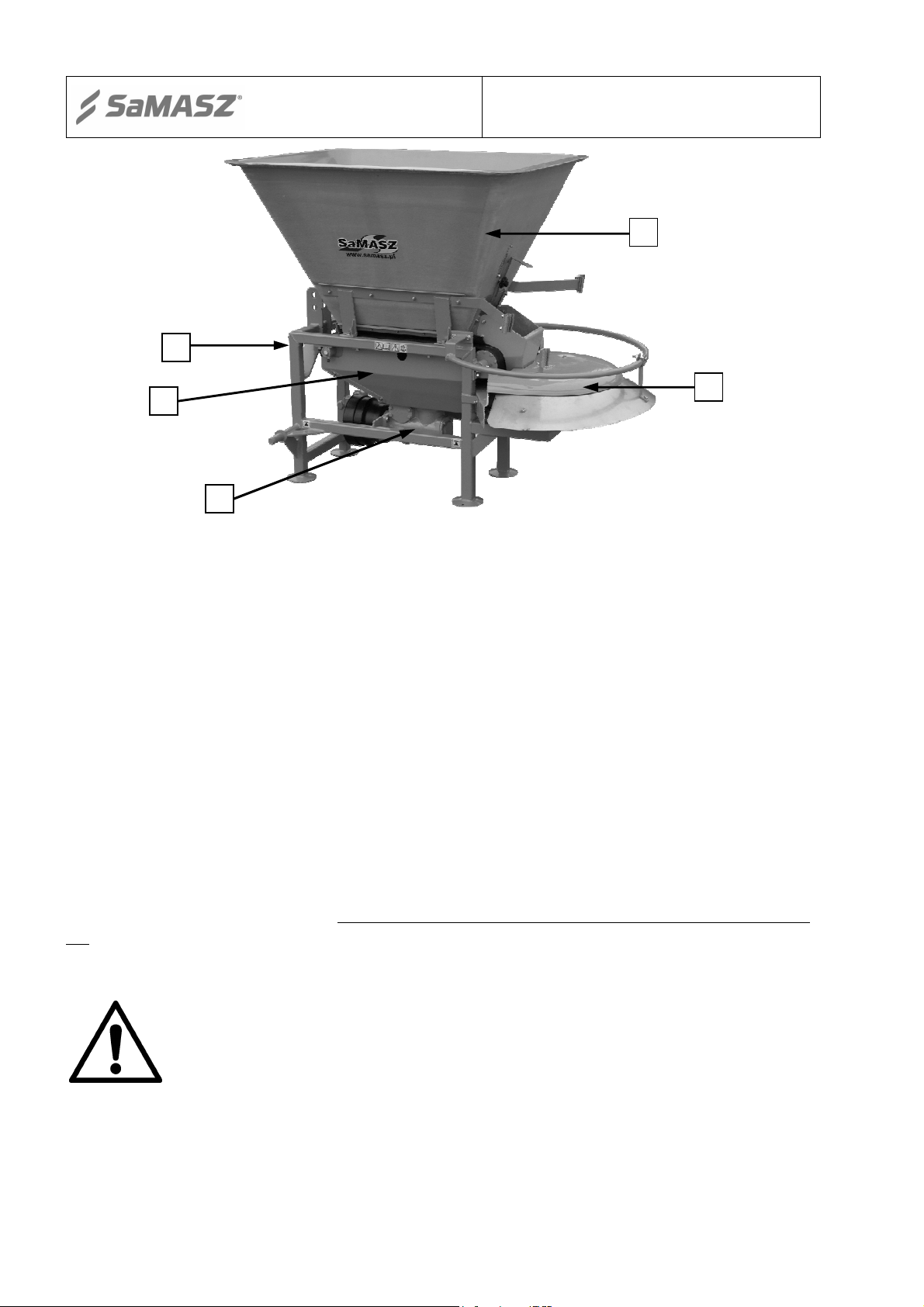

User's manual

Tractor gritter

SAND 400 (H); SAND 600 (H)

- 7 -

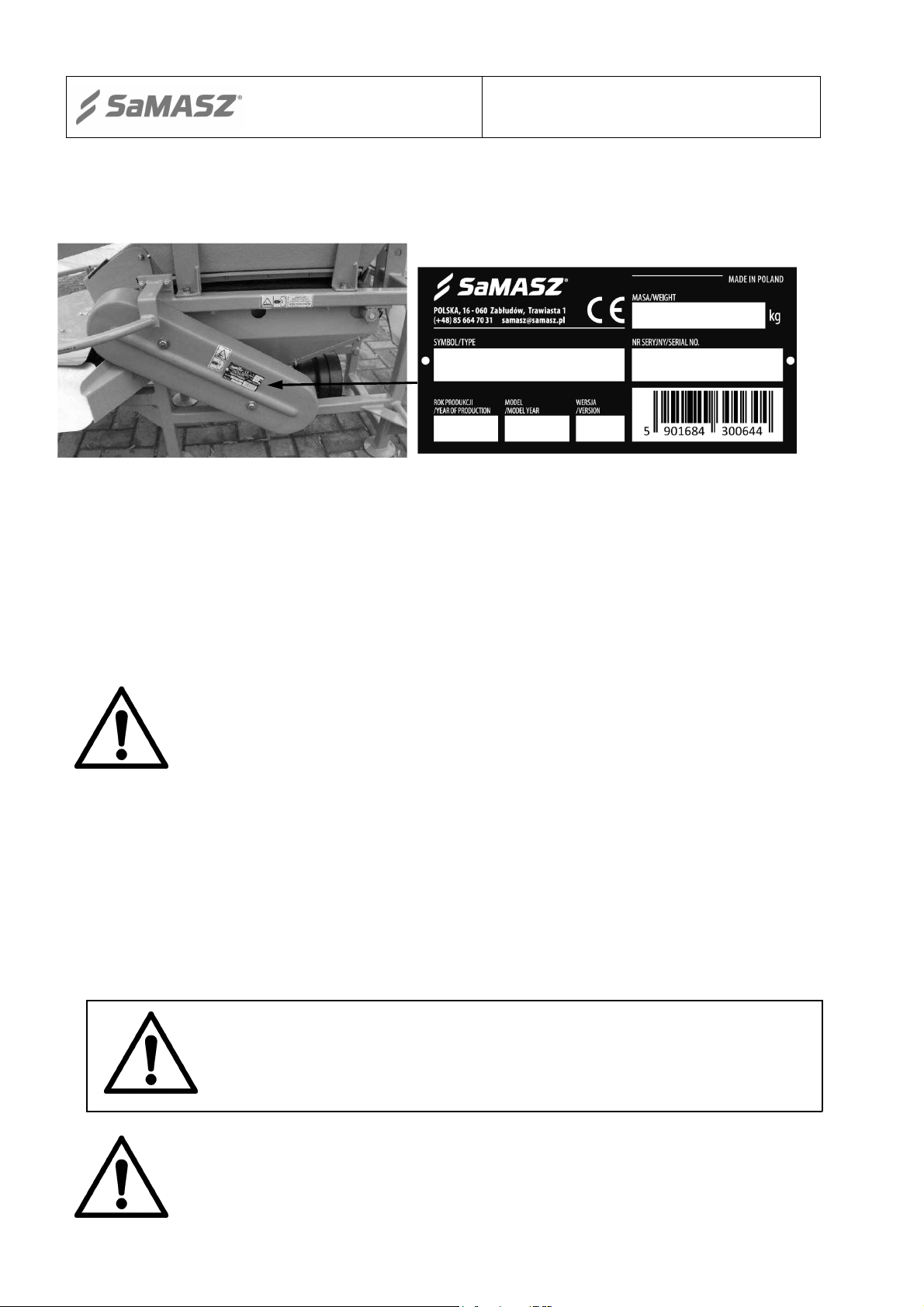

Mounting machine on and dismounting it from tractor should be performed on even and paved

surface.

Gritter should be dismounted from tractor only if tractor’s engine is turned off and ignition

key taken out.

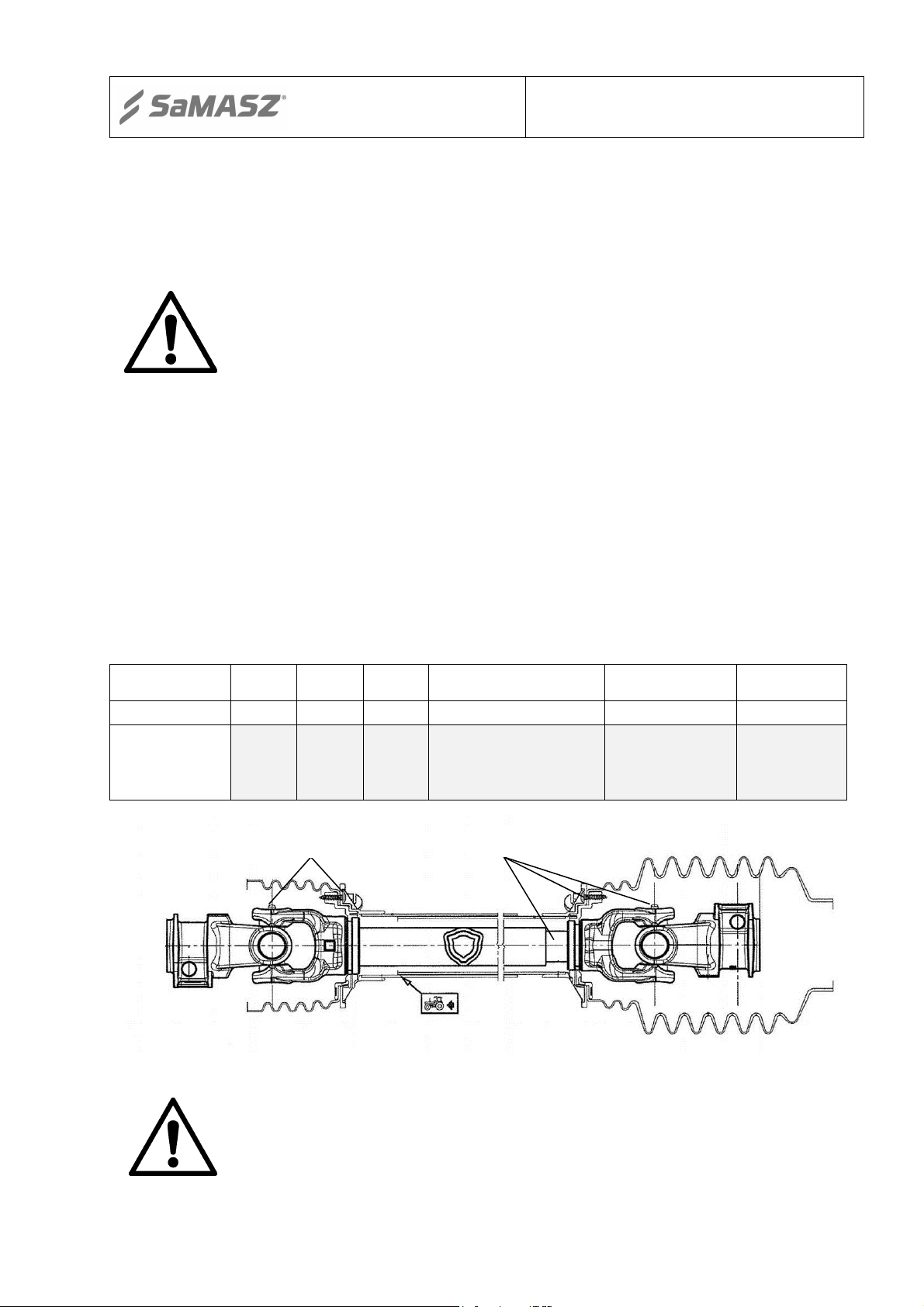

When near telescopic articulated shaft pay attention to guards in transport and working

position due to existing potential risk of damaging the guards with tractor’s parts.

Use telescopic articulated shaft holding CE marking with guards in good condition.

Pay attention that telescopic articulated shaft guard is always on and secured with chains

against rotation.

It is inadmissible to use telescopic articulated shaft with no full guards on from tractor’s PTO

and machine's PTO shafts’ side.

Mounting and dismounting of telescopic articulated shaft can only take place with

transmitter’s shaft, PTO shaft and engine all turned off and ignition key taken out.

Prior to turning off tractor’s transmitter’s shaft make sure, whether the following are true:

chosen number and direction of tractor's transmitter's shaft rears and admissible number and

direction of gritter's rears.

Prior to turning on transmitter’s shaft make sure whether there are no persons or animals

within machine's operating reach.

Be careful when telescopic articulated shaft is rotating. Danger of hand catching or crushing.

Turn off the transmitter’s shaft, whenever any obstacle is on the way or its operation is not

necessary.

Put the dismounted telescopic articulated shaft away onto intended support.

Once the telescopic articulated shaft is dismounted put a cap onto the transmitter’s shaft end.

Using damaged telescopic articulated shaft is forbidden.

Repair and maintenance works as well as other works related to removing functional defects

should be conducted with both drive and engine off and ignition key taken out.

Examine nuts and bolts on regular basis and if need be tighten.

When replacing parts, use only adequate tools and protective gloves.

Spare parts must comply with technical requirements provided by the manufacturer.

Hydraulic hoses should be inspected on regular basis and if any damage is found or they

expire, replace these with new ones. Expiry period for hydraulic hoses should be no longer

than 5 years,

Never use scotch tape to repair damaged hydraulic hoses,

When connecting hydraulic hoses to tractor hydraulic connectors make sure, that either

tractor’s or gritter’s hydraulics are pressure free,

When servicing hydraulic assembly, always wear protective gloves and eyewear. Hydraulic

oil leaking under pressure (16 MPa) may permeate through the skin and cause its infection

thereafter. If such is experienced, visit a doctor immediately,

NOTE:

1. Comply with the abovementioned provision to prevent an

accident and avoid life and health hazard.

2. Operating the machine by persons, who are unauthorized,

unskilled, ill, drunk or under influence of drugs, and children in

particular is forbidden.