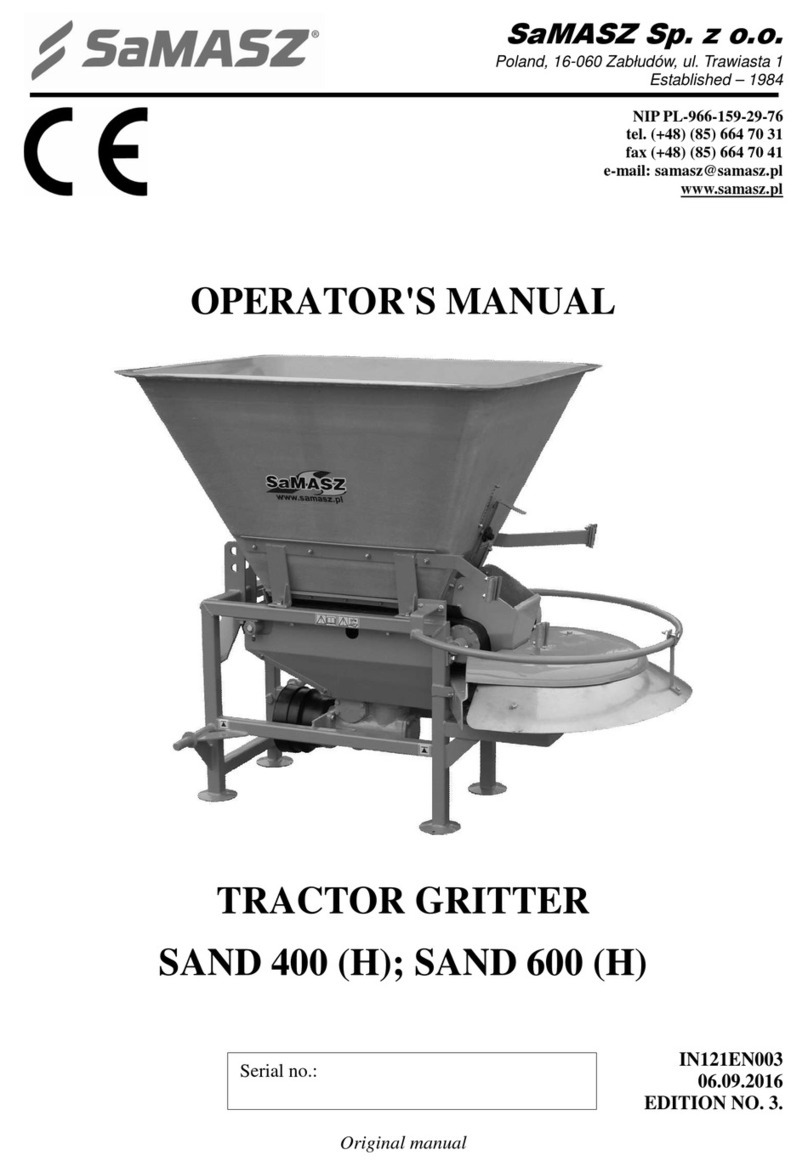

Operating manual Tractor mounted snow plow

PSV, PSV Up, PSV Up H

- 8-

Construction of the PSV Up (H) plow

A. –

Spring mechanism of the plowshare

G. – Suspension system.

B. – Rotational actuator H. – directional valve.

C. – Right moldboard. I. – Support leg.

D. – Left modlboard. J. – Side bumper.

E. – Plowshare. K. –Electric pump*

F. – Rubber blade insert. – Transport points

* PSV Up plows have no electric pump

4. EQUIPMENT AND SPARE PARTS

4.1. Standard equipment

PSV plows PSV Up (H) plows

warranty card,

operating manual and spare parts

catalogue,

rubber or metal (Hardox) blade inserts,

hydraulic plowshare steering,

protection – inclined shield,

hydraulic overloading protection,

support leg,

marker lights LED 12-24V,

electric installation 12V,

posibility of mounting flags,

safety bumpers,

hitch on front 3-ponit linkage cat. II Euro/

SMS/ Frame.

warranty card,

operating manual and spare parts catalogue,

rubber or metal (Hardox) blade inserts,

hydraulic plowshare steering,

protection – inclined shield,

own independent hydraulic unit (PSV Up H),

hydraulic overloading protection,

posibility of mounting flags,

marker lights,

road lights,

electric installation (24V – PSV Up H,

12V – PSV Up),

safety bumpers,

mounting on front plate (PN-EN 15432 plate

DIN 76060).

4.2. Optional equipment

PSV plows PSV Up (H) plows

rubber or metal (Hardox) blade inserts,

mount with a different connection Błd!

Nie mona odnale ródła odwołania.,

set of support wheels,

set of support skids,

set of support Küpera skids,

marker flag.

rubber or metal (Hardox) blade inserts,

electric installation 12V,

set of support wheels,

set of support skids,

set of support Küpera skids,

marker flag.

4.3. Spare parts

Spare part should be ordered according to the spare parts catalogue, using full name of

the part and the part number from the catalogue.