Nice X-Bar Technical specifications

Other Nice Automatic Barrier manuals

Nice

Nice M3BAR Technical specifications

Nice

Nice X-BAR barrier User manual

Nice

Nice M7BAR User manual

Nice

Nice LBar Technical specifications

Nice

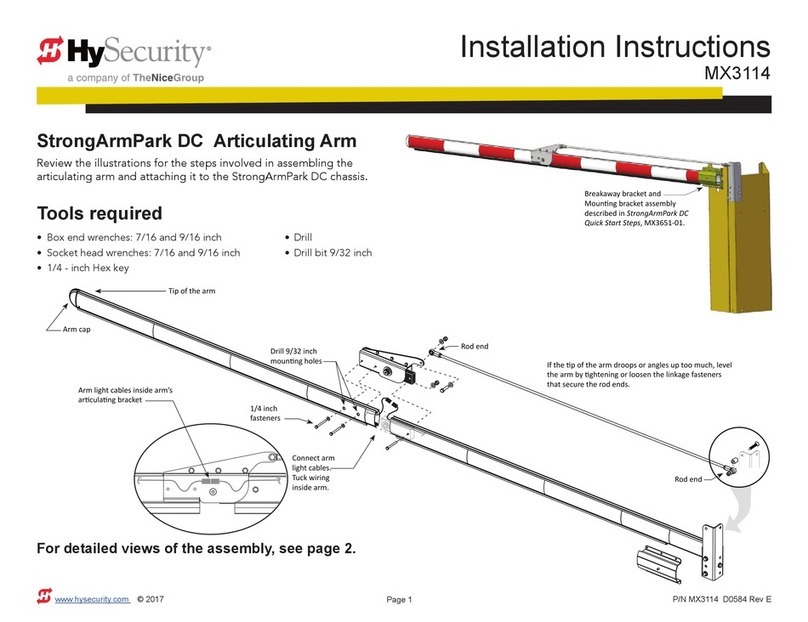

Nice HySecurity StrongArmPark DC Series User manual

Nice

Nice Signo User manual

Nice

Nice MAESTRO200 Series Technical specifications

Nice

Nice WIDE M User manual

Nice

Nice S4BAR Technical specifications