1-1

EB 31a-23_EN

Edition: November 2021

Specifications subject to change

Safety instructions and measures

1 Safety instructions and measures

Intended use

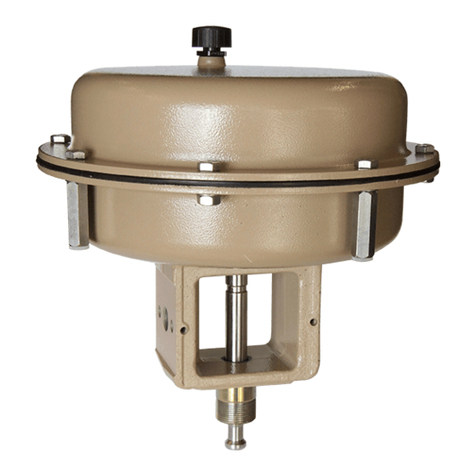

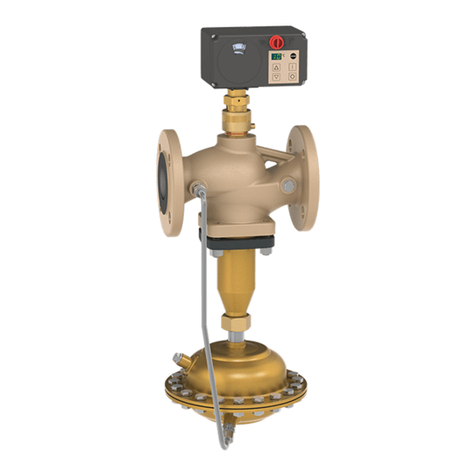

The PFEIFFER HCD actuators are designed for the automation

and operation of quarter-turn valves such as butterfly valves, ball

valves and plug valves in both indoor and outdoor applications.

Depending on the configuration, the actuator is suitable for on/

off or modulating duties. The actuator can be used in process

and industrial plants.

The actuator is designed to operate under exactly defined condi-

tions (e.g. temperature, pressure, travel). Therefore, operators

must ensure that the actuator is only used in operating conditions

that meet the specifications used for sizing the actuator at the or-

dering stage. In case operators intend to use the actuator in other

applications or conditions than specified, contact PFEIFFER.

PFEIFFER does not assume any liability for damage resulting from

the failure to use the device for its intended purpose or for dam-

age caused by external forces or any other external factors.

ÖRefer to the technical data and nameplate for limits and fields

of application as well as possible uses.

Reasonably foreseeable misuse

The actuator is not suitable for the following applications:

−Use outside the limits defined during sizing and by the tech-

nical data.

−Use outside the limits defined by the accessories connected to

the actuator.

Furthermore, the following activities do not comply with the in-

tended use:

−Use of non-original spare parts.

−Performing service and repair work not described in these in-

structions.

Qualifications of operating personnel

The actuator must be mounted, started up, serviced and re-

paired by fully trained and qualified personnel only; the accept-

ed industry codes and practices are to be observed. Ac- cording

to these mounting and operating instructions, trained personnel

refers to individuals who are able to judge the work they are as-

signed to and recognize possible hazards due to their special-

ized training, their knowledge and experience as well as their

knowledge of the applicable standards.

Personal protective equipment

We recommend wearing the following personal protective equip-

ment when handling the PFEIFFER actuators:

−Protective gloves and safety footwear when mounting or re-

moving the actuator.

−Eye protection and hearing protection while the actuator is

operating.

ÖCheck with the plant operator for details on further protective

equipment.

Revisions and other modifications

Revisions, conversions or other modifications of the product are

not authorized by PFEIFFER. They are performed at the users

own risk and may lead to safety hazards, for ex- ample. Further-

more, the product may no longer meet the requirements for its in-

tended use.

Safety devices

The PFEIFFER pneumatic actuators alone do not have any special

safety equipment.

Warning against residual hazards

To avoid personal injury or property damage, plant operators

and operating personnel must prevent hazards that could be

caused in the actuator by the signal pressure, stored spring ener-

gy or moving parts by taking appropriate precautions. They must

observe all hazard statements, warning and caution notes in

these mounting and operating instructions.

Responsibilities of the operator

The operator is responsible for proper operation and compliance

with the safety regulations. Operators are obliged to provide

these mounting and operating instructions as well as the refer-

enced documents to the operating personnel and to instruct them

in proper operation.

Furthermore, the operator must ensure that operating personnel

or third persons are not exposed to any danger.

These instructions should not supersede or replace any customer’s

plant safety or work procedures. If a conflict arises bet- ween

these instructions and the customer’s procedures, the differences

should be resolved in writing between an authorized end users

representative and an authorized PFEIFFER representative.

Responsibilities of operating personnel

Operating personnel must read and understand these mounting

and operating instructions as well as the referenced documents

and observe the specified hazard statements, warnings and cau-

tion notes. Furthermore, the operating personnel must be familiar

with the applicable health, safety and accident prevention regu-

lations and comply with them.

Referenced standards and regulations

−PFEIFFER actuators are designed, produced and classified ac-

cording to the European ATEX directive 2014/34/EU. Before

using the actuators in potentially explosive atmosphere areas,

verify the actuator compliance with the required ATEX classifi-

cation.

ÖRefer to the nameplate and the ATEX safety instructions.

−PFEIFFER actuators are SIL certificated.

ÖRefer to the SIL Certificate available from PFEIFFER for the ac-

tuators SIL capability.

−Referring to Machine Directive 2006/42/EC, actuators are

classified as “partly machinery” (see Declaration of incorpo-

ration).