2IVH / VVH

The present instruction is only valid for the follo-

wing variants of the shortening hook

• IVH ICE-Shortening hook in ICE-Pink (Purple colour,

quality grade 120, D1 stamping)

• VVH VIP-Shortening hook in VIP-Pink

(Magenta colour, quality grade 100, H1 stamping)

Please read assembly instruction carefully

before initial operation of the Shortening

hook. Make sure to understand all volumes.

Nonobservance of this assembly manual

can lead to serious physical injury and pro-

perty damage and eliminates warranty.

In doubt or in misconception please note

that the German version of this document

is decisive.

1 Safety instructions

ATTENTION

Wrong assembled or damaged lifting and

lashing means as well as improper use can

lead to injuries of persons and damage of

objects when load drops.

Please inspect all lifting points before each

use.

• Please consider extreme circumstances or shock

loading when choosing the used Shortening hook

and the components.

• Only RUD round steel link chains of the corres-

ponding nominal size must be attached to the

Shortening hook.

• RUD Shortening hook must only be used by instruc-

ted and competent persons considering DGUV

100-500, 2.8 (BGR 500) and outside Germany

noticing the country specic statutory regulations.

2 Intended use

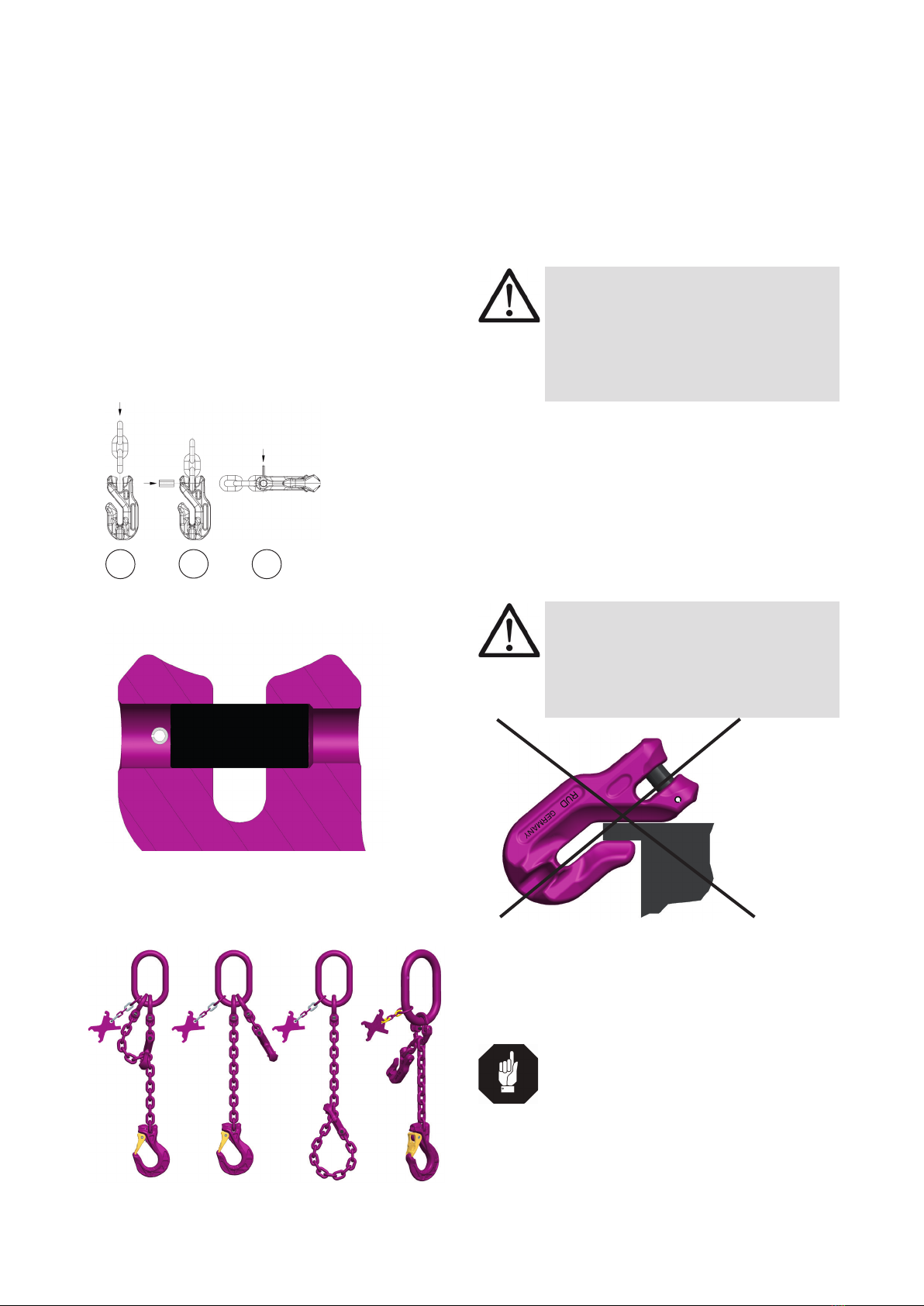

Hereby described shortening hooks must only be used

for lifting, lashing or transporting of loads.

Please observe that the shortening hook/chain can

straighten out in the loading direction

Only RUD round steel link chains of the corresponding

nominal size must be attached to the shortening hook.

The shortening hooks are designed acc. to DIN 5692.

3 Assembly- and instruction manual

3.1 General information

• Capability of temperature usage ICE-components

(IVH): When using the ICE Shortening hook at

temperatures beyond 200°C the permissible WLL

has to be reduced.

-60°C up to 200°C no reduction

200°C up to 250°C minus 10 %

250°C up to 300°C minus 40 %

Temperatures exceeding 300°C are prohibited!

• Capability of temperature usage VIP-components

(VVH): When using the VIP Shortening hook at

temperatures beyond 200°C the permissible WLL

has to be reduced.

-40°C up to 200°C no reduction

200°C up to 300°C minus 10 %

300°C up to 380°C minus 40 %

Temperatures exceeding 380°C are prohibited!

• RUD VIP Shortening hooks must not be used with ag-

gressive chemicals such as acids, alkaline solutions

and their vapours.

• The WLL oft he components are depending on the

following variables:

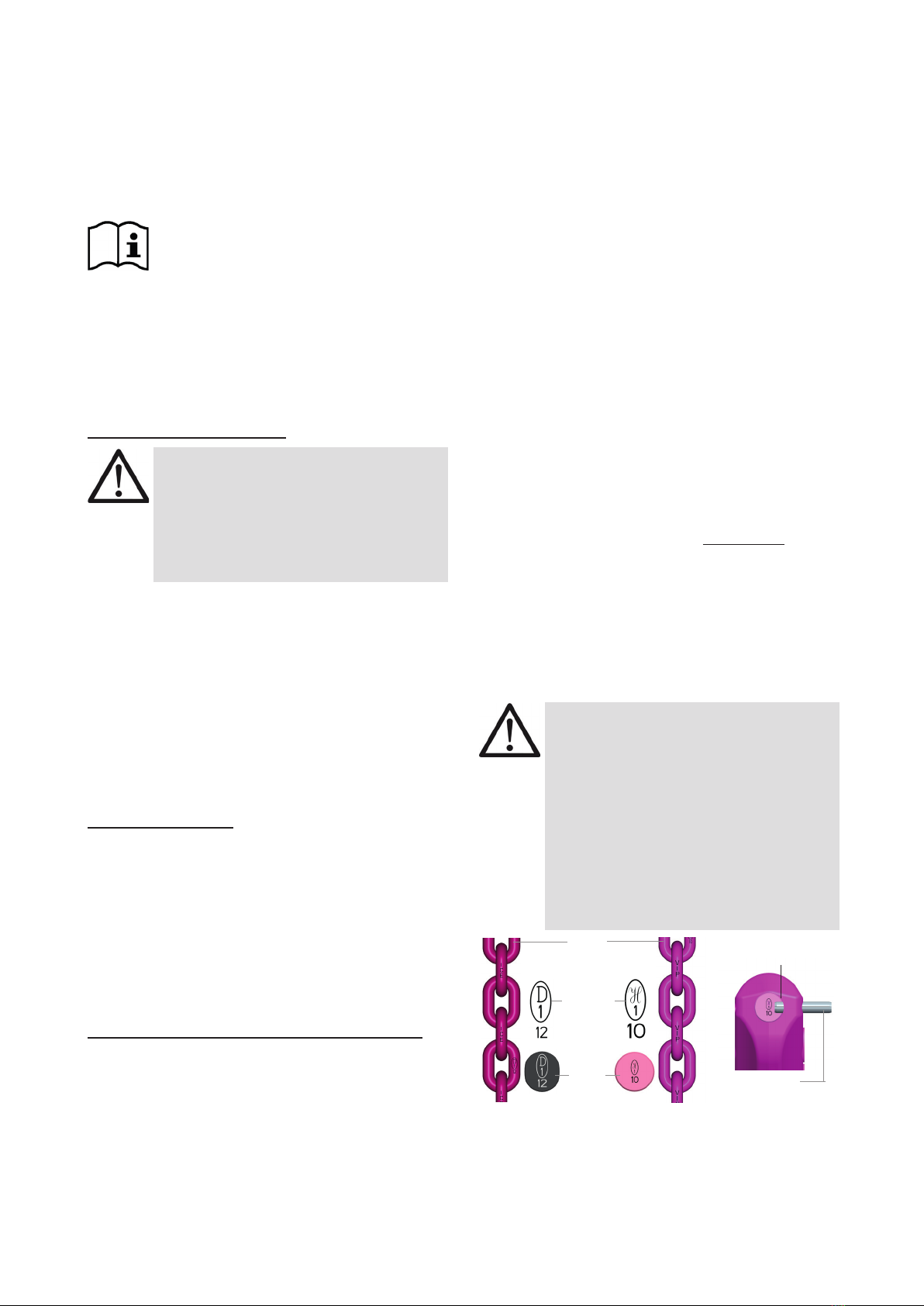

- Quality grade of component (picture 1 to 3)

- Nominal size of component

- Present load factor

The permissible WLL can be taken out oft he

corresponding ICE- and VIP user instructions (or

alternatively from the website ww.rud.com).

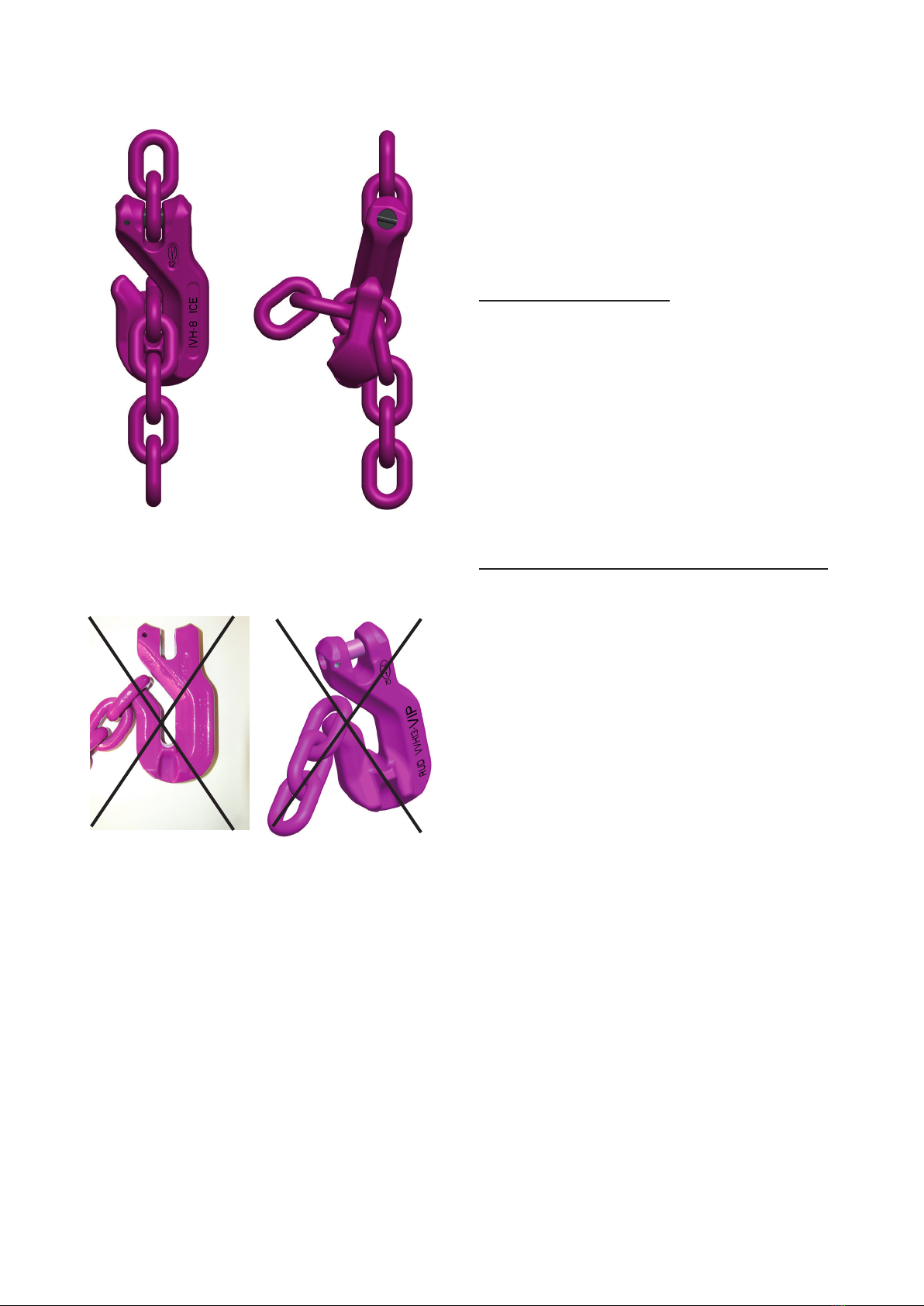

3.2 Hints for the assembly

When assembling the shortening hook please observe

the correct dimensioning of chain and component. The

quality grade/nominal size can be recognized by the

stamping/marking at the component/pin/chain resp.

by the colour.

HINT

Observe in any case the quality grade

assignment at the components

- Please assemble only load pins with

D1-12 stamping into the ICE com-

ponents (IVH)

- Please assemble only load pins with

H1-10 stamping into the VIP

components (VVH)

Mixing of system components of dierent

quality grades/ nominal sizes is not allo-

wed.

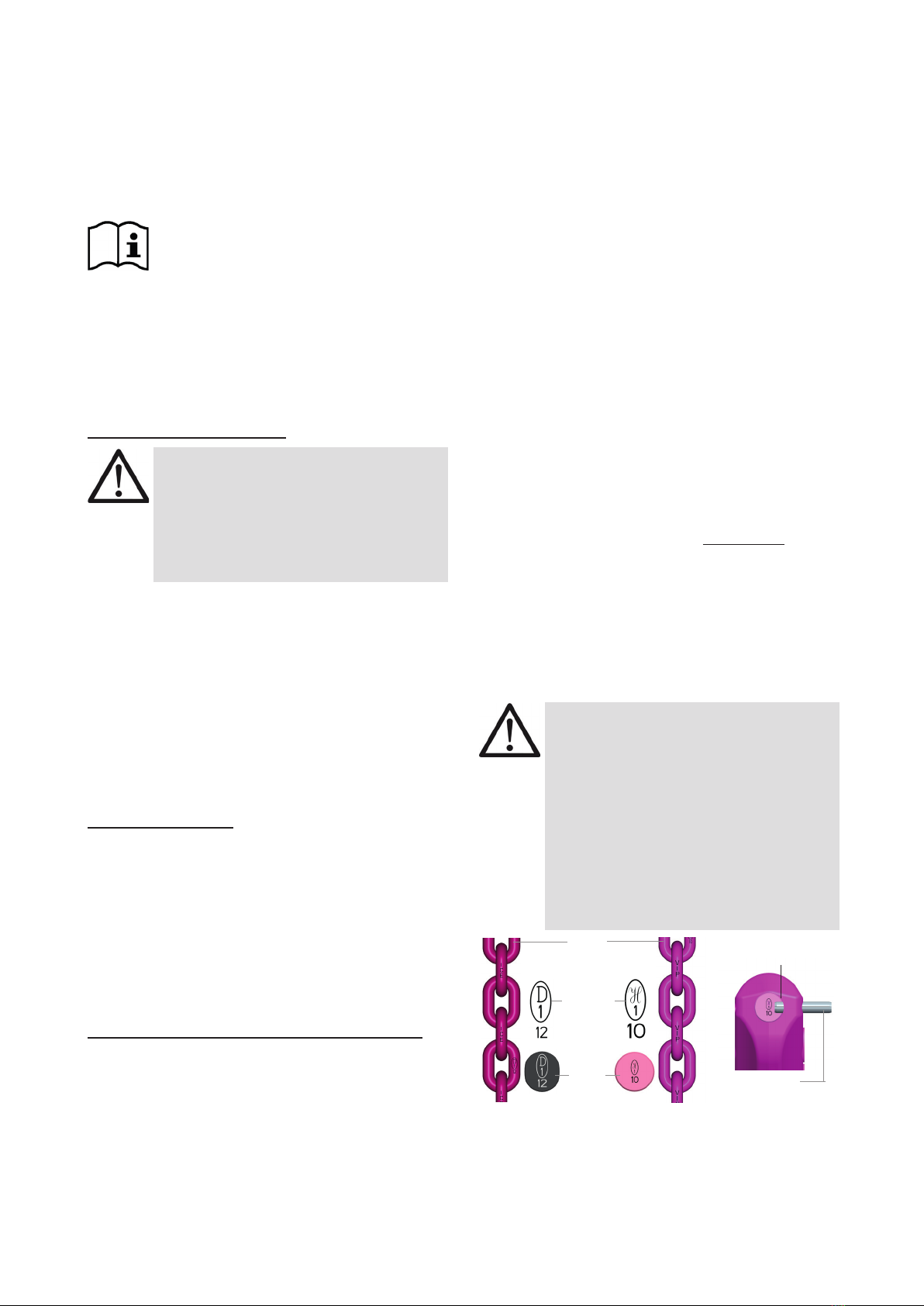

chain

stam-

ping

load

pin

G-Pin

including stamping

sleeve pin

Pic. 1:

Quality Grade 120

ICE- chain,

stamping D1-12

Oval pin D1-12

Pic. 2:

Quality Grade 10

VIP- chain,

stamping H1-10

Round pin H1-10

Pic. 3:

VIP- G-pin

incl. VIP-

stamping +

sleeve pin