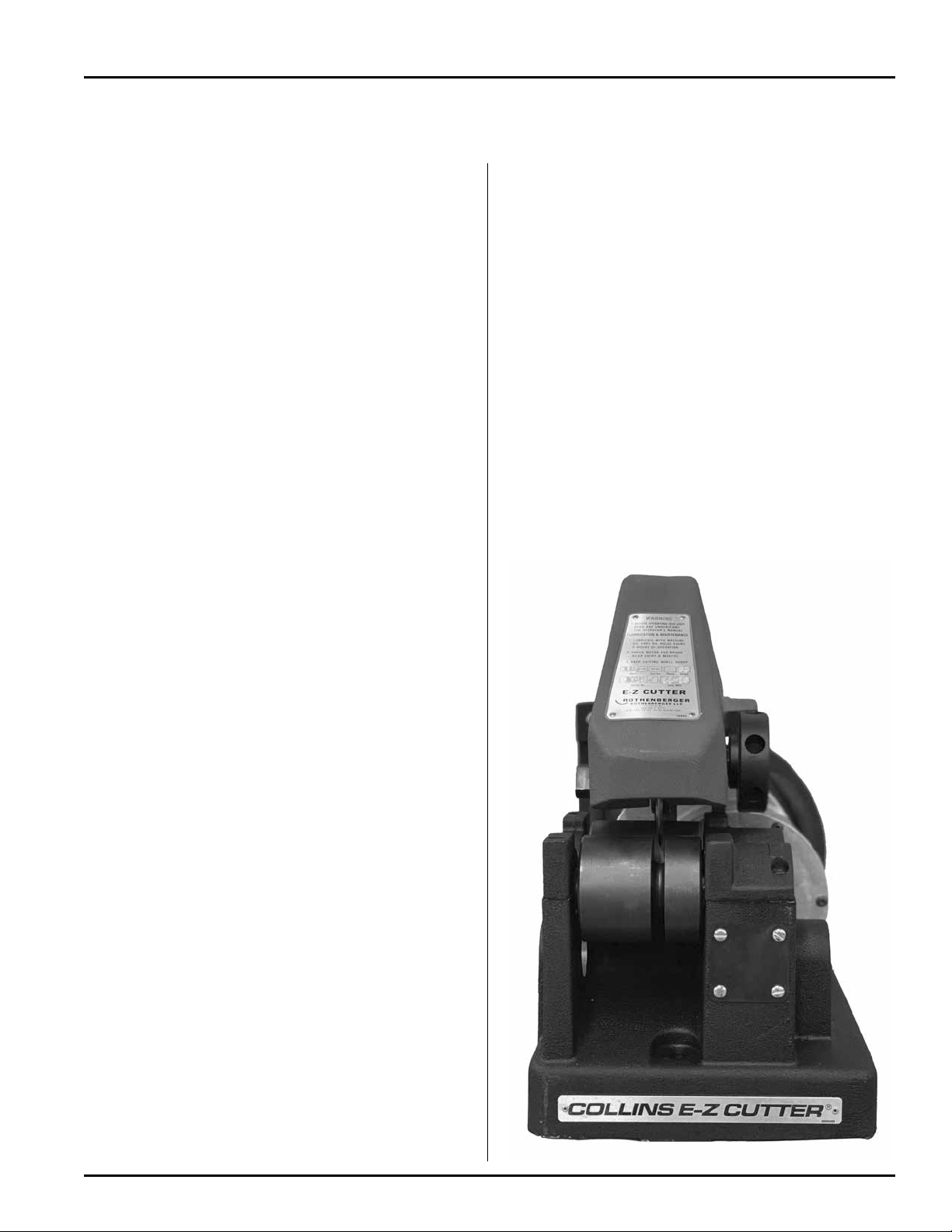

This E-Z Cutter is designed for cutting pipe and tubing

as specified. To accomplish the cutting function

requires dexterity and mechanical skills as well as

sound safety habits.

Although this machine is manufactured for safe,

dependable operation, it is impossible to anticipate

those combinations of circumstances which could

result in an accident. The following instructions are

recommended for safe operation of the machine.

The operator is cautioned to always practice ”Safety

First” during each phase of use, including setup and

maintenance of this unit.

1. Read and understand the Instruction Manual.

Before operating or performing maintenance on

this machine, read the operator‘s manual carefully.

Become familiar with the machine's operations,

applications and limitations. Be particularly aware

of its specific hazards. Store the operator‘s manual

in a clean area and always at a readily available

location. Additional copies are available for a

nominal charge.

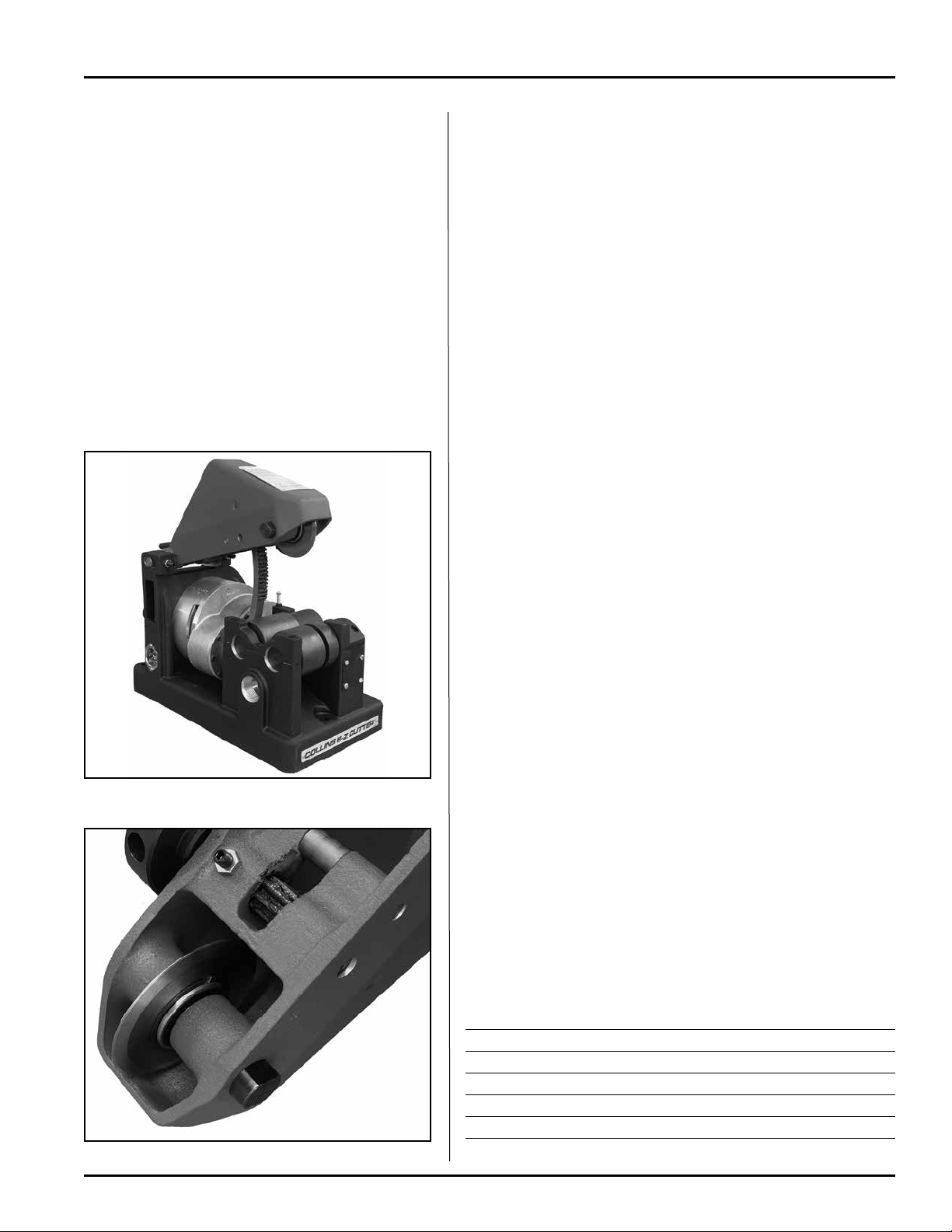

2. Inspect the equipment. Prior to starting the

machine, check the movable parts for obstructions

such as rags, packing remnants, etc. Be sure that

guards and machine parts are properly installed

and secured.

3. Ground the machine. The machine power cord

includes a plug with a ground connector. Be

certain the machine is connected to an internally

grounded electrical system.

4. Keep the work area clean. Keep the work area

adjacent to the machine clear of clutter for

unobstructed movement of the operator.

5. It is mandatory to use a pipe/tubing support

system with the Collins E-Z Cutter. (See pages 6

and 7 for suggested systems.)

6. Wear proper clothing. Loose clothing can get easily

entangled in moving parts. When operating the

machine, do not wear unbuttoned jackets, loose

sleeve cuffs, neckties, long hair, etc. Safety glasses

and shoes should be worn.

7. Secure machine and work. Make certain that the

machine is bolted to a heavy work bench or proper

stand.

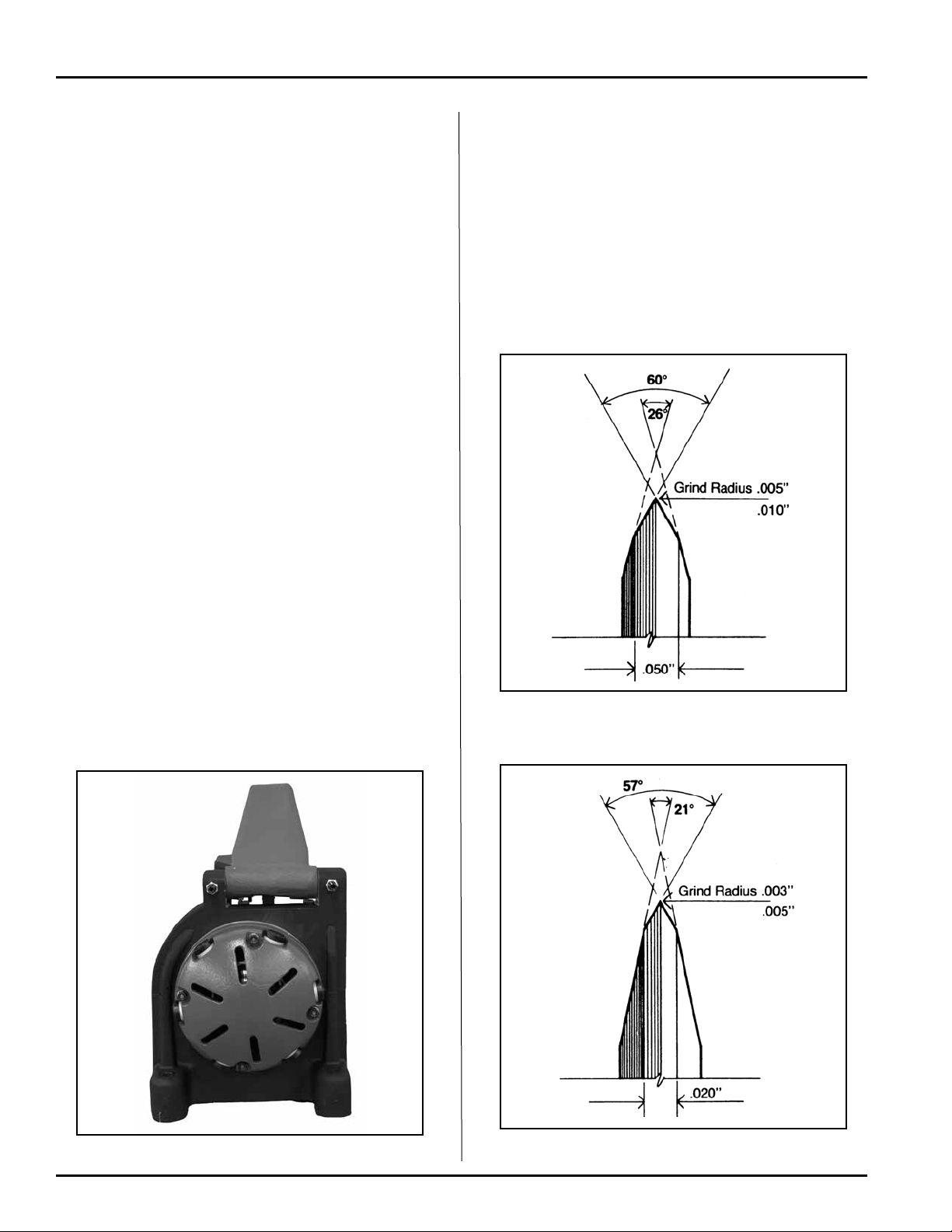

8. Always maintain machine. Keep machine clean

and cutting tools sharp for safe, dependable oper-

ation. Follow lubricating instructions. Report any

unsafe condition for immediate correction.

9. Keep alert. Do not operate machine if ill or drowsy

from medication or fatigue. Avoid horseplay

around equipment and keep bystanders a safe dis-

tance from equipment.

10. Operate on switch side only. Machine should be

operated on switch side only. Never reach across

moving parts or material being worked on. On/Off

Switch should always be accessible to operator.

11. Operate in proper environment. Machine should

not be operated in damp locations. Wear hearing

protection in noisy shop environments. Ensure of

proper illumination in work area.

12. Do not misuse machine. Perform only the

functions for which the machine is designed. Do

not force machine.

13. Disconnect power cord prior to servicing. Repair

should be attempted only by authorized person-

nel. Always disconnect power cord before making

any adjustments or servicing the machine.

14. Keep visitors away. All visitors should be kept at a

safe distance from work area.

15. Use recommended accessories only. Refer to

Operator‘s Manual. Use of improper accessories

may be hazardous.

Operator Safety Information

3

Phone 800-545-7698 • FAX 815-633-0879 www.rothenberger-usa.com

COLLINS E-Z CUTTER