Safeplace Magna 800C Instruction Manual

Popular Safe manuals by other brands

Honeywell

Honeywell 2077D - 1.21 Cubic Foot Anti-Theft Safe user guide

Hornady

Hornady SnapSafe Trunk Safe II owner's manual

SPORTS AFIELD

SPORTS AFIELD SA-HD5-BIO instruction manual

Honeywell

Honeywell 5912 user guide

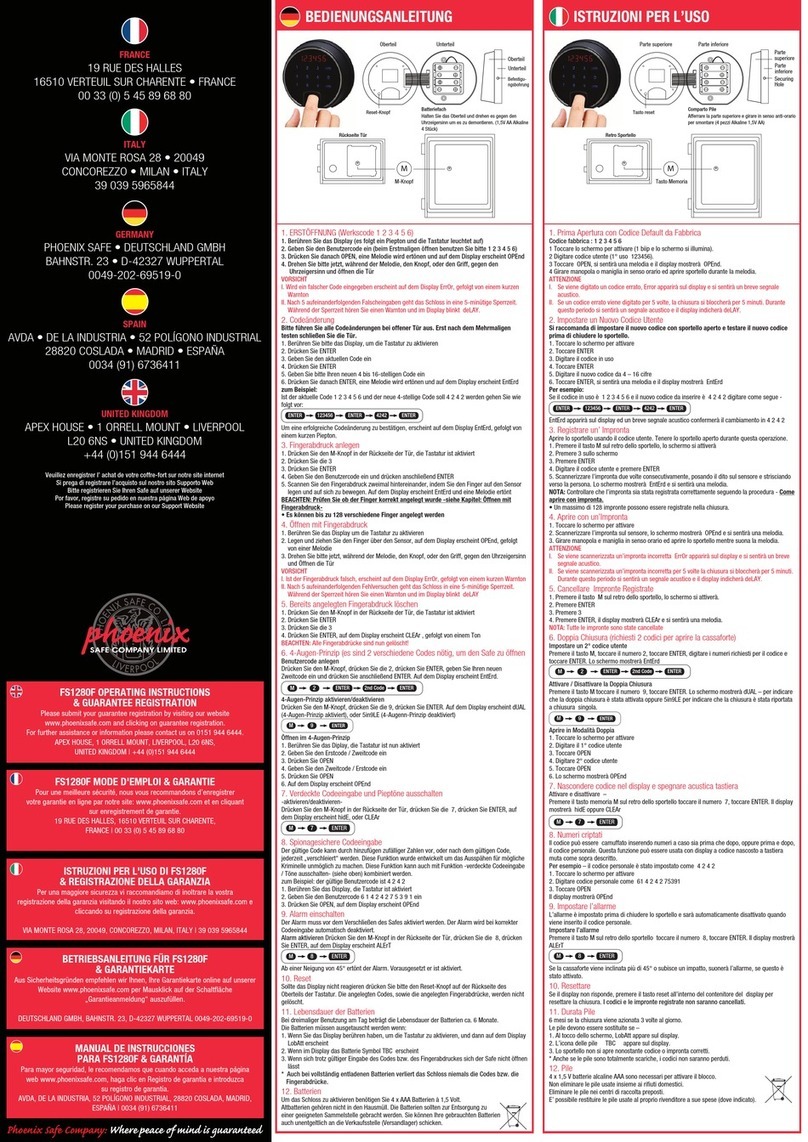

Phoenix

Phoenix FS1280F operating instructions

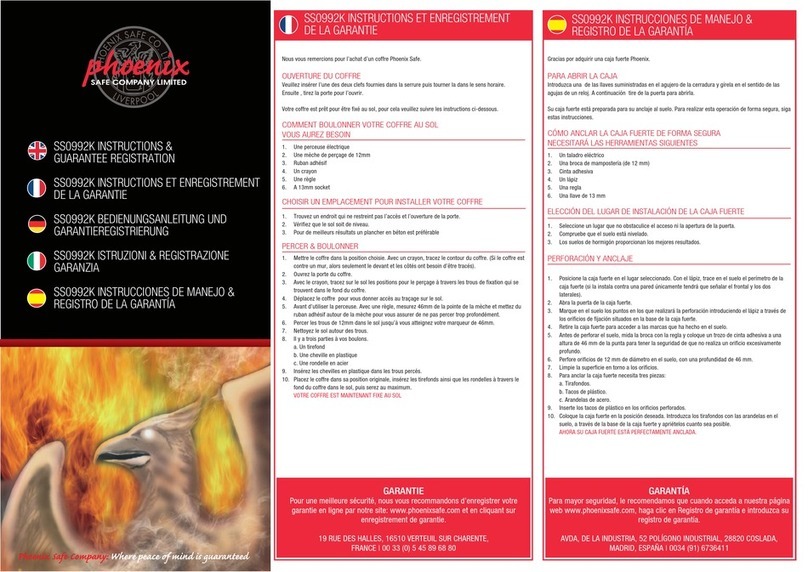

Phoenix

Phoenix SS0992K Instructions & Guarantee Registration

Technomax

Technomax Trony Series Instruction handbook

SPORTS AFIELD

SPORTS AFIELD INSTINCT BIOMETRIC Series instruction manual

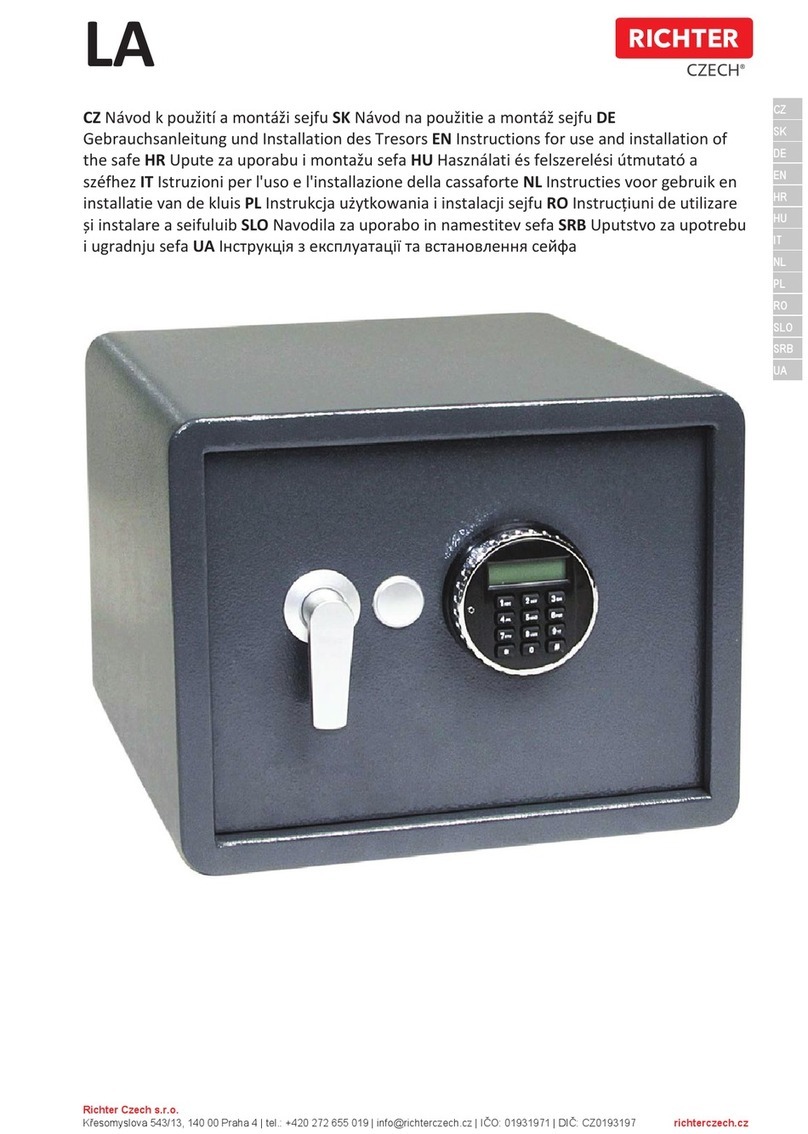

RICHTER CZECH

RICHTER CZECH LA Instructions for use and installation

Olymp

Olymp GOsafe 110 operating instructions

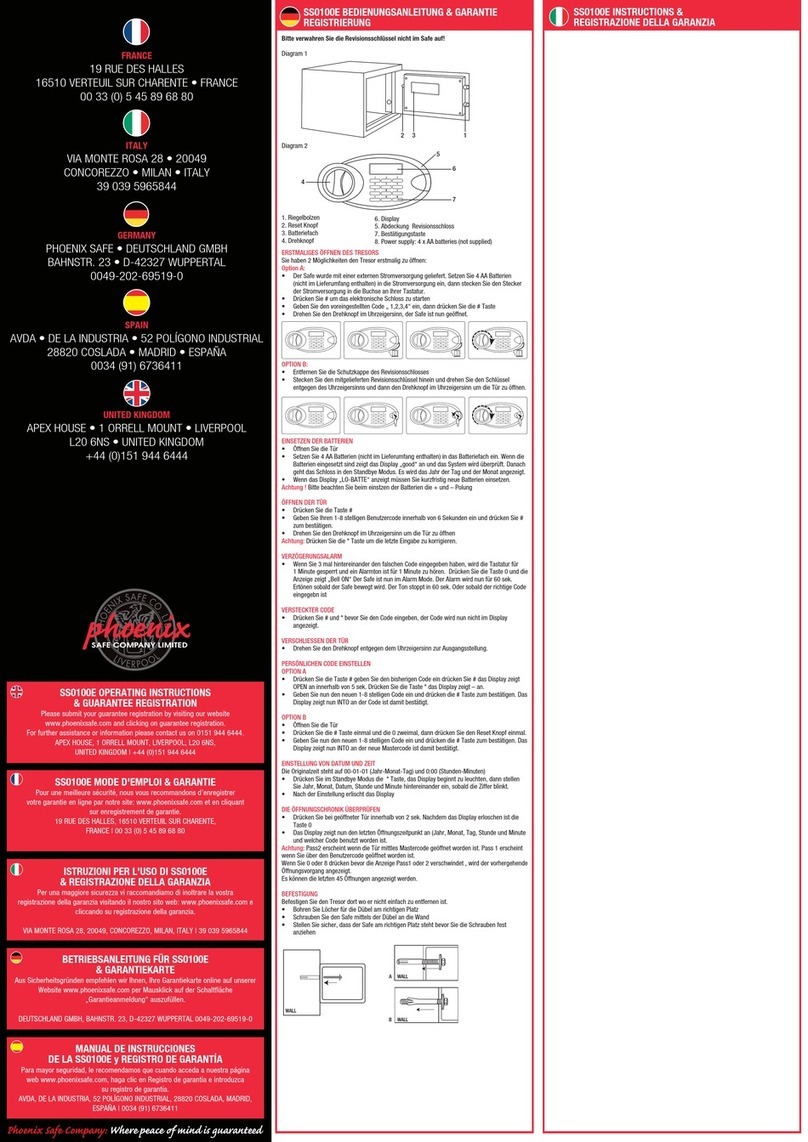

Phoenix

Phoenix SS0100E Operating Instructions & Guarantee Registration

Clarke

Clarke Strong-Arm CS1000K Operation & maintenance instructions