4 M0619-1 ver. 2.6

CONTENTS

1 INTRODUCTION......................................................................................................6

1.1 Safety.........................................................................................................................7

1.1.1 General...............................................................................................................................7

1.1.2 Explanation of warnings .....................................................................................................7

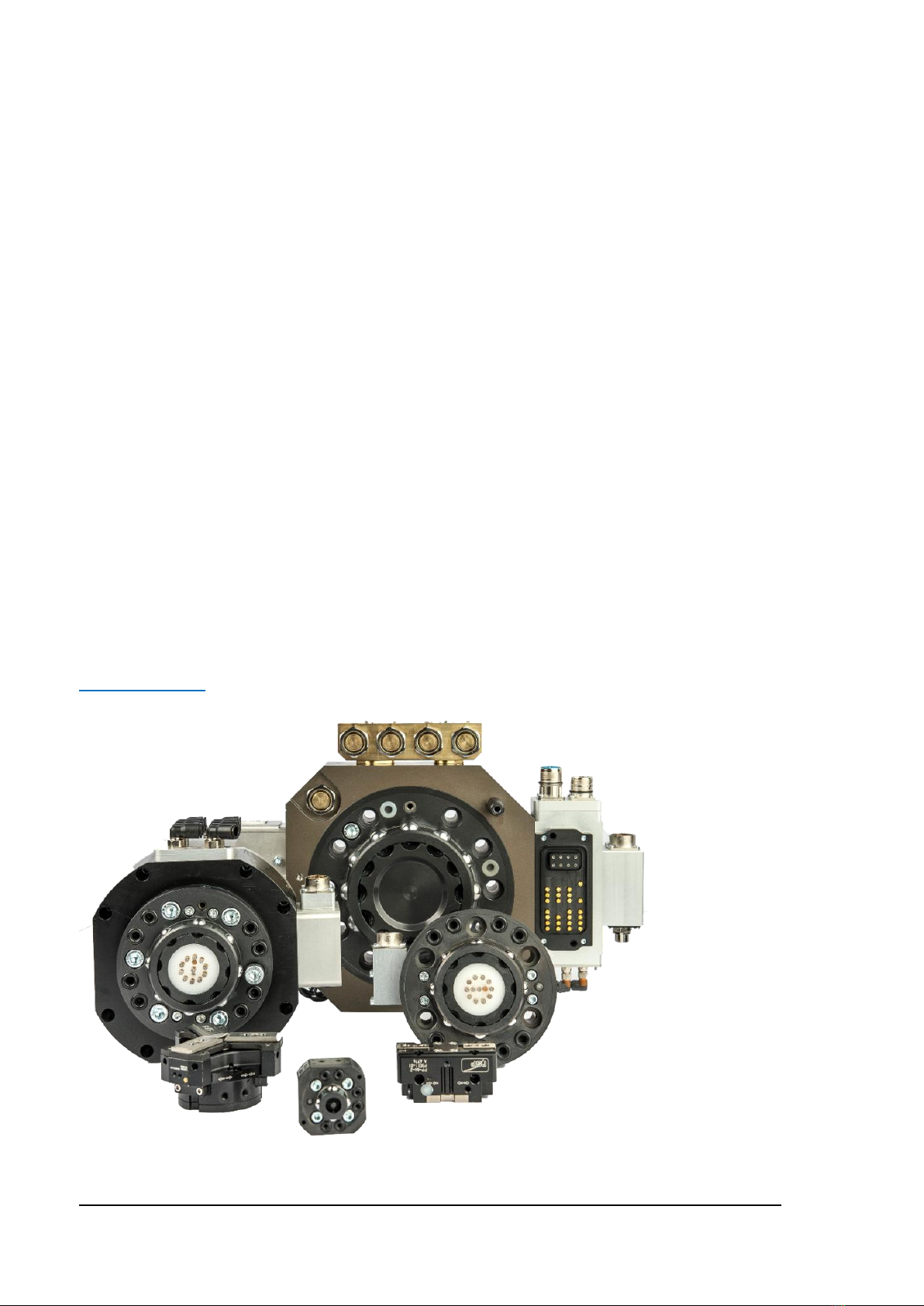

1.2 Description of RSP tool changers...............................................................................8

1.3 Complementary Equipment........................................................................................8

2 TECHNICAL SPECIFICATIONS..............................................................................9

2.1 Description of tool changers and tool attachments .....................................................9

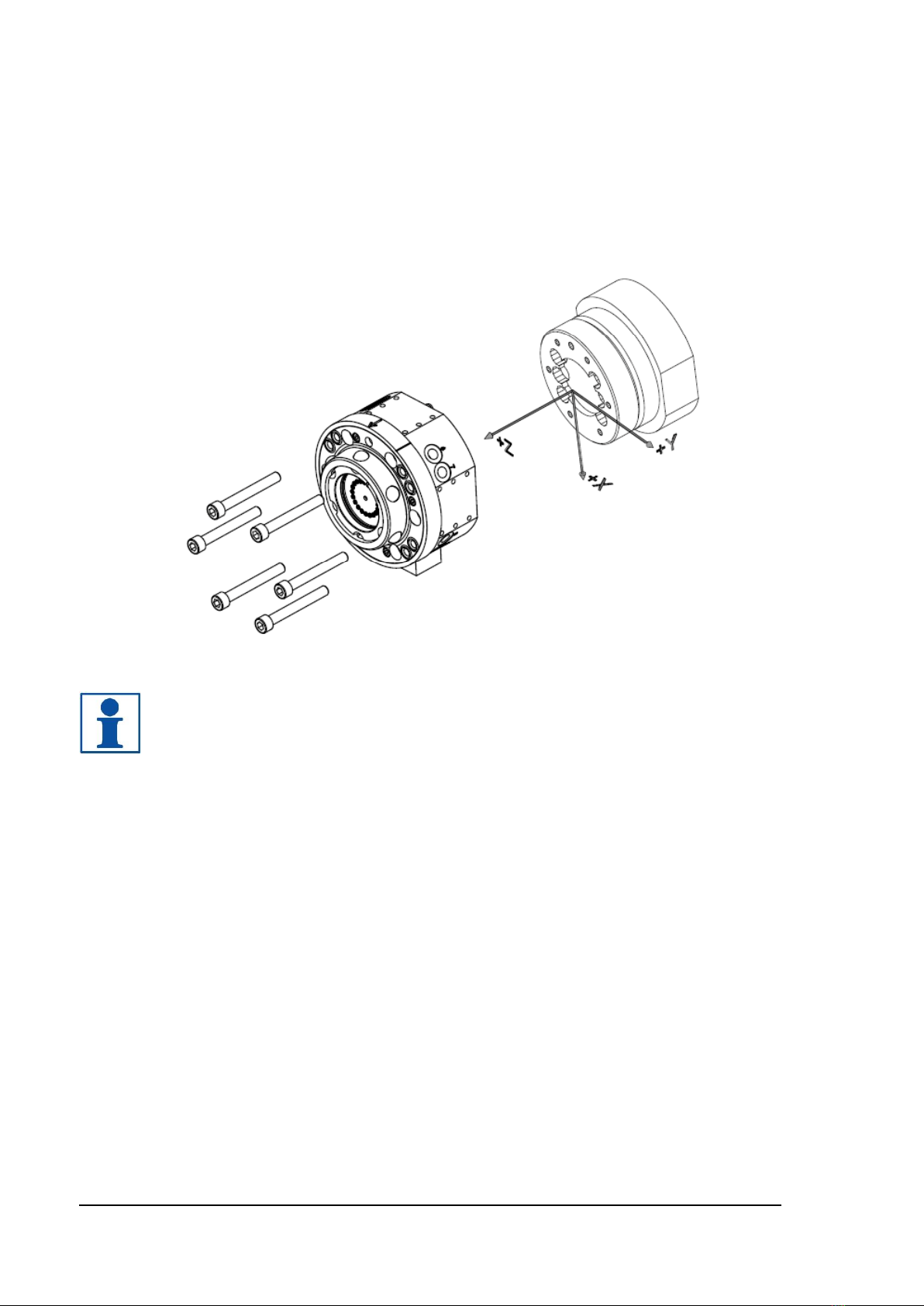

2.1.1 Coordinate System Definition...........................................................................................10

2.1.2 Tool Changer with air, TC250-8. Article no: P6411..........................................................11

2.1.3 Tool Attachment, TA250-8. Article no: P6417..................................................................12

2.1.4 Square Tool Attachment TA250-8. Article no: P6474......................................................13

2.1.5 Tool Changer with air and electric signals TC250-8E. Article: P6412 .............................14

2.1.6 Tool Attachment, TA250-8E. Article no: P6418 ...............................................................16

2.1.7 Tool Attachment, TA250-8E. Article no: P6431 ...............................................................17

2.1.8 Square Tool Attachment, TA250-8E. Article no: P6473...................................................18

2.1.9 Pneumatic diagram for tool changers P6411 and P6412 ................................................19

2.1.10 Circuit diagram E0196-001 for P6412............................................................................20

2.1.11 Circuit diagram E0196-002 for P6418............................................................................21

2.1.12 Circuit diagram E0196-009 for P6431 and P6473 .........................................................22

2.2 Options to TC...........................................................................................................23

2.2.1 Robot adaptation kit .........................................................................................................23

2.2.2 Tool stand kit. Article no: P6472.......................................................................................24

2.2.3 Limitation of Robot movements........................................................................................24

2.2.4 Connection kits and cables ..............................................................................................24

3 INSTALLATION.....................................................................................................25

3.1 Tightening torques....................................................................................................25

3.2 Recommended tools for installation..........................................................................25

3.3 Installation of tool changer on robot..........................................................................26

3.4 Installation of tool attachment P6623A/ P6624A on tool ..........................................27

3.5 Hints.........................................................................................................................28

3.5.1 Programming....................................................................................................................28

3.5.2 Sparking ...........................................................................................................................28

3.5.3 Electrical installation.........................................................................................................28

3.5.4 Tool stand.........................................................................................................................28

3.5.5 Tool Identification .............................................................................................................28