INM725B 725B Instruction Manual – Rev 21

Page 2 of 124

SECTION 1 - INTRODUCTION .................................................................... 6

General ...........................................................................................................................6

Programmable Features..................................................................................................6

Glossary of Terms...........................................................................................................7

Annunciator Model Code Definition .................................................................................8

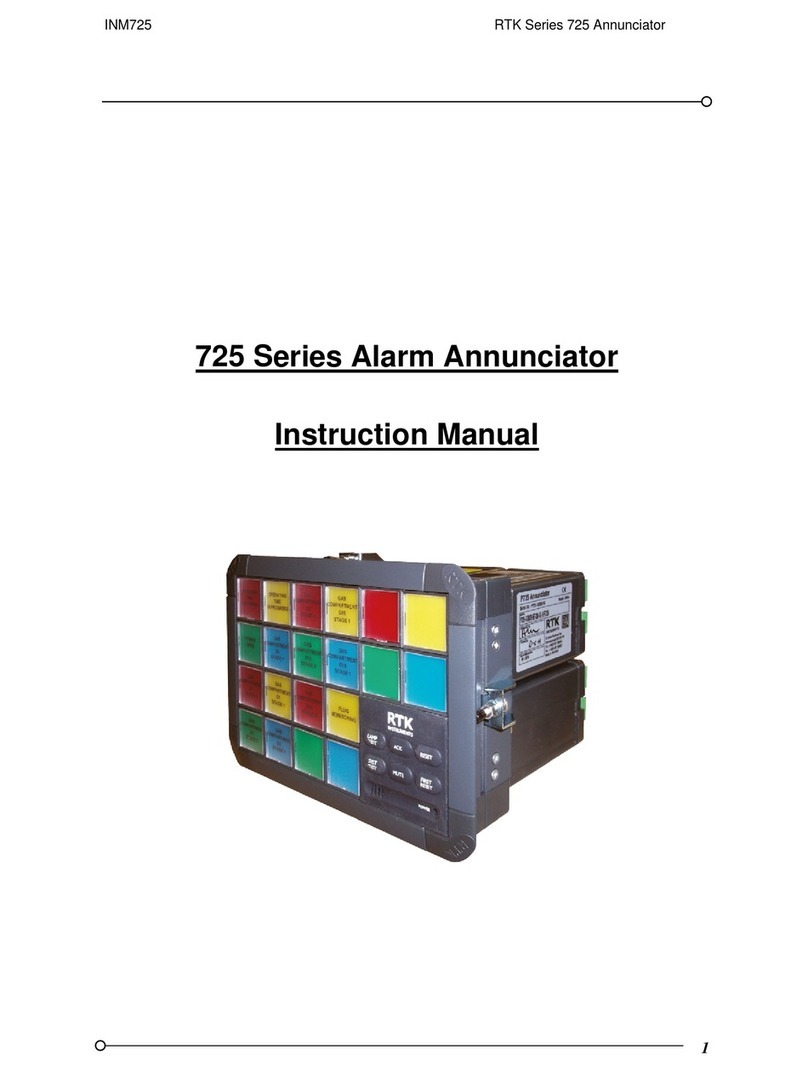

Product Overview..........................................................................................................10

System Front View ........................................................................................................10

Window Illumination.......................................................................................................11

Window Colours ............................................................................................................13

Adding or Changing Film Legends ................................................................................13

Filter & Bezel Spare Parts Numbers..............................................................................14

Laser Printed Legends ..................................................................................................14

Window Numbering System ..........................................................................................14

Integral Pushbutton Module...........................................................................................15

Watchdog Monitoring LED’s..........................................................................................15

USB Programming port .................................................................................................16

CAL Mode .....................................................................................................................17

Signal Input Contact Status...........................................................................................18

Configuring Alarm Inputs for use with N/O or N/C field contacts....................................18

Remote Pushbutton Module..........................................................................................20

Audible Alarms..............................................................................................................20

SECTION 2 – CELL TYPES....................................................................... 21

A Cell Detail...................................................................................................................21

A Cell - Differential Input Version...................................................................................22

AR Cell Detail................................................................................................................23

AR Cell - Differential Input Version................................................................................24

AP Cell Detail................................................................................................................25

APR Cell Detail..............................................................................................................26

AP6 Cell Detail..............................................................................................................27

AWR Cell Detail.............................................................................................................28

AS Cell Detail................................................................................................................29

AS Cell - Differential Input Version ................................................................................30

S Cell Detail...................................................................................................................31

SS Cell Detail................................................................................................................32

WR Cell Detail...............................................................................................................33

WRS Cell Detail.............................................................................................................34

WRR Cell Detail ............................................................................................................35

Optional WR Cell Detail.................................................................................................36

WRP Cell Detail.............................................................................................................38

AC Cell Detail................................................................................................................39

APC Cell Detail..............................................................................................................40

C Cell Detail ..................................................................................................................41

WRC Cell Detail ............................................................................................................42

ACE Cell Detail..............................................................................................................44

WRCE Cell Detail..........................................................................................................45

CEC Cell Detail .............................................................................................................46

PCE Cell Detail..............................................................................................................47

USB Programming Port Location...................................................................................48

SECTION 3 – LOGIC SUPPLY & FUSING................................................ 49

Externally Powered Systems.........................................................................................49

SI/O Card Versions........................................................................................................49

Systems using Internal Power Cards.............................................................................50

SI/O Card Versions........................................................................................................50

SECTION 4 – POWER SUPPLY MONITORING ....................................... 51

Power Monitor Relays ...................................................................................................51

Power Monitor LED’s.....................................................................................................51

Setting Inputs for use with 24VDC or 125VDC ..............................................................52

Setting Inputs for use with 24VAC or 125VAC...............................................................52