MINI 3 p. 2 MARCH 2011

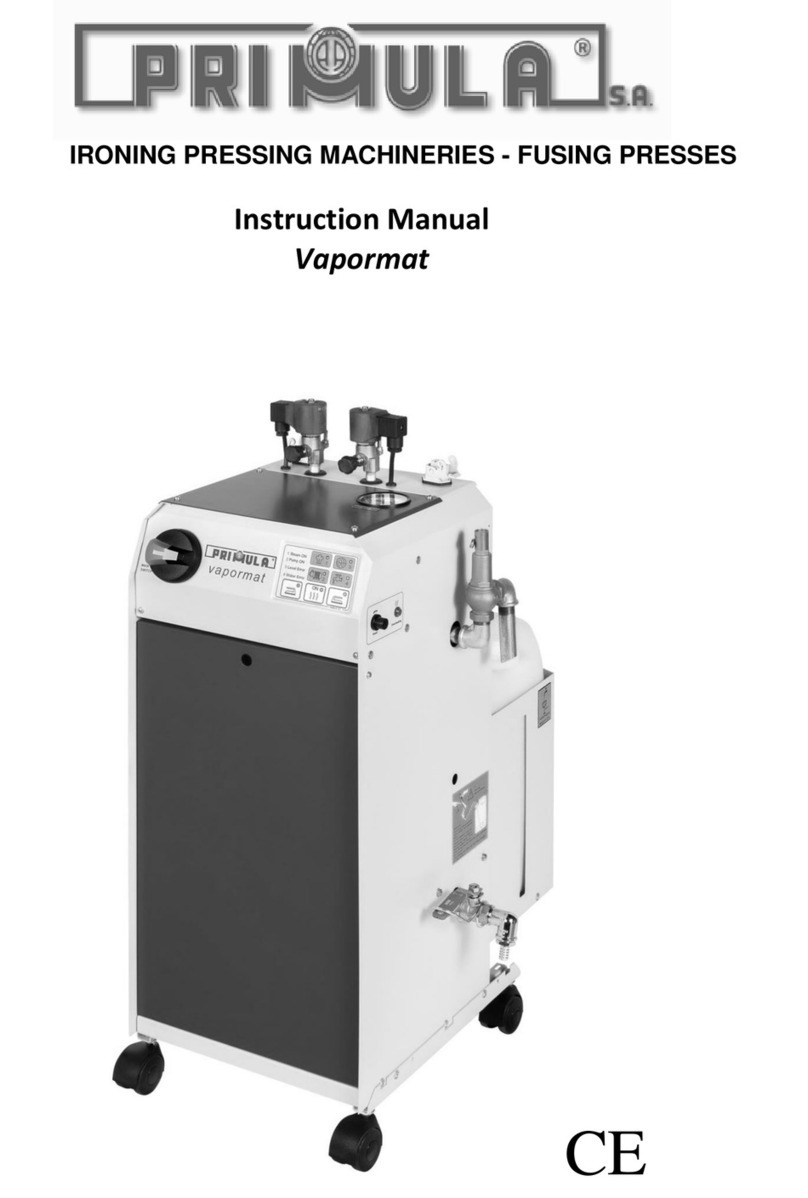

4. CONNECTION AND STARTING

With MINI 3 switched ff and disc nnected plug:

1. Unscrew the security valve plug (fig. 1), fill the b iler with water (fig. 2) till verfl w r at

pleasure. Take the plug by the plastic part and screw it again: d n t tighten t much r

its gasket might get sp ilt.

2. Insert the plug int a 220 V 16 A s cket.

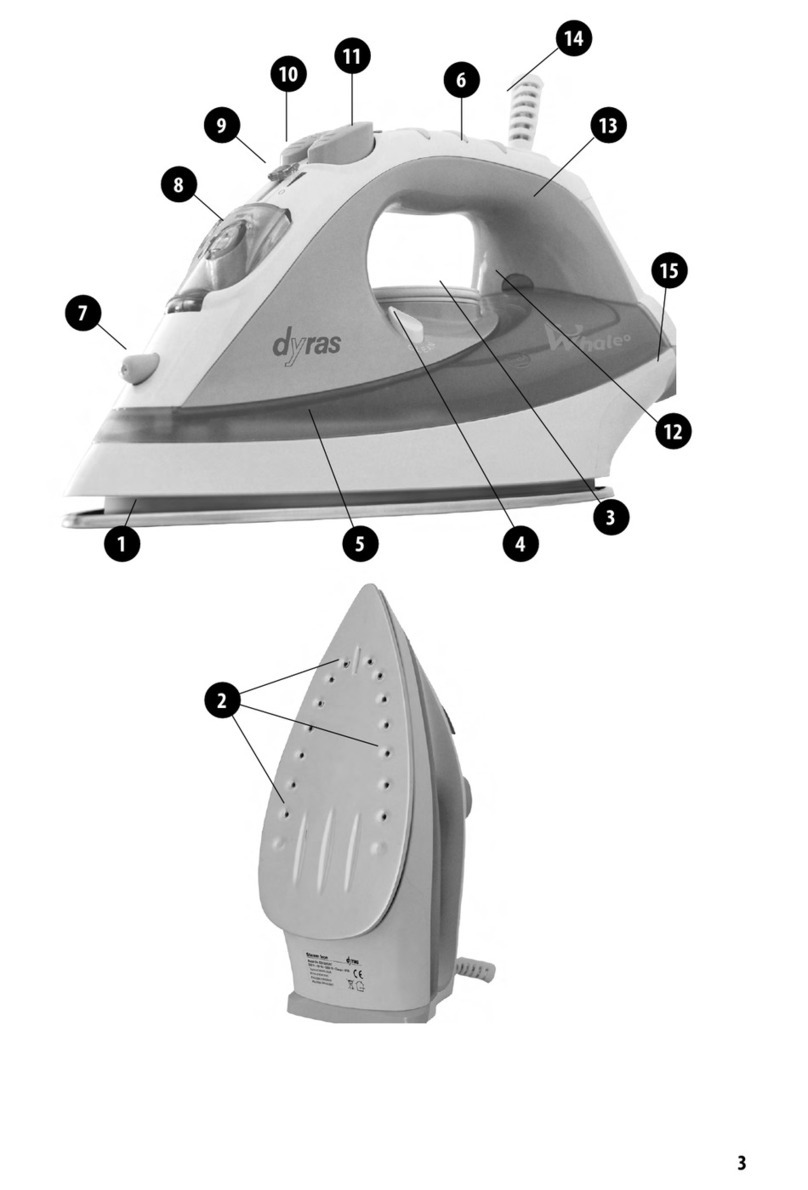

3. Switch n the b iler (fig. 2 B), the ir n (fig. 2 A) and adjust the therm stat (fig. 3) n “c tt n”.

4. Wait f r the b iler lamp t switch ff (fig. 2 C). At this p int seize the ir n by c rk handle and

press red butt n 3 r 4 times (fig. 4), s that steam c mes ut: this perati n must be

carried ut in rder t heat up the tubes which take steam t the ir n. In this way y u

prevent als the falling f small dr ps f water n garments. T adjust steam flux, y u must

w rk n the hand-wheel f r steam adjustment (fig. 2). During ir ning perati n, the b iler

lamp switches n and ff (fig. 2 C).

5. COMPULSORY

1. Use nly n rmal water c ming fr m the

aqueduct.

2. Never add additives t water.

3. Empty the b iler nly when it is switched ff and

c ld (with n pressure). F r carrying ut this

perati n, wear gauntlets against p ssible burns.

4. Never rep ace the security va ve p ug (fig.

1) with other types of p ug. N.B. the security

valve plug is set n 4,5 BAR and it has the

functi n f a security valve.

5. C nnect MINI 3 t suitable pr tected s cket.

6. Always keep children away fr m MINI 3, b th

when it is n and ff.

7. D n t ir n garments directly n pers ns r

things.

8. D n t empty the b iler during the ir ning

perati n, wait at least 1 h ur after the switching

ff.

9. D n t leave h t ir n n garments r n the

b ard.

10. Put the tr lley n a steady surface and next t

the ir ning b ard. D n t pull the ir n cable t

hard r the tr lley might be verturned.

6. IRONING OPERATION

1. Run the ir n n garments, pressing the ir n

micr switch (fig. 4) f r steam. F r a better

result, set the therm stat (fig. 3) n “c tt n”.

2. F r delicate, blue and black garments, we advise

y u t use the anti-sheen sh e.

3. During ir ning perati n, always put the ir n n

its rubber rest (fig. 1) and pay attenti n t the p siti n f the wires: if they twine r get in

t uch with ir ning b ard, they might cause sh rt circuits.

4. F r dry ir ning it is p ssible t adjust the therm stat (fig. 3) n different p siti ns

acc rding t the type f fabric (l k at garment label). F r steam ir ning set the

therm stat n “c tt n” r “linen”.

5. If y u w rk n a n n-vacuum b ard, s me circular water sp ts might f rm because f

c ndensed steam. T get r und this pr blem, put a felt under the usual padding and adjust

the hand-wheel f r steam regulati n n minimum (fig. 2).

HAND-WHEEL

FOR STEAM ADJUSTMENT

TROLLEY

CONNECTION

HAND-WHEEL

SOLENOID VALVE