C. INSTRUCTIONS

English

4.

TRANSLATION OF THE ORIGINAL

Assembly

Once you have unpacked your machine, check to make sure that there are no damaged or

broken parts. If there are and they need to be changed these must only be replaced by original

of the manufacturer.

We recommend two people for transporting of the machine, although the wheels allow trans-

port by one person .

The DC machines are supplied and packed with the supporting legs in transport position and

the wheels disassembled.

1.

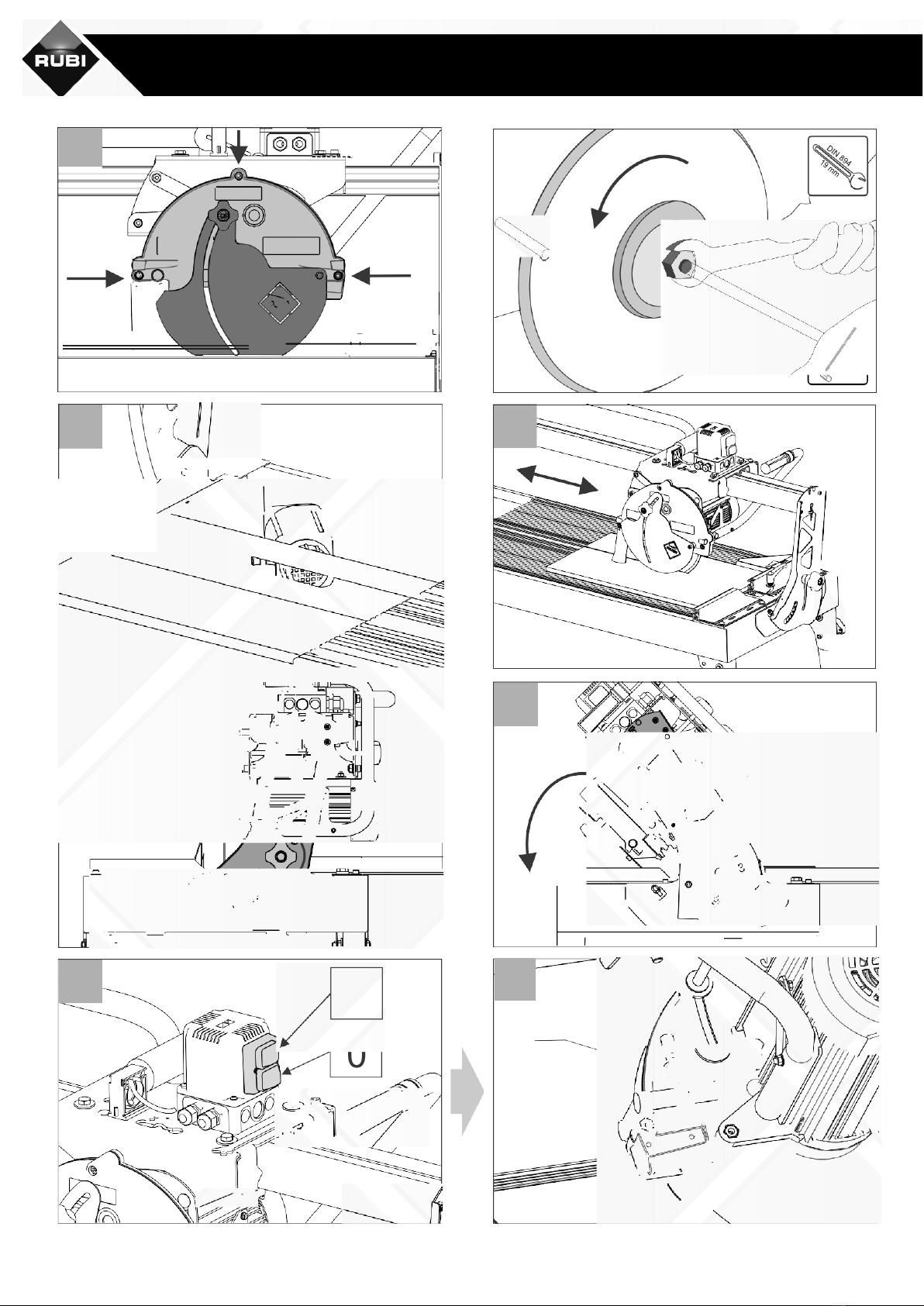

Assembly and deployment of machine ( fig.1, 2)

2.

It is recommended that the machine only be operated on smooth, level surfaces. Also,

verify that the machine is properly fixed to the floor before beginning to work.This will

provide safe working conditions.. (fig. 3, 4)

3.

The movable head of the machine is fixed to the side support to avoid movement during

transport (position A or B).To release the head: remove the pin C and place in position

D

.

(

fig.

6,

7,

8)

Safety

Read carefully and understand the safety measures before using the machine.

Among other safety measures, DC machines have a safety system that prevents direct contact

with the blade while cutting.

Electricity

Coil feeding cable during transport. Never move the machine by tugging at the cable.

Machines sold without their cables. Please see references for cable on pages 22.

Applications

Use: Models DC are professional precision machines for the straight or mitred cutting of buil-

ding materials, and work by means of a guided bearing system. Such cuts are made with water-

cooled diamond blades.

Working area advises

Pay close attention to the state of the area where the job is to be done. Keep it clean and well

lit.The machine should be kept clean at all times in order to ensure optimum performance and

the safest working conditions.

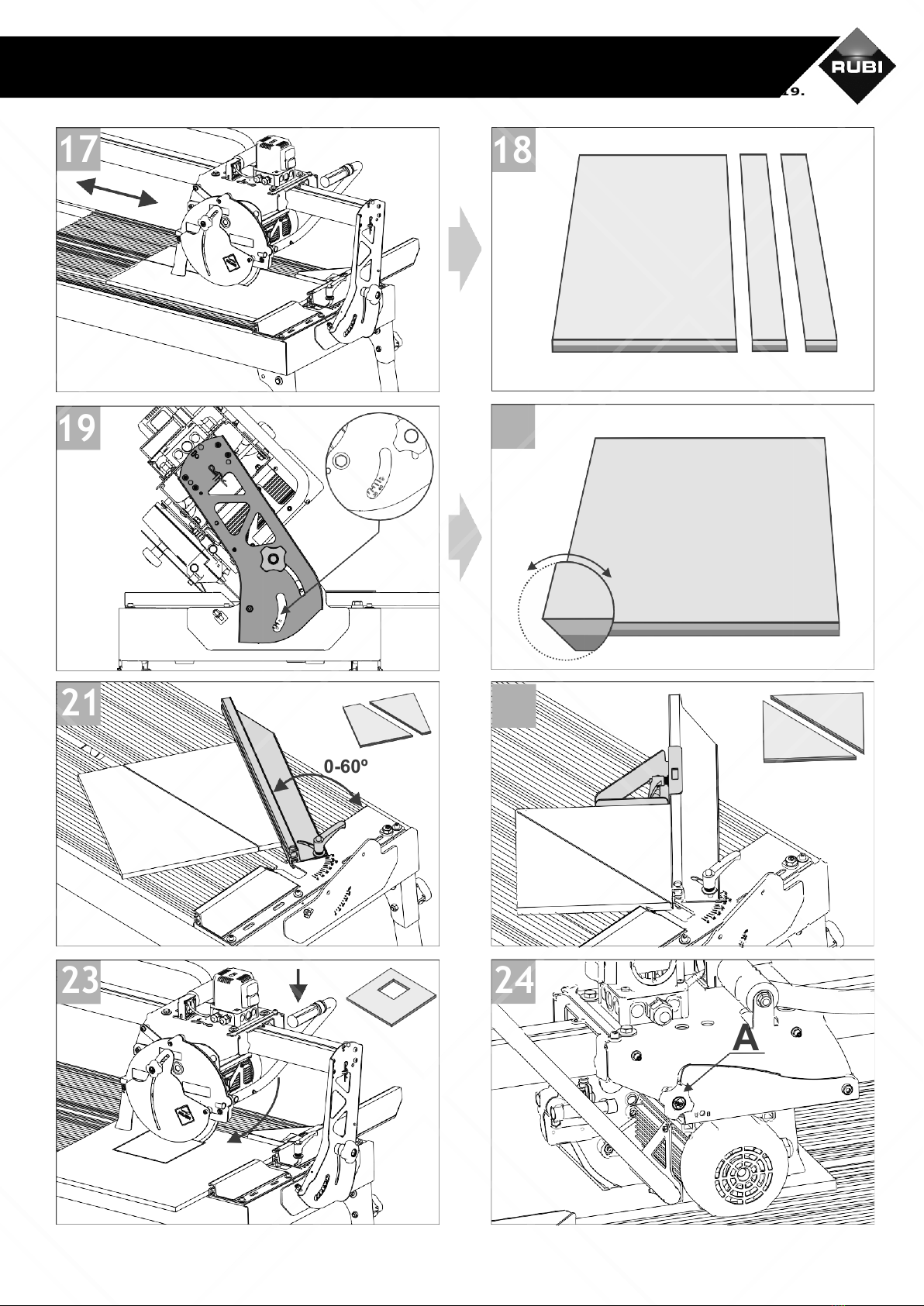

13. The additional table offers a greater surface for support while cutting large pieces, and

can be situated on both sides of the machine.(pag. 22 / ref.54993). For 45º cuts (mitred

cuts), there is a system of mechanical blockage, which enables you to position the head

with great precision. (fig. 19, 20)

14.

The bracket (A) assembly rotates between 0 ° and 60 ° (factory set) supporting the

pieces to cut and allows repetitive cutting (fig. 21). (B) side stop, permits repetitive cutting

of 90 ° and 45 ° accurately. (fig. 22)

15. The cutting head permits the plunge effect,Which allows adjustment in blade height.The

Recoil is by a spring that at the same time compensates the motor weight as improves

user ergonomics.The knob (A) allows the lock of the discs position. (fig. 23, 24)

16.

To get a quality cut either normal or 45 degrees, it is very important to work on level

ground. (fig. 3,4)

17.

Never use a cracked or chipped diamond blade.

18.

Do not brake or stop the blade by lateral pressure.

19. By keeping cutting tools clean, you ensure better performance and enhanced security:

•

Carefully follow the instructions when changing accessories.

•

Periodically check the cables of this machine, If they are damaged repair them at an

authorised technical service.

•

Keep handlers clean, dry and free of grease and oil.

20.

Remove tools before starting the machine.

21.

When using the machine outdoors, use only extensible cord designed for this purpose.

22.

Before using a machine again, check carefully to ensure that it is in proper working

order for the task you have in mind for it. Any damaged element, whether protective

or not, should be repaired or replaced by an authorised technical service outlet, unless

otherwise specified in this instruction manual. Do not use the machine if it cannot be

switched on and off.

23. It is essential to have adequate lighting in work areas.

24.

Recommended working temperatures should be between 5 and 40 ° C and between 0.8

and 1.1 bar. (maximum humidity 95%)

25. Wheel assembly of the machine. (fig. 25)

Checking list

Before using this machine, verify that no parts are worn out, damaged or broken. Should you find

any part that is not in proper condition, have it repaired or replaced immediately.

Check that the stops of the machine are perpendicular to the blade. These are regulated before

leaving the factory. Ensure that the voltage and frequency of the machine shown on the charac-

teristics plate match the electric system. (fig. 5)

The electrical outlet must have an earth connection and protection in the event of leaking (diffe-

rential).When using an extension,check that the cable section is at least 2.5 mm².

The blade protector protects the user from potential injury while cutting.When cutting, the top

will be adjusted according to the thickness of the piece to be cut.

If the disc is mounted incorrectly, proceed to stop the machine and re-assemble.

1.

Read these instructions carefully before using this product and save. Keep them in a safe

place for future reference.

2.

To install or replace the blade, first remove the protective cover, place the blade between

the discs flanges, turning in the direction shown on the machine. Tighten the screw as

illustrated. (fig. 9, 10)

3.

Fill the frame tank with water until the water pump is completely covered.Working with

clean water gives your blade longer working life and improved performance. (fig. 11)

4.

Models DC are equipped with a table-stand for placing the ceramic tile, and a sliding motor

unit. This system enables you to handle all types of ceramic tile with maximum precision

and comfort. (fig.12)

5.

The sliding is done through wheels with ball bearings greased and sealed.

6.

To prevent accidents, shut the motor off when changing from the straight cutting position

to that of mitred cutting (and vice versa), and adjusting stops for repeated cuts. (fig. 13

and 14)

7.

Start the machine by pressing the green switch and turn off with the red. (fig. 15)

8.

Models DC have a safety system that protects the motor from overheating.

9.

If the motor should stop for no apparent reason, wait a few minutes as it has probably

been overworked. Moderate the cutting speed.

10.

Once the machine is operating, wait until the motor and the water supply by the pump

return to normal (4 or 5 seconds).The flow of water for cooling the blade can be ad-

justed using tap A. (fig. 16)

11.

To make correct cuts, guide the blade firmly and evenly, without brusque movements and

without forcing the motor. One incorrect move can break the work piece and seriously

damage the blade. (fig. 12)

12.

DC machines make it possible to make precise parallel cuts for repetitive projects using

Cleaning and maintenance

1.

Before cleaning, repairing or transporting the machine it must be turned off and unplu-

gged.

2.

Do not use aggressive cleaning products for cleaning the machine.

3.

Do not immerse The machine in water.

4.

Examine periodically the machine cables, if they are damaged must repair them through an

authorized technical service.

5.

Keep handles dry, clean, free of grease and oil.

6.

To keep your machine in good condition, run clean water through the cooling system

after every use and cleanse the machine.

7.

Before cleaning the machine, remove the lower tray. Having previously positioned a buc

ket to collect the water, the decanter will fall into it. Regularly check the disk head set and

proceed to adjust it if necessary. Slightly loosen the screw nut B and C. Gently tighten the

prisoner D with the help of a 4 mm wrench. Check the head set and tighten the nut C,

B below. (fig. 26, 27)

8.

With continued use, or abuse, the square guide can lose squareness.To adjust it to exactly

at 90º place a bevel aligned to the disc at 90º supported in the square and act on the three

screwsA (fig. 28).

9.

To square the disc at 90º, remove the disc protectio n cover (3 screws) (fig.9), loosen the

locknut A and B, place the bevel on the table touching the disc. Adjust the tilt of the disc

through the prisoner C. Ensure that the upper and lower bevel touches the disk at once.

Tighten nut B and knob A below. Perform this on both sides of the machine (fig. 29, 30).

10.

We recommend cleaning the tracks of the guide with a cotton cloth dampened with

water.You do not need any lubrication.

11.

The machine put out off service must be carried out according to the instructions of

each country at a collection point, for proper classification and treatment of materials.

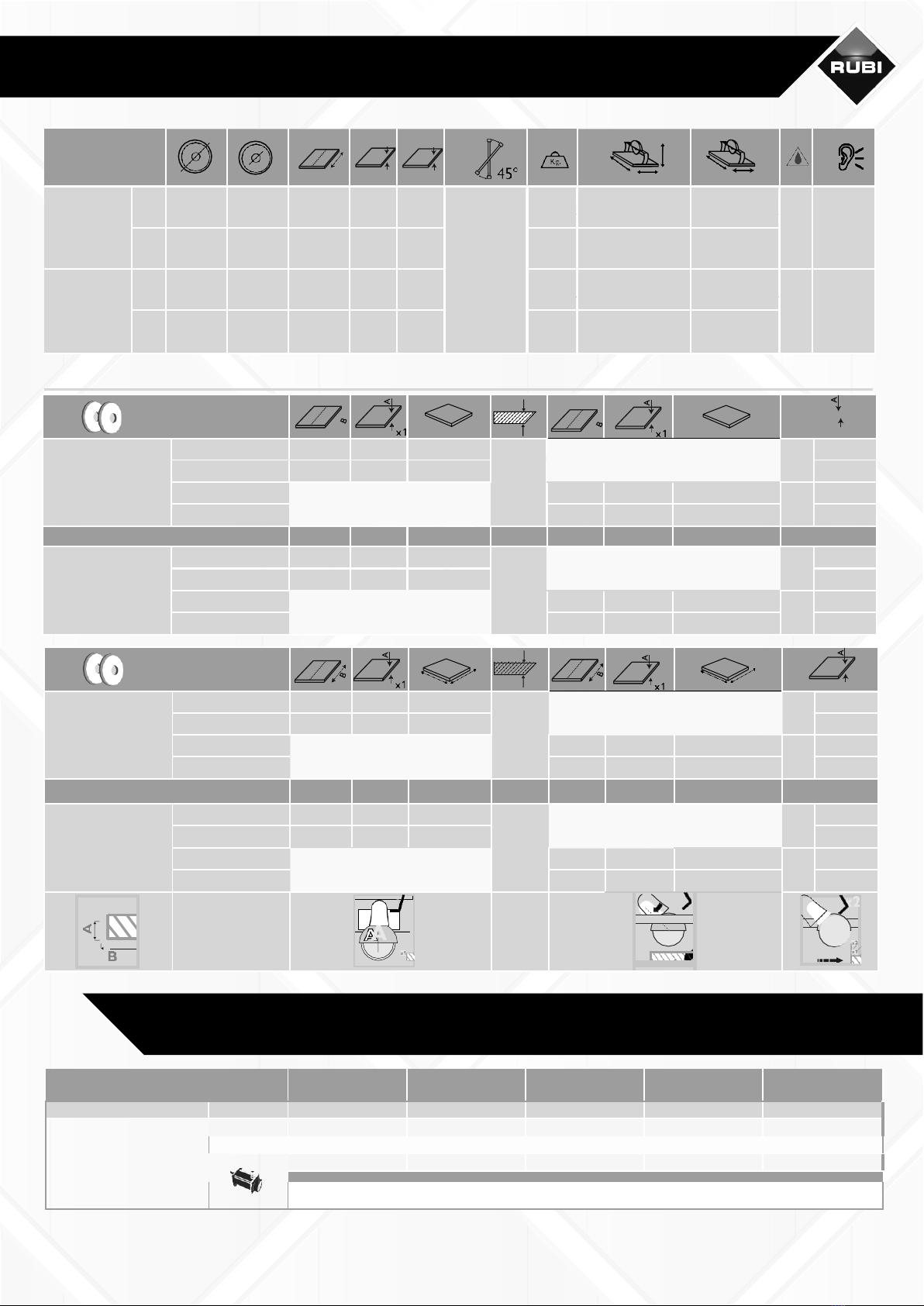

Technical data.

...................................................................................................................................................................

Pag.21

The overall machine.....................................................................................................................................Pag.21

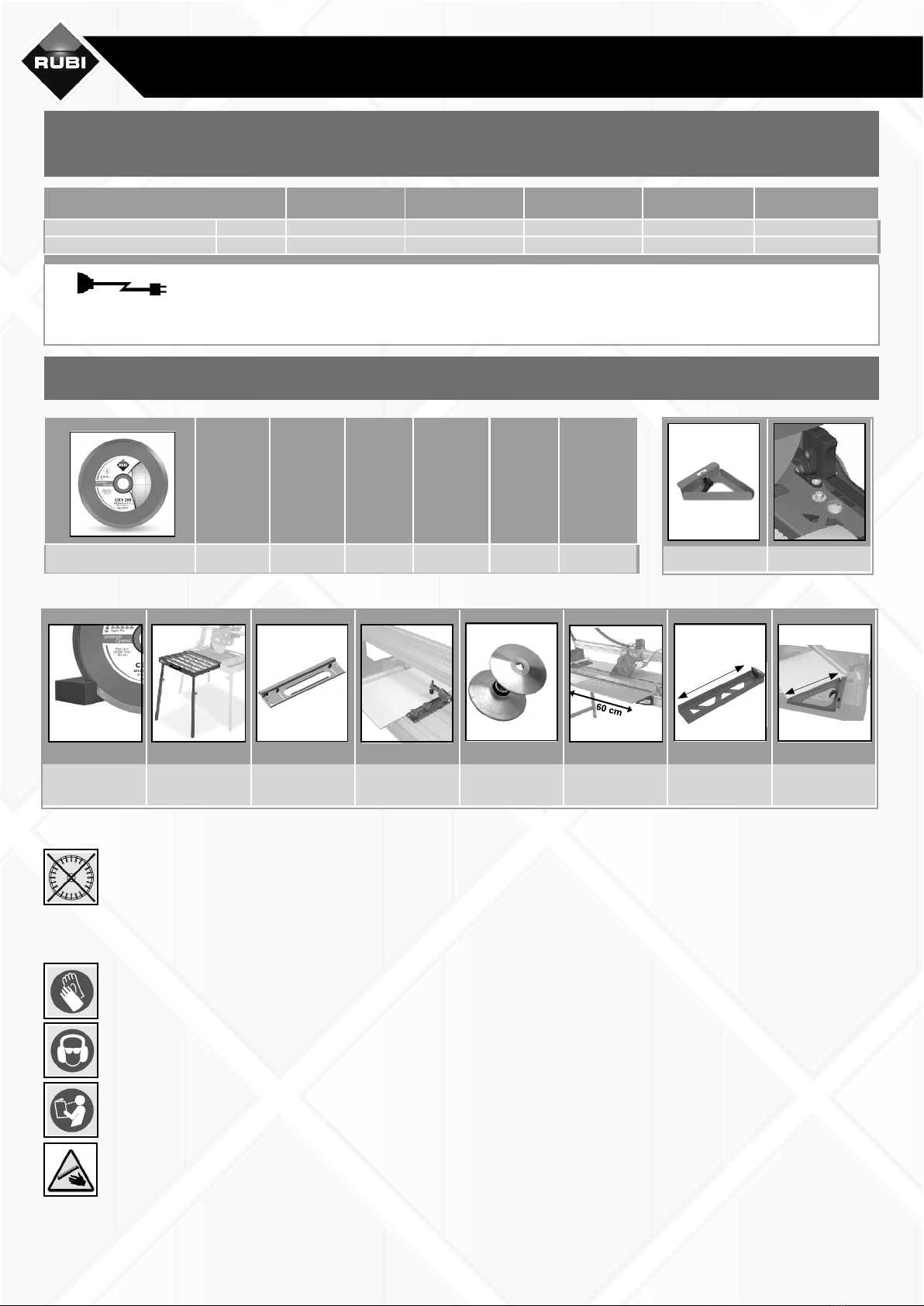

Accessories....................................................................................................................................................Pag.22

Declaration of compliance with EC regulations...................................................................Pag.23/24

Electric

diagram.................................................................................................................................Pag.25

Explodings.

...............................................................

http://www.rubi.com/moduls/explodings

Without the previous authorisation of GERMANS BOADA S.A., the partial or total reproduction of this manual, in any format or by any means or process, is strictly prohibited, whether such reproduction be mechanical, photographic or electronic.

Any of these activities will incur legal liability and may give rise to penal action being taken.

GERMANS BOADA S.A. reserves the right to make any technical modification without previous notice.

E. SPECIFICATIONS

B.STARTINGTHE MACHINE

D. MAINTENANCE

CONTENTS

ASSEMBLY INSTRUCTIONS

Assembly

Safety

Electricity

Applications

Working area advises

STARTING THE MACHINE

Checking list

INSTRUCTIONS

D. MAINTENANCE

•

Cleaning and maintenance

E. SPECIFICATIONS

•

Technical data

•

The overall machine

•

Accessories

•

Decalaration of compliance with EC regulations

•

Electric diagram

the ceramic fixing accessory. (fig. 17,18)