6

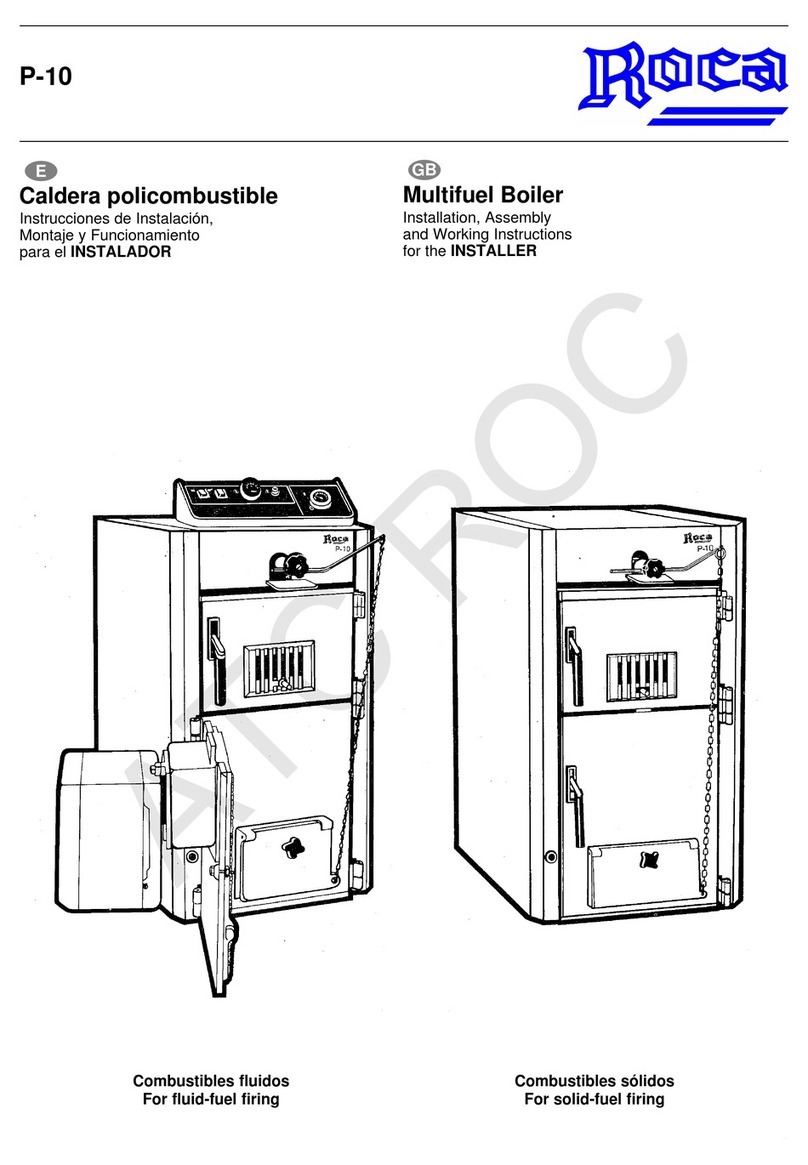

The P-10 boiler that you have chosen for your installation is

basicallymadeupfromcast-ironsectionsandsoitisaproduct

ofunbeatablequalitythatwillprovideyouwiththeconvenience

of individual central heating for many years. You will obtain

the level of comfort that you expect from its use.

In this information we offer you the main features of the boiler

as well as the operations that are necessary for its correct

performance and proper maintenance.

We are at your disposal through your Installer to solve any

problem that might arise.

Main features

Boiler type

Heat output

kcal/h

1) Solid fuel Fluid fuel

P-10-3

P-10-4

P-10-5

7.000

10.000

13.000

10.000

14.000

18.000

1) Output obtained with coal.

Maximum working temperature: 100°C

Maximum working pressure: 4 bar

Operation

Checks and operations to follow at the beginning and end of

each heating season, and also while using the boiler.

Operations prior to the first lighting

1 - Check that the installation flow and return cocks, if there

are any, are open.

2 - Check that the installation is full of water and that the fixed

pointer on the altitude or combined temp./altitude gauge

has been placed by the Installer in the position which

corresponds to the static head of the system. (See figure)

3 - Check the pump for correct operation. To do this, remove

theturn and bleed control plug (10)with a screwdriver and

look at the shaft*.

* After long periods of non-use, the pump may have become jammed.

In this case, press a screwdriver into the slot on the shaft-end and at

the same time, turn it.

4 - Bleed the air from the installation and radiators.

5 - In installations with asealedexpansionvessel, top up with

water (if necessary) until the mobile pointer on the altitude

orcombinedtemp./altitudegaugeisslightly above the fixed

one. Where an open expansion vessel has been installed,

refill until the mobile pointer levels with the fixed one.

First lighting with solid fuels

6 - Check that the damper (11)inthesmokehood(12) isopen;

otherwise open it by turning the handle (13). Get the end

of the handle (13) to point at the letter “A” (open) on the

smokehood.

7 - Open the ashpit door (8) by turning its handle (14).

8 - Lower the front section grille (15) hinged on the built-in

section brackets (16) and leave it upside down.

9 - Put a sufficient amount of straw or paper, kindling or coal

on the grate bars (17) so as to aid lighting up.

While doing this, keep the firedoor (7) and its observation

window(18) closed. Thelatterwillbekeptopenonlywhen

using fuel with an excessive content of volatile material

requiring a secondary supply of air for burning.

GB 10 - Switch on the system circulating pump.

11 - Followingtheinitialcombustion, put the grille (15)backin

its original position and close the ashpit door (8).

12 - Openthefiredoor and stoke with the chosenfuel,loading

it so as not to smother the fire, to an appropriate level.

Close the firedoor and check that there no leaks of flue

gases.

13 - Adjustment ofthe automatic damperregulator (6)will have

been done by the Installer. Nevertheless, if you have to

setit,proceedaccordingtotheinstructionsthatcomewith

it.

14 - Bleed all the radiators and ensure that they reach the

required operating temperature in accordance with that

selected on the damper regulator (6).

First lighting with fluid fuels

6 - Checkthatthedamper (11)inthesmokehood(12)is open;

otherwise open it by turning the handle (13). Get the end

of the handle (13) to point at the letter “A” (open) on the

smokehood.

7 - Turn ON the main switch for the power supply to reach

the control panel (19).

8 - TurnONtheswitch(1)onthecontrol panel to start upthe

system pump.

9 - TurnONtheswitch(2)onthecontrol panel to start upthe

burner and check its running against the instructions that

come with it.

10 - Set the control thermostat (3) on the control panel to the

required temperature. A minimum temperature of 60 ºC

is recommended.

Where an ambient thermostat has been installed, set its

dial in the position corresponding to the chosen indoor

temperature.

11 - Bleed all the radiators and ensure that they reach the

required operating temperature in accordance with that

selected on the control thermostat (3).

Cleaning

The cleaner the boiler is kept the lower will fuel consumption

be. Foreverymillimetrethicknessof soot adheringtoitsinterior

surfaces, consumption increases by approximately 3%.

To aid operating and cleaning the boiler, a set of tools is

supplied,comprising:

20 - Shovel

21 - Scraper

22 - Slice bar

23 - Flue brush & handle

The shovel (20) is used in stoking the boiler, for putting solid

fuel in the combustion chamber, as well as for gathering and

withdrawing cinders from the ash-pan.

The scraper (21) permits drawing ashes and slag which might

have fallen on the base of the boiler, from the back to a more

accessible place for gathering and withdrawing.

The slice bar (22) eases cleaning of the grates in such a way

thatwithits helpthecinderswhich haveremainedonthe surface

can fall onto the ash-pan. It can also be used –if necessary–

for stirring up the solid fuel.

Thefluebrush(23)isusedfor cleaning thefluesandtheinterior

walls of the boiler.

Using solid fuels

Before each stoking proceed to:

1 - Open the ashpit door (8) using its handle (14), lower the

front section grille (15) as described in point 8 of the “First

lighting with solid fuels” section and use the slice bar (22)

to remove cinders from the grate bars, which will drop into

the ash-pan (24).

2 - Put the front section grille (15) back in position, withdraw

theash-pan(24)and,withtheaidoftheshovel(20),empty

it. Replace the empty ash-pan and close the ashpit door.