Version: V1.1 Page 1 of 28

Content

1. Information...........................................................................................................................................................2

1.1 Validity..........................................................................................................................................................2

1.2 Target Group ...............................................................................................................................................2

1.3 Levels of warning messages ....................................................................................................................2

1.4 Symbol Description ....................................................................................................................................3

1.5 Abbreviation Description............................................................................................................................4

2. Safety.....................................................................................................................................................................5

2.1 Safety precautions......................................................................................................................................5

2.2 Safety instructions......................................................................................................................................5

2.2.1 Safety gear.......................................................................................................................................6

2.2.2 Emergency safety measures.........................................................................................................6

2.2.3 Other Tips.........................................................................................................................................7

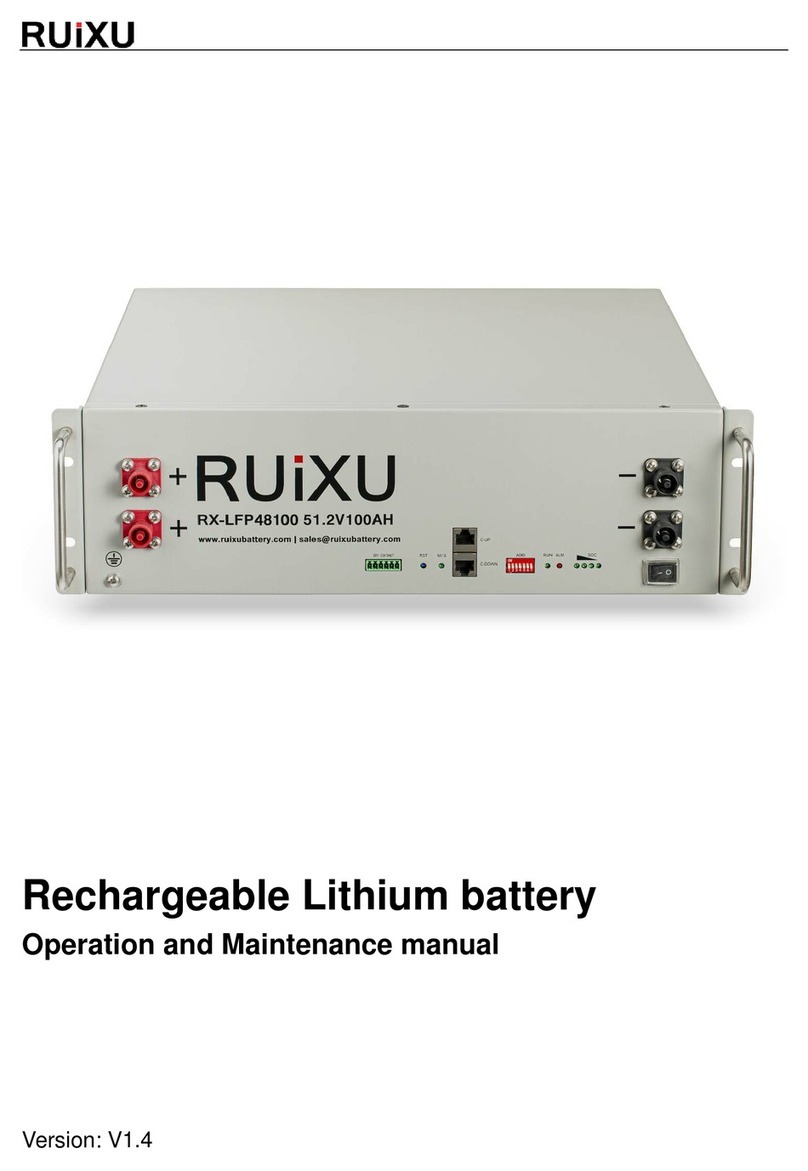

3. Product Overview...............................................................................................................................................8

3.1 Introduction..................................................................................................................................................8

3.2 Features.......................................................................................................................................................9

3.3 Specification..............................................................................................................................................10

3.3.1 Dimension ......................................................................................................................................10

3.3.2 Parameters.....................................................................................................................................10

3.3.3 Panel Interface ..............................................................................................................................11

3.4 Protection...................................................................................................................................................14

4 Installation...........................................................................................................................................................16

4.1 Preparation................................................................................................................................................16

4.1.1 Safety Compliance........................................................................................................................16

4.1.2 Environment...................................................................................................................................16

4.1.3 Tools................................................................................................................................................16

4.2 Inspection ..................................................................................................................................................17

4.2.1 Unpack precautions ......................................................................................................................17

4.2.2 Scope of delivery...........................................................................................................................17

4.2.3 External cable kits.........................................................................................................................18

4.3 Start Installation........................................................................................................................................19

4.3.1 Remainder......................................................................................................................................19

4.3.2 Procedures.....................................................................................................................................19

5. Cable connection and commissioning .......................................................................................................20

5.1 Get battery ready......................................................................................................................................21

5.2 Grounding cable connection...................................................................................................................21

5.3 Communication cable connection..........................................................................................................22

5.4 DC power cable connection....................................................................................................................23

5.5 Connecting with inverter..........................................................................................................................23

5.6 Commissioning .........................................................................................................................................25

5.7 Switch off battery......................................................................................................................................25

6. Transport, Storage ...........................................................................................................................................27

7. Disposal of battery...........................................................................................................................................27

Appendix I...............................................................................................................................................................28