A wnnrulruc'

Always

hold

thestring

trimmerawayfrom

thebodykeep-

ing

clearance

between

thebody

andthe

product.

Any

contact

with

thehousing

orstringtrimmer

cuttinghead

can

result

inburns

and/or

otherserious

personal

injury.

TO ADVANCETHE CUTTING LINE

String

advance

iscontrolled

bytapping

thestringhead

on

grasswhilerunning

engineatfullthrottle.

I Runengine

atfull

throttle.

r Tap

thespool

retaineron

ground

to

advance

string.The

stringadvances

eachtimethespoolretaineris

tapped.

Donot

holdthespoolretaineronihe

ground.

NOTE:

The

linetrimmingcut-offbladeonthe

grass

deflector

willcut

thelinetothecorrectlength.

NOTE:

lfthe

string

isworntooshod

you

maynotbeableto

advance

thestringbytappingiton

the

ground.

lfso,stop

theengine,

andmanuallyadvance

thestring.

TO ADVANCETHE CUTTING LINE MANUALLY

I Stop

theengine.

I Push

thespoolretainerdown

while

pulling

onstring(s)

to

manuallyadvancethestring.

CUTTING

TIPS

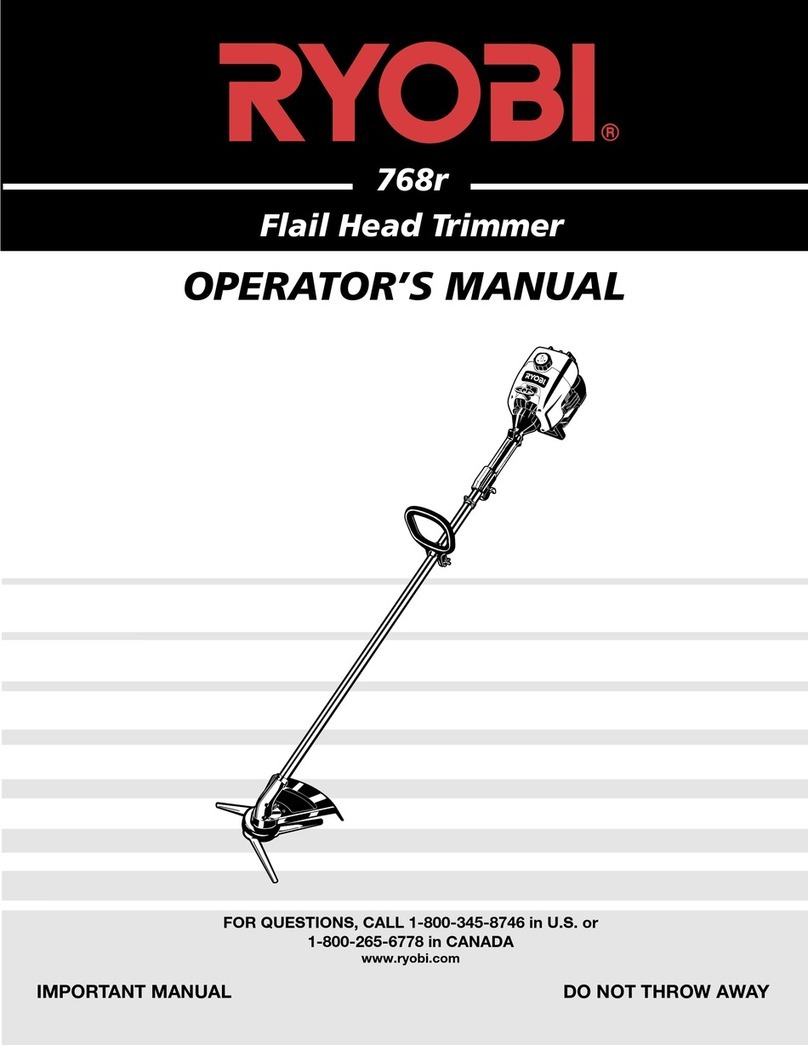

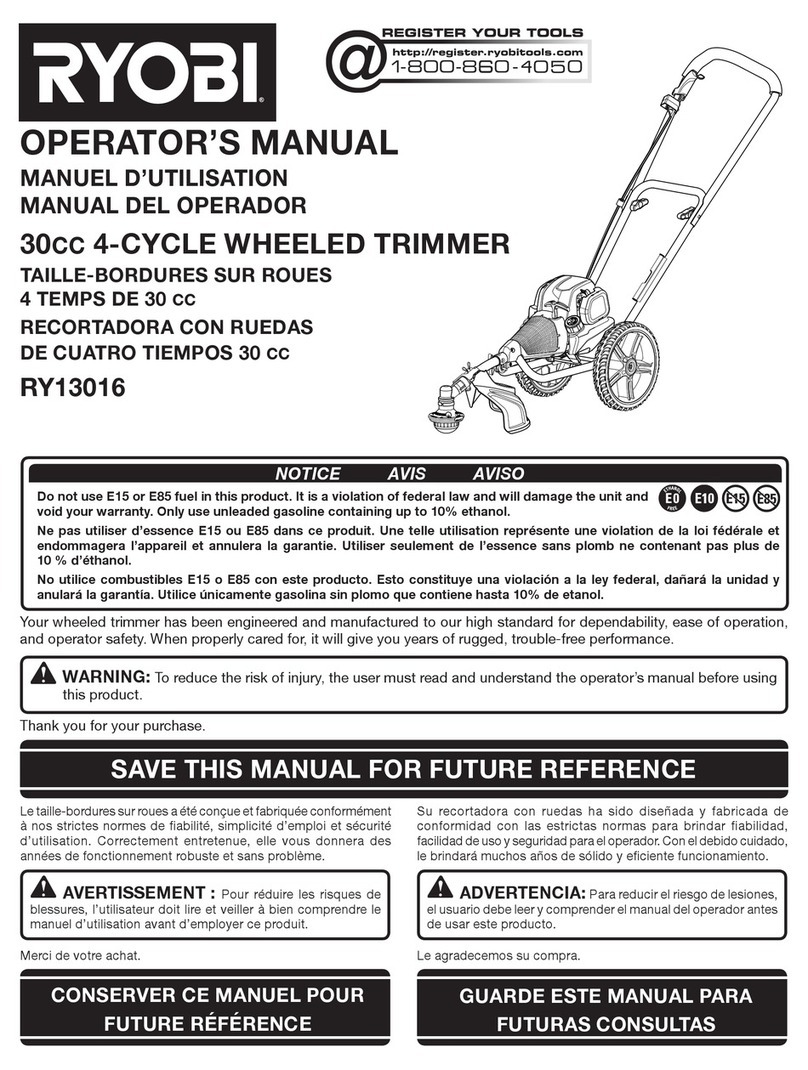

SeeFigures

16

-17.

r Avoidhotsurfaces

byalwayskeeping

thetoolaway

from

your

body.

(Proper

operating

position

shownin

figure15.)

r Keepthe

trimmertiltedtoward

theareabeingcut;

thisis

the

best

cuitingarea"

r Thecurved

shafttrimmercuts

when

passing

theunit

from

righttoleft.Thestraightshaft

trimmercuts

when

passing

theunitfromleftto

right.Thiswillavoid

throwingdebrisat

theoperator.

Avoidcuttinginthedangerous

areashown

inillustration.

r Usethetipofstring

todothecutting;do

notforcestring

headintouncut

grass.

I Wireand

picket

fencescauseextrastring

wear,even

breakage.Stone

andbrickwalls,curbs,

andwood

may

wearstring

rapidly.

I Avoid

treesandshrubs.Treebark,wood

moldings,siding,

and

fence

posts

caneasilybedamaged

bythestring.

GRASS

DEFLECTOR

LINETRIMMINGCUT-OFF

BLADE

See

Figure18.

Thetrimmerisequipped

withaline

trimmingcut-off

blade

onthe

grass

deflector.

Forbestcutting,advance

string

until

itistrimmed

to lengthbythecut-off

blade.Advance

the

stringwhenever

you

heartheengine

runningfaster

than

normal,

orwhen

trimmingefficiency

diminishes.

This

maintain

best

performance

andkeep

the

stringlong

toadvance

properly.

OPERATING

THEBRUSHCUTTER

See

Figures19

-20.

Hold

thebrushcuiterwith

your

righthandontherearhandle

and

the

your

handon

the

"J"BarrierHandle.Keepafirm

grip

withbothhands

whileinoperation.Brushcuttershould

beheldatacomfortableoosition

withtherearhandleabout

hipheight.Maintain

your

grip

andbalanceon both

feet.

Position

yourself

so

that

you

willnotbedrawnoffbalance

by

thekickbackreactionofthecuttingblade.

Adjusttheshoulderharnessto position

thebrushcutter

atacomfortableoperating

position

and

toassurethatthe

shoulderharness

willreducetherisk

ofooerator

contact

withtheblade.

BLADETHRUST

Exerciseextremecautionwhenusing

thebladewiththis

unit.Bladethrust

is

the

reactionthatmayoccurwhenthe

spinningbladecontactsanything

itcannotcut.Thrscontact

maycause

thebladeto stop

foraninstant,andsuddenly

"thrust"

theunitawayfromtheobjectthat

washit.Thisre-

actioncanbeviolentenoughtocause

theoperatortolose

controloftheunit.

Bladethrust

canoccur

withoutwarning

ifthebladesnags,

stalls,orbinds.Thisismorelikely

tooc-

cur

in

areas

whereitisdifficulttoseethematerialbeing

cut.

Forcuttingeaseandsafety,approach

theweedsbeingcut

withthebrushcutter

fromtherighttotheleft.Intheevent

anunexpected

objectorwoodystockisencountered,

this

practice

couldminimizetheblade

thrustreaction.

A wnnrurruc,

To

avoidburns

fromhotsurfaces,neveroperateunit

with

thebottomoftheenoineabovewaist

level.

TRI-ARC@BLADE

TheTri-Arc@bladeissuitedonlyforthicker

weedsand

pu

lpy

stalks.Whenthebladebecomesdull,

itcanbeturnedover

to extendthelife

ofthe blade.

Donotsharpen

theTri-Arc@

blade.

Useonly

Tri-Arc@

blade,

part

numberAP04105,available

at

your

localretailer.

CUTTING

TECHNIQUE

- BLADE

A wnRrurruc,

Extremecaremust

be

takenwhenusingblades

toen-

sure

safeoperation.Readthesafetyinformation

forsafe

operationusingtheblade,refertoSpecificSafety

Rules

forBrushcutterandBladeUseearlierin

thismanual.

I Always

holdbrushcutter

on

your

rightsidewithbothhands

when

operating.Use

a

firm

grip

on

bothhandles.

I Maintain

yourgrip

andbalanceonboth

feet.Position

yourself

sothat

you

will

notbedrawnoffbalance

bythe

kickback

reaction

of

the

cuttinqblade.

I Inspectandcleartheareaofanyhiddenobjectssuch

as

glass,

rocks,concrete,fencing,

wire,wood,metal,etc.

r Neveruseblades

near

sidewalks,

fencing,

posts,

build-

ingsorother

immovable

objects.

I Neveruseabladeafterhitiinga

hardobjectwithoutfirst

inspecting

itfor

damage.Do

not

use

ifanydamageis

detected.

I The

unitisusedasascyihe,cutting

fromtherighttothe

left

inabroadsweepingactionfromside

toside.

r Useonly

theTri-Arc@blade.Toinstallanyotherbrand

bladeorcutting

headto thisbrushcuttercan

resultin

serious

personal

injury.

DANGER()US

CUTTING

AREA

CURVED

SHAFT

TRIMMER

BESTCUfiING

STRAIGHT

SHAFT

TRIMMER

STRAIGHT

SHAFT

TRIMMER

LINETRIMMING

CUT-OFF

BLADE

CURVED

SHAFTTRIMMER

LINE

TRIMMING

CUT-OFT

BLADE

PR()PER

OPERATING

P0stTt0N

trin lO

DIRECTI()NOFROTATION

CUTTINGAREA Fig.20

17