C

C

Contents

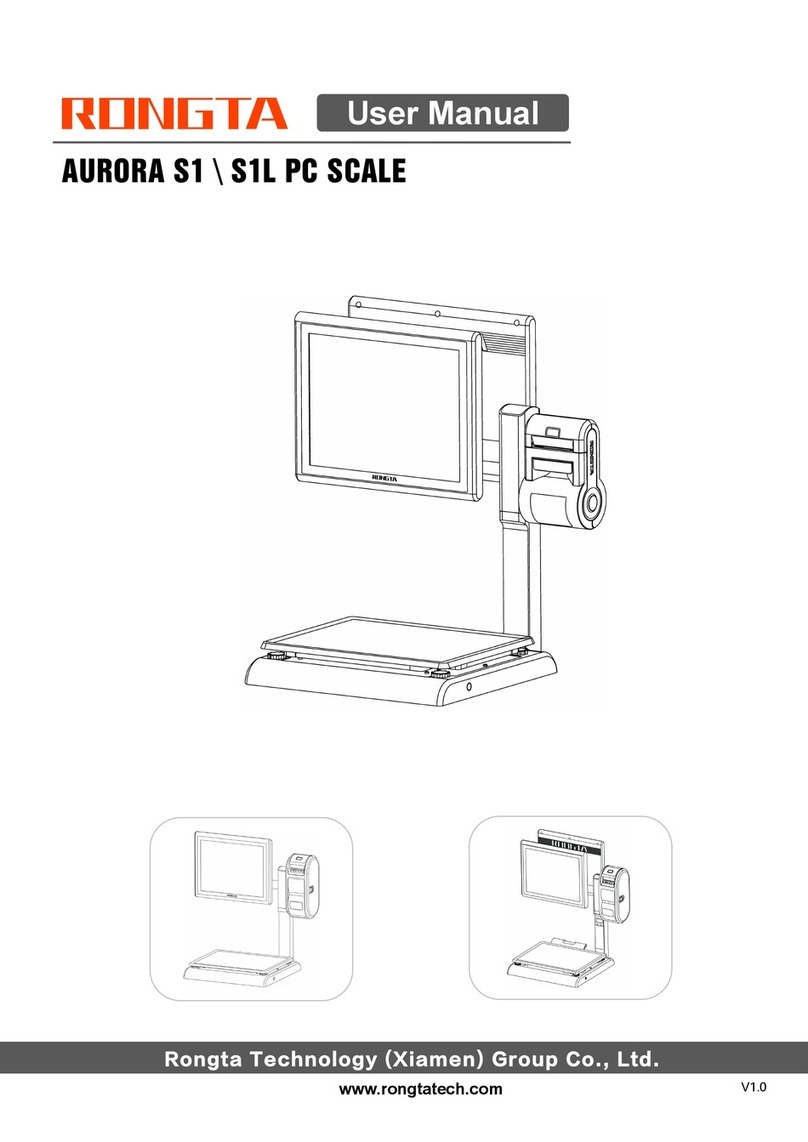

Introduction...................................................................................................................1

1. The Label scale’s specification............................................................................. 2

2. Features Summary................................................................................................. 3

2.1 Unique and powerful network..................................................................... 3

2.2 Usage is easy to learn................................................................................. 3

2.3 Advanced functions and durable quality....................................................3

3. Label scale installation steps................................................................................ 4

3.1 Installation......................................................................................................4

3.2 The installation of the thermal label paper................................................5

3.3 Keyboard........................................................................................................6

3.4 Description of label paper............................................................................6

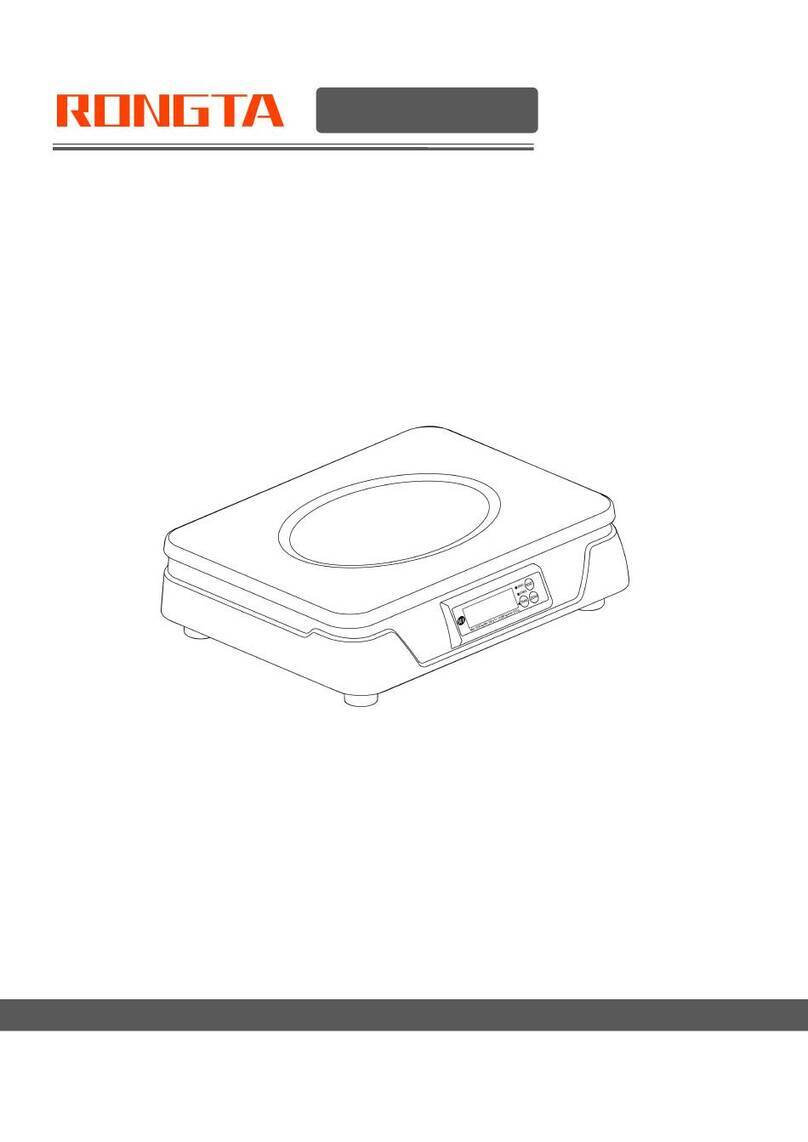

4. Overall Appearance................................................................................................ 6

5. Common easy-to -use operations........................................................................ 7

5.1 Switch on and off.......................................................................................... 7

5.2 Weighing and pricing....................................................................................7

5.3 Tare operation................................................................................................8

5.4 Discount......................................................................................................... 8

5.5 Price Changing..............................................................................................8

5.5.1 Permanent Changing........................................................................8

5.5.2 Temporary Changing.........................................................................9

5.6 Choosing Unit of Weight.............................................................................. 9

5.7 Charging by Piece........................................................................................ 9

5.8 Automatic fast packaging.............................................................................9

5.9 Operation button in common use.............................................................10

6. Wireless Label Scale Setting Instruction...........................................................10

6.1 Network connection mode.........................................................................10

6.2 Router set up...............................................................................................10

6.3 Label Scale Setting.....................................................................................11

6.4 Computer RLS1000 software settings.....................................................11

7. Function setting..................................................................................................... 11

7.1 Input settings of single item.......................................................................11

7.2 System set up............................................................................................. 12

7.3 Lock.............................................................................................................. 13

8. Troubleshooting.....................................................................................................14

8.1 Scales crash................................................................................................14

8.2 Print related issues.....................................................................................14

8.3 The key issues............................................................................................ 17

8.4 Weigh problem............................................................................................ 17

8.5 Communication problem........................................................................... 18

8.6 Display problem.......................................................................................... 18

8.7 Error code.................................................................................................... 18

8.8 Other problems........................................................................................... 19

9. The acceleration of gravity revised table.......................................................... 20