4 M0627-1 version 3.3

CONTENTS

1 INTRODUCTION......................................................................................................5

1.1 Installation and Maintenance manual .........................................................................5

1.2 Safety.........................................................................................................................6

1.2.1 General...............................................................................................................................6

1.2.2 Explanation of warnings .....................................................................................................6

1.3 Tightening torques......................................................................................................7

1.4 Recommended equipment .........................................................................................7

1.5 Required products......................................................................................................7

2 INSTALLATION.......................................................................................................8

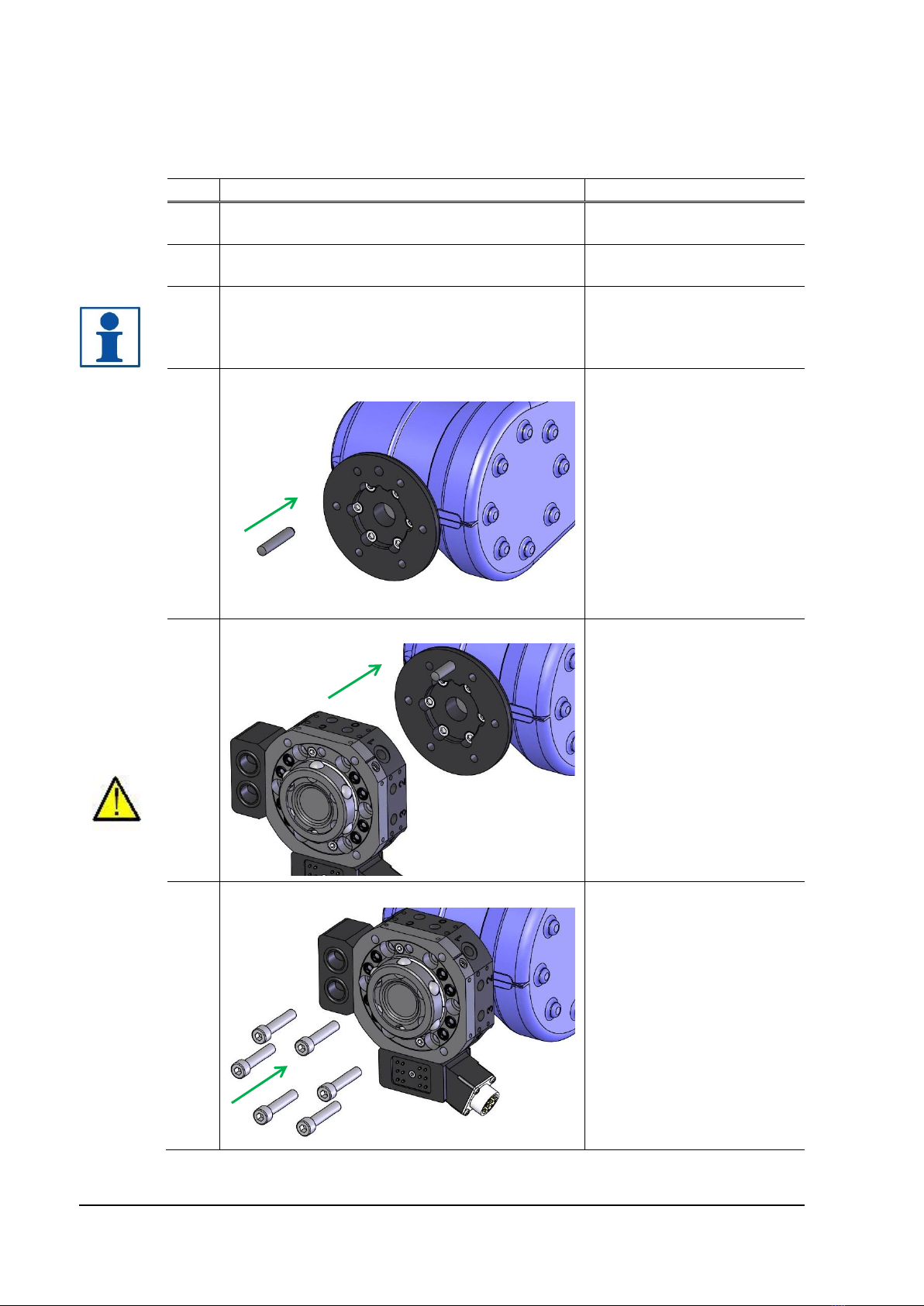

2.1 Installation of tool changer on robot............................................................................8

2.2 Installation of tool attachment to tool ........................................................................10

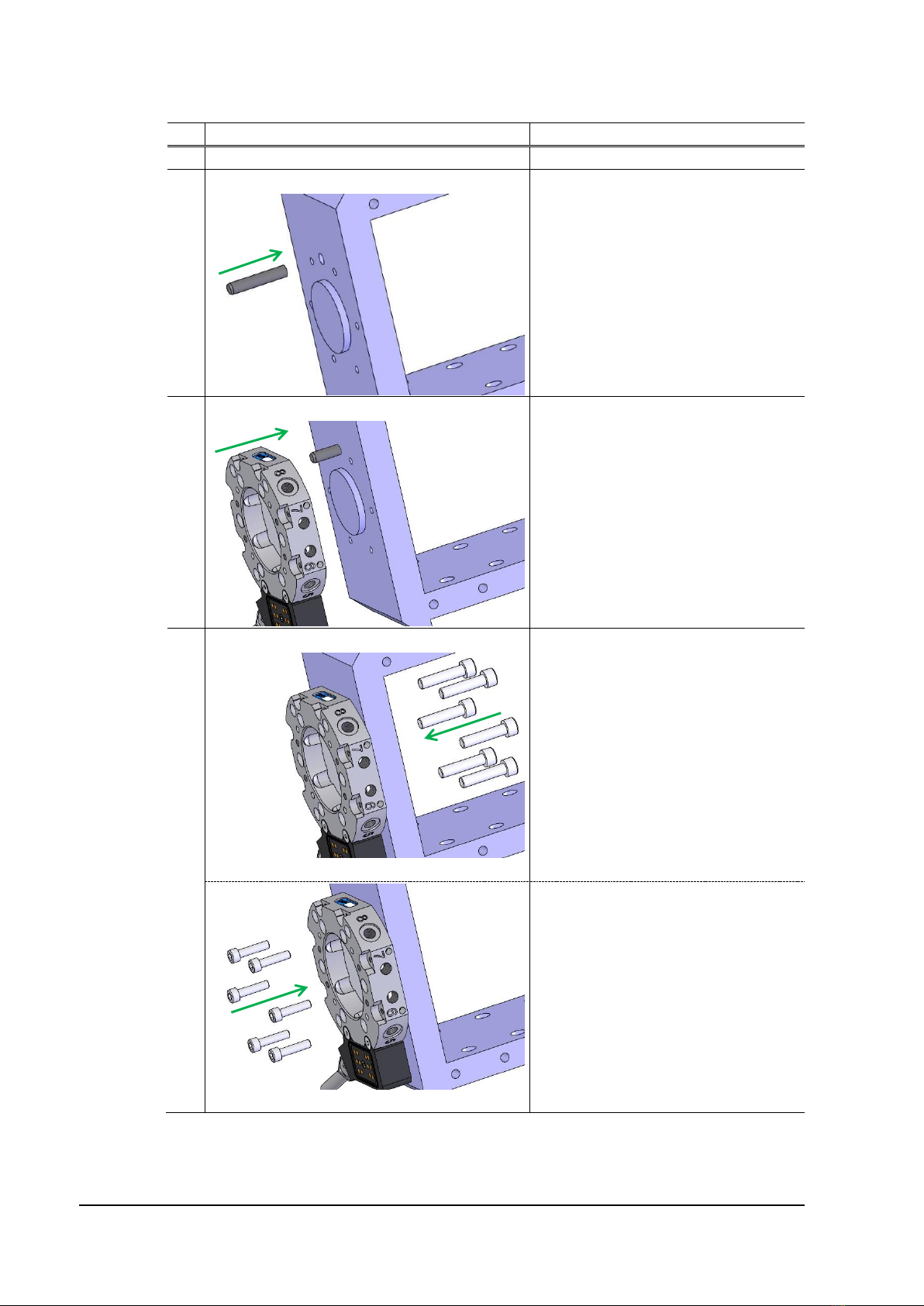

2.3 Mounting of parking bracket plate.............................................................................11

2.4 Mounting of parking bracket kit.................................................................................12

3 MAINTENANCE AND SERVICE............................................................................13

3.1 Maintenance scheme ...............................................................................................13

3.1.1 Every second week ..........................................................................................................13

3.1.2 Every six-months or 250,000 tool changes......................................................................14

3.1.3 To replace when damaged or worn-out ...........................................................................14

3.2 Specification of maintenance activities.....................................................................15

3.2.1 Visual inspection of tool changer (every 2nd week).........................................................15

3.2.2 Visual inspection and cleaning of tool attachment (every 2nd week) ..............................16

3.2.3 Cleaning and lubrication of TC (every 6th month or 250,000 tool changes).....................18

3.2.4 Cleaning and lubrication of TA (every 6th month or 250,000 tool changes)....................21

4 DISMOUNTING AND REPLACEMENT.................................................................22

4.1 Replacement of tool changer....................................................................................22

4.2 Replacement of tool attachment...............................................................................24

4.3 Replacement of wear parts.......................................................................................26

4.3.1 Replacement of air sealings on TC180............................................................................26

4.3.2 Replacement of air sealings on TC60, TC120 and air module, TC-side..........................27

4.3.3 Replacement of guide pins (P1314) on tool changers.....................................................28

4.3.4 Replacement of spring-loaded signal pins on signal interface, TC-side..........................29

4.3.5 Replacement of signal, servo power, high voltage interface and air module, TC-side....30

4.3.6 Replacement of signal interface/air module, TA-side ......................................................31

4.3.7 Replacement of O-rings on signal interface, TA-side ......................................................32

5 DISPOSAL AND RECYCLING ..............................................................................33