pag. 2

Series Mini 5REV. 2015

3.

OPENING OF PACKAGE

1.

2.

3.

4.

5.

4.

CONNECTION AND STARTING

5.

COMPULSORY

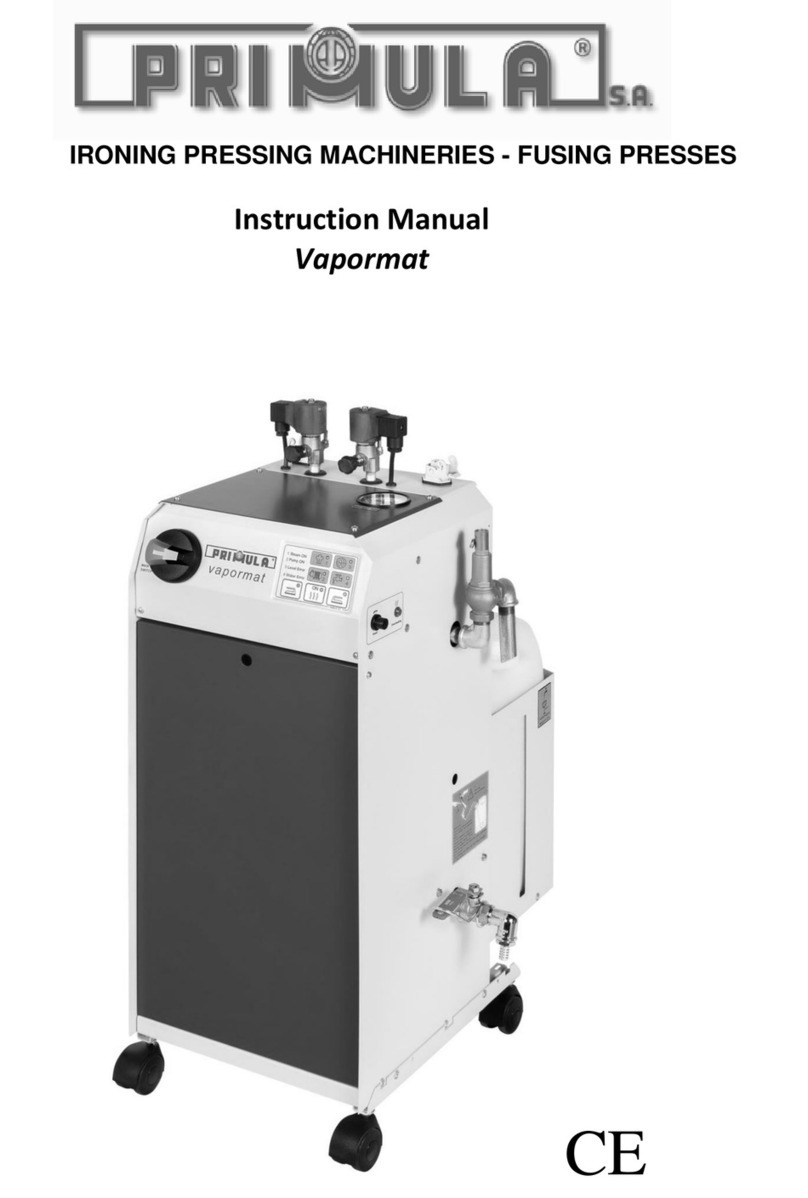

Open the box containing MINI 5, take the instruction manual and read it carefully.

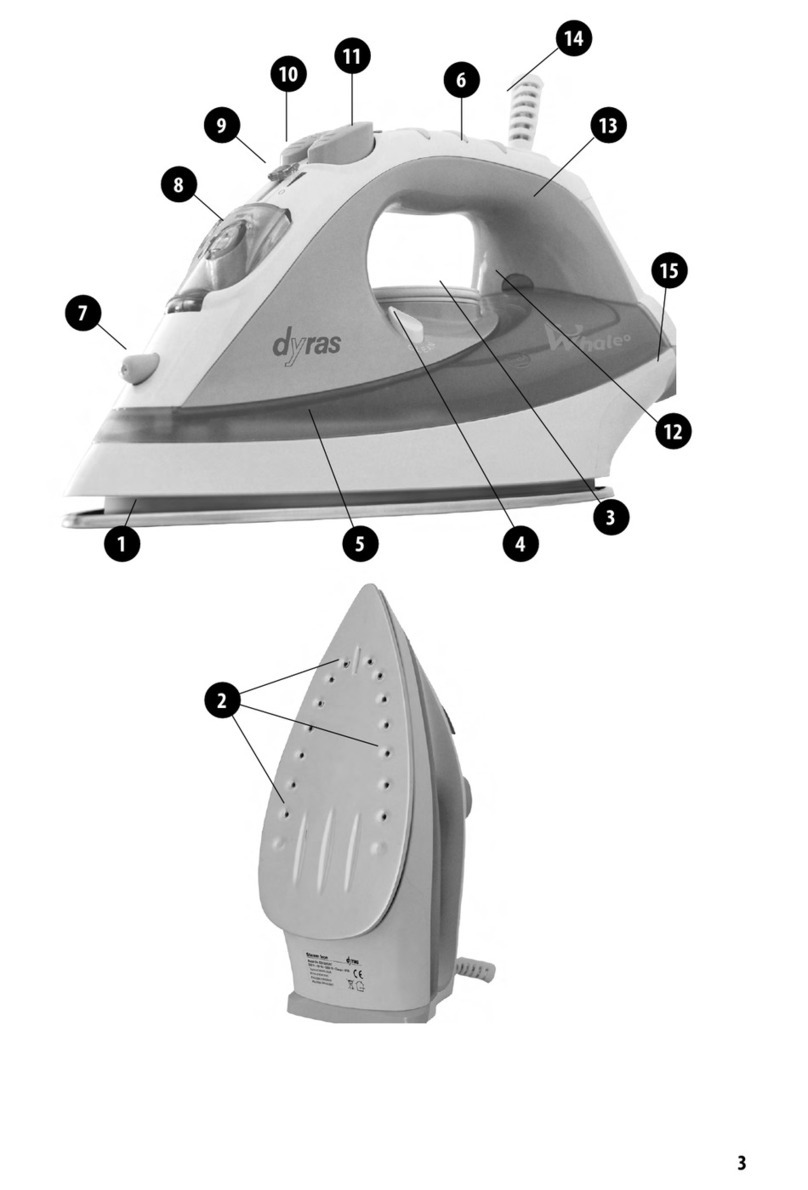

Remove MINI 5 from the box, insert the cable support deep into the

special support holder (fig. 1) placed on the back side of the generator.

Fix iron cable to the support hook (avoid twining).

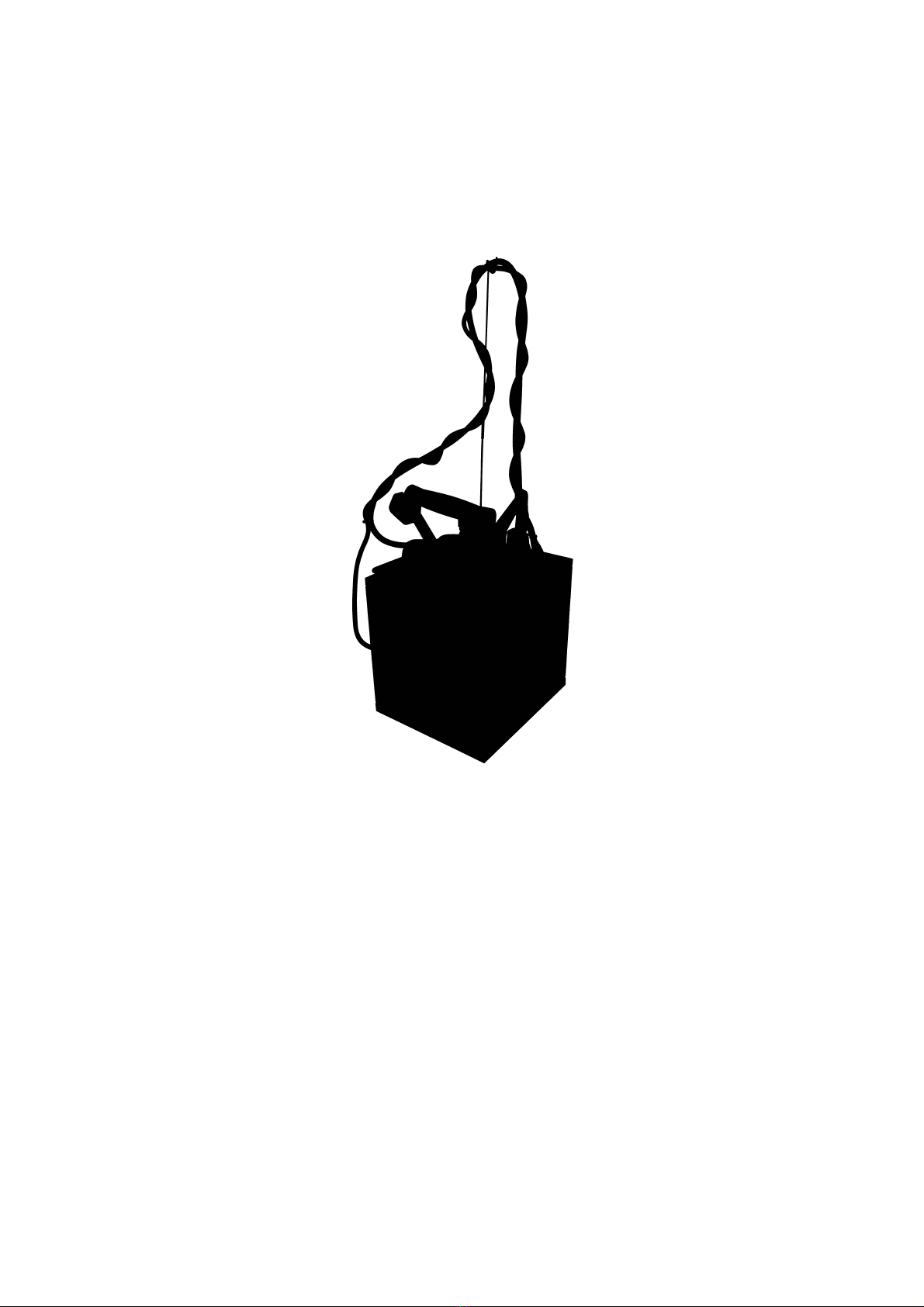

For MINI 5 supplied with trolley: screw the trolley knob on

the proper connection under the base of the machine .

With MINI 5 switched off and disconnected plug:

1. Unscrew the security valve plug (fig. 3), fill the

boiler with water (fig. 3) till overflow or at

pleasure. Take the plug by the plastic part and

screw it again: do not tighten too much or its

gasket might get spoilt.

Insert the plug into a 220 V 16 A socket.

Switch on the boiler (fig. 2 A), the iron (fig. 2 B)

and adjust the thermostat (fig. 5) on “cotton”.

Wait for the boiler lamp to switch off (fig. 2 C).

At this point seize the iron by cork handle and

press red button 3 or 4 times (fig. 6), so that

steam comes out: this operation must be carried

out in order to heat up the tubes which take

steam to the iron. In this way you prevent also

the falling of small drops of water on garments.

To adjust steam flow, you must work on the hand-

wheel for steam adjustment (fig. 3). During

ironing operation, the boiler lamp switches on and

off (fig. 2 C).

2.

3.

4.

Use only normal water coming from the aqueduct.

Never add additives to water.

Empty the boiler only when it is switched off and cold (with no

pressure) less than 0,5 Bar (fig.2 E). For carrying out this operation,

wear gloves against possible burns.

1.

2.

3.

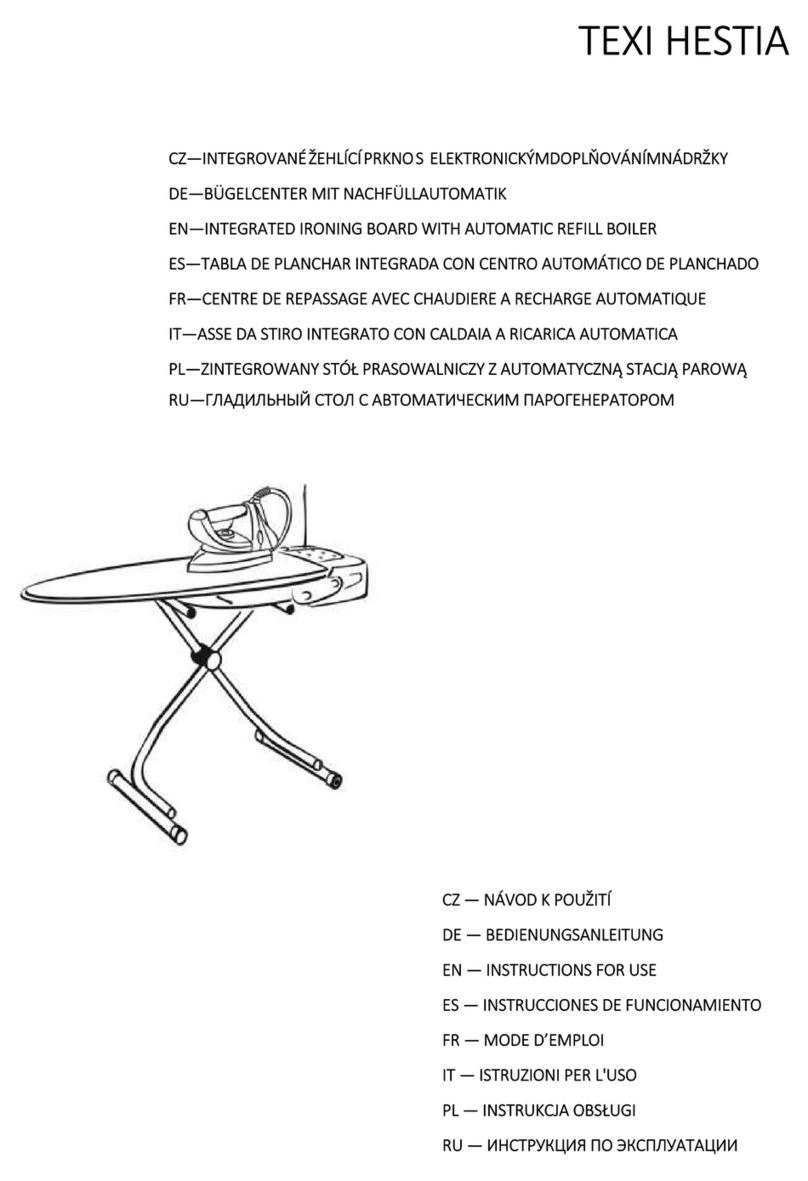

Put the iron on its rubber iron rest (Fig.1).

Fig. 2

SECURITY VALVE PLUG

(FILL IN WATER)

SOLENOID VALVE

HAND-WHEEL FOR

STEAM ADJUSTMENT

Fig. 3