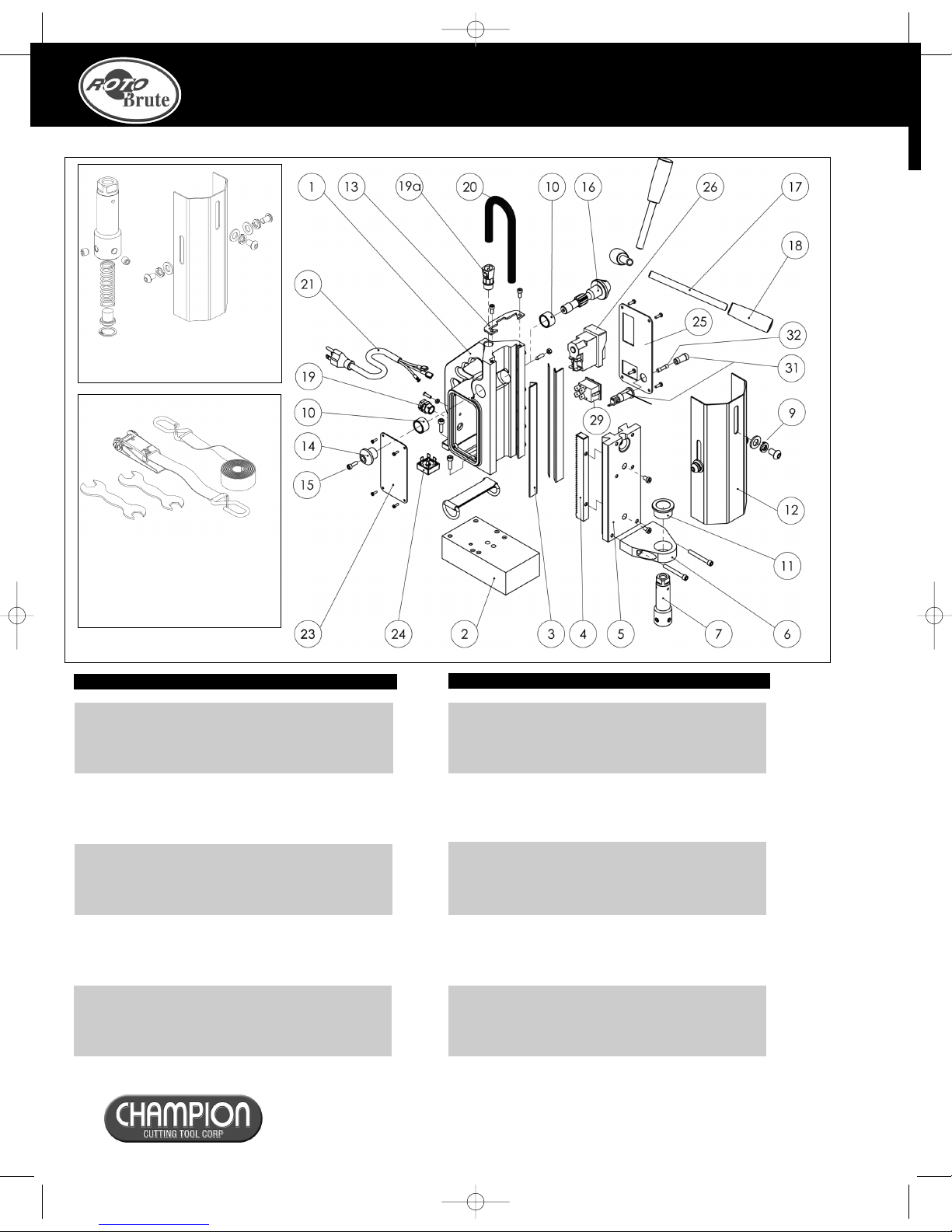

INCLUDED WITH EVERY RB32

Carrying case, safety strap, RB334 3/4” arbor, RB3212 1/2” drill chuck,

D-handle, cutting fluid, safety guard, chuck key, hex keys and spanner wrenches

Ear and eye protection MU T be worn during operation of this equipment. Do NOT

touch the cutter while it is in motion. Always follow the Personal Protection

Equipment (PPE) recommendations while operating this tool.

This machine is designed specifically for drilling holes in steel using annular cutters

or with twist drills when using the optional drill chuck. We recommend Champion®

Rotobrute™ annular cutters. Please consult your Champion authorized distributor for

a complete range of sizes.

DO NOT modify and / or use your Rotobrute™ magnetic drill press for any application

other than for which it is intended.

AFETY

Be sure to read and follow these important safety instructions:

When using your RB32 MiniBrute, be sure to follow these important safety precautions:

1. Before operating the machine, check supply voltage and general conditions, i.e. cable/cord

damage. A machine with damaged cable must be returned or repaired prior to use.

2. Always use the safety strap in all drilling applications.

4. Since cutting tools can shatter, eye and head protection should be worn at all times.

5. After use, clean machine and cutters and keep in the case provided.

6. Store when not in use, in a dry environment.

7. Always provide a method of catching slug, where the ejected slug may cause injury (slug

ejects at end of cut).

8. Should the cutter jam in the work-piece, stop the machine immediately. Isolate the

machine at the main supply. Loosen the cutter by rotating the arbor. Do not attempt to free

cutter by starting and stopping the motor.

9. Always use the safety guard provided.

Electrical afety

1. Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or modify the

plug in any way.

2. Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as to

whether the outlet is properly grounded. If the tools should electrically malfunction or break-

down, grounding provides a low resistance path to carry electricity away from the user.

3. Never use the cord to carry the tools or pull the plug from an outlet. Replace damaged

cords immediately.

4. When operating a power tool outside, use an outdoor extension cord marked “W-A” or

“W”. These cords are rated for outdoor use and reduce the risk of electric shock. Minimal

gauge external cord should be 12/3.

5. Use the RB-32 with 110 A/C voltage only. Not for use with generators, welders or any dc

power source. Do not use on any surface where welding is taking place.

Personal afety

Stay alert, watch what you are doing and use common sense when operating a power tool.

Do not use tool while tired or under the influence of drugs, alcohol, or medication.

Do not wear loose clothing or jewelry. Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or plugging in tools that have the

switch on invites accidents.

Remove adjusting keys before turning the tool on.

Do not overreach. eep proper footing and balance at all times.

Safety equipment (eye protection, dust mask, nonskid safety shoes, hard hat, hearing

protection) should be used for appropriate conditions.

Tool Use and Care

Use clamps or other practical ways to secure and support the work-piece to a stable

platform.

Do not force tool. Use the correct tool for the application.

Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tool.

Store idle tools out of reach of children and other untrained persons.

Maintain tools with care. eep cutting tools sharp and clean.

Check for misalignment or binding of moving parts, breakage of parts and any other condi-

tion that may affect the tool’s operation. If damaged, have the tool serviced before using.

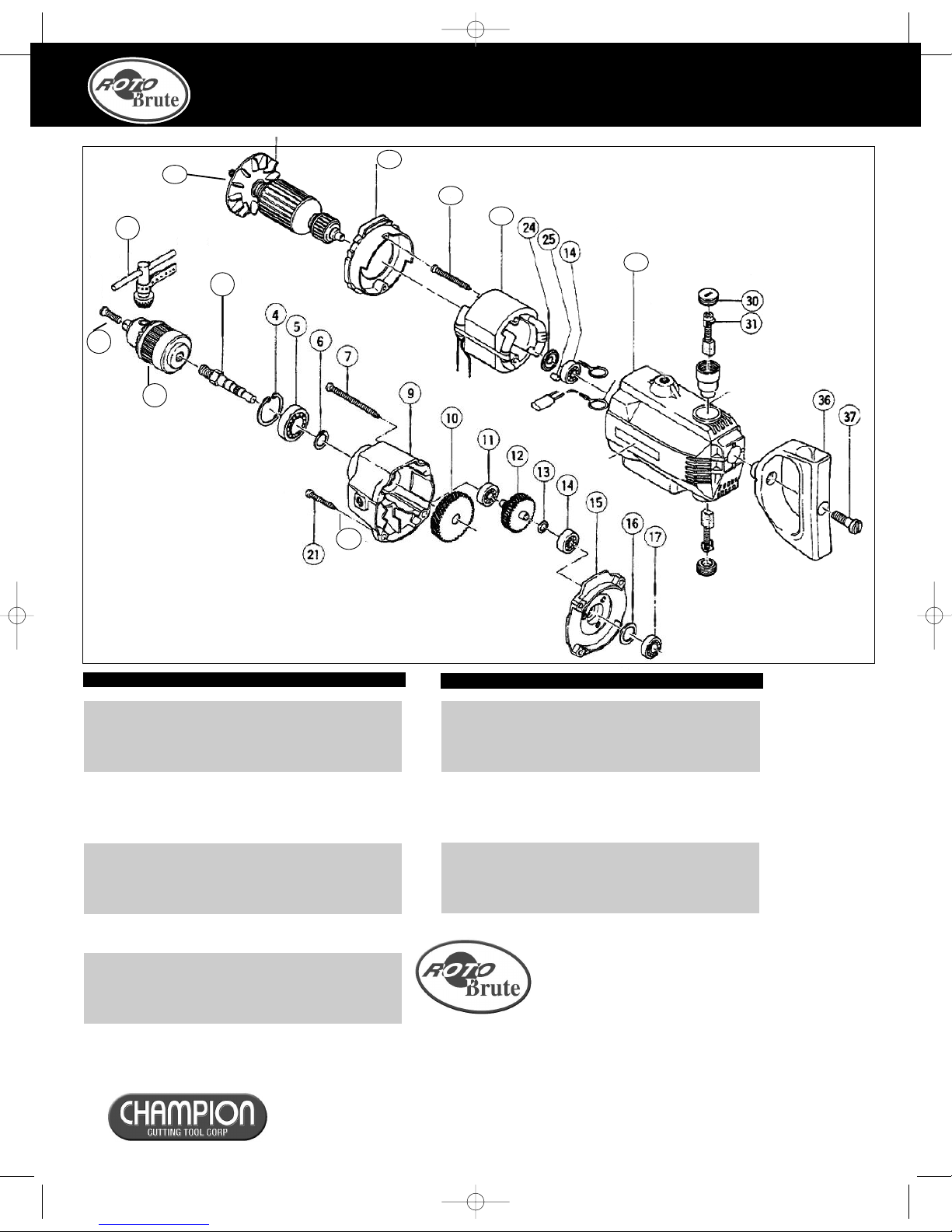

ervice

Tool service must be performed only by qualified personnel.

When servicing a tool, use only original replacement parts.

Use of unauthorized parts will void the warranty.

Use of unauthorized parts or failure to follow maintenance instructions may create a risk of

electric shock or injury.

Magnetic Drill afety

The drill’s magnetic adhesion depends on the thickness of the work-piece. 1/2” (13mm) is

the minimum thickness for safe operation. eep the magnet clean of metal chips and other

dirt and debris. These will seriously reduce the magnetic adhesion. The drill must be

operated on its own electrical outlet. Always use the supplied safety strap or chain. An

electrical overload can result in loss of adhesion.

CAUTION: The slug ejects at end of cut and is very hot.

WARNING: Do not attempt to drill a work-piece, which is thicker than the maximum cutting

depth of the cutter being used. Never exceed 1-3/8” (35mm) cutter diameter.

Maintenance and Troubleshooting

eep the drill press and the cord clean. In case of electrical or mechanical malfunction,

immediately switch off the tool and disconnect the plug. Excessive sparking generally

indicates the presence of dirt in the motor or worn out carbon brushes. Periodically check

brushes for wear and replace when they reach 1/4” (6mm). Also check that the machine is

well lubricated.

For all other service and maintenance, please contact a Champion® authorized service

center.

COMPONENT & AFETY

2

RB32

The RB32 is available in one other configuration:

RB32-V R - The same features as the RB32 but has variable speed control and reverse. It

also features an isolating power relay for improved handling safety. The RB32-VSR can run

twist drills at the correct RPM and has optical attachments.

Please see Champion’s website for additional technical information downloads on this

configuration.

MINIBRUTE

RB32

IMPORTANT

Please read these operating and safety instructions carefully and completely. For your own safety, before using this equipment check that the voltage

is correct and that all handles and parts are firmly secured. If you are uncertain about any aspect of using this equipment, contact your distributor.

PLEA E KEEP THE E IN TRUCTION