1 Design and principle of

operation

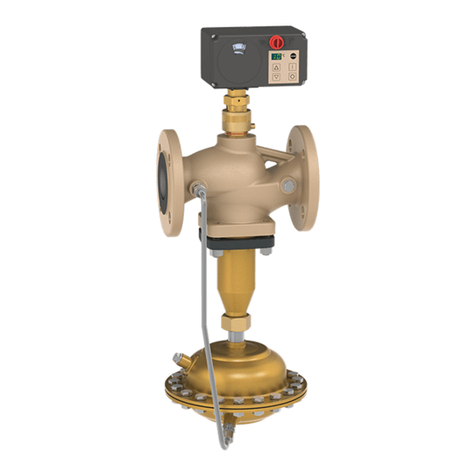

The regulators limit the flow rate in the pipe-

line. The set point for the flow rate is adjusted

at the restriction and the set point for the dif-

ferential pressure or the downstream pressure

is adjusted at the actuator. The largest signal

is always used to actuate the valve.

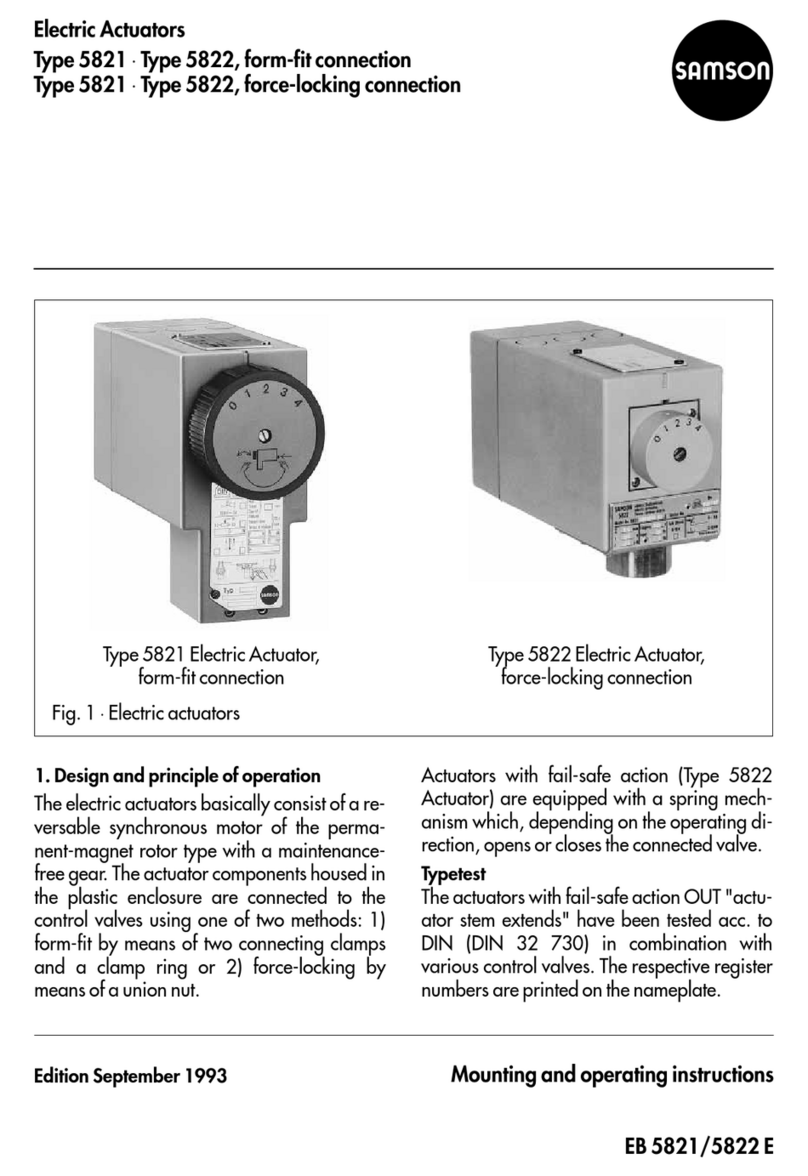

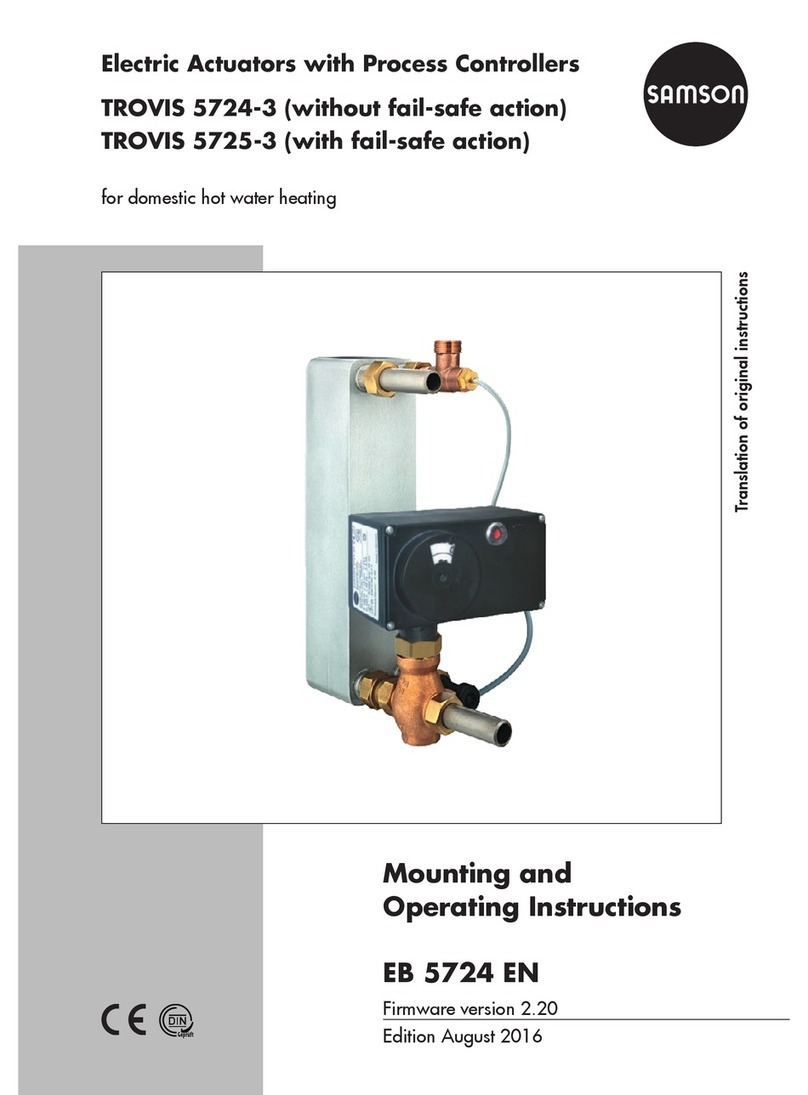

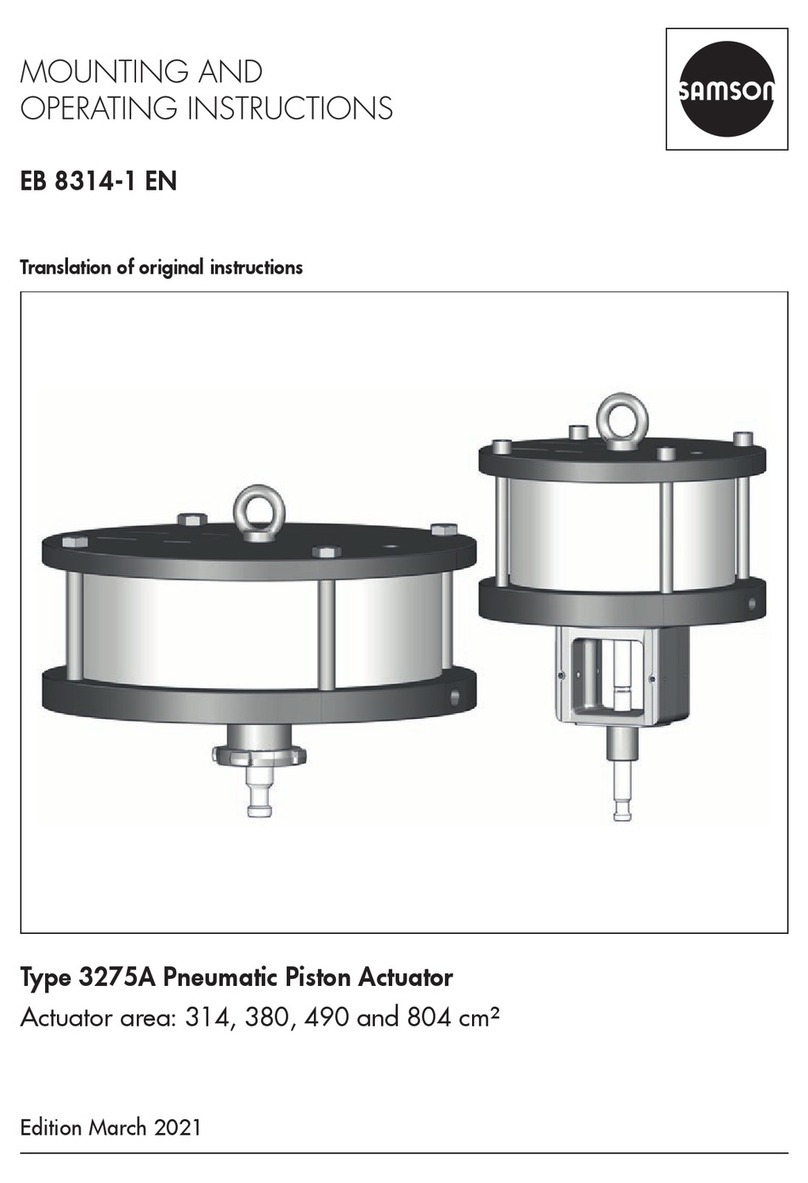

The regulators mainly consist of the

Type 2423 Valve with seat, plug and restric-

tion together with the Type 2427 or

Type 2429 Closing Actuator with operating

diaphragms. Valve and actuator are deliv-

ered separately and must be assembled on

site using a coupling nut

The medium flows through the valve in the di-

rection indicated by the arrow. The position

of the restriction (1.1) and the area released

by the valve plug (3) determine the flow rate

and the differential pressure Δp across the

plant.

The valve is fully balanced. The forces acting

on the valve plug created by the upstream

and downstream pressures are balanced by

a balancing bellows (5) or balancing dia-

phragm (Type 2423 balanced by a dia-

phragm, DN 125 to 250).

The principle of operation of the regulators

with valves balanced by a bellows or dia-

phragm only differ concerning the pressure

balancing. The valves balanced by a dia-

phragm have a balancing diaphragm (Fig. 2)

instead of a bellows (Fig. 1). The downstream

pressure p2acts on the inside and the up-

stream pressure p1on the outside of the dia-

phragm. As a result, the forces acting on the

valve plug are balanced out.

Type 42-37: The high pressure of Δp is trans-

mitted through the control line (18) to the dia-

phragm chamber D. The high pressure of the

flow rate (V

.) upstream of the restriction (1.1)

is transmitted through the control line (19) to

the diaphragm chamber C. This pressure is

equal to the low pressure of Δp. The low pres-

sure of V

.downstream of the restriction is

transmitted through holes in the plug and dia-

phragm stems to the diaphragm chamber A.

If, for example, the differential pressure rises,

the positioning force at the bottom operating

diaphragm (13.2) rises, too. This change in

force causes the diaphragm stems (12.2 and

12.1) and the valve plug (3) to move in the

closing direction until the set point adjusted at

the set point spring (16) is reached.

If the flow rate increases, the differential pres-

sure at the restriction (1.1) and the resulting

positioning force at the top diaphragm (13.1)

increase. This change in differential pressure

at the restriction causes the top diaphragm

stem (12.1) to push the plug stem and the

valve plug (3) in the closing direction until the

adjusted flow set point is reached. The largest

signal is always used to actuate the valve.

The overload protection (force limiter with in-

ternal excess pressure limiter) (15) protects

the seat, plug and plant during extreme oper-

ating conditions against overloading.

Type 42-39: The principle of operation is al-

most the same as for Type 42-37. However,

the high pressure of the flow rate V

.is sepa-

rate from the low pressure of the differential

pressure Δp in the Type 2429 Actuator. The

diaphragm chambers for these pressures

have their own control line connections.

4EB 3017 EN

Design and principle of operation