Contents

EB 8823 EN 3

1 Safety instructions and safety measures .........................................................5

1.1 Notes on possible severe personal injury .........................................................7

1.2 Notes on possible personal injury ...................................................................7

1.3 Notes on possible property damage................................................................9

2 Markings on the control valve......................................................................10

2.1 Valve nameplate ..........................................................................................10

2.2 Actuator nameplate......................................................................................11

2.3 Material number..........................................................................................11

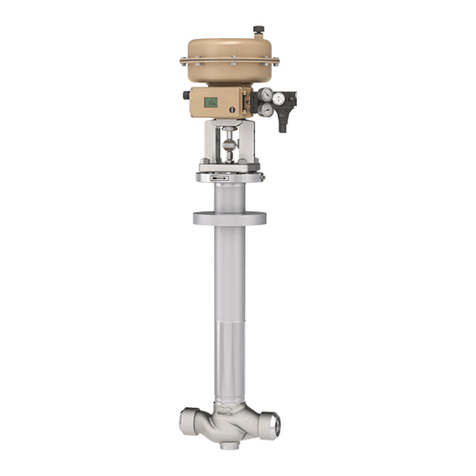

3 Design and principle of operation ................................................................12

3.1 Fail-safe positions ........................................................................................14

3.2 Technical data .............................................................................................15

4 Preparation.................................................................................................20

4.1 Unpacking ..................................................................................................20

4.2 Transporting and lifting ................................................................................20

4.2.1 Transporting ................................................................................................21

4.2.2 Lifting..........................................................................................................21

4.3 Storage.......................................................................................................23

4.4 Preparation for installation............................................................................24

5 Mounting and start-up.................................................................................26

5.1 Mounting the actuator onto the valve.............................................................26

5.2 Installing the valve into the pipeline ...............................................................26

5.2.1 Checking the installation conditions...............................................................26

5.2.2 Additional ttings.........................................................................................28

5.2.3 Installing the control valve.............................................................................28

5.3 Quick check ................................................................................................29

6 Operation...................................................................................................30

6.1 Reversing the ow direction ..........................................................................30

7 Maintenance ...............................................................................................32

7.1 Standard version..........................................................................................33

7.1.1 Replacing the O-rings ..................................................................................33

7.1.2 Replacing the packing..................................................................................36

7.1.3 Replacing the seat and plug..........................................................................38

7.1.4 Tools and tightening torques..........................................................................39