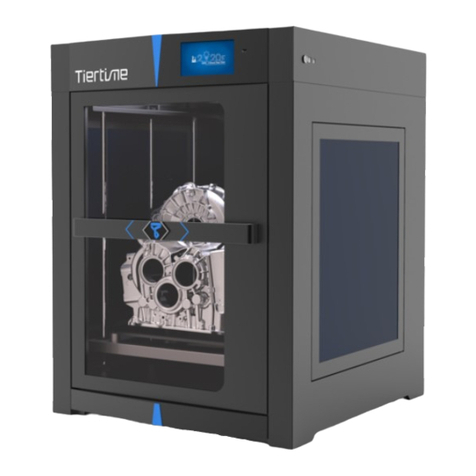

Tiertime UP300D

User Manual

www.tiertime.com

2

Index

1. Safety and Printing Environment.........................................................................................5

1.1 Safety Precautions........................................................................................................................5

1.2 Printing Environment..................................................................................................................6

1.3 One Year Warranty..................................................................................................................... 6

1.4 Compliance................................................................................................................................... 6

2. Unboxing............................................................................................................................... 7

2.1 Unboxing the UP300D................................................................................................................. 7

2.2 What’s in the box......................................................................................................................... 8

3. Introduction...........................................................................................................................9

3.1 Main Parts of UP300D.................................................................................................................9

4. Printer Installation..............................................................................................................10

4.1 Install the Print Board...............................................................................................................10

4.2. Install the Software UP Studio 3.0...........................................................................................11

4.3 Update the Touchscreen Firmware.......................................................................................... 11

5. Prepare UP300D for Printing.............................................................................................12

5.1 Connectivity................................................................................................................................12

5.2 Auto Calibration........................................................................................................................ 12

5.3 Auto Calibration from Touchscreen........................................................................................ 12

5.3 Load the Filaments.....................................................................................................................13

6. First Print............................................................................................................................ 16

6.1. Slicing......................................................................................................................................... 16

6.1.1 Open UP Studio 3....................................................................................................................16

6.1.3. Load an STL file.....................................................................................................................17

6.1.4. Auxiliary Support (A.S.)........................................................................................................18

6.2 Connect and Send Print Job to Printer....................................................................................20

6.3 Remove Printed Models.............................................................................................................21

7. Printer Calibrations.............................................................................................................22

7.1 Nozzle Height Measurement..................................................................................................... 23

7.2 Setup Nozzle Height Value through Wand..............................................................................23

7.3 Matrix Leveling (9-Point Compensation)................................................................................ 25

7.3.1 Auto Matrix Leveling through Wand................................................................................... 26

7.4 Manual Calibration....................................................................................................................27

8. Introduction to UP Studio 3 Package.................................................................................29

9. Introduction to the UP Studio, the Slicer........................................................................... 31

9.1 Interface...................................................................................................................................... 31

9.2 Quick Setting Bar.......................................................................................................................31

9.3 Print Layout Tools..................................................................................................................... 31

9.4 Support Editor............................................................................................................................33

3

9.5 Print Settings.............................................................................................................................. 36

9.5.1 Print Modes............................................................................................................................. 37

9.6 Introduction to Print Parameters.............................................................................................38

9.6.1. Slicer Settings......................................................................................................................... 39

9.6.2 Path...........................................................................................................................................43

9.6.3.Special...................................................................................................................................... 45

9.6.4 Speed........................................................................................................................................ 46

9.6.5 Temperature............................................................................................................................ 47

9.6.6 Seams Settings......................................................................................................................... 47

9.6.7 Printer...................................................................................................................................... 48

9.6.8 Extruder...................................................................................................................................48

9.6.9 Script........................................................................................................................................ 48

Chapter 10. Material Library (Mat Lib) and Custom Materials........................................... 50

Chapter 11. Part Sub-setting...................................................................................................51

11.1 Optimize along Z axis (Vertical Sections)..............................................................................51

11.2 Optimize on X-Y plane............................................................................................................ 52

12. Wand - the Printer Hosting Software............................................................................... 54

12.1 Wand Interface .......................................................................................................................54

12.2 Wi-Fi Connection..................................................................................................................... 56

12.3 Ethernet Connection............................................................................................................... 56

12.4 Editing Network Configuration..............................................................................................57

13. Touchscreen Introduction.................................................................................................58

13.1 Printer Status Bar.................................................................................................................... 58

13.2 Main Menu................................................................................................................................59

13.3 Material.....................................................................................................................................60

13.4 Print...........................................................................................................................................62

13.5 Calibrate................................................................................................................................... 65

13.6 Information...............................................................................................................................66

13.7 Config........................................................................................................................................ 67

13.8 Network Connection................................................................................................................ 68

13.9 Wi-Fi Network Connection and Settings:..............................................................................70

13.10. Initialize .................................................................................................................................72

Chapter 14. Print Boards........................................................................................................ 73

14.1 Perf Glass Boards.....................................................................................................................73

14.2 Flex Glass Boards.....................................................................................................................73

14.3 Glass Surface............................................................................................................................ 73

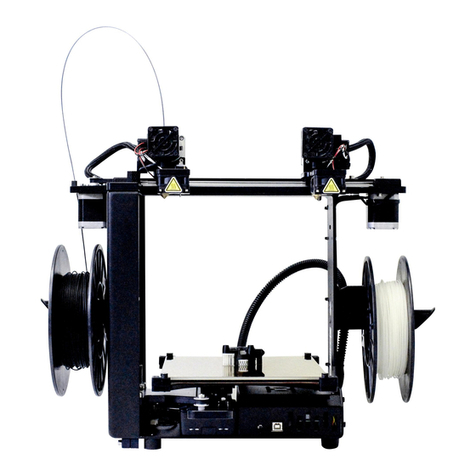

Chapter 15. Extruders............................................................................................................. 74

15.1 Single Extrusion Print Heads..................................................................................................74

15.2 Convergence Dual Extruder................................................................................................... 75

Chapter 16. Maintenance........................................................................................................76

4

16.1 Replacing Nozzle:.....................................................................................................................76

16.3 Extruder Maintenance.............................................................................................................77

16.3.3 Convergence Dual Extruder................................................................................................ 79

16.3.3 Releasing the heater block....................................................................................................80

16.3.4 Remove/Replace Stepper Motor.......................................................................................... 82

16.3.5 Remove the extrude block................................................................................................... 82

16.4 Unclogging Extruder................................................................................................................83

16.4.1 Partial Blockage.................................................................................................................... 83

16.4.2 Completely Blockage.............................................................................................................84

16.4.3 Remove blockage at heater module.....................................................................................84

16.5 Clean the Waste Tray.............................................................................................................. 85

16.6 Dual Filtration System.............................................................................................................86

Chapter 17. Specification........................................................................................................ 87

Chapter 18. Customer Service and Community.....................................................................88

5

1. Safety and Printing Environment

1.1 Safety Precautions

1. The UP300D 3D printer requires the power adapter provided by the original

manufacturer, otherwise the machine could be damaged or even cause fire. Keep

the power adapter away from water and out of high temperature environments.

2.During printing, the temperature of the nozzle of the printer could reach 300°C and

the temperature of the print platform could be over 100°C. Do not touch these parts

with your bare hands when the printer is in the operation mode, not even with the

heat resistant gloves included in the accessories, as the temperature could damage

the gloves and injure your hands.

3. During printing, the print head and other mechanical parts move at high speed.

Touching these parts while they are moving could cause injuries.

4. Wear goggles when removing the supporting material from models or detaching

models from the build plates.

5. When printing with plastic filaments, the process could generate slight and, for

some people, annoying odor. It is recommended to run the printer in a well ventilated

environment. We also suggest to keep the printer in an environment with a stable

temperature as unwanted cooling could cause adverse effects to the print quality.

6. When using the “Extrude” function, make sure there is enough space between the

print head nozzle and the build platform. 50mm is recommended, otherwise the

nozzle could be blocked.

7. Fasten moving parts. Tie back loose hair, secure loose clothing and keep all

printer doors closed during operation.

8. Do not leave the printer unattended during operation. Watch to make sure the first

a few layers adhere correctly.

9. Adult Supervision: Adult supervision is required in the presence of children. Small

printed parts are a choking hazard, and always keep sharp tools away from children.

6

1.2 Printing Environment

As the slight odor could be generated during printing, keep the printer in a well

ventilated environment. The UP300D's ideal working temperature is between 15°C

and 30°C with a relative humidity between 20–50%. Printing at temperatures out of

this range could cause adverse effects to the printing process and print quality.

1.3 One Year Warranty

Tiertime and its authorized resellers warrant to the original purchaser that this

product is free from defects in material and workmanship. Tiertime or its resellers will

for one year, at its option, repair or replace at no charge for parts and labor from the

date you purchased the product from Tiertime or a reseller. Print heads, and Print

Boards are warranted for thirty (30) days.

• Tiertime reserves the right to determine the validity of all warranty claims.

• Warranty is voided if the product serial number has been altered or removed.

• Warranty is voided if the product has been misused or damaged or if evidence is

present that the product was altered, modified, or serviced by unauthorized service

people.

For the detailed Warranty and Service Level Agreement, please visit our website

https://www.tiertime.com.

1.4 Compliance

FCC

RoHS

CE

7

2. Unboxing

2.1 Unboxing the UP300D

1. Cut open the tape on the top of the cardboard box, and open the box from the top.

2. Take out the two boards on the top foam, and remove the top foam.

3. Remove the plastic cover and the square shaped foam wrapping around the

machine.

4. Lift the printer out of the cardboard box using two handles on both sides of the

printer, and place it on a flat surface.

5. Open the Top Lid and remove all the tights and foams inside the printer. There are

six tights in the machine.

6. Open the Front Door, and take out the two foams and two extruders beneath the

build platform. As figures show below:

7. Take out the roll of filament, the accessory box and the power cord at the bottom

of the cardboard box.

8. Put all the foams back to the box, and keep the box for the future use.

8

2.2 What’s in the box

The Convergence dual extruder is installed on the UP300D.

1. Accessory box

One ABS Type single extruder

One USB Cable

One Pliers

One Scarper

One Nozzle Wrench: 8mm

One Nozzle Wrench: 10mm

One Pair of Gloves

One SD Card Reader

One SD Card

One Calibration Card

One Nozzle Height Detector

Two PTFE Tube: Shorter one for PLA Extruder; Longer one for TPU Extruder

Three Allen Keys: 2mm, 2.5mm, 3mm

Three Nozzles: 0.2mm, 0.4mm, 0.6mm

2. In the UP300D box

One roll of 500g PLA Filament

One roll of 500g Water Soluble Support Filament

One Flex Glass Board

One Perf Glass Board

One Power Adapter

One Power Cord

Notice: All accessories may be subject to change without prior notice. If anything is

missing, please contact your local distributor, or Tiertime’s global technical support

9

3. Introduction

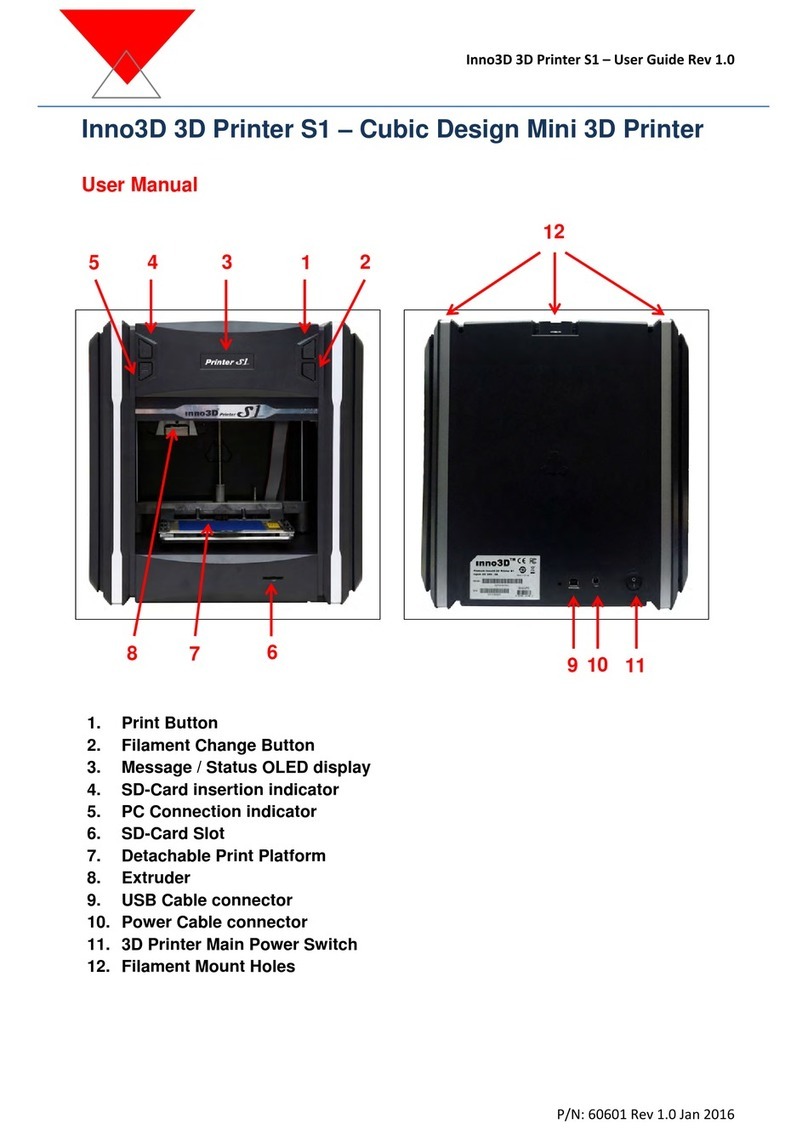

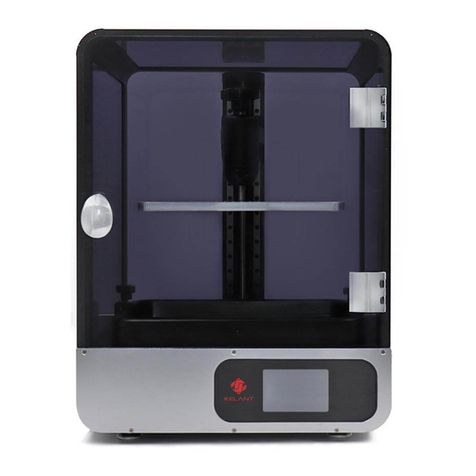

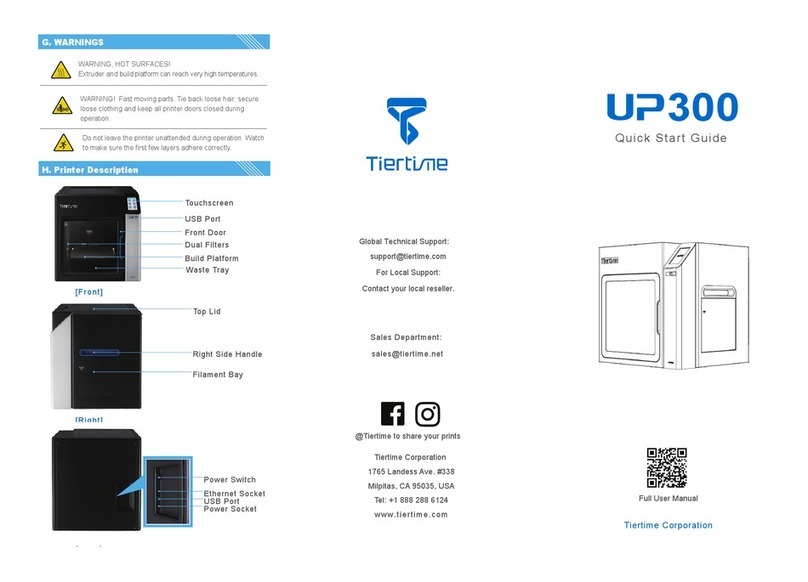

3.1 Main Parts of UP300D

1. Dual Filter

2. Build Platform

3. Waste Tray

4. Front Door

5. Touchscreen

6. Front USB Port

7. Top Lid

8. Right Side Handle

9. Heated Filament Chamber

10. Power Switch

11. Ethernet Socket

12. USB Port

13. Power Socket

Y- Axis

X-Axis

Z-Axis

Build Platform

Extruder Mount

10

4. Printer Installation

4.1 Install the Print Board

Find the “perforated print board”, slide the board onto the build platform and make

sure to push the board all the way to the back.

Plug in the power on the back of the UP300D.

11

4.2. Install the Software UP Studio 3.0

To operate the UP300D, you need to install the UP Studio 3.0 software on your

computer. Although UP Studio 2.X can also work with UP300D, it does not support

dual extrusion function and will be obsoleted once the UP Studio 3.0 becomes stable.

You can download the installation files of UP studio software from the following url:

https://www.tiertime.com/software

System Requirements:

Supported Operating Systems:

Windows 7 (SP1) or higher (64 bit only)

Mac OS 10.10 or higher

Hardware requirements:

Open GL 2.0

At least 4GB of RAM

Installation

Make sure you download the correct version of software based on your computer’s

configuration, and follow the instructions of the installation program.

4.3 Update the Touchscreen Firmware

We regularly update the Tiertime 3D printer’s touchscreen program. It is important to

make sure your UP300D’s touchscreen system is up-to-date before the first use and

pay attention to the upgrade announcement for touchscreen system in the future.

1. Download the UP300D Touchscreen Upgrade Program from

https://www.tiertime.com/touchscreen-upgrade-program/

2. Save the file to the root directory of the USB drive which comes with the UP300D,

and make sure the file is named as “UP300D_x.x.x_update.tt” (Case sensitive), x.x.x

being the version number.

3. Turn on the printer and go to the Information Page of the touch screen. Insert the

USB drive to the USB port under the touchscreen and press the “Update” button.

Follow the instructions on the touchscreen to finish the update process. Remove the

USB drive once the update process finishes.

12

5. Prepare UP300D for Printing

5.1 Connectivity

UP300D supports USB and other networking communications. For Wi-Fi, and

Ethernet connection please refer to page 53-54, 66-68.

5.2 Auto Calibration

Auto Calibration can be triggered from the touchscreen, or from Wand software

when the printer is connected to a computer (refer to page 64). The calibration

process consists of leveling of the build plate, and measurement of nozzle height.

For more info please refer to page 25-30.

5.3 Auto Calibration from Touchscreen

1. When the machine is switched on, user needs to first run the initialization in order

to operate the printer. Go to touchscreen press the initialize button.

2. Click Calibration.

3. AUTO. The printer will start the process of auto calibration.

1. Initialize Printer

2. Press “Calibrate”

3. Press “Auto”

4.When Leveling procedure

finishes, the touchscreen will

ask the user to confirm nozzle

height value.

5. Put the nozzle height detector

under the nozzle.Adjust the + and -

button to make the nozzle just

touching the sensor pad.

6. When the nozzle touch

the sensor it will emit a

buzz sound, press OK

button to save the value.

OK

13

5.3 Load the Filaments

You will find two spools of filaments in the package.

1. 500g Tiertime PLA

2. 500g Tiertime PVA

In order to achieve good consistency and print quality, we recommend use Tiertime

filaments. The default print settings of UP Studio are optimized using Tiertime

materials, so you can start printing confidently without adjusting any parameters.

Heated Filament Chamber

The filament chamber of UP300D has two

heating elements, designed to keep the

chamber at 55℃.The heaters will generate

warm air current to keep filaments dry. By

default, the chamber will start heating as soon

as the machine is powered on. If user is printing

water soluble support, it is highly recommended

to keep the heaters on, as moisture could have

adverse effect on such materials. If the heaters

are not needed, they can be turned off by a

physical switch on the heater (marked on right).

5.3.1 Load Main Material (1)

To install the filament, please following the instruction below:

1. Remove the vacuumed bag.

2. Find the end of the filament, and use pliers to make a clean cut of the end.

3. Open the door of the filament bay, feed it into the guiding tube. You should be

able to feel the filament triggering the mechanical switch (the filament sensor) at the

opening.

4. Keep feeding the filament until the end of the filament sticks out from the other

end of the guiding tube (You can open the top lid, and make sure the filament sticks

out).

Insert the filament into the guiding tube.

It must go through the filament sensor.

14

5. Go to touchscreen

4. When the extruder starting to extrude

(starting with a buzz), push the filament into

entry 1 on extruder until the extrusion appears

from the nozzle.

5. The filament should be able to be extruded

from nozzle and form a clean straight thin

thread.

1. Press Material

2. Press “Filament 1”Material

Button until it shows “PLA”,

then press “+” button to

increase material weight to

500g.

3. Press “ ” to extrude

material. The machine will heat

up and buzz when start to

extrude. It will stop

automatically

15

5.3.2 Load Support Material (2)

Loading of the support material is the same as that of the main material but use the

Filament 2 entry from the filament bay and the extruder head. On touchscreen, user

should choose the correct support material that matches the main material. For PLA,

the matching support material could be Tiertime PVA; for ABS, it should be the

Tiertime Breakaway.

Important!!!

For the Convergence Dual Extruder, both main and support materials must be loaded into

the extruder.

When loading filament, do not continuously load one extruder while leaving the other

empty. Leaving one side of the hotend empty will inevitably results in hotend clogging.

16

6. First Print

This chapter intends to guide the new users to print an object with the Convergence Dual

extruder. As mentioned in the previous chapter, the printer should be loaded with Tiertime

PLA and Tiertime PVA support for dual material printing.

-For more info on the Convergence Dual extruder please refer to page 73,77-82.

-UP300D can also use LT (Low Temp) / HT (High Temp) Single Extruder for single material

printing, for more info on printing with single material, please refer to page 72,75-76.

6.1. Slicing

6.1.1 Open UP Studio 3.

6.1.2 Turn on the Extruder 2.

1. At the Left column click the “gear”

icon to open the print setting menu.

2. Then click the “Basic” button switching to

the “Advanced” mode.

17

3. Select the “Extruder” Tab, Check the

“Extruder 2” Option, then select filament

“Tiertime PVA” or PVA for the filament

option. Click “Apply” or “OK” to commit the

change.

4. Go to the top menu print settings, select the correct machine type and the print

settings, e. g. Layer thickness and nozzle diameter, the filament type for both extruders.

For the material on the left, the filament 1(the main material), select PLA. For the one on

the right, the filament 2, (the support material), select Tiertime PVA or PVA.

6.1.3. Load an STL file

Clicking the “+” button on the vertical menu to load an STL file.

18

After the activation of the second extruder, once you load an STL, an Auxiliary Support will

be automatically loaded to the software. The object list on the left of the software interface

will show two entries, one is the STL, and the other is the Auxiliary Support with .AUX

extension.

6.1.4. Auxiliary Support (A.S.)

Auxiliary Support (A.S.) is a special preset object for material switching during a print. The

A.S. is printed as a column and material will be switched within the path of A.S region of the

current layer. User should be able to observe a gradient of material change in A.S.. It is

important to have A.S. for printing dual material, as all the mixture of the two materials

during shifting main(1) and support (2) material will be dumped into the A.S. and the

support and main objects will retain high purity of its own corresponding material. This is

important as mixing the two materials not only affects the color of the print, but also affects

the strength of the main object and the solubility of the support.

Auxiliary Support print setting is partially depend on the print parameter of the current print

job, and its shape and path are NOT adjustable by users.

Due to the structure of Covergence Dual Extruder, prolonged stagnent material flow in the

hotend could casue the material degradation or backflow which eventually could result in

the hotend clogging.

1. Even for a print job that does not need any support structure, the Auxiliary support(A.S)

is still required for periodic material purge to prevent clogging.

2. When using the same material for both main (1) and support (2), the A.S. is still

required.

STL loaded

19

6.1.5 Positioning the Auxiliary Support

Move the Auxiliary Support pillar to a suitable location.

a. First left click on the Auxiliary Support to select it, then click the “ ” move button.

b. Right-click-drag the Auxiliary Support to an area not overlapping with the STL model.

c. Alternatively user can adjust the location by using the key pad.

6.1.6. Print preview.

After the adjustment of the model layout, select the stl file by clicking the model or click its

name the model list. Then click the “ ” preview button to slice the model for preview (not

saved).

Click “ ” (save) button of the task file to save it to hard drive or USB drive.

20

6.2 Connect and Send Print Job to Printer

U300D supports USB, Wi-Fi, and Ethernet connection. For Connecting with WiFi or

Ethernet, please refer to page 66-69.

USB Connection

Use the USB cable included, connect to one of your computers USB port and

UP300D’s back side USB port (Type-B).

Open UP Studio 3 on the computer, click the “ ” button (Print) to bring up the

“Wand” program, the printer hosting module.

1. Click “connect printer”

2. Select the connected printer, click “Ok”

3. Click “Print” to bring up task list.

4. Click “Print Task”to load the .TSK file that just

saved.

Once selected, the task file will be transferred to the printer. When data transfer is

finished, the printer will start to heat up and print the job after reaching the adequate

temperature.

Once the data transfer is finished, user can disconnect the printer from the computer,

and the printer will be able to carry out the print job on its own.

Other manuals for UP300D

1

Table of contents

Other TierTime 3D Printer manuals

TierTime

TierTime UP300D User manual

TierTime

TierTime UP BOX User manual

TierTime

TierTime UP BOX User manual

TierTime

TierTime UP300 User manual

TierTime

TierTime UP600 User manual

TierTime

TierTime UP mini 3 User manual

TierTime

TierTime UP BOX+ User manual

TierTime

TierTime UP Plus 2 User manual

TierTime

TierTime UP Mini 2 ES User manual

TierTime

TierTime UP mini User manual