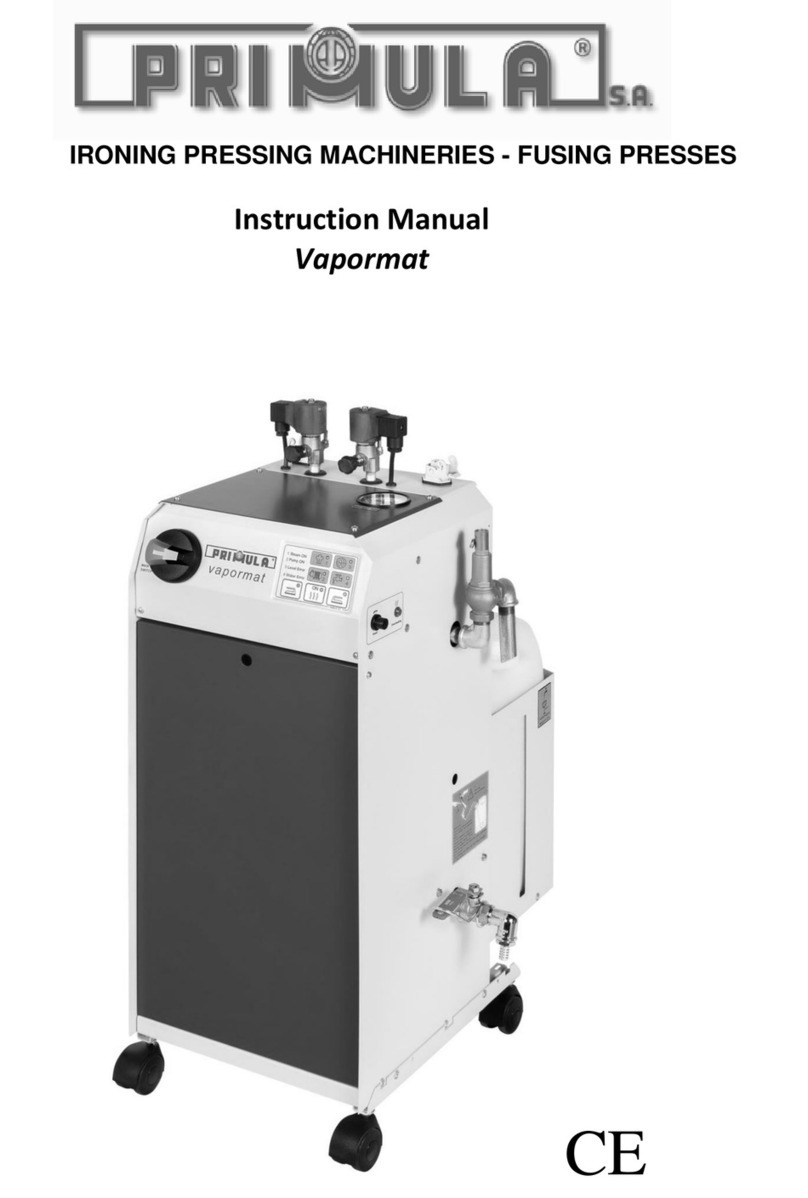

MINI 4 p. 4 MARCH 2011

It is recommended to replace:

1. the internal security valve every 2100 hrs. of ironing or maximum 3 years;

2. the internal thermostats every 2100 hrs. of ironing or maximum 3 years;

3. steam tube and iron cable once they seem spoilt (fig. 5).

It is recommended also to clean the boiler from limestone every 2500 hrs. of ironing or

maximum 3 years.

12.

ELECTRICAL RISKS

The following situations are considered dangerous for the operator:

1. earth protector switch is activated when turning on the main switch,

2. using MINI 4 during thunderstorms,

3. using MINI 4 without proper protection for feet (without shoes) or with wet feet,

4. damage of electric wires,

5. loss of water from iron,

6. iron overheating,

7. cleaning or washing the iron using water,

8. filling the boiler when the machine is on.

13.

MECHANICAL RISKS

The following situations are considered dangerous for the operator:

1. using MINI 4 for different purposes other than ironing,

2. replacing the valve plug gasket with non-original gaskets.

14.

THERMIC RISKS

The following situations are considered dangerous for the operator:

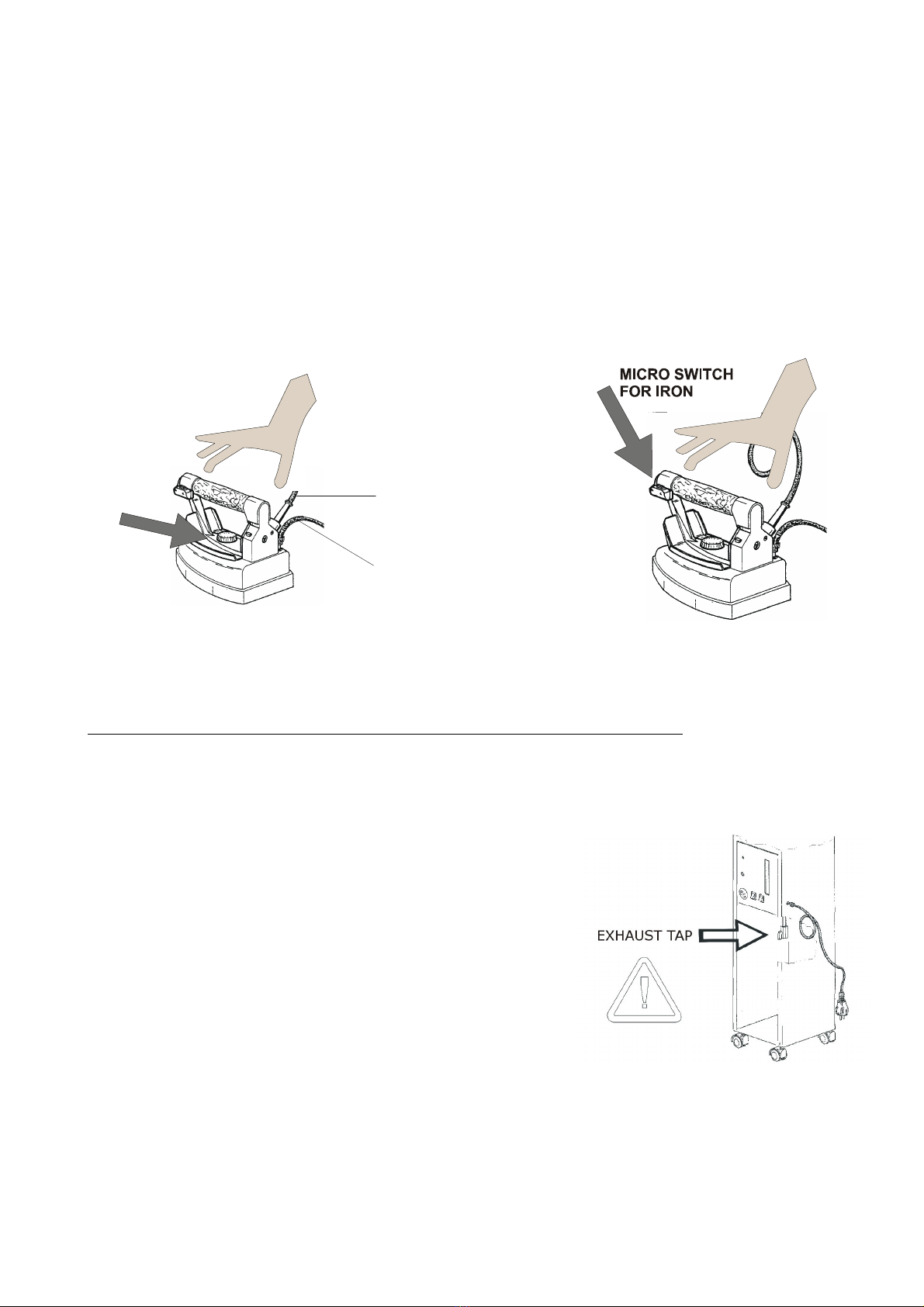

1. touching iron base when working,

2. touching the solenoid valve when the machine is under pressure,

3. emptying the boiler under pressure or touching the exhaust tap,

4. touching the valve plug when MINI 4 is under pressure.

- Do not iron garments directly on persons.

- Do not leave hot iron on garments.

- After use, always put iron on its iron rest.

15.

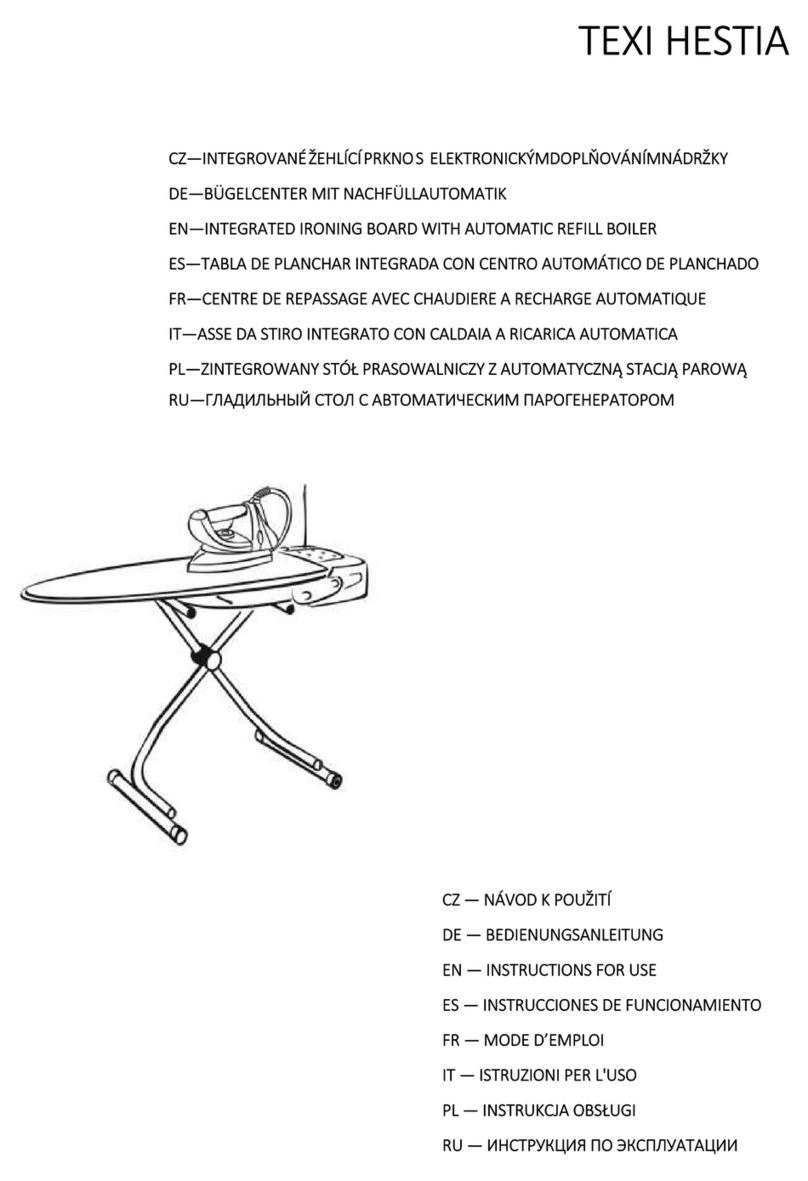

PACKING, STORAGE AND TRANSPORT

MINI 4 can be packed with cellophane and cardboard boxes. It is not a stiff package, therefore

it is not shock-resistant. We advise you to handle the box with maximum care. Do not use it as

stool or support. MINI 4 cannot be piled one on top of another (HANDLE WITH CARE).

16.

WASTE

MINI 4 is mainly made of iron and aluminium materials, therefore it must be discharged in

proper warehouses for used iron recovery. A smaller part consisting in gaskets and rubber

screws may be discharged in urban litterbins.

Every product manufactured by ROTONDI GROUP S.r.l. is sub ect to the following limitations:

ROTONDI GROUP S.r.l. guarantees that this machine, correctly installed and used, works

accordingly to this manual of instructions. Each implicit guarantee is limited by law as from purchase

date.

INCANDESCENT

IRON BASE