TABLE OF CONTENTS

Splash! 300-0000/EU/K - Splash! Hi-Lo 350-0000/EU/K - Splash! Extended Reach 370-0000/EU/K -

Splash! Spa 375-0000/EU/K - Splash! ER Hi/Lo 385-0000/EU/K

INTENDED HOIST USER.............................................................................................................................2

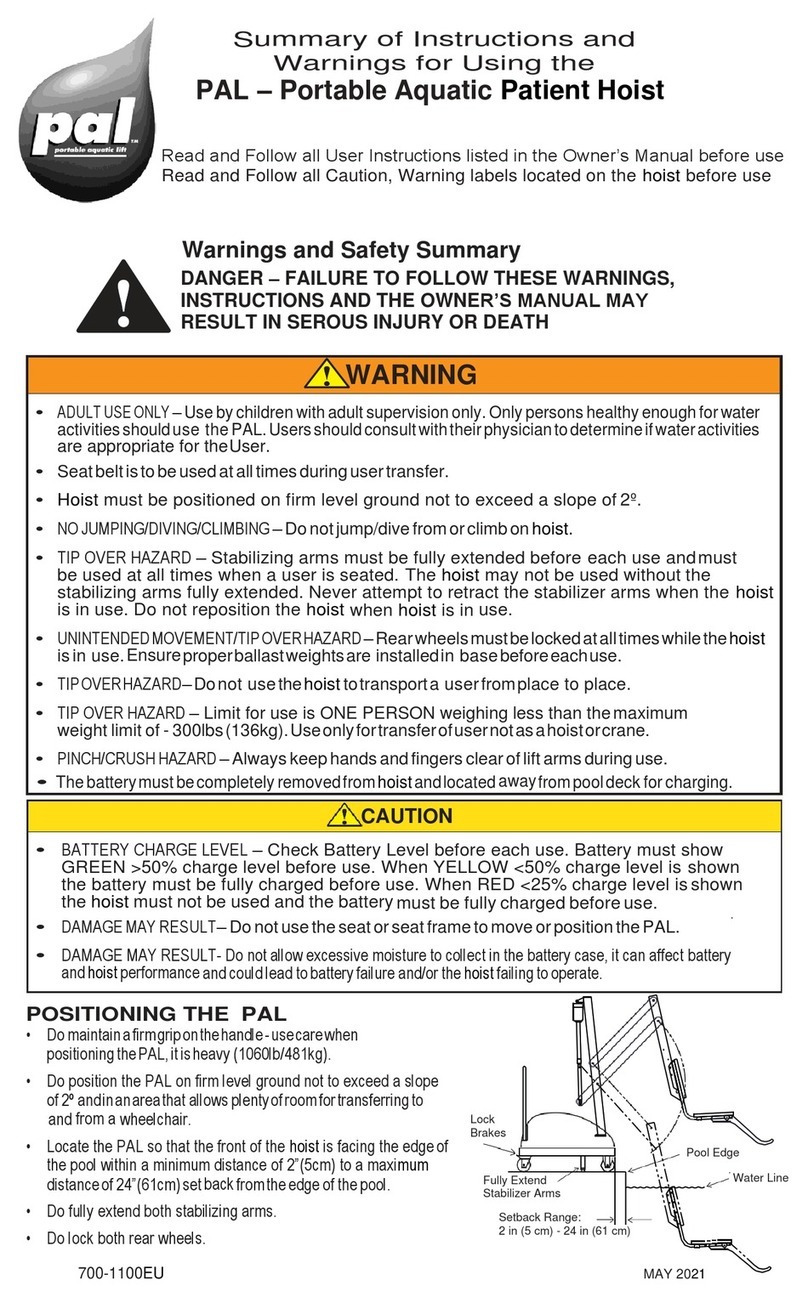

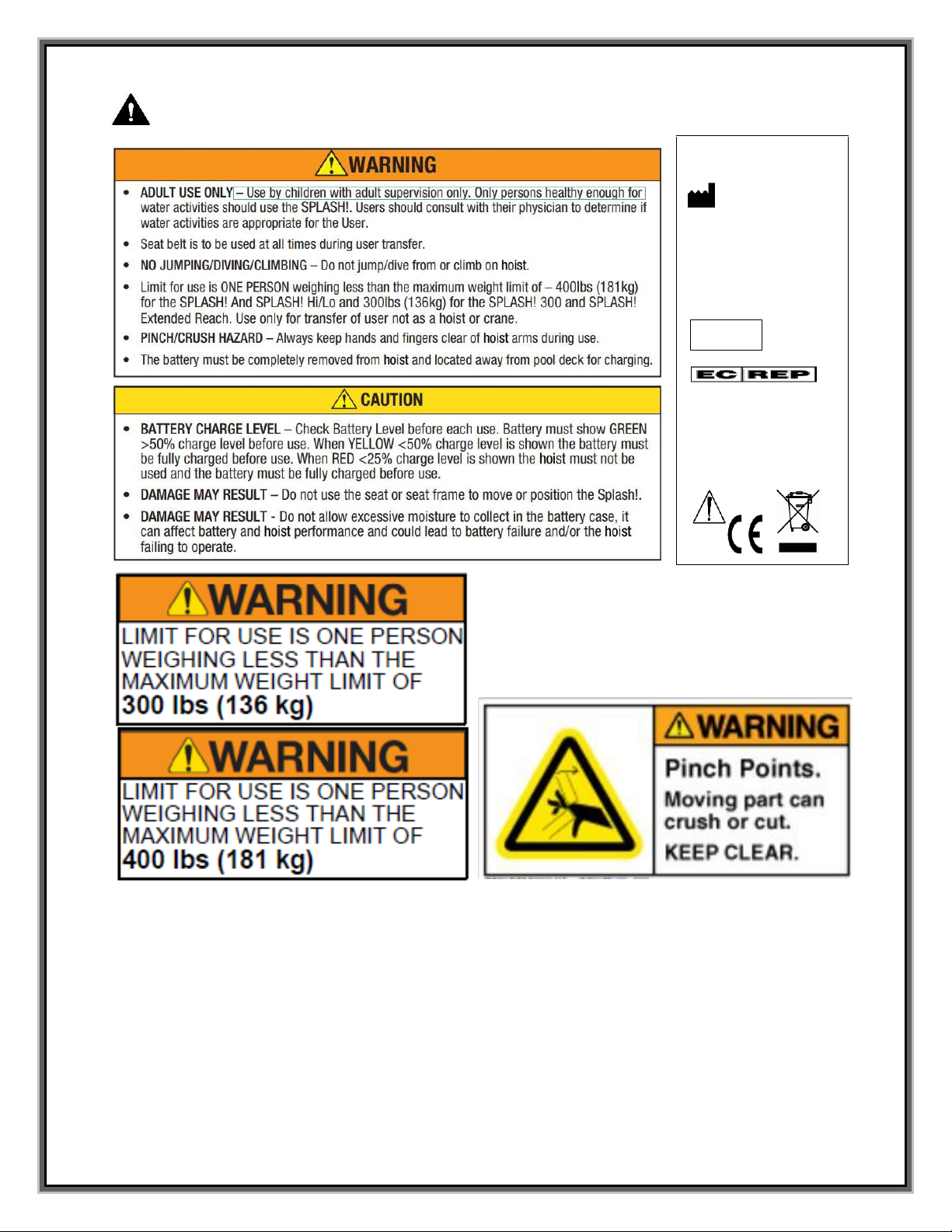

WARNINGS AND SAFETY SUMMARY .......................................................................................................3

PRODUCT OVERVIEW................................................................................................................................4

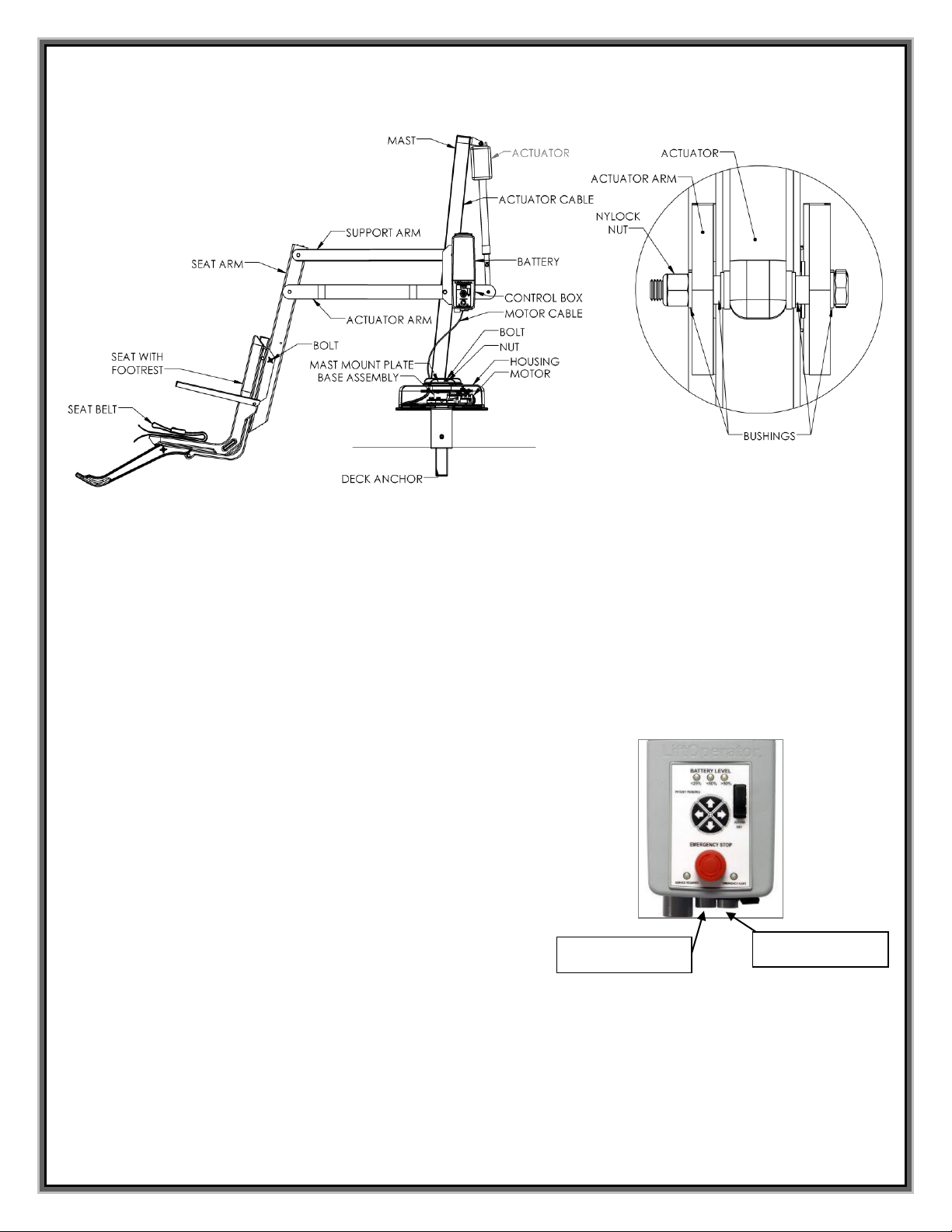

SPLASH! - PRODUCT COMPONENTS.......................................................................................................5

COMPONENT DESCRIPTION.....................................................................................................................5

UNPACKING & ASSEMBLY INSTRUCTIONS.............................................................................................9

POOL DECK INSTALLATION FOR THE SPLASH! LOCKING ANCHOR .................................................11

USING THE Splash! Hoist ..........................................................................................................................12

TRANSFERRING........................................................................................................................................13

MAINTENANCE and CLEANSING.............................................................................................................14

TROUBLE SHOOTING...............................................................................................................................15

LONG-TERM STORAGE............................................................................................................................16

CUSTOMER CARE.....................................................................................................................................16

PRODUCT REGISTRATION & WARRANTY INFORMATION...................................................................17

SPECIFICATIONS ......................................................................................................................................18

1. Dimensions/Capacity.......................................................................................... 18

2. Actuator ........................................................................................................... 18

3. Motor ...............................................................................................................18

4. Battery.............................................................................................................18

5. Range of Motion ................................................................................................ 18

7. Materials and Finish ........................................................................................... 18

PARTS LIST (SPLASH!).............................................................................................................................19

PARTS LIST (SPLASH EXTENDED REACH)............................................................................................20

PARTS LIST (SPLASH EXTENDED REACH HI/LO or SPA).....................................................................21

Appendix - A................................................................................................................................................22

Appendix - B................................................................................................................................................22

Appendix - C ...............................................................................................................................................22

Read these instructions in their entirety before installation and use:

INTRODUCTION

Reading this document will help ensure safe operation and maintenance of the Splash! 300-0000/EU/K -

Splash! Hi-Lo 350-0000/EU/K - Splash! Extended Reach 370-0000/EU/K - Splash! Spa 375-0000/EU/K -

Splash! ER Hi/Lo 385-0000/EU/K.

INTENDED HOIST USER

All of S.R. Smith’s aquatic patient hoists have been designed to assist anyone who has problems entering

or exiting a swimming pool or spa - the only restriction is that the User does not exceed the weight limit of

the product (300 lb/136 kg to 400 lb/181 kg depending upon model). It is the responsibility of the hoist

Owner to ensure that the correct safety procedures have been put in place and a risk assessment carried

out. If a User is mentally challenged or has severe physical disabilities these issues must be taken into

account to determine the number of persons required to complete the transfer onto the seat and the

number of persons required to be in the water, ready to receive the User. The seat belt must be attached

to the seat and fully fastened and used during each transfer.

Our goal is to provide our customers with the most advanced and innovative designs offering exceptional

quality at affordable prices. All of our hoists meet the specifications set forth by the Access Board -

ADAAG 2004 (US only), Medical Device Directive, 93/42/EEC, RoHS2 Directive 2011/65/EU, EN

50581:2012 and ISO10535:2006 including repeating the lifting cycle of the hoist (lift) for a total of 11,000

cycles. The hoist system and AC powered battery charger complies with EN60601-1-2, 2007/03.

US Patent No. 5,790,995 Splash! and the Splash! Logo and LiftOperator are registered trademarks of S.R. Smith, LLC.