WARNING

When using the product, the safety rules must be

followed. For your own safety and that of bystanders,

please read these instructions before operating the

product. Please keep the instruction safe for later use.

WARNING

Never allow children or people with reduced physical,

sensory or mental capabilities to operate, clean or

maintain the product. Local regulations may restrict the

age of the operator.

Tragic accidents can occur if the operator is not alert to

the presence of children. Children are often attracted to

the product and the blowing/vacuuming activity. Never

assume that children will remain where you last saw them.

Keep children out of the work area and under the watchful

care of a responsible adult other than the operator, be

alert and turn the product off if a child enters the area.

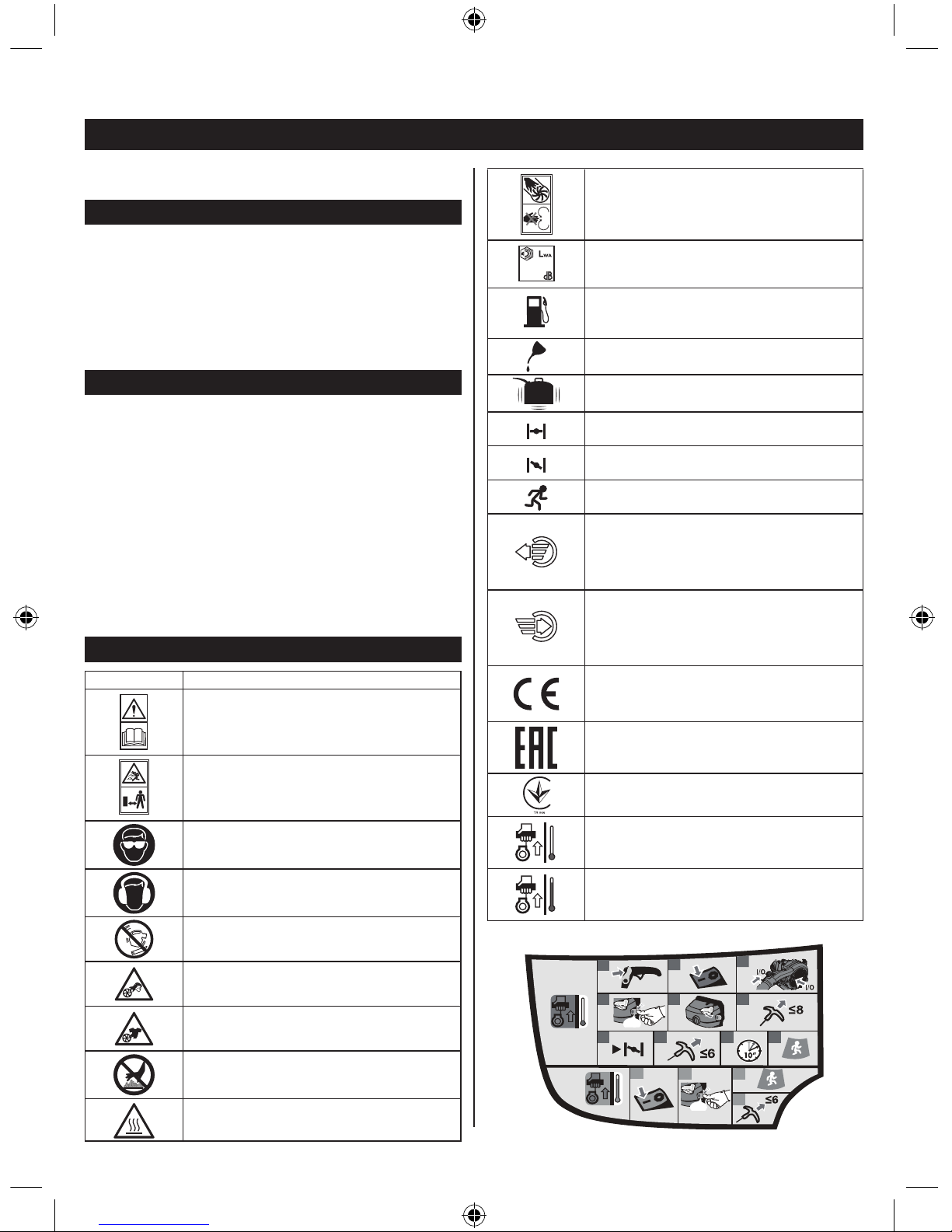

GENERAL SAFETY WARNINGS

■Some regions have regulations that restrict the use of

the product to some operations. Check with your local

authority for advice. Read all instructions.

■Do not allow children or untrained individuals to use

this product.

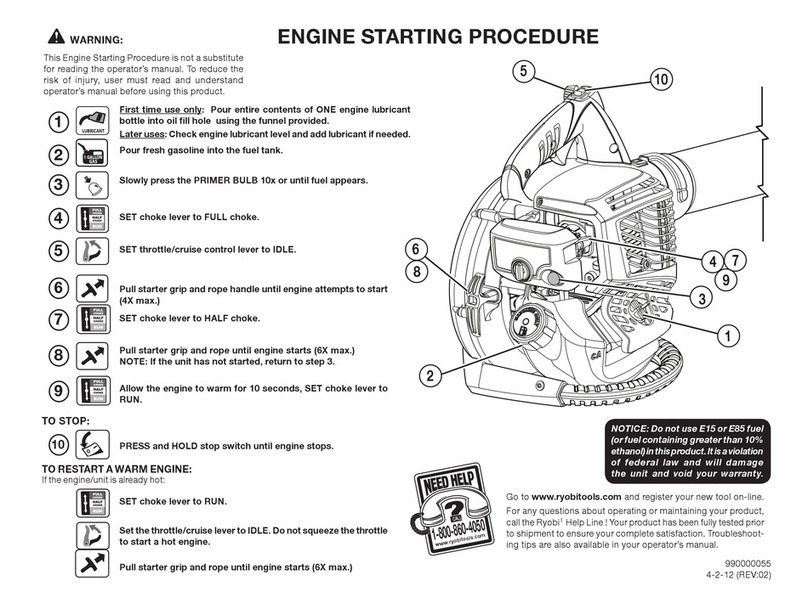

■Ensure before each use that all controls and safety

devices function correctly. Do not use the product if

the “off” switch does not stop the engine.

■Never start or run the engine in a closed or poorly

ventilated area; breathing exhaust fumes can kill.

■Clear the work area before each use. Remove all

objects such as rocks, broken glass, nails, wire, or

string which can be blown a considerable distance by

high velocity air.

■Wear full eye and hearing protection while operating

the product. This product is extremely noisy and

permanent hearing may result if precautions to

limit our exposure, reduce noise and wear hearing

protection are not strictly adhered to.

■Wear heavy long trousers, boots, and gloves. Do not

wear loose fitting clothing, short trousers, jewellery of

any kind, or use with bare feet.

■Secure long hair so it is above shoulder level to

prevent entanglement in moving parts.

■Beware of thrown objects; keep all bystanders,

children, and pets at least 15 m away from work area.

■Operate the product only at reasonable hours – not

early in the morning or late at night when people might

be disturbed.

■Use rakes and brooms to loosen debris before

blowing/vacuuming.

■Never operate the product in an explosive atmosphere.

■Do not use this product when you are tired, ill, or under

the influence of alcohol, drugs, or medication.

■Do not operate in poor lighting. The operator requires

a clear view of the work area to identify potential

hazards.

■Use of hearing protection reduces the ability to hear

warnings (shouts or alarms). The operator must pay

extra attention to what is going on in the working area.

■Only use enough throttle (power) to complete the task,

this will reduce the potential for injury caused by noise

and vibration.

■Operating similar products nearby increases both

the risk of hearing injury and the potential for other

persons to enter your working area.

■Keep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or exposure

to hot surfaces.

■Keep all parts of your body away from any moving part.

Rotating impeller blades can cause severe injury. Stop

the engine and ensure impeller blades have stopped

rotating before opening the vacuum door, installing/

changing tubes, opening or removing debris bag.

■Do not touch the area around the silencer or engine of

the product, these parts get very hot during operation.

■Inspect the product before each use. Check for loose

fasteners, fuel leaks, etc. Make sure all guards, and

handles are properly and securely attached. Replace

any damaged parts before use.

■Never run the product without the proper equipment

attached. When used as a blower, always install the

blower tubes and close the door. When used as a

vacuum, always install the vacuum tubes and vacuum

bag.

■Do not modify the product in any way or use parts

and accessories which are not recommended by the

manufacturer.

WARNING

If the product is dropped, suffers heavy impact or

begins to vibrate abnormally, immediately stop the

product and inspect for damage or identify the cause of

the vibration. Any damage should be properly repaired

or replaced by an authorised service centre.

■Stop the engine and allow it to cool before refueling,

storing or transporting the product.