3

VVS/RS-VVS

VVS/RS-VVS 6

3.3 Sequence of assembly

In the following description the assembly of the con-

necting link will be described exemplarily with the

example of a masterlink and an VIP chain.

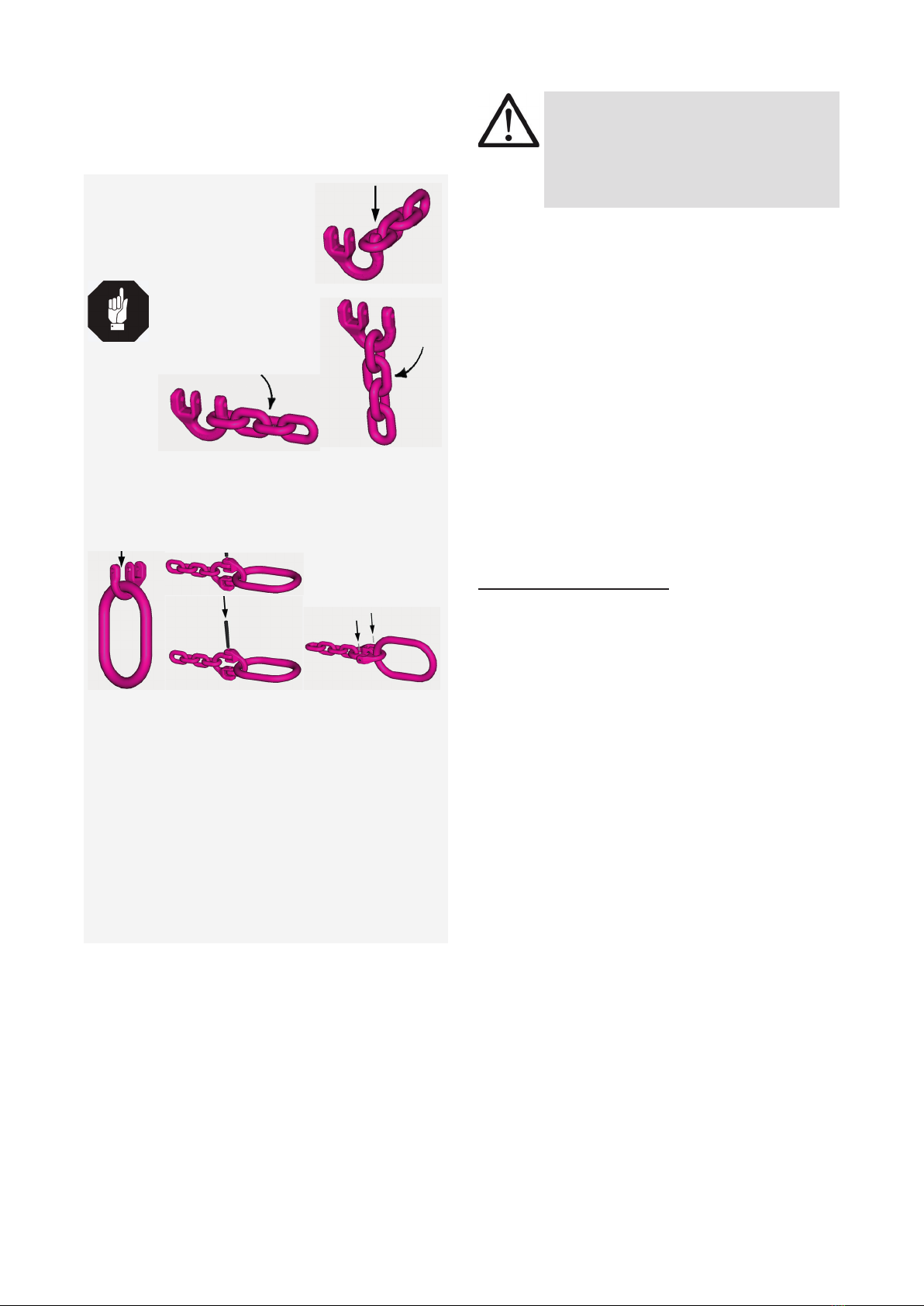

1. Install last chain link into the single

bow eye (Pic. 4).

In this case there is no addi-

tional connector necessary.

HINT

At the beginning of the

bow rounding, chain link

can be turned by 90°

within the bow (Pic. 5).

Pic. 5 Pic. 6

2. Position chain strand to the bottom of the bow part

(Pic. 6).

3. Put into the second bow part a desired connecting

part, f.e. a masterlink (Pic. 7).

Pic. 7 Pic. 8 / 9 Pic. 10

4. Assemble both bow parts together in such a way

that components are aligned (Pic. 8).

5. Install pin into the bore of the eye (Pic. 9). Both

bow parts are now connected with each other.

6. Secure the assembled connecting link as follows

(Pic. 10):

- Position both securing pins/sleeve pins in

such a way, that the slot faces the outside.

- Knock both sleeve pins in with a hammer.

7. Finally Check the correct assembly (see chapter

4 Inspection / repair).

3.4 User instructions

• Check before each loading of the connecting link,

that connecting pin is installed correct in the bow

eye. Secure pin by hammering the sleeve pins in.

• Make sure that the load force happens in the straight

leg without being twisted, fold-over or kinked.

• Always regularly observe the appearance of the

whole lifting mean (e.g. by the person responsible

für attachment) before using it (strong corrosion,

wear, cracks on load-bearing parts, deformations).

Refer to chapter 4 Inspection / repair.

ATTENTION

Wrong assembled or damaged lifting and

lashing means as well as improper use can

lead to injuries of persons and damage of ob-

jects when load drops down. Please inspect

all lifting and lashing means before each use.

• RUD components are designed according to DIN

EN 818 and DIN EN 1677 for a dynamic load of

20,000 load cycles.

• Keep in mind that several load cycles can

occur with a lifting procedure.

• Keep in mind that, due to the high dynamic stress

with high numbers of load cycles, that there is a

danger that the product will be damaged

• The BG/DGUV recommends: For higher dynamic

loading with a high number of load cycles (contin-

uous operation), the working load stress must be

reduced according to the driving mechanism group

1Bm (M3 in accordance with DIN EN 818-7). Use

a lifting mean with a higher working load limit.

• Leave hazardous area when possible.

• Watch always attached loads.

• Read for all lifting means the RUD sling chain Sa-

fety instructions for RUD lifting means.

4 Inspection / repair

4.1 Hints for periodical inspections

The operator must determine and specify the nature

and scope of the required tests as well as the periods

of repeating tests by means of a risk assessment (see

sections 4.2 and 4.3).

The continuing suitability of the lifting mean must be

checked at least 1x year by an expert.

Depending on the usage conditions, f.e. frequent usage,

increased wear or corrosion, it might be necessary to

check in shorter periods than one year. The inspection

has also to be carried out after accidents and special

incidents. The operator must specify the test cycles.

4.2 Test criteria for the regular visual inspection

by the user

• Completeness of the VIP Connecting link

• Complete readable size and manufacturer sign

• Deformations on load-bearing parts

• Mechanical damage like strong notches, especially

in areas where tensile stress occurs

4.3 Additional test criteria for the

competent person / repair worker

• Damaging and reduction of cross section caused

by wear > 10 %, especially at connecting pins and

at the eyes of the VVS bows.

• Strong corrosion

• further checks may be required, depending on the

result of the risk assessment (e.g. testing for cracks

in load-bearing parts).