User's manual

Tractor gritter

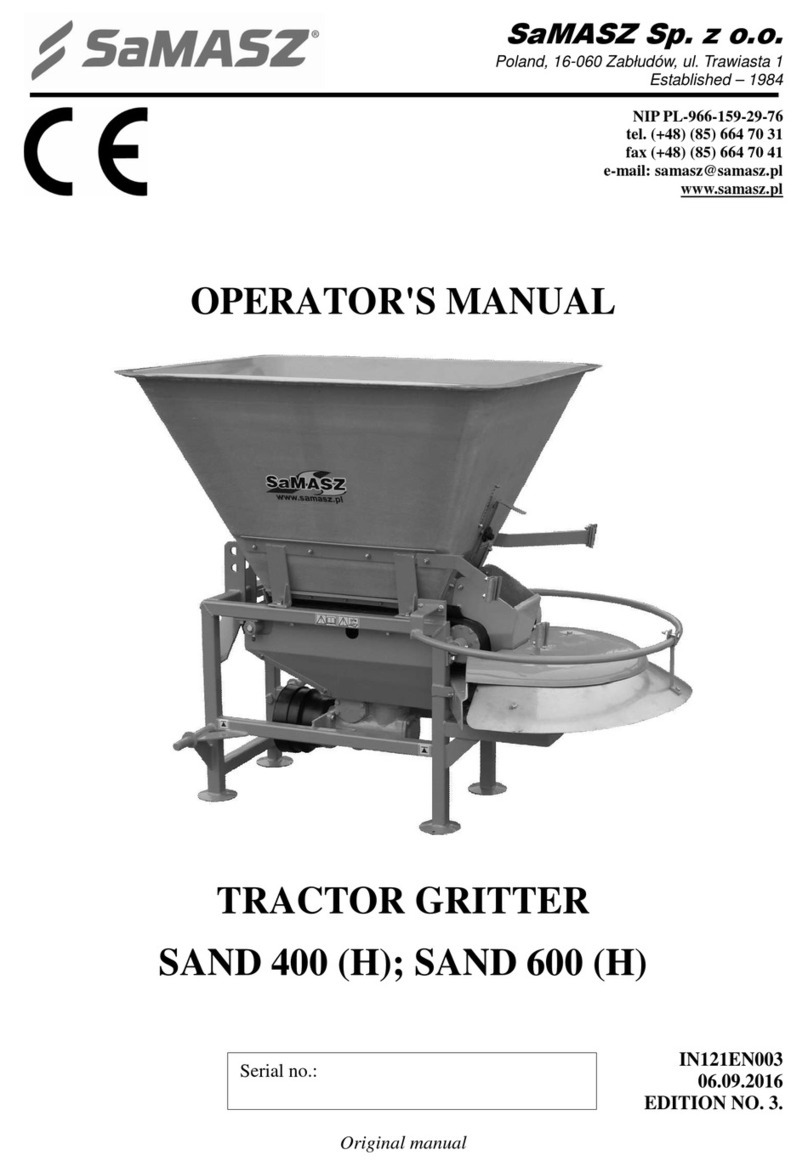

SAND 400 (H)

SAND 600 (H)

- 1 -

Table of contents page

1. IDENTIFYING THE MACHINE ............................................................................................................2

2. INTRODUCTION .....................................................................................................................................2

3. INTENDED USE OF THE GRITTER ....................................................................................................3

3.1. Technical data.....................................................................................................................................3

3.2. Construction and operation ................................................................................................................4

3.3. Standard equipment and spare parts...................................................................................................5

4. SAFETY WARNINGS AND CAUTIONS...............................................................................................6

4.1. General rules.......................................................................................................................................6

4.2. Qualifications of operator...................................................................................................................8

4.3. Conditions of connecting gritter with vehicle ....................................................................................8

4.4. Transport ............................................................................................................................................8

4.4.1. Placing the gritter onto a transport vehicle.................................................................................8

4.5. Safety rules when driving on public roads .........................................................................................9

4.6. The articulated telescoping shaft......................................................................................................10

4.7. Operation..........................................................................................................................................10

4.8. Stability of the unit ...........................................................................................................................11

4.9. Residual risk.....................................................................................................................................11

4.9.1. Residual risk description ..........................................................................................................11

4.9.2. Residual risk assessment ..........................................................................................................11

4.10. Warning signs and their meanings ...............................................................................................12

5. OPERATION OF THE GRITTER........................................................................................................13

5.1. Preparing the gritter to operation......................................................................................................13

5.2. Loading gritter's container................................................................................................................14

5.3. Connecting the PTO shaft ................................................................................................................14

6. OPERATING ...........................................................................................................................................16

6.1. Startup ..............................................................................................................................................16

6.2. Adjustments......................................................................................................................................17

6.2.1. Adjusting clearance over transmission belt..............................................................................17

6.2.2. Adjusting the angle of blades on spreading disk ......................................................................17

6.2.3. Adjusting tensioning and position of transmission belt............................................................18

6.2.4. Adjusting tensioning of v-belt..................................................................................................18

6.2.5. Adjusting tensioning v-belts of transmission belt’s drive ........................................................18

7. MAINTENANCE SERVICE ..................................................................................................................19

7.1. Everyday maintenance and storing........................................................................................................19

7.1.1. Restarting the machine after storing period ...................................................................................19

7.2. Inspections........................................................................................................................................20

7.3. Lubricating and maintenance ...........................................................................................................20

7.3.1. Examining oil level in gear box................................................................................................21

7.3.2. Risks present when lubricating.................................................................................................21

8. DEFINING THE TOTAL WEIGHT, AXIS LOAD, TYRE LOAD CAPACITY AND MINIMUM

LOAD ..............................................................................................................................................................22

9. DEFECTS AND THEIR REPAIR .........................................................................................................24

10. REPAIR AND DISPOSAL .....................................................................................................................24

10.1. Repair ...........................................................................................................................................24

10.2. Dismounting and withdrawal from use ........................................................................................25

11. WARRANTY CARD...............................................................................................................................25

12. WARRANTY TERMS ............................................................................................................................26

12.1. Warranty claim procedure ............................................................................................................26

12.2. Warranty repairs record................................................................................................................27