4 M6624-1 ver 2.2

CONTENTS

1 INTRODUCTION......................................................................................................6

1.1 Safety.........................................................................................................................7

1.1.1 General...............................................................................................................................7

1.1.2 Explanation of warnings .....................................................................................................7

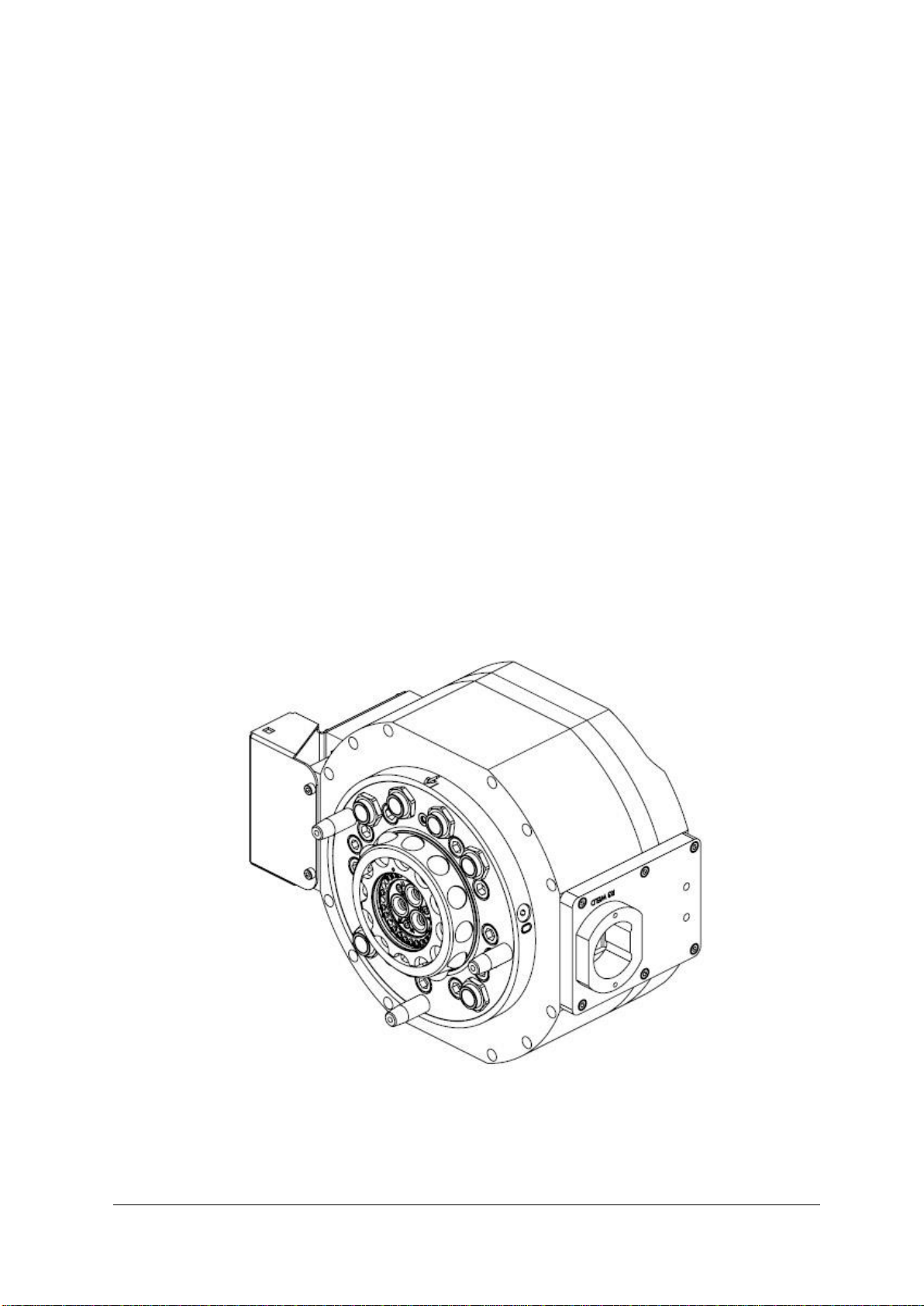

1.2 Description of RSP swivel with tool changer...............................................................8

1.3 Complementary Equipment........................................................................................8

2 TECHNICAL SPECIFICATIONS..............................................................................9

2.1 Description of swivel with tool changers and tool attachments....................................9

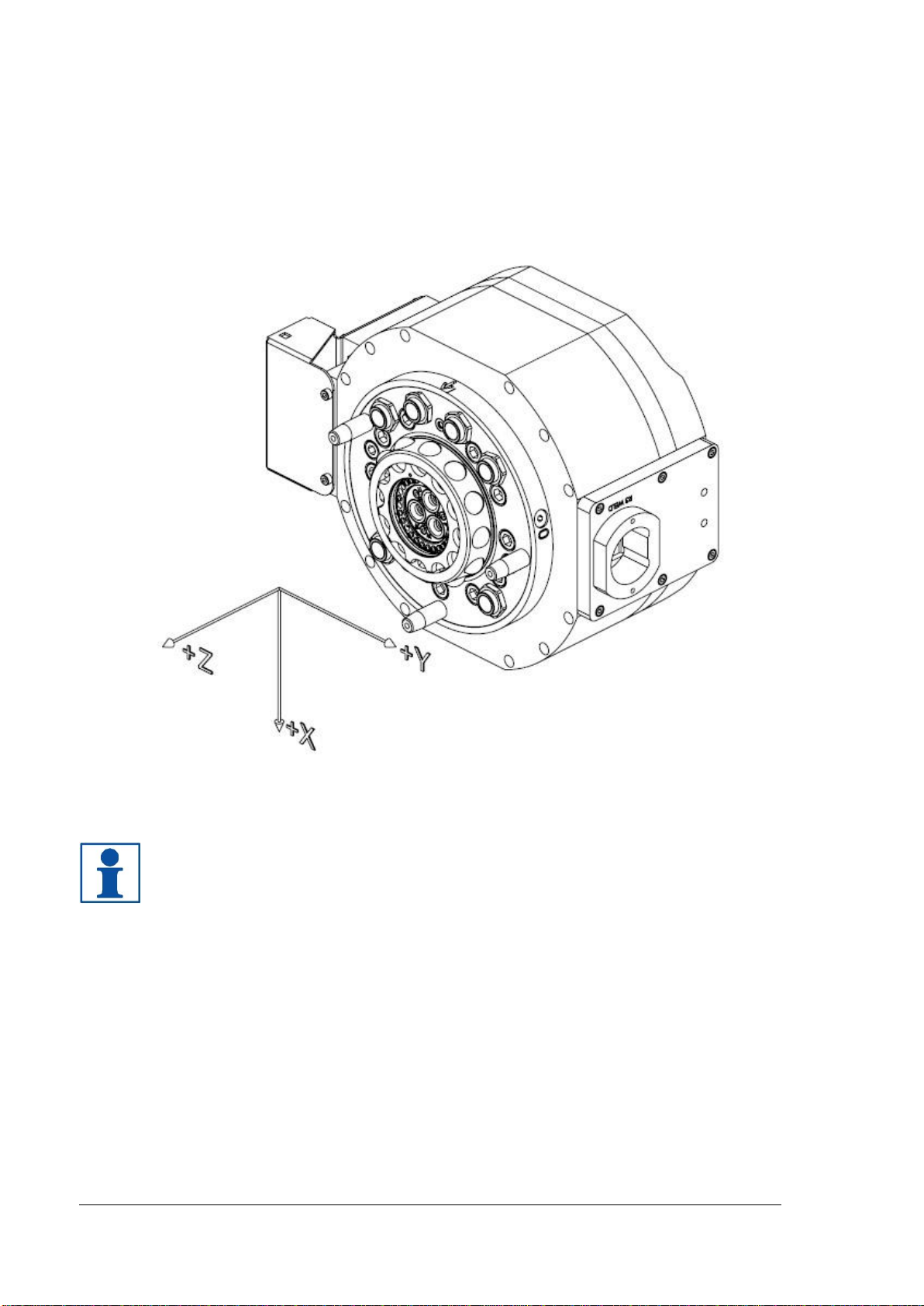

2.1.1 Coordinate System Definition...........................................................................................10

2.1.2 Swivel with tool changer STC350-SWS. Article no: P6621A...........................................11

2.1.3 Swivel with tool changer STC350-SWS with steel shaft. Article no: P6670 ....................13

2.1.4 Tool attachment TA350-SWS, Article no: P6623A...........................................................14

2.1.5 Tool attachment TA350-SWMH, Article no: P6624A .......................................................15

2.1.6 Pneumatic diagram ..........................................................................................................16

2.1.7 E0172-004 for P6621A/P6670 with P6623A....................................................................17

2.1.8 E0172-007 for P6624A.....................................................................................................19

2.2 Options for swivel with tool changer ........................................................................20

2.2.1 Robot adaptation kit/rotation stop ....................................................................................20

2.2.2 Adaptation plates..............................................................................................................20

2.2.3 Manifolder.........................................................................................................................21

2.2.3 Limitation of Robot movements........................................................................................21

2.3 Cooling water ...........................................................................................................22

2.3.1 Water without chemical additives.....................................................................................22

2.3.2 Water with chemical additives..........................................................................................22

2.3.3 Water with alkalinity exceeding pH 8.5 ............................................................................22

2.4 Connection kits and cables.......................................................................................22

3 INSTALLATION.....................................................................................................23

3.1 Tightening torques....................................................................................................23

3.2 Recommended tools for installation..........................................................................23

3.3 Installation of swivel with tool changer on robot........................................................24

3.4 Connect air and water couplings, weld and signal power..........................................26

3.5 Connections on TA350-SWS, P6623A and TA350-SWMH, P6624A........................27

3.6 Installation of tool attachment P6623A/ P6624A on tool ..........................................29

3.7 Manual unlocking of tool changer.............................................................................30

3.8 Hints.........................................................................................................................31