Manual

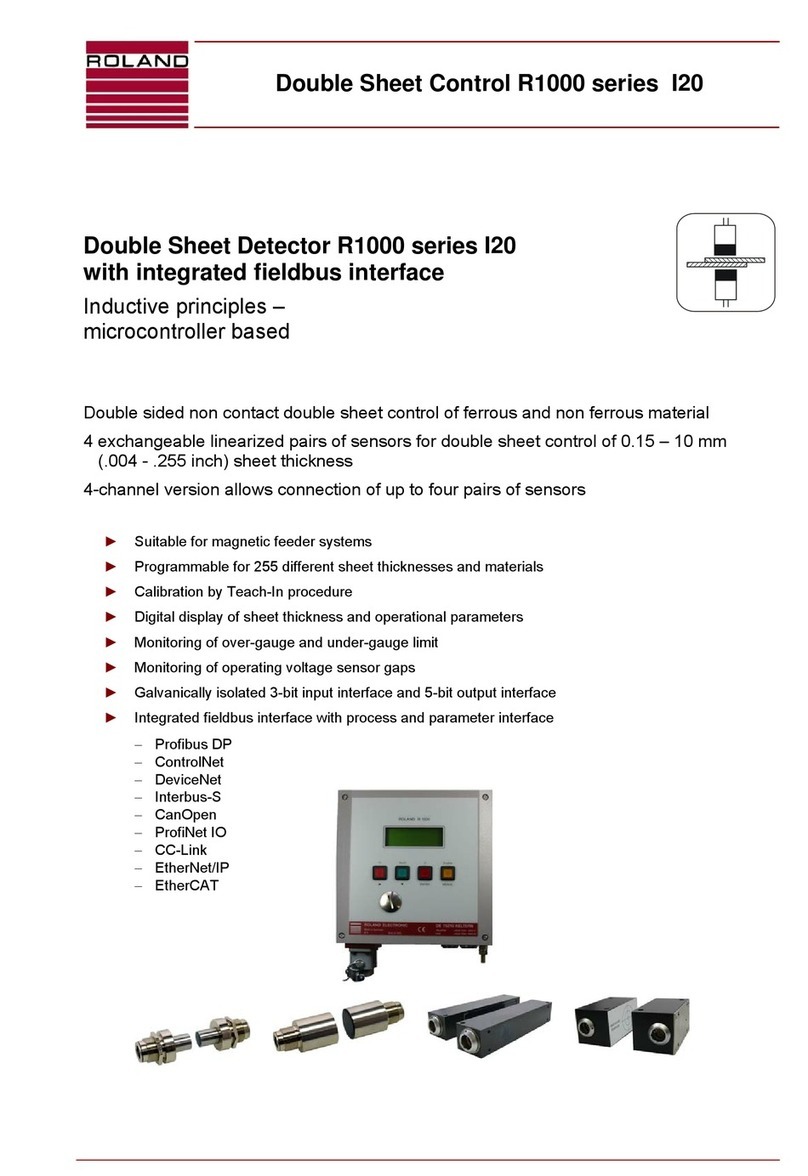

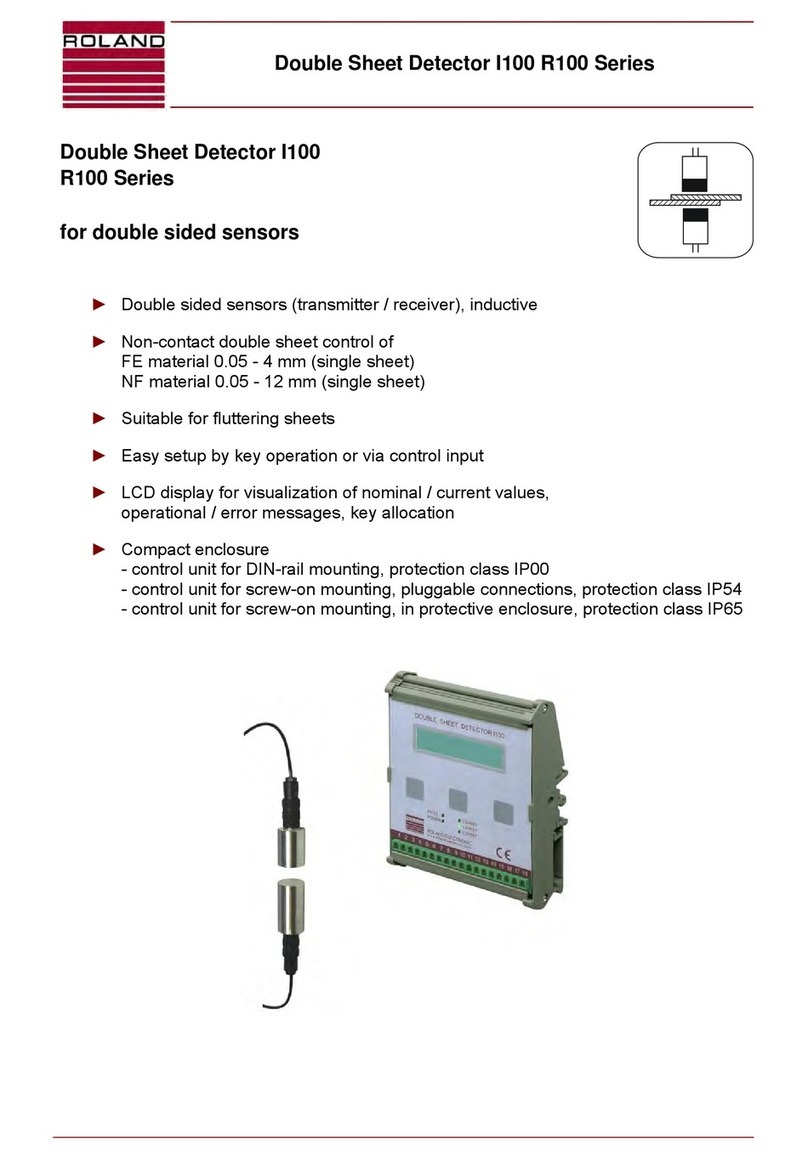

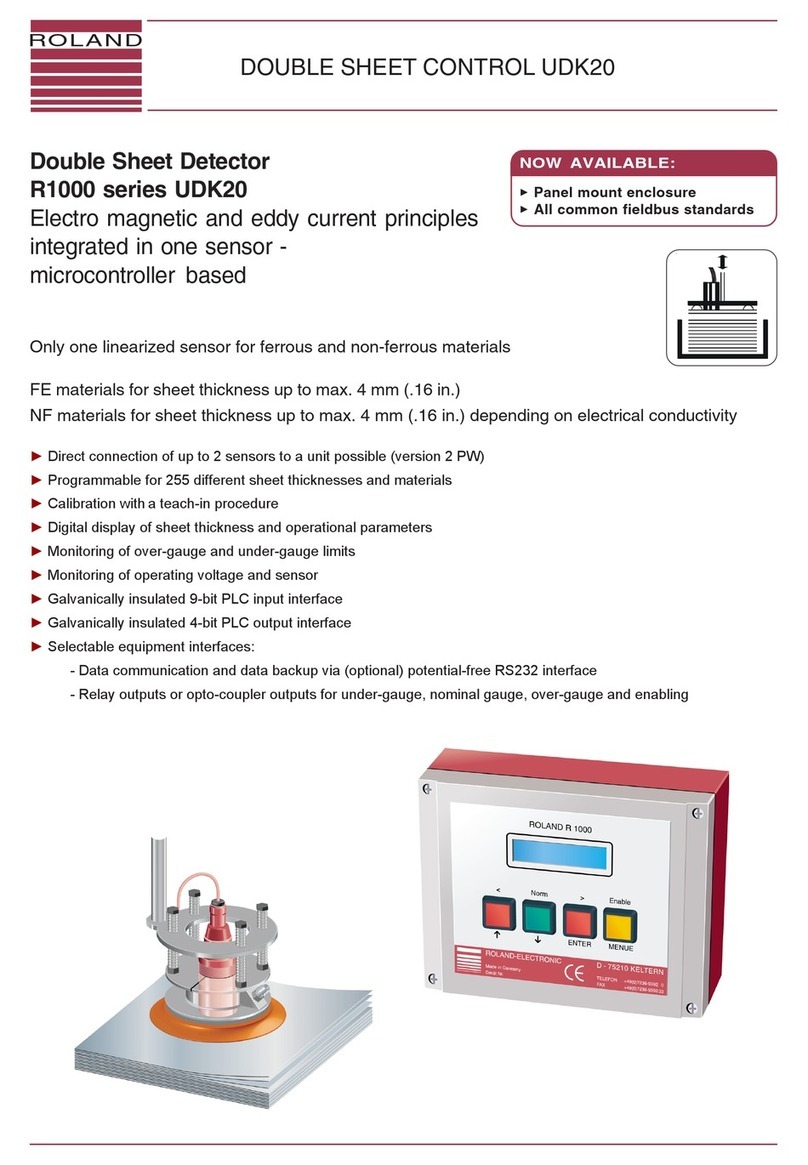

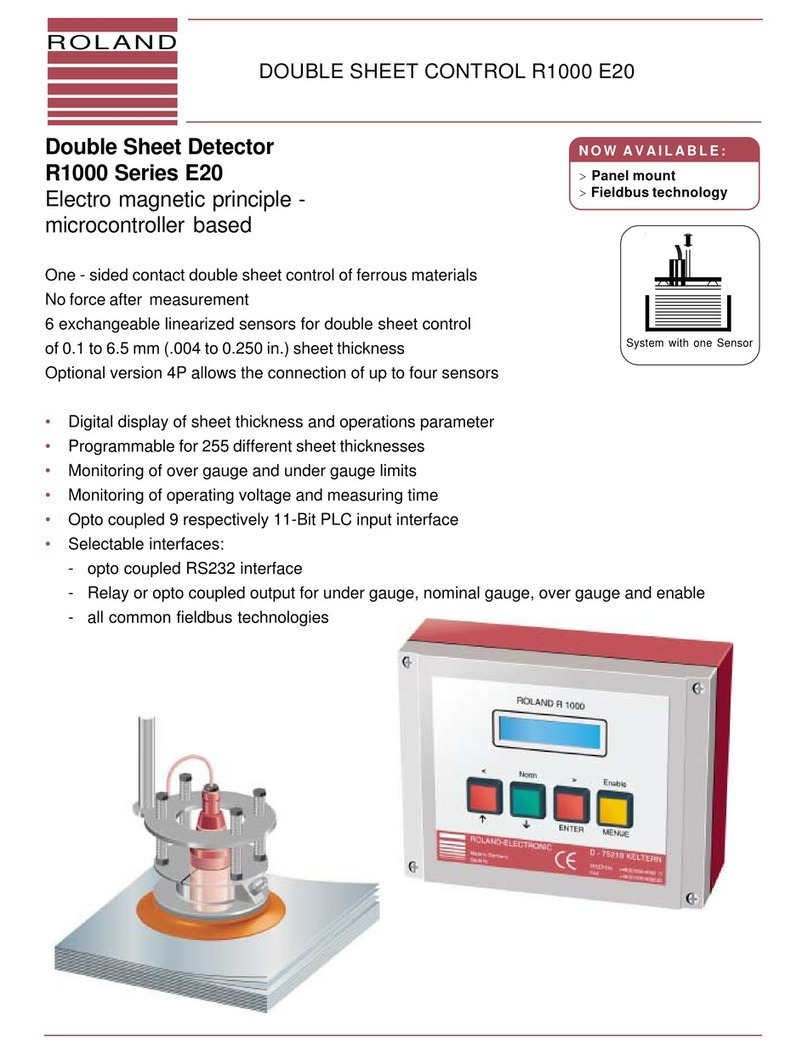

Double Sheet Detector R1000 series E20

with integrated fieldbus interface

B0046191 / Rev. 1.12 Inhaltsverzeichnis

ROLAND ELECTRONIC GmbH · Otto-Maurer-Str. 17 · DE 75210 Keltern · Phone +49 (0)7236-9392-0 · Fax +49 (0)7236-9392-33 3

Declaration of conformity according to EC directives.....................................................................................5

1Safety advice ..........................................................................................................................................7

1.1Safety instructions and warnings for user ..........................................................................................7

1.2Declaration of icons............................................................................................................................7

1.3Intended use.......................................................................................................................................8

1.4Fieldbus terminology ..........................................................................................................................8

2Technical data ........................................................................................................................................9

2.1Technical data control unit E20..........................................................................................................9

2.2Versions of the control unit E20........................................................................................................11

2.3Sensors.............................................................................................................................................12

2.4Sensor performance data (Measuring time).....................................................................................16

2.5Sensor cables...................................................................................................................................22

2.6Connectors of the P-sensors and the sensor cable .........................................................................22

2.7Scope of Delivery .............................................................................................................................26

3System description..............................................................................................................................27

3.1Measurement principle.....................................................................................................................27

3.2General hints for process security....................................................................................................27

3.3Control unit .......................................................................................................................................28

3.4Parameters of the control unit ..........................................................................................................28

3.5Application samples..........................................................................................................................33

4Mounting...............................................................................................................................................39

4.1General mounting instructions..........................................................................................................39

4.2Dimensions of the system ................................................................................................................40

4.3Mounting of sensors.........................................................................................................................44

5Electrical installation ...........................................................................................................................59

5.1General instructions..........................................................................................................................59

5.2Configuration of connectors..............................................................................................................60

5.3Connecting diagram - examples.......................................................................................................70

6Communication with the PLC .............................................................................................................73

6.1Fieldbus specific messages..............................................................................................................73

6.2Data transmission communication....................................................................................................74

6.3Process channel...............................................................................................................................75

6.4Parameter channel...........................................................................................................................89

6.5External I/O control...........................................................................................................................97

6.6Fieldbus configuration file...............................................................................................................102

7Start-up................................................................................................................................................107

7.1Initially applying power to the system.............................................................................................107

7.2Operation........................................................................................................................................107

7.3Configuration menu........................................................................................................................108

7.4General information regarding the configuration............................................................................110

7.5Changing, setting-up or checking the configuration.......................................................................110

7.6Program parameters.......................................................................................................................111