RS Technical Services MINI TRACTOR STANDARD User manual

Document Number 900-21806 Rev B

Design and Manufacture of Video Pipeline Inspection Systems

A full Service Company

www.rstechserv.com

M

MI

IN

NI

I

T

TR

RA

AC

CT

TO

OR

R

S

ST

TA

AN

ND

DA

AR

RD

D

M

M

Mo

o

od

d

de

e

el

l

l

3

3

32

2

2-

-

-3

3

30

0

00

0

00

0

0

O

OP

PE

ER

RA

AT

TI

IO

ON

NS

S

M

MA

AN

NU

UA

AL

L

M

M

M

a

a

a

d

d

d

e

e

e

i

i

i

n

n

n

t

t

t

h

h

h

e

e

e

U

U

U

S

S

S

A

A

A

Document Number 900-32028 Rev A 2

Table Of Contents:

Page 3 Product Information

Page 4 Technical Specifications

Page 5 Operator and Equipment Safety

Page 6 Equipment Compatibility

Page7 Accessory Kits

Page 8 Options

Page 10 Operation and System Power

Page 11 Mini Tractor Operations

Page 15 Maintenance

Page 17 Warranty

Page 18 MRA

Copyright © 2002 RS Technical Services

Document Number 900-32028 Rev A 3

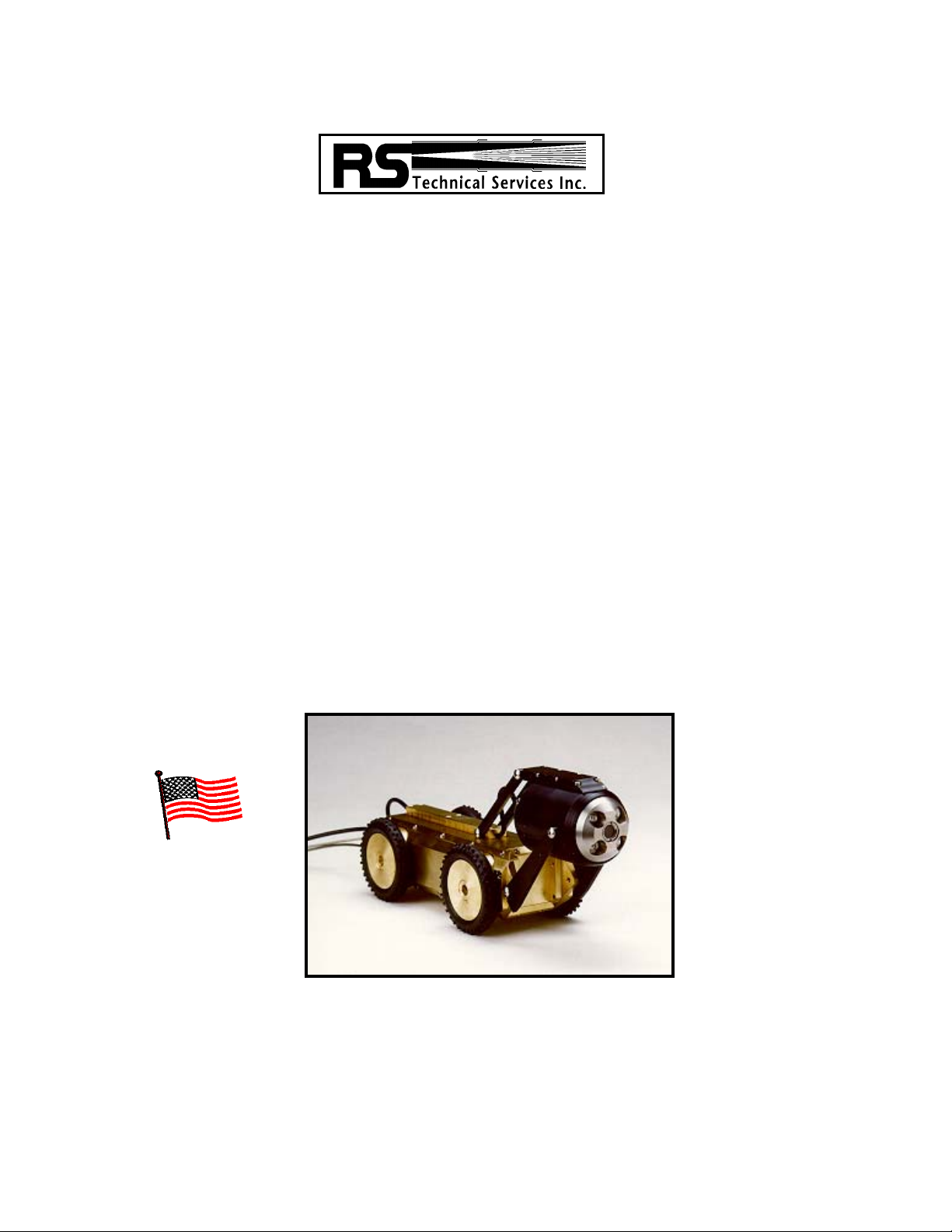

Product Overview

MIGHTY MINI TRACTOR, STANDARD

The RST Mini Tractor is a four-wheel drive inspection vehicle developed

for 4-inch lines. It has an adjustable (manual) camera mounting for central

viewing in lines up to 12 inches with an optional set of tires. The Mini Tractor

is designed to transport R.S.T. 1300 series cameras. It can be supplied with a

dedicated camera or with a dual-purpose camera used with the R.S.T. Push

Cable System. The Push Cable Cameras already in field need on a minor

factory modification to allow use of the Mini Tractor to transport them. The

camera can be used with either device.

The compact, easy to use unit is adaptable for use in sanitary sewer, storm

sewer, and water main pipelines 4 inch to 10 inches (by using the optional larger

tires). The weight of the Mini Tractor can be adjusted to improve traction if needed.

Using Sincon cable, the unit travels three-speed in forward, with freewheel for

practical operation. The auxiliary control box or the hand held control box and the

Controller Power Supply control the Mini Tractor.

For optimum performance, the Mini Tractor must be clean and properly

maintained.

The Mini Tractor should be setup to the proper width adjustment for the

diameter pipe being inspected. Operate transport with the flow. Water flow should

be minimal.

The pipeline should be clean as possible.

Document Number 900-32028 Rev A 4

Technical Specifications

MINI TRACTOR

PERFORMANCE INFORMATION

Minimum Pipeline Size 4-inches

Maximum Pipeline Size 10-inches to 12-inches

Range Up to 500-feet

(depending on pipeline conditions)

Nominal Pulling Force 50 pounds with optimum traction

Speed Up to 25-feet per minute

with 2-1/2-inch tires

Power Requirement 90 to 120 Volts from Camera Cable

Motor Type Permanent Magnet

Drive System 4-Wheel Drive with 3 speed

changes

Drive Type Internal Gear and Chain with

freewheel

Tire Size 2-1/2-inch High Traction Tires are

standard issue

Camera Mount Cantilevered Sleeve

Lighting System Internal Camera Lights

PHYSICAL INFORMATION

Length 15-inches

Width 3-1/4-inches

Height 3-inches

Weight

14-pounds, no camera, with 2-1/2-

inch wheels

16-pounds with camera, with 2-1/2-

inch wheels

18-pounds, no camera, with 3-1/2-

inch wheels

20-pounds with camera, with 3-1/2-

inch wheels

Document Number 900-32028 Rev A 5

Operator and Equipment Safety

It is important to be familiar with operations, maintenance, and safety issues when working

with RST equipment.

Read the entire manual before operating the equipment.

To prevent personal injury or damage to equipment, turn off Camera power. When

making electrical connections, width adjustments and when maintaining the tractor or

camera, disconnect all power to the control station before servicing.

Inspect all transport, camera, lighting cables, and bridles before and after each use.

Replace any broken, worn or frayed bridles or cables.

Always use care when near an open manhole, and when climbing in or out of a TV

inspection vehicle. The tractor and camera assembly can be placed into the

pipeline without personnel entering the manhole. Use proper lifting ropes, cranes

and winches for lifting equipment in/out of pipes.

Document Number 900-32028 Rev A 6

Equipment Compatibility

The R.S. Technical Service Mini Tractor is designed for use with mainline vehicle mounted

systems as well as Portable Mainline systems. This transport requires the use of a power

unit, control box, cable reel and camera.

It may be possible for the RST Mini Tractor to operate with other brands of inspection

equipment. Contact your dealer or RST for possible applications.

Document Number 900-32028 Rev A 7

Accessory Kits for Mini Tractor

The RST Mini Tractor generally comes with the following accessories:

840-30967 KIT, ACCESSORIES, MINI TRACTOR

1701-30543 BOX, TOOL, PLASTIC, W/TRAY 1.0 EA.

2 701-15593 BAG,PLASTIC,2.5 X 3,4 MIL 1000/CS 1.0 EA.

3 316-16857 WASHER,FLT,#6,.438OD,.040T SS 5.0 EA.

4 301-12007 MSCR,PAN,PHH,6-32X.37 SS 5.0 EA.

5 301-11653 MSCR,PAN,PHH,6-32X.25 SS 5.0 EA.

6 560-16073 ADPTR,CBL,10",TNCf > 3PIN MALE PIGTAIL 1.0 EA.

7 867-30925 ASSY, WHEEL ,HEX DRIVE,W/3.5" KNOBBY TIRE, MINI TRACTOR V2 4.0 EA.

8 867-30926 ASSY,CBL,3 PIN MALE(SCREW-ON) - 3 PIN FEM (PUSH-ON) PIGTAIL 1.0 EA.

Document Number 900-32028 Rev A 8

Options

A Dedicated Color Mini Camera

A Dual Purpose Color Mini Camera that can be used with a Push Cable Reel.

Alternative Tire types

Alternative Cable types

Addition bolt on weight.

Document Number 900-32028 Rev A 9

Placement of Inspection Truck

Locate the back of the truck so that the cable reel lines up in the direction of the

pipeline to be inspected.

Allow room to work around the opening while carrying the equipment.

Pull camera/tractor far enough into pipeline to clear the bridle or cable grip.

Check all camera and tractor functions again before proceeding.

Move tractor forward so the rear of the tractor and the cable connections are fully

inside the pipe.

Set up down-hole poles, shoes and manhole roller.

Reset the footage counter.

Release the drag brake on the cable reel.

Set cable reel in the free wheel.

Keep enough room to work around the opening while carrying the equipment.

Placing the equipment into the line

Follow cable grip, bridle and pig tail instructions.

Re-check the pipeline size and extension adjustments.

Do not let cable “loop” at the location where it enters pipeline.

Use guide poles with hook to keep the Mini Tractor stable as it enters pipeline.

Caution: Maintain control of equipment while loading and unloading into

manhole.

Most equipment damage occurs when camera is lowered into hole.

Pull camera/Mini Tractor far enough into pipeline to clear the bridle or cable grip.

Set the cable guide.

Use double roller and/or single rollers, for protecting the cable and allowing it to

slide down the hole without drag on the line.

Use enough poles to clear top of the manhole by 2 feet

Caution: Watch out for people, power lines and traffic when handling the

downhole pole

Document Number 900-32028 Rev A 10

Operation System Power

CAUTION: NEVER HOOK UP OR DISCONNECT ANY EQUIPMENT WITH

POWER TURNED ON!

The Inspection System requires a steady supply of 120VAC to operate properly. Before

starting of the generator or connecting shore power, make sure that ALL equipment inside

the vehicle has been turned OFF. Turn down the controls for camera power and cable reel

speed. After all equipment has been checked, connect the shore power cord.

If a generator is to be used, allow the generator to warm up for a few minutes.

Note: Diesel generators use a different control panel that is separate from the controller

power supply. Refer to the appropriate generator operator’s manual for starting.

Verify that the voltage and frequency indicators on the controller power supply are in the

green zone.

Caution: Before turning on any equipment, plug the keyboard into the

data collection system. Plug the Auxiliary Control Box into the

Auxiliary Control jack on the controller power supply.

Caution: If the voltage or frequency fluctuate into the red zones, DO NOT turn on

any of the equipment in the truck. Check shore power or the generator for proper

operation, or have them checked by a qualified technician.

This manual suits for next models

1

Table of contents

Other RS Technical Services Analytical Instrument manuals