EB 6111 EN 5

Description

2 Description

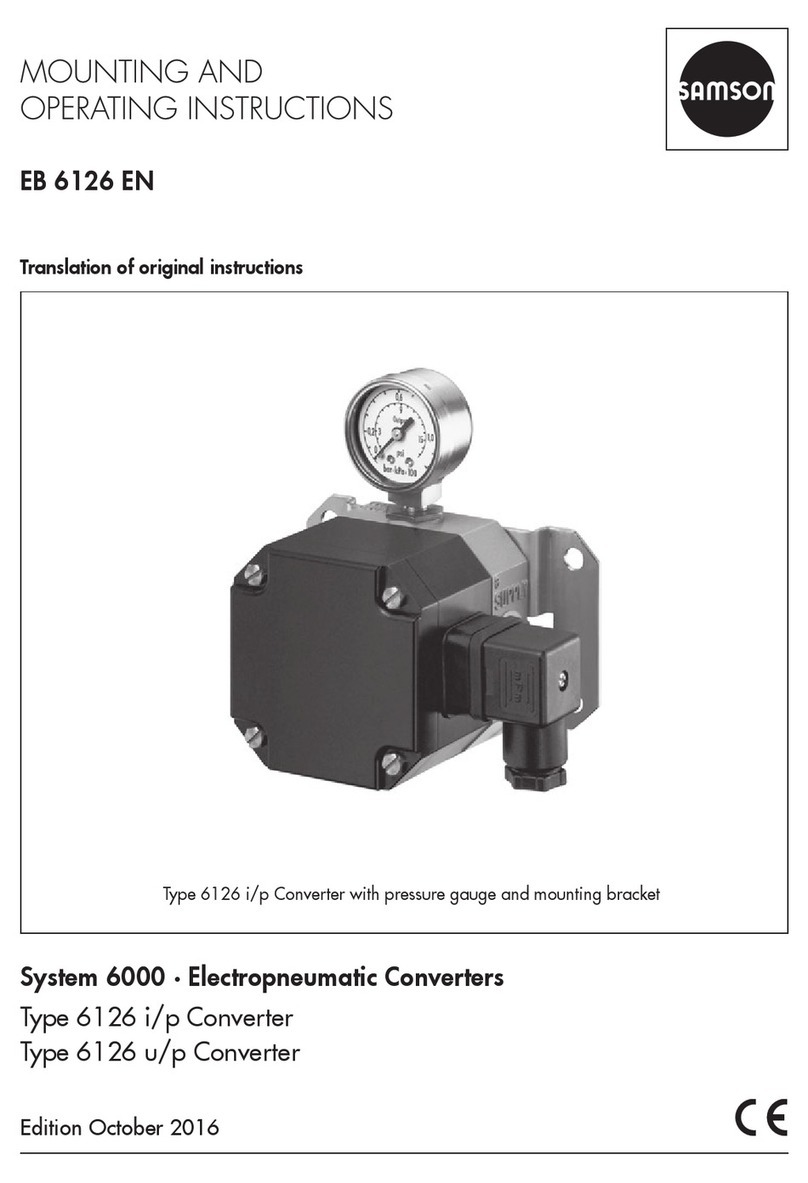

2.1 Application

The device is used to convert a direct current

input signal into a pneumatic output signal

for measuring and control tasks.

It is particularly suitable as an intermediate

element between electric measuring devices

and pneumatic controllers or between elec-

tric control devices and pneumatic control

valves.

The input is a load-independent direct cur-

rent of 4 to 20mA or 0 or 20mA.

The output is a pneumatic signal of 0.2 to

1bar or other signal ranges up to max.

8bar.

2.2 Principle of operation

See Fig.1 on page7.

The devices consist of an i/p converter mod-

ule and a downstream volume booster.

When operated, the supplied direct current i

ows through the plunger coil (2) located in

the eld of a permanent magnet (3). At the

balance beam (1), the force of the plunger

coil, which is in proportion to the current, is

balanced against the force of the dynamic

backpressure pK, which is produced on the

apper (6) by the air jet leaving the nozzle

(7). The supply air (9) ows to the bottom

chamber of the volume booster (8) and a

certain amount of air determined by the dia-

phragm position ows past the sleeve (8.5)

and leaves through the output (OUTPUT 36).

The output signal pAis used also to supply

the nozzle (7). The offset spring (8.2) ensures

that the output signal is at least 100mbar

even at an input signal of 0mA. As the input

current and the forces acting on the plunger

coil increase, the apper (6) moves closer to

the nozzle (7).

This causes the backpressure pKupstream of

the restriction (8.4) increase until it corre-

sponds with the input current.

The increasing backpressure pushes the dia-

phragm (8.3) and the plug sleeve (8.5)

downwards. As a result, the supply air caus-

es the output pressure pA to increase until a

new state of equilibrium is reached in the di-

aphragm chambers.

When the backpressure pK drops, the dia-

phragm moves upwards, releasing the plug

sleeve. The output pressure pA can escape

through the sleeve until the forces are equal

again.

Volume booster

See Fig.1 on page7.

Booster I (top

diagram)

II (bottom

diagram)

Output signal 0.1bar or

higher

0.0bar or

higher

i/p converter

module

Type6109

or

Type6112

Type6112

only

Note:

A relatively stable supply air network

is required for the version with volume

booster II.