4 M8307-1 version 2.4

CONTENTS

1 INTRODUCTION .........................................................................................................6

1.1 Safety ..............................................................................................................................7

1.1.1 General................................................................................................................................7

1.1.2 Explanation of warnings......................................................................................................7

2 TECHNICAL SPECIFICATIONS ................................................................................8

2.1 Tool parking system overview ........................................................................................8

2.1.1 Complementary products....................................................................................................8

2.2 Tool parking system single, TPS400-1. Articles: P8365 and P8385 .............................9

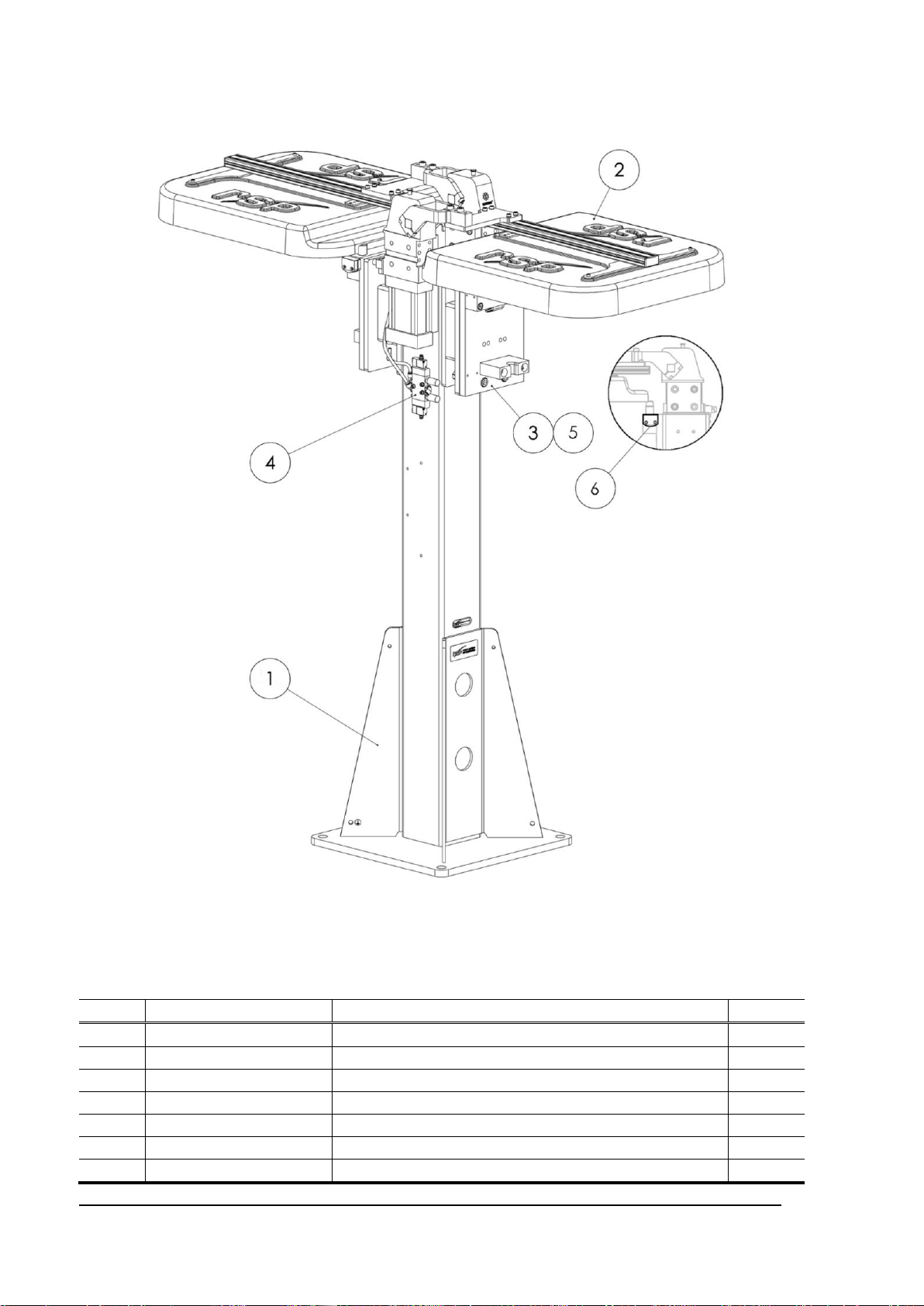

2.3 Tool parking system double, TPS400-2. Articles: P8366 och P8386......................... 10

2.4 Tool parking system single, TPS400-1. Article: P8383............................................... 11

2.5 Tool parking system single, TPS400-2. Article: P8384............................................... 12

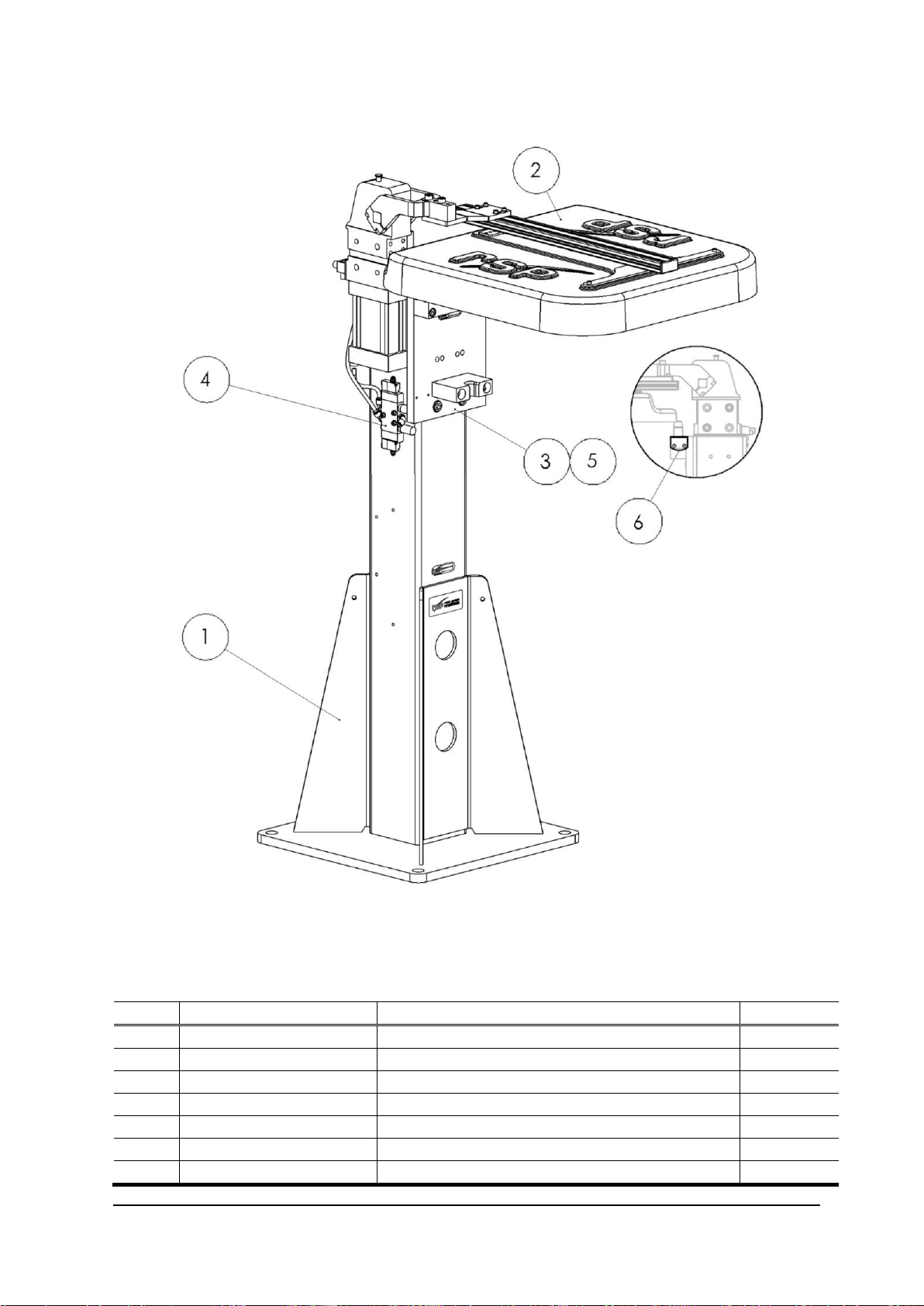

3 TOOL PARKING SYSTEM COMPONENTS............................................................13

3.1 Tool stand columns. Article: P8380............................................................................. 13

3.2 Dust covers with pneumatic tilting clamp..................................................................... 14

3.2.1 Dust cover with pneumatic tilting clamp, large. Articles: P8327/P8377............................15

3.2.2 Dust cover with pneumatic tilting clamp, small. Article: P8379.........................................15

3.3 Valve unit for dust cover. Article: P8308A................................................................... 16

3.3.1 Circuit diagram E0186-056 ...............................................................................................17

3.4 Tool hanger. Article: P8302 ......................................................................................... 18

3.5 Load diagram for tool parking system ......................................................................... 19

4 OPTIONS...................................................................................................................20

4.1 Tool plate. Article: P8303A .......................................................................................... 20

4.2 Extension for tool hanger kit. Article: P8371 / P8381.................................................. 21

4.3 Spacer between tool attachment and tool plate. Article: P0186-049.......................... 22

4.4 Tool present sensor, inductive. Article: P8312............................................................ 22

4.5 Tool in stand sensor, passive side. Article: P8369...................................................... 23

4.6 Tool in stand sensor, assembly. Article: P8364 .......................................................... 23

4.7 Spacer for tool in stand sensor. Article: P8373........................................................... 24

4.8 Pedestal for tool stand column. Article: P8376............................................................ 24

4.9 Connection module. Article: P8372 ............................................................................. 25

4.10 Connection module. Article: P8378 ........................................................................... 25

4.11 Connection module. Article: P8372-2........................................................................ 26

4.12 Connection module. Article: P8378-2........................................................................ 27

4.13 Circuit diagram E0186-075 for P8382....................................................................... 28

4.14 Circuit diagram E0186-040 for P8312....................................................................... 29

4.15 Circuit diagram E0186-062-1 for P8372.................................................................... 30

4.16 Circuit diagram E0186-062-2 for P8372-2................................................................. 31

4.17 Circuit diagram E0186-072-1 for P8378.................................................................... 32

4.18 Circuit diagram E0186-072-2 for P8378-2................................................................. 33