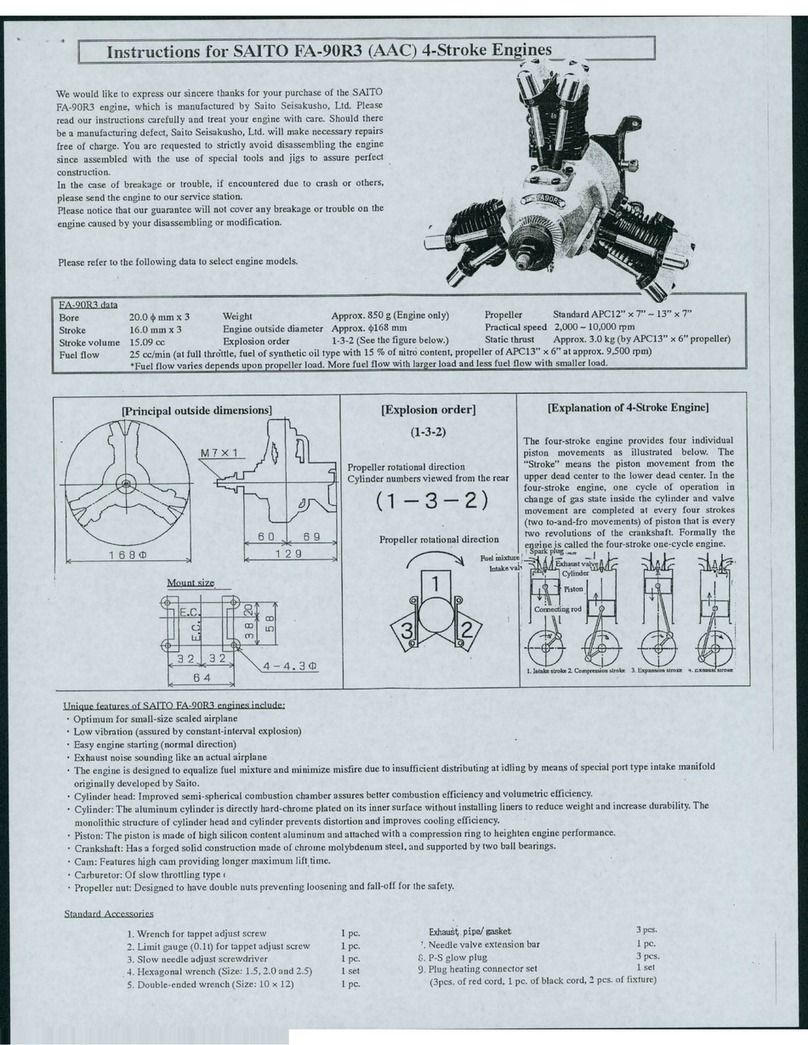

Ø27.0mm 19.2mm 32.98cc

D16”xP8”~D17”xP6”

・Filterwithweight[G36-154]・Rubbertubeforgasoline(1m)[G36-155]

・Aluminumspinnernut[120S-30]・Tappetadjustingkit[30-161]・Digitaltachometer[G17-167]

Bore

Body:1,440g/Mufflers:90g/Ignitionsystem:200g

Stroke Disp.

Weight(Approx.) RPMRange Approx.1,700-9,500rpm Maxonground Approx.8,500-9,500rpm

Propeller 1/4-32sparkplug

SP-1orSP-2

Plug

Optionalparts

2stGas-engine20~30ccclassApplications

Batteryforignitionsystem Voltage:6-12V,greaterthan1,500mA

・Limitgauge(0.1t)fortappetadjustment 1pc ・Plugwrench 1pc

・Wrenchfortappetadjustinglocknut 1pc ・Hexagonalwrench1.5mm 1pc

・Sparkplug[SP-2](Attachedtotheengine) 3pcs ・Mufflerset 1set

・Ignitionsystem(w/sensor) 1set

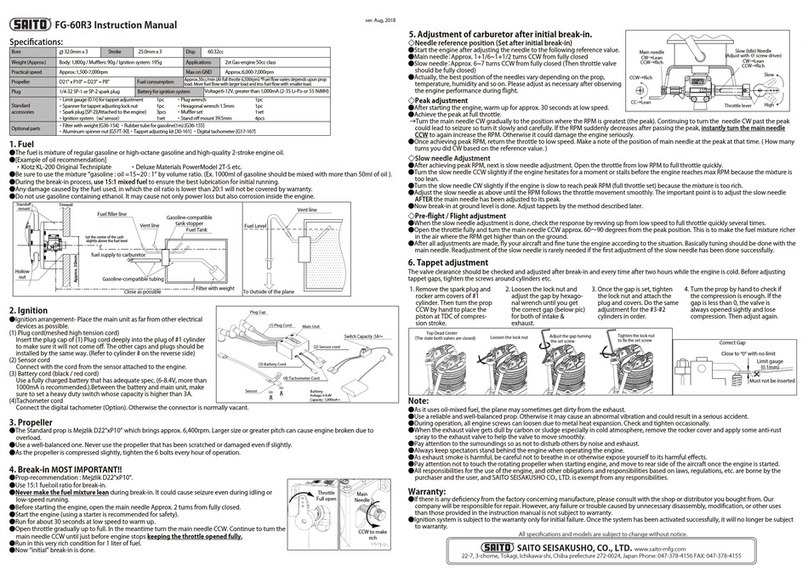

Specifications

FG-33R3InstructionManual

Standard

accessories

FuelTank

FuelLevel

ToOutsideoftheplane

Ventline

Fuelsupplytocarburetor

Fuelfillerline

Ventline

Gasoline-compatible

tankstopper

Gasoline-compatibletubing

Filterwithweight

Setthecenterofthecarb

slightlyabovethefuellevel

Closeaspossible

Hollowout

CW→Lean

CCW→Rich

CW→Lean

CCW→Rich

CCW→Rich

CW→Lean

Mainneedle Slow(Idle)Needle

(Adjustwith⊖screwdriver)

Slow

High

Throttlelever

5.Adjustmentofcarburetorafterinitialbreak-in.

◇Needlereferenceposition(Setafterinitialbreak-in)

●Starttheengineafteradjustingtheneedletothefollowingreferencevalue.

●Mainneedle:Approx.1+1/4~1+1/2turnsCCWfromfullyclosed

●Slowneedle:Approx.8turnsCCWfromfullyclosed(Thenthrottlevalve

shouldbefullyclosed)

●Actually,thebestpositionoftheneedlesvarydependingontheprop,

temperature,humidityandsoon.Pleaseadjustasnecessaryafterobserving

theengineperformanceduringflight.

◇Peakadjustment

●Afterstartingtheengine,warmupforapprox.30secondsatlowspeed.

●Achievethepeakatfullthrottle.

→TurnthemainneedleCWgraduallytothepositionwheretheRPMisgreatest(thepeak).ContinuingtoturntheneedleCWpastthepeak

couldleadtoseizuresoturnitslowlyandcarefully.IftheRPMsuddenlydecreasesafterpassingthepeak,instantlyturnthemainneedle

CCWtoagainincreasetheRPM.Otherwiseitcoulddamagetheengineseriously.

●OnceachievingpeakRPM,returnthethrottletolowspeed.Makeanoteofthepositionofmainneedleatthepeakatthattime.(Howmany

turnsyoudidCWbasedonthereferencevalue.)

◇SlowneedleAdjustment

●AfterachievingpeakRPM,nextisslowneedleadjustment.OpenthethrottlefromlowRPMtofullthrottlequickly.

●IftheenginehesitatesforamomentorstallsbeforetheenginereachesmaxRPM,Itʼsbecausethemixtureistoolean.Thenturntheslow

needleCCWslightly.

●IftheengineisslowtoreachpeakRPM(fullthrottleset),itʼsbecausethemixtureistoorich.ThenturntheslowneedleCWslightly.

●AdjusttheslowneedleasaboveuntiltheRPMfollowsthethrottlemovementsmoothly.Theimportantpointistoadjusttheslowneedle

AFTERthemainneedlehasbeenadjustedtoitspeak.

●Nowbreak-inatgroundlevelisdone.Adjusttappetsbythemethoddescribedlater.

◇Pre-flight/Flightadjustment

●Whentheslowneedleadjustmentisdone,checktheresponsebyrevvingupfromlowspeedtofullthrottlequicklyseveraltimes.

●OpenthethrottlefullyandturnthemainneedleCCWapprox.60〜90degreesfromthepeakposition.Thisistomakethefuelmixturericher

intheairwheretheRPMgethigherthanontheground.

●Afteralladjustmentsaremade,flyyouraircraftandfinetunetheengineaccordingtothesituation.Basicallytuningshouldbedonewiththe

mainneedle.Readjustmentoftheslowneedleisrarelyneededifthefirstadjustmentoftheslowneedlehasbeendonesuccessfully.

4.Break-inMOSTIMPORTANT!!

●Beforestartingtheengine,injectasuitableamount(approx.20〜30cc)ofengineoilintothe

lubricationnippleonthecrankcaseusingasyringeorpumpwhileturningthepropellerbyhand.

Afterthat,plugthisnipple.Asexcessisdischargedfromthebreathernipple,attachatubetothe

breathernipple.

●Prop-recommendation:APC-17x6.

●Use15:1fuel:oilratioforbreak-in.

●Nevermakethefuelmixtureleanduringbreak-in.Itcouldcauseseizureevenduringidlingor

low-speedrunning.

●Beforestartingtheengine,openthemainneedleApprox.1+1/2turnsfromfullyclosed.

●Starttheengine(usingastarterisrecommendedforsafety).

●Runfor15~20secondsatlowspeedtowarmup.

●Openthrottlegraduallyuptofull.InthemeantimeturnthemainneedleCCW.ContinuetoturnthemainneedleCCWuntiljustbefore

enginestopskeepingthethrottleopenedfully.

●Runinthisveryrichconditionfor1literoffuel.

●Now“initial”break-inisdone.

Throttle

Fullopen

CCWtomake

rich

Main

Needle

CorrectGap

Mustnotbeinserted

Closeto“0”withnolimit

Limitgauge

(0.1mm)

Loosenthelocknut

Adjustthegapturning

thesetscrew

TopDeadCenter

(Thestatebothvalvesareclosed) Tightenthelocknut

tofixthesetscrew

6.Tappetadjustment

Thevalveclearanceshouldbecheckedandadjustedafterbreak-inandeverytimeaftertwohourswhiletheengineiscold.Beforeadjusting

tappetgaps,tightenthescrewsaroundcylindersetc.

1.Removethesparkplugand

rockerarmcoversof#1

cylinder.Thenturntheprop

CCWbyhandtoplacethe

pistonatTDCofcompres-

sionstroke.

2.Loosenthelocknutand

adjustthegapbyhexago-

nalwrenchuntilyouget

thecorrectgap(belowpic)

forbothofintake&

exhaust.

3.Oncethegapisset,tighten

thelocknutandattachthe

plugandcovers.Dothesame

adjustmentforthe#3-#2

cylindersinorder.

4.Turnthepropbyhandtocheckif

thecompressionisenough.Ifthe

gapislessthan0,thevalveis

alwaysopenedslightlyandwill

losecompression.Thenadjust

again.

Note:

●Asitusesoil-mixedfuel,theplanemaysometimesgetdirtyfromtheexhaust.

●Useareliableandwell-balancedprop.Otherwiseitmaycauseanabnormalvibrationandcouldresultinaseriousaccident.

●Duringoperation,allenginescrewscanloosenduetometalheatexpansion.Checkandtightenoccasionally.

●Whentheexhaustvalvegetsdullbycarbonorsludgeespeciallyincoldatmosphere,removetherockercoverandapplysomeanti-rust

spraytotheexhaustvalvetohelpthevalvetomovesmoothly.

●Payattentiontothesurroundingssoasnottodisturbothersbynoiseandexhaust.

●Alwayskeepspectatorsbehindtheenginewhenoperatingtheengine.

●Asexhaustsmokeisharmful,becarefulnottobreatheinorotherwiseexposeyourselftoitsharmfuleffects.

●Payattentionnottotouchtherotatingpropellerwhenstartingengine,andmovetorearsideoftheaircraftoncetheengineisstarted.

●Allresponsibilitiesfortheuseoftheengine,andotherobligationsandresponsibilitiesbasedonlaws,regulations,etc.arebornebythe

purchaserandtheuser,andSAITOSEISAKUSHOCO.,LTD.isexemptfromanyresponsibilities.

1.Fuel

●Thefuelisamixtureofregulargasolineorhigh-octanegasolineandhigh-quality2-strokeengineoil.

●[Exampleofoilrecommendation]

・KlotzKL-200OriginalTechniplate・DeluxeMaterialsPowerModel2T-S・ENEOSRACINGSPECPRO-2T(SAITOSTANDARD)etc.

Ifsuchoilsarenotavailableinyourcountry,thenpleaseasktheofficialSAITOdistributorinyourcountryforanalternative.

NEVERuse“cheapoil”designedforutilityenginesforbrushcutter,lawnmower,orchainsawetc.

●Besuretousethemixture“gasoline:oil=15~20:1”byvolumeratio.(Ex.1000mlofgasolineshouldbemixedwithmorethan50mlofoil).

●Duringthebreak-inprocess,use15:1mixedfueltoensurethebestlubricationforinitialrunning.

●Anydamagecausedbythefuelused,inwhichtheoilratioislowerthan20:1willnotbecoveredbywarranty.

●Donotusegasolinecontainingethanol.Itmaycausenotonlypowerlossbutalsocorrosioninsidetheengine.

※

※IfyouuseaLi-Po,werecommendthespeclessthan2,500mAcapacityand

lessthan30Cdischargerate

2.Ignition

●Placethemainunitasfarfromotherelectricaldevicesaspossible.

●PlacethetwoswitchesoftheignitionandtheRCreceiverasfarfrom

eachotheraspossible.

(1)Plugcord(meshedhightensioncord)

Inserttheplugcapof(1)Plugcorddeeplyontotheplugof#1cylinder

tomakesureitwillnotcomeoff.Theothercapsandplugsshouldbe

installedbythesameway.(Refertocylinder#onthereverseside)

(2)Sensorcord

Connectwiththecordfromthesensorattachedtotheengine.

(3)Batterycord(black/redcord)

Useafullychargedbatterythathasadequatespec.(6-12V,morethan

1,500mAisrecommended.).Betweenthebatteryandmainunit,make

suretoinstallaheavydutyswitchwhosecapacityishigherthan3A.

(4)Tachometercord(optional)

Connectthedigitaltachometer(Option).Otherwisetheconnectorisnormallyvacant.

ver.June,2021

3.Propeller

●RecommendedpropellerisAPC17x6.

●Useareliablepropwhichbringsmaximum8,500~9,500rpminconformitytoyourplane.

●Useawell-balancedprop.Neveruseapropthathasbeenscratchedordamagedevenifslightly.

●Neveruseexcessivelylightorheavyloadedprop.Theymaycauseenginefailure,bigaccident,oreveninjury.

●Asthepropelleriscompressedslightly,tightenthepropellernuteveryhourofoperation.

PlugCap

SwitchCapacity:3A〜

Sensor

(2)Sensorcord

Battery

Voltage:6-12V

Capacity:1,500mA〜:

(

1)PlugCord MainUnit

(3)BatteryCord

(4)TachometerCord