7

Maintenance and care

The gears of the Rohloff SPEEDHUB 500/14 are protected from dust and harmful moisture

due to running in a oil bath. The maintenance and care of the Rohloff system is limited to the

following points:

-Chain and chain tensioner (where applicable) should in regard to regular use (at the latest

after riding in rain) be cleaned and re-lubricated.

-The cable box of the external gear mech should be demounted approx. every 500km,

cleaned and the cable pulley lightly greased from the hub-facing side.

-The shifter cable tension should be regularly checked, and when necessary altered by the

cable adjusters.

-The Rohloff shifter cables are made from high-quality stainless steel and run in a nylon lined

steel, spiral-wound cable housing which is protected at each end with a sealed ferrule. The

cables are routed lubricant free and must not be greased or oiled. The stainless steel/nylon

combination runs service-free.

The Rohloff SPEEDHUB 500/14 is filled with 25ml of Rohloff SPEEDHUB OIL. This exact

amount of oil is optimum for both the bearings and gears of the Rohloff SPEEDHUB 500/14.

The oil must be changed at least once a year or every 5000km. This process enables us to

ensure any lost oil is replaced and any penetrated moisture is rinsed back out (see chapter

'Service', paragraph 1. 'Oil change').

Use only un-pressurized water and gentle cleaning fluids. Do not use a high power jet wash

system, brushes or abrasive materials for cleaning purposes.

Changing the oil in the

Cleaning the

Rohloff SPEEDHUB 500/14:

Rohloff SPEEDHUB 500/14:

Water may pass under the SPEEDHUB seals when using a high pressure wash system,

steam cleaner, transporting the bicycle on a car through heavy rain or submerging the rear

wheel. For this reason, these situations should be avoided. If not avoidable, we

recommend that an oil change is performed immediately after so as to ensure any

potentially penetrated moisture is rinsed back out of the SPEEDHUB before it can do any

damage.

A T T E N T I O N

Riding with the SPEEDHUB 500/14

8

5

34

21

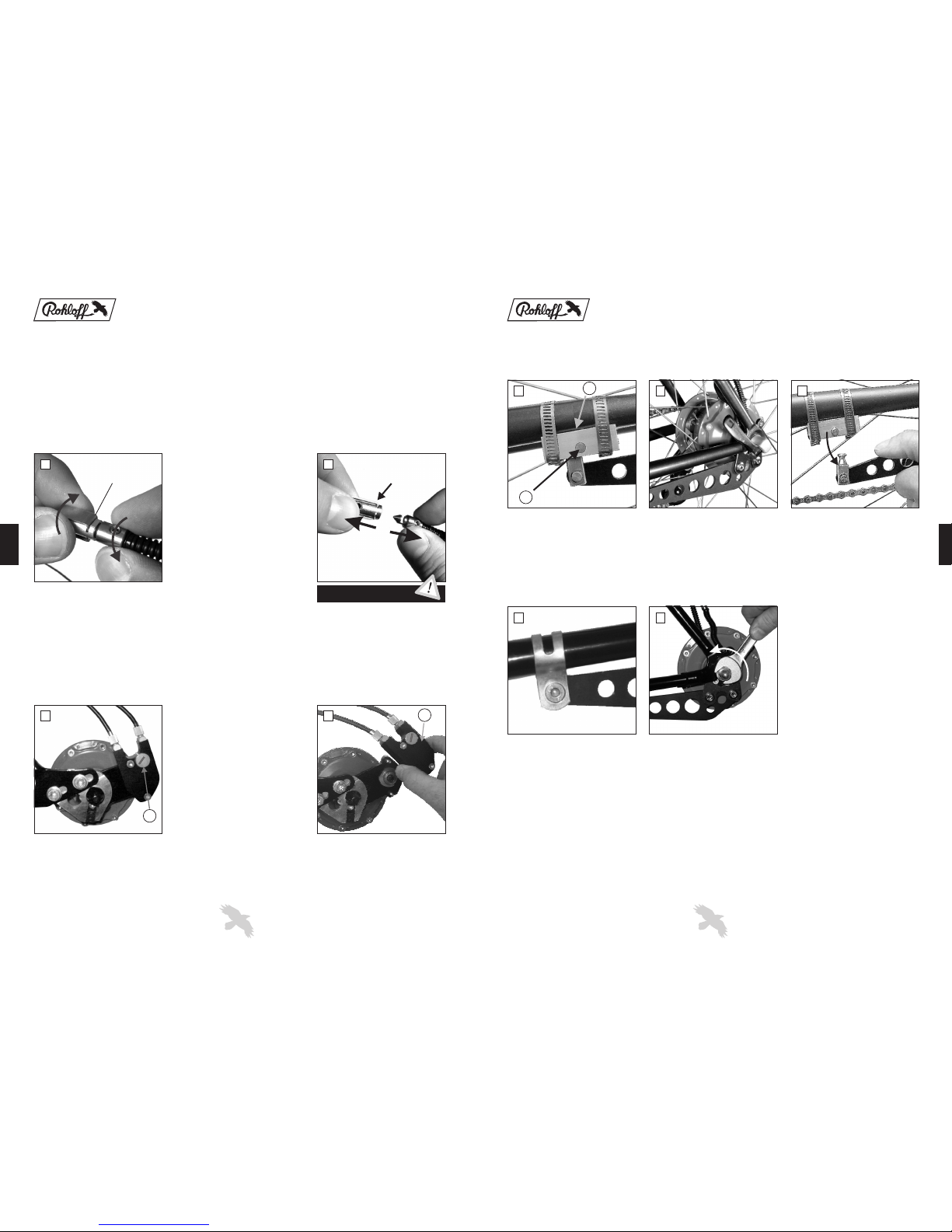

On the versions with an internal

gear mech the cable adjusters are

to be found on the cable guide.

This can be found on the left hand

chain stay or attached to the left

hand brake boss of the frame.

On the versions with an external

gear mech the cable adjusters are

to be found on the cable box which

sits directly on the left hand side of

the Rohloff SPEEDHUB 500/14.

To lubricate the chain tensioner

place a drop of oil on the left and

right side of the upper jockey

wheel on the pivot point.

Rohloff SPEEDHUB 500/14

versions with external gear mech:

To lubricate the cable pulley

bearing remove the cable box and

place a little grease on the parts

arrowed in the diagram above.

When lubricating the chain place a

thin thread of lubricant on the

outside of the chain over the centre

rollers, this process is carried out

quicker and easier when running

the chain backwards whilst

applying the lubricant.

Maintenance and care

The shifter cable tension can be

altered by the cable adjusters.

Winding the cable adjusters out

increases cable tension.

The mark

on the twist shifter body can be

aligned to the correct gear number

without altering the cable tension

by winding one cable adjuster in

and the other out.

Too much cable tension raises the

amount of friction within the

shifter cables and in turn raises the

force needed on the twist shifter to

select other gears.

For the

lightest possible gear change, the

tension should be just enough

that on the twist shifter there is

approx. 2mm rotational play

when in a selected gear.

A T T E N T I O N

Riding with the SPEEDHUB 500/14

A T T E N T I O N

When using a disc brake in conjunction with the , the hub cap screws should be

checked that they are correctly tightened before every ride.

To reduce the chance of a flange breaking due to unequal spoke tension, we recommend that this is regularly

checked by a professional bicycle mechanic.

Rohloff SPEEDHUB 500/14